0% found this document useful (0 votes)

420 views2 pagesSlab Inspection Checklist for A3 Project

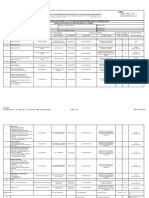

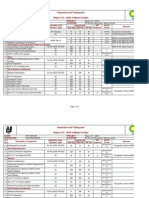

This document outlines inspection requirements for wet lean concrete work for a development project in Laemchabang, Thailand. It specifies inspection criteria for concrete mix design, slump, elapsed time before pouring, compressive strength, curing, formwork dimensions and alignment, formwork strength, cleanliness, concrete elevation, in situ density, and surface finish. Inspections will be carried out by Italian-Thai Development and verified by Sindthu Maunsell with approval from Scott Wilson according to the specified frequencies and acceptance criteria.

Uploaded by

tunaungkyawCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

420 views2 pagesSlab Inspection Checklist for A3 Project

This document outlines inspection requirements for wet lean concrete work for a development project in Laemchabang, Thailand. It specifies inspection criteria for concrete mix design, slump, elapsed time before pouring, compressive strength, curing, formwork dimensions and alignment, formwork strength, cleanliness, concrete elevation, in situ density, and surface finish. Inspections will be carried out by Italian-Thai Development and verified by Sindthu Maunsell with approval from Scott Wilson according to the specified frequencies and acceptance criteria.

Uploaded by

tunaungkyawCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd