Professional Documents

Culture Documents

AISI 4130: Low Alloy 4130:ASTM A29 (VO1.05) Chemical Composition

Uploaded by

Parthiban AruchamyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AISI 4130: Low Alloy 4130:ASTM A29 (VO1.05) Chemical Composition

Uploaded by

Parthiban AruchamyCopyright:

Available Formats

Howco Group oilfield, wellhead and completion tool materials

Page 1 of 1

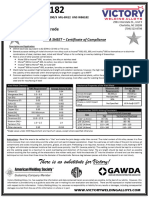

AISI 4130

Low alloy 4130:ASTM A29 (VO1.05) Chemical composition

C Min Max 0.28 0.33 Si 0.15 0.35 Mn 0.40 0.60 P 0.035 S 0.040 Cr 0.80 1.10 Mo 0.15 0.25 Fe 0.00 0.00

Download a Technical Guide

Various hybrid analyses are available to improve the hardenability of the grade.

Click for Tech Guide

Mechanical properties

Condition: Hardened and Tempered to 22 HRC max. U.T.S 0.2% Proof Stress Elongation Red of Area 85 KSI Min 60 KSI Min 20 % 40 % (586 N/mm2) (414 N/mm2)

NACE MR0175 limits the supply hardness to 22HRC max.

Size range: 3 - 51

General scope

AISI 4130 low alloy steel containing nominally 0.3% Carbon, 1% Chromium and 0.2% Molybenum is widely used in oil patch applications. It is similar to 4140 which has a higher carbon level giving 4130 improved weldability, at the expense of through thickness strength. The hardenability limitations of this grade (depth to which it will harden / obtain the specified mechanical properties after heat treatment) must always be taken into account when designing and selecting equipment. Primarily manufactured in: Dubai, UAE Edmonton, Canada Houston, Texas Sheffield, England Singapore

http://www.howcogroup.com/materials/low-alloy-steels/4130

20/2/2014

You might also like

- WS410Document7 pagesWS410Martin OusephNo ratings yet

- Rules For Materials and Welding 2021 AmendmentsDocument29 pagesRules For Materials and Welding 2021 AmendmentsSUEZSHIPYARD QCNo ratings yet

- 4140 30-36HRc Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi Metals PDFDocument1 page4140 30-36HRc Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi Metals PDFHeri Fadli SinagaNo ratings yet

- 4140 30-36HRc Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi Metals PDFDocument1 page4140 30-36HRc Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi Metals PDFHeri Fadli SinagaNo ratings yet

- Structural Steels: SABS 1431 Technical DataDocument3 pagesStructural Steels: SABS 1431 Technical DataZdravko Vidakovic100% (1)

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- D.A.Cooper Sons Product Datasheet AISI SAE 4140 1Document1 pageD.A.Cooper Sons Product Datasheet AISI SAE 4140 1Muhamad Wahyu BudiawanNo ratings yet

- Pinnacle Alloys E8018-B6 Code and Specification DataDocument2 pagesPinnacle Alloys E8018-B6 Code and Specification DataMurad AlmoudiNo ratings yet

- Cast Materials: Sulzer PumpsDocument6 pagesCast Materials: Sulzer PumpsElmey Bin JulkeplyNo ratings yet

- EN24 and EN24T SteelDocument3 pagesEN24 and EN24T Steelpatrik710No ratings yet

- Hardox 450: General Product DescriptionDocument2 pagesHardox 450: General Product DescriptionTeodor EzaruNo ratings yet

- Hardox 400 PlateDocument3 pagesHardox 400 PlateAli TalebiNo ratings yet

- AISI SAE 4130 Product Datasheet D.A.Cooper SonsDocument1 pageAISI SAE 4130 Product Datasheet D.A.Cooper SonsHaris AliNo ratings yet

- Hardox450 380Document2 pagesHardox450 380pedroNo ratings yet

- SAE Steel Grades - WikipediaDocument30 pagesSAE Steel Grades - Wikipediamanoj ranathiive100% (1)

- Product Manual: BarrettDocument52 pagesProduct Manual: Barrettbrajendra1020No ratings yet

- Tata Steel - AR400 & 450Document2 pagesTata Steel - AR400 & 450Gabriel CamargoNo ratings yet

- Materials Castings E00510 SulzerDocument5 pagesMaterials Castings E00510 SulzerAmir SafdarNo ratings yet

- API 2W50 Data Sheet 2012 04 01Document2 pagesAPI 2W50 Data Sheet 2012 04 01Alfon TampubolonNo ratings yet

- Carpenter 20CB-Data SheetDocument14 pagesCarpenter 20CB-Data SheetAxent BrotherNo ratings yet

- New 4130 Alloy SteelDocument3 pagesNew 4130 Alloy SteelfsijestNo ratings yet

- BS3100 A2Document11 pagesBS3100 A2AlexNo ratings yet

- Metrode 410NiMo B-11Document4 pagesMetrode 410NiMo B-11Claudia MmsNo ratings yet

