Professional Documents

Culture Documents

Receiver Sizing:: Squire-Cogswell/Aeros Instruments Inc

Receiver Sizing:: Squire-Cogswell/Aeros Instruments Inc

Uploaded by

Samik Mukherjee0 ratings0% found this document useful (0 votes)

4 views5 pagesOriginal Title

Vacuum Pump Sizing 130310063531 Phpapp02

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views5 pagesReceiver Sizing:: Squire-Cogswell/Aeros Instruments Inc

Receiver Sizing:: Squire-Cogswell/Aeros Instruments Inc

Uploaded by

Samik MukherjeeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Squire-Cogswell/Aeros Instruments Inc

1111 Lakeside Drive, Gurnee, Il 60031-4099

800-448-0770 Fax: 847-855-6300

www.selectorr.com

RECEIVER SIZING:

In vacuum thermoforming it is customary to generate deep vacuum in a short

period of time. A vacuum receiver is usually employed to produce this quick

initial pulldown. If the installation is new, the following formula may be used to

determine the size of the appropriate vacuum receiver.

V

2

= V

1

(P

3

-P

1

)/P

2

-P

3

Equ. 1.1

Where: V

2

= Applicable vacuum receiver size [Ft

3

]

V

1

= Total mold volume (forming volume + box volume) [Ft

3

]

P

1

= Initial pressure in the mold [PSIA]

P

2

= Pressure in vacuum system [PSIA]

P

3

= Pressure in combined system [PSIA]

Example: A vacuum receiver needs to be sized for a new installation. The forming

volume is 0.8 Ft

3

, and the box volume is 1.2 Ft

3

. The initial pressure in the

mold is 29.75 Hg (barometric pressure). The required pressure to form the

sheet in the mold is 22 Hg. The pressure produced by the vacuum pump will

be considered to be a maximum of 28 Hg.

First one must determine what are the appropriate variables, and then covert them to

the appropriate units.

V

2

To be determined

V

1

2 Ft

3

(0.8 Ft

3

+ 1.2 Ft

3

)

P

1

14.61 PSIA (29.76 Hg(A) converted to PSIA)

P

2

0.98 PSIA (28 Hg(G) first converted to 2 Hg(A), then converted to PSIA)

P

3

3.93 PSIA (22 Hg(G) first converted to 8 Hg(A), then converted to PSIA)

V

2

= 2 (3.93 14.61)/(0.98-3.93)

V

2

= 7.24 Ft

3

or times 7.48 gal/1 Ft

3

;

V

2

= 54 gal

In this case, a 60 gal receiver would be appropriate.

Another formula is useful where an existing tank is to be used. If the receiver size is

known, one will wish to calculate the pressure in the combined system.

P

3

= (P

1

V

1

+P

2

V

2

)/(V

1

+V

2

) Equ. 1.2

Where: V

2

= Existing vacuum receiver size [Ft

3

]

V

1

= Total mold volume (forming volume + box volume) [Ft

3

]

P

1

= Initial pressure in the mold [PSIA]

P

2

= Pressure in vacuum system [PSIA]

P

3

= Pressure in combined system [PSIA]

Squire-Cogswell/Aeros Instruments Inc

1111 Lakeside Drive, Gurnee, Il 60031-4099

800-448-0770 Fax: 847-855-6300

www.selectorr.com

Example: Say that a 60 gal receiver is available from stock, what will be the final

pressure in the combined system?

First one must determine what are the appropriate variables, and then convert them to

the appropriate units.

V

2

8.02 Ft

3

(60 gal * 1 Ft

3

/7.48 gal)

V

1

2 Ft

3

(0.8 Ft

3

+ 1.2 Ft

3

)

P

1

14.61 PSIA (29.75 Hg(G) converted to PSIA)

P

2

0.98 PSIA (28 Hg(G) first converted to 2 Hg(A), then converted to PSIA)

P

3

to be determined

P

3

= (14.61 * 2 + 0.98 * 8.02)/(2 + 8.02)

P

3

= 3.7 PSIA or converted to Hg(G) (29.92 Hg(A)-3.7 PSIA (29.92 Hg(A)/14.7 PSIA))

P

3

= 22.4 Hg(G)

In most cases the system volume is equivalent to the tank volume. Generally if the

pipework associated with the system is greater than 10% of the tank volume, that the

volume of the pipework should be taken into account. These formulas also do not

account for the collapse of the plastic in the mold. In most cases, the forming volume is

so much smaller than the system volume that it does not add much to the calculations.

