Professional Documents

Culture Documents

Coolant: Inspection

Uploaded by

Aiman NasirOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coolant: Inspection

Uploaded by

Aiman NasirCopyright:

Available Formats

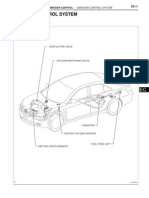

CO08J-01

- COOLING COOLANT

CO-1

1414 Author : Date :

1997 SUPRA (RM502U)

COOLANT

INSPECTION

1. CHECK ENGINE COOLANT LEVEL AT RADIATOR RESERVOIR

The engine coolant level should be between the LOW and FULL lines, when the engine is cold.

If low, check for leaks and add engine coolant up to the FULL line.

2. CHECK ENGINE COOLANT QUALITY

(a) Remove the radiator cap.

CAUTION:

To avoid the danger of being burned, do not remove the radiator cap while the engine and radiator

are still hot, as fluid and steam can be blown out under pressure.

(b) There should not be any excessive deposits of rust or scale around the radiator cap or radiator filler

hole, and the coolant should be free from oil.

If excessively dirty, replace the coolant.

(c) Reinstall the radiator cap.

CO0ZY-01

Z07402

Drain Plug

Drain Plug

CO-2

- COOLING COOLANT

1415 Author : Date :

1997 SUPRA (RM502U)

REPLACEMENT

1. DRAIN ENGINE COOLANT

(a) Remove the radiator cap.

CAUTION:

To avoid the danger of being burned, do not remove the ra-

diator cap while the engine and radiator are still hot, as fluid

and steam can be blown out under pressure.

(b) Loosen the 2 drain plugs (for the engine and radiator),

and drain the coolant.

HINT:

To prevent the coolant from spraying over the cylinder block,

connect the rubber hose (inside diameter 6 - 8 mm) in the mar-

ket to the union pipe under.

(c) Close the drain plugs.

Torque:

Engine drain plug

29 Nm (300 kgfcm, 22 ftlbf)

2. FILL ENGINE COOLANT

(a) Slowly fill the system with coolant.

L Use a good brand of ethylene-glycol base coolant

and mix it according to the manufacturers direc-

tions.

L Using coolant which includes more than 50 % ethyl-

ene-glycol (but not more than 70 %) is recom-

mended.

NOTICE:

L Do not use an alcohol type coolant.

L The coolant should be mixed with demineralized wa-

ter or distilled water.

Capacity (w/ Heater):

M/T A/T

2JZ-GE

7.3 liters

(7.7 US qts, 6.4 lmp. qts)

8.3 liters

(8.8 US qts, 7.3 lmp. qts)

2JZ-GTE

8.9 liters

(9.4 US qts, 7.8 lmp. qts)

8.8 liters

(9.3 US qts, 