- +44 (0) 1786 475 662 Sales@amsmetals - Co.ukDocument2 pages+44 (0) 1786 475 662 Sales@amsmetals - Co.ukidontlikeebooksNo ratings yet

- ASTM A537 Class 1: General Product DescriptionDocument2 pagesASTM A537 Class 1: General Product Descriptionfelipercaliariyahoo.com.brNo ratings yet

- Properties of en 24 and en 28Document1 pageProperties of en 24 and en 28Subbarayan SaravanakumarNo ratings yet

- New 4140 Alloy SteelDocument3 pagesNew 4140 Alloy SteelShariq KhanNo ratings yet

- 117 Weldox 420 Uk DatasheetDocument2 pages117 Weldox 420 Uk DatasheetAndrewFranciscoNo ratings yet

- S420N (1.8902)Document2 pagesS420N (1.8902)Rupesh SinghNo ratings yet

- Hardox 450 Plate: General Product DescriptionDocument2 pagesHardox 450 Plate: General Product Descriptiongorane11No ratings yet

- Catalogo de Ejes CromsteelDocument20 pagesCatalogo de Ejes CromsteelJhonFerneyBohorquezSaldarriagaNo ratings yet

- Cartech Trimrite® Stainless: IdentificationDocument7 pagesCartech Trimrite® Stainless: IdentificationYassinSalahNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetermusatNo ratings yet

- ASTM A234 2010 (No Oficial)Document10 pagesASTM A234 2010 (No Oficial)Santiago Loría NavaNo ratings yet

- Metallic Material Specification: Title: 4140 Mod / 4145 Mod, 125 KSI YS, 285-340 BHNDocument5 pagesMetallic Material Specification: Title: 4140 Mod / 4145 Mod, 125 KSI YS, 285-340 BHNReginaldo SantosNo ratings yet

- Pinnacle Alloys E8018 C3Document2 pagesPinnacle Alloys E8018 C3Sajeev SivanandanNo ratings yet

- Introduction NACEDocument7 pagesIntroduction NACEyohesh KaleNo ratings yet

- AISI 1045 Carbon Steel G10450 Din CK45 W-Nr. 1.1191 JIS S45C Sheet PlateDocument3 pagesAISI 1045 Carbon Steel G10450 Din CK45 W-Nr. 1.1191 JIS S45C Sheet Platenhirpara1No ratings yet

- Welding Stainless SteelDocument4 pagesWelding Stainless SteelJohan ZraghozNo ratings yet

- 4 Material StandardsDocument29 pages4 Material Standardsloqueluq100% (3)

- Material Cross Reference TableDocument3 pagesMaterial Cross Reference TableLuis Pol SistiNo ratings yet

- UR45 NPlusDocument4 pagesUR45 NPlusMaiara Lima PereiraNo ratings yet

- Sandvik SAF 2205: Duplex Stainless SteelDocument8 pagesSandvik SAF 2205: Duplex Stainless SteelIuliu HurducaciNo ratings yet

- Sandvik SAF 2507: Duplex Stainless SteelDocument8 pagesSandvik SAF 2507: Duplex Stainless SteelmattiaNo ratings yet

- 168 Hardox 450 Uk Data SheetDocument2 pages168 Hardox 450 Uk Data SheetBambang WibisonoNo ratings yet

- Spec 4140 & 4130Document7 pagesSpec 4140 & 4130Nisa_nisheNo ratings yet

- Alloy Steel Astm A217 Grade Wc6 1Document1 pageAlloy Steel Astm A217 Grade Wc6 1didi sudiNo ratings yet

- WS412Document7 pagesWS412Martin OusephNo ratings yet

- Alloy SteelDocument33 pagesAlloy SteelDhana LakshmiNo ratings yet

- 1%ni For Improved Toughness: Data SheetDocument4 pages1%ni For Improved Toughness: Data Sheetmohamed AdelNo ratings yet

- Class: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageDocument2 pagesClass: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageAditya PrajasNo ratings yet

- Data Sheet Raex 450Document3 pagesData Sheet Raex 450Amit GauravNo ratings yet

- EN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 OnwardsDocument1 pageEN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 Onwardsgowtham_venkat_4No ratings yet

- 61fc14bb88a7a1f60f3b6a69 - SAE Steel GradesDocument6 pages61fc14bb88a7a1f60f3b6a69 - SAE Steel Gradesابو اسامةNo ratings yet

- Data SAF2205 04Document8 pagesData SAF2205 04il_yoo_1No ratings yet

- AISI SAE 4145 Product Datasheet D.a.cooper SonsDocument1 pageAISI SAE 4145 Product Datasheet D.a.cooper SonsDragan SorinNo ratings yet

- Ductile Iron SpecificationsDocument12 pagesDuctile Iron SpecificationsDouglas BooyensNo ratings yet

- Material Steel StandardsDocument25 pagesMaterial Steel StandardssamadhankadamNo ratings yet

- Pinnacle Alloys E11018 MDocument2 pagesPinnacle Alloys E11018 MMoch_adiganjarNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)