These formulas also do not account for leaks in the system.

PUMP SIZING

After the vacuum receiver has produced the initial quick pulldown, the vacuum

pump can be used to generate the final deep vacuum. The following formula is

the general pump down formula.

t = V * LN (P

I

/P

F

)/Q

AVG

Equ. 1.3

Where: t Time to evacuate volume [min] LN Natural Log

V Total volume to be evacuated [Ft

3

]

P

1

Initial pressure (PSIA)

P

F

Final pressure (PSIA)

Q

AVG

Average volumetric flowrate of the pump (ACFM)

Note that this formula does not account for leaks in the system

Example: The 60 gal receiver from the previous example has been installed. The

process requires that the vacuum pump should pull the combined system from

22.4 Hg to 28 Hg in approximately 10 seconds to increase the detail on the

molded plastic. Will the SC-6TR be able to accomplish this?

Once again the appropriate variables need to be determined.

Squire-Cogswell/Aeros Instruments Inc

1111 Lakeside Drive, Gurnee, Il 60031-4099

800-448-0770 Fax: 847-855-6300

www.selectorr.com

t = To be determined

V 9.22 Ft

3

(1.2 Ft

3

= 8.02 Ft

3

) {note that the forming volume is approximately 0}

P

1

3.7 PSIA (22.4 Hg(G) determined by equation 1.2)

P

F

0.98 PSIA (28 Hg(G) first converted to 2 Hg(A), then converted to PSIA)

Q

AVG

37 ACFM

The average flowrate is determined by adding the flows at different vacuum levels. The

average capacity of the pump should be taken between the starting vacuum level and

the ending vacuum level. For this example, the values are for the SC-6TR.

5 Hg 55 ACFM

19 Hg 47 ACFM

22 Hg 43 ACFM

25 Hg 38 ACFM 43 + 38 + 31

28 Hg 31 ACFM 3 = 37.33 or 37 Avg. ACFM

29 Hg 21 ACFM

Solving for time:

t = 9.22 * LN (3.8/0.98)/37

t = 0.331 min or times 60 s/1 min;

t = 20 s

Basically the SC-6TR will take 10 seconds too long to accomplish this pulldown. Try the

SC-10TR using the same parameters. All of the values remain the same, except for the

average flowrate of the pump For the SC-10TR from 22 Hg to 28 Hg:

Q

AVG

= 82 ACFM

Once again solving for time:

t = 9.22 * :N (3.8/0/98)/82

t = 0.149 min or times 60 s/1 min;

t = 9 s

In answer to the question that was posed in the example, the SC-6TR will not be able to

satisfy the requirement, but the SC-10TR does satisfy the requirement.

Another way to work this problem is to determine what flowrate is required given a

specific time period.

Example: The 60 gal receiver from the previous example has been installed. The

process requires that the vacuum pump should pull the combined system from

22.4 Hg to 28 Hg in approximately 10 seconds to increase the detail on the

molded plastic. Will the SC-6TR be able to accomplish this?

Squire-Cogswell/Aeros Instruments Inc

1111 Lakeside Drive, Gurnee, Il 60031-4099

800-448-0770 Fax: 847-855-6300

www.selectorr.com

Change the formula to the following format:

Q

AVG

= V * LN (P

I

/P

F

)/t Equ. 1.4

From the values that been used in the previous pump down examples:

Q

AVG

= 9.22 * LN (3.7/0.98)/0.1667

{t = 10 s * (1 min/60 s) = 0.1667 min}

Q

AVG

= 73 ACFM

From what has been shown here, knowing the average volumetric flowrates, is that the

SC-10TR will be the best choice.

Converting from SCFM to ACFM is as follows:

V

2

= V

1

(P

1

/P

2

)(T

2

/T

1

) Equ. 1.5

Where:V

2

ACFM P

1

Absolute Pressure @ STP

V

1

SCFM P

2

Absolute Pressure @ Vacuum Condition

T

1

Absolute Temperature @ STP

T

2

Absolute Temperature @ Vacuum Condition

MW Average Molecular Weight

STP (Standard Temperature and Pressure)

is 520

o

R and 760 mmHg(A)

An easy way to remember is:

V that you want = V that you have x

(P that you have / P that you want) x

(T that you want / T that you have)

Converting from a mass flowrate to a volumetric flowrate is as follows:

V = m (1/60)(379/MW)(P

1

/P

2

)(T

2

/T

1

) Equ. 1.6

Squire-Cogswell/Aeros Instruments Inc

1111 Lakeside Drive, Gurnee, Il 60031-4099

800-448-0770 Fax: 847-855-6300

www.selectorr.com

Where:V ACFM P

1

Absolute Pressure @ STP

m - #/Hr P

2

Absolute Pressure @ Vacuum Condition

T

1

Absolute Temperature @ STP

T

2

Absolute Temperature @ Vacuum Condition

MW Average Molecular Weight

STP (Standard Temperature and Pressure)

is 520

o

R and 760 mmHg(A)

Example:

Convert 20#/Hr of air to volumetric flowrate 25 Hg and 100

o

F.

V = m (1/60)(379/MW)(P

1

/P

2

)(T

2

/T

1

)

m = 20#/Hr

P

1

= 760 mmHg(A) = 29.92 Hg(A)

P

2

= 25 Hg(G) = 125 mmHg(A), or 4.92 Hg(A)

T

1

= 460 + 60

o

F = 520

o

R

T

2

= 460 + 100

o

F = 560

o

R

V = 20 (1/60)(379/29)(760/125)(560/520), or V = 20

(1/60)(379/29)(29.92/4.92)(560/520)

V = 29 ACFM @ 25 Hg and 100

o

F (Volumetric flowrates should be described at a

specific pressure and temperature

Converting from a volumetric flowrate to a mass flowrate is as follows:

M = V (60/1)(MW/379)(P

2

/P

1

)(T

1

/T

2

),

using the same symbols as above. Equ. 1.7

Example:

Convert 300 ACFM of air @ 28.5 Hg and 60

o

F to a mass flowrate.

m = V (60/1)(MW/379)(P

2

/P

1

)(T

1

/T

2

)

V = 300 ACFM

P

1

= 760 mm Hg = 29.92 Hg

P

2

= 28.5 Hg = 36 mmHg, or 1.42 Hg(A)

T

1

= 460 + 60

o

F = 520

o

R

T

2

= 460 + 100

o

F = 520

o

F, note that since T

1

= T

2

, the division is 1, and it may be

neglected

m = 300 (60/1)(29/379)(36/760), or m = 300 (60/1)(29/379)(1.42/29.92)

m = 65#/Hr

Note that all calculations involving pressure and temperature should be performed at

absolute conditions.

You might also like

- Air Receiver SizingDocument4 pagesAir Receiver SizingAnonymous a4Jwz14WNo ratings yet

- Vacuum Technique: Proceedings of a Meeting of the German Society for Vacuum Technique, Heidelberg, September 18–21, 1962From EverandVacuum Technique: Proceedings of a Meeting of the German Society for Vacuum Technique, Heidelberg, September 18–21, 1962G. GüntherschulzeNo ratings yet

- Vacuum Engineering Calculations, Formulas, and Solved ExercisesFrom EverandVacuum Engineering Calculations, Formulas, and Solved ExercisesRating: 4.5 out of 5 stars4.5/5 (2)

- Vacuum Book EDocument71 pagesVacuum Book EChristian Vargas100% (5)

- Process Design Documentation From Ch29 - Mihir - S HandbookDocument14 pagesProcess Design Documentation From Ch29 - Mihir - S HandbookHa LongNo ratings yet

- Vacuum Pump Sizing PDFDocument1 pageVacuum Pump Sizing PDFLiem NguyenNo ratings yet

- Vacuum PumpDocument126 pagesVacuum PumpJessicalba Lou100% (1)

- Falling Film Evaporator VolumeDocument2 pagesFalling Film Evaporator VolumeHemant K Patil100% (1)

- Vacuum PresentationDocument277 pagesVacuum Presentationavinashpatil2408100% (2)

- Vacuum Science Amp Engineering PDFDocument239 pagesVacuum Science Amp Engineering PDFXantos Yulian100% (3)

- Best Practice Compressed Air PDFDocument28 pagesBest Practice Compressed Air PDFfestradavNo ratings yet

- Estimating Air LeakageDocument5 pagesEstimating Air Leakagenasirmuzaffar100% (1)

- 8 Vacuum LeakDocument42 pages8 Vacuum Leakapi-3856548100% (3)

- An Overview of Vacuum System DesignDocument9 pagesAn Overview of Vacuum System Designhwang2100% (2)

- 4 Vacuum PumpDocument126 pages4 Vacuum Pumpapi-3856548100% (2)

- Liquid Ring PumpDocument48 pagesLiquid Ring Pumpkalyanm203515100% (1)

- Vacuum Pipe SizingDocument3 pagesVacuum Pipe SizingYaseen Mallick86% (7)

- Compressed Air Systems, PDH Course M146Document91 pagesCompressed Air Systems, PDH Course M146cramerps2084No ratings yet

- VacuumBook FundamentalsDocument200 pagesVacuumBook FundamentalsChirag DobariyaNo ratings yet

- Torque Agitator CalculationDocument3 pagesTorque Agitator CalculationGeorge Markas100% (1)

- EmersonDocument21 pagesEmersoncrustytheclown99No ratings yet

- Efficient Pneumatic ConveyingDocument14 pagesEfficient Pneumatic Conveying설동하100% (2)

- A Venturi Scrubber Used To Clean Gasifier Syngas Results in PDFDocument5 pagesA Venturi Scrubber Used To Clean Gasifier Syngas Results in PDFPaoLa MonTañoNo ratings yet

- P & I Design LTDDocument34 pagesP & I Design LTDYunping Huang100% (1)

- Performance Thermo CompressorsDocument8 pagesPerformance Thermo CompressorsclintoncNo ratings yet

- Sizing Air ReceiverDocument3 pagesSizing Air ReceiverAnkon Mukherjee100% (3)

- Vacuum PumpsDocument1 pageVacuum PumpsMarcelo Peretti0% (1)

- Vacuum ClassDocument90 pagesVacuum ClassdesrytandiNo ratings yet

- 5.4.3. Power Requirements For Pumping Liquids: 5.4. Pumps and CompressorsDocument3 pages5.4.3. Power Requirements For Pumping Liquids: 5.4. Pumps and Compressorsamir885No ratings yet

- Engineered Nitrogen Generator Systems - E4Document8 pagesEngineered Nitrogen Generator Systems - E4herdin56No ratings yet

- Vacuum Engineering FundamentalsDocument33 pagesVacuum Engineering FundamentalsChristian Vargas100% (3)

- Rotary Screw Compressor Discussion and Calculations: NotesDocument9 pagesRotary Screw Compressor Discussion and Calculations: Notesfarshad100% (2)

- Graco Vacuum CalculationsDocument3 pagesGraco Vacuum CalculationsAbsalon Fernando Riascos100% (2)

- Sizing Technical Brief FinalDocument3 pagesSizing Technical Brief FinalBelalNorNo ratings yet

- Agitator Spreadsheet DetailsDocument7 pagesAgitator Spreadsheet DetailsAndrewNo ratings yet

- Compressor Air CalculationDocument3 pagesCompressor Air CalculationmohamedbadawyNo ratings yet

- PSV Sizing - Non Ideal GasesDocument1 pagePSV Sizing - Non Ideal GasesSaeid Rahimi MofradNo ratings yet

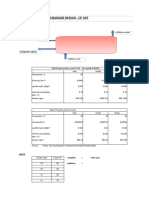

- Heat Exchanger DesignDocument8 pagesHeat Exchanger Designkikokiko KarimNo ratings yet

- Sparger Calc MotDocument5 pagesSparger Calc MotRajesh NareNo ratings yet

- Blower InformationDocument36 pagesBlower InformationshreemugNo ratings yet

- Scrubber DesignDocument31 pagesScrubber Designmakwana1No ratings yet

- Air DryerDocument4 pagesAir Dryerrashm006ranjanNo ratings yet

- System OneDocument4 pagesSystem OnerasottoNo ratings yet

- P&ID Process Cooling Symbols and Their Usage PDFDocument4 pagesP&ID Process Cooling Symbols and Their Usage PDFHV UioNo ratings yet

- Receiver SizingDocument7 pagesReceiver SizingjsaulNo ratings yet

- Air Receiver SizingDocument3 pagesAir Receiver Sizinglutfi awnNo ratings yet

- Air Receiver Sizing Metric UnitsDocument4 pagesAir Receiver Sizing Metric UnitsAnonymous Od7nYs8No ratings yet

- Process Dynamics and Control 4th Edition Seborg Solutions ManualDocument10 pagesProcess Dynamics and Control 4th Edition Seborg Solutions Manualmarthanhati5s100% (27)

- Process Dynamics and Control 4Th Edition Seborg Solutions Manual Full Chapter PDFDocument31 pagesProcess Dynamics and Control 4Th Edition Seborg Solutions Manual Full Chapter PDFkarinawarrenpkmgsxdfrc100% (10)

- Calculation Note For Actuator Air Consumption - Rev 1Document4 pagesCalculation Note For Actuator Air Consumption - Rev 1dadyjoshNo ratings yet

- Centrifugal Compressor Performance CalculationsDocument4 pagesCentrifugal Compressor Performance CalculationsFreddy RoaNo ratings yet

- Ej Vol Control Pelu oDocument8 pagesEj Vol Control Pelu oPablo Martínez CavieresNo ratings yet

- Non Flow Processes Gases Closed SystemDocument9 pagesNon Flow Processes Gases Closed SystemNjabulo NgobeseNo ratings yet

- Refrigerantion Complete 2Document27 pagesRefrigerantion Complete 2Ricardo Wan Aguero50% (2)

- Lab 2Document17 pagesLab 2Callum BiggsNo ratings yet

- Flow Formulas: For Computing Gas and Liquid Flow Through Regulators and ValvesDocument4 pagesFlow Formulas: For Computing Gas and Liquid Flow Through Regulators and ValvesAhmed AbdelatyNo ratings yet

- KV FactorDocument8 pagesKV FactorPrasit MeeboonNo ratings yet

- Absorption NotesDocument79 pagesAbsorption Noteshanisshi100% (2)

- Fans BlowersDocument23 pagesFans BlowersPhilip Anthony MasilangNo ratings yet

- Filosofia de ControlDocument40 pagesFilosofia de Controlejzuppelli8036No ratings yet

- Aos 330 Lab 11Document3 pagesAos 330 Lab 11Ariyan Abrar SaifNo ratings yet

- Seers of The Ages Embracing Spiritual AltyDocument394 pagesSeers of The Ages Embracing Spiritual AltyRev Timothy ChaseNo ratings yet

- A Study On Overlay Design of Repeatedly Deteriorating Flexible PavementDocument6 pagesA Study On Overlay Design of Repeatedly Deteriorating Flexible PavementAJER JOURNALNo ratings yet

- UD01138d BCU ABFIFF01 V002Document27 pagesUD01138d BCU ABFIFF01 V002Catalin PelinNo ratings yet

- Underground Work in Hard Rock Tunnelling and MiningDocument87 pagesUnderground Work in Hard Rock Tunnelling and MiningMiguel CastillejoNo ratings yet

- Bachelor Series 1 A Night With A StrangerDocument188 pagesBachelor Series 1 A Night With A Strangercam UyangurenNo ratings yet

- TR1212 Ver201Document55 pagesTR1212 Ver201vNo ratings yet

- Ashok Sir Arch WireDocument130 pagesAshok Sir Arch WireDeepuUrs100% (1)

- ELME Manual For 817, 1-2676Document89 pagesELME Manual For 817, 1-2676mario80% (10)

- 2004-08-01 The Sense of Synthetics in Worm Gear LubricationDocument11 pages2004-08-01 The Sense of Synthetics in Worm Gear LubricationJose FarroNo ratings yet

- The BFG - Roald Dahl - 1989 - Penguin Group - Anna's ArchiveDocument64 pagesThe BFG - Roald Dahl - 1989 - Penguin Group - Anna's ArchivePruNo ratings yet

- Standard Operating Procedures (Sops) : Fact Sheet #21Document2 pagesStandard Operating Procedures (Sops) : Fact Sheet #21Ria UtamiNo ratings yet

- GUTS Olivia RodrigoDocument13 pagesGUTS Olivia RodrigohirugamitayaliNo ratings yet

- James Frank McGrath - The Only True God - Early Christian Monotheism in Its Jewish Context (2009, University of Illinois Press) PDFDocument170 pagesJames Frank McGrath - The Only True God - Early Christian Monotheism in Its Jewish Context (2009, University of Illinois Press) PDFJPrakash100% (1)

- Edig@s Example XML Messages As Used by GTS 5.1R2 - v1.2.2Document56 pagesEdig@s Example XML Messages As Used by GTS 5.1R2 - v1.2.2serefbingolNo ratings yet

- Hyper Duplex in Europe Sswsup1005 - Duplex - ChaterDocument4 pagesHyper Duplex in Europe Sswsup1005 - Duplex - ChaterThinh NguyenNo ratings yet

- Alexandrov Geometry: Foundations: Stephanie Alexander, Vitali Kapovitch, and Anton PetruninDocument301 pagesAlexandrov Geometry: Foundations: Stephanie Alexander, Vitali Kapovitch, and Anton PetruninMohammad AbuyahyaNo ratings yet

- 30 Minute Shortbread Cookies - Cloudy KitchenDocument2 pages30 Minute Shortbread Cookies - Cloudy Kitchenharidas venkateshNo ratings yet

- Ece Vii Power Electronics (10ec73) AssignmentDocument6 pagesEce Vii Power Electronics (10ec73) AssignmentThomas PriceNo ratings yet

- Nemio XG Service ManualDocument127 pagesNemio XG Service ManualMULTIMED ENGINEERINGNo ratings yet

- Chem 213 Module 5A-Aqueous Soln and Chemical EquilibriaDocument7 pagesChem 213 Module 5A-Aqueous Soln and Chemical EquilibriaNatalie GaidNo ratings yet

- Transcript - Five Years of ML in Weather and Climate ModellingDocument6 pagesTranscript - Five Years of ML in Weather and Climate ModellingIrida LazicNo ratings yet

- Air Flow DesignDocument65 pagesAir Flow DesignmajortayNo ratings yet

- 11 - Semua Jurusan - EnglishDocument11 pages11 - Semua Jurusan - EnglishYoe ZakieNo ratings yet

- Lah Dum 863 20190326 enDocument4 pagesLah Dum 863 20190326 enBruno BrasseurNo ratings yet

- Annex 6: Guidance On Good Manufacturing Practices (GMP) : Inspection ReportDocument5 pagesAnnex 6: Guidance On Good Manufacturing Practices (GMP) : Inspection Reportumarn1582No ratings yet

- UNIT OF COMPETENCE: - Perform Bench Work MODULE TITLE: Performing Bench Work LO1: Lay-Out and Mark Dimensions/ Features On Work PieceDocument63 pagesUNIT OF COMPETENCE: - Perform Bench Work MODULE TITLE: Performing Bench Work LO1: Lay-Out and Mark Dimensions/ Features On Work Pieceahmed jemal100% (1)

- Indanthren Brilliant Blue RCL Coll: Short ProfileDocument2 pagesIndanthren Brilliant Blue RCL Coll: Short ProfileOOlii MejiaNo ratings yet

- 2.308 - Vehicle Entry Permit ProcedureDocument5 pages2.308 - Vehicle Entry Permit Procedurekirandevi1981No ratings yet

- HP 15 - Ab225ur DAX12AMB6D0 Quanta X12 6L R1aDocument40 pagesHP 15 - Ab225ur DAX12AMB6D0 Quanta X12 6L R1asaffunnutretro-9095No ratings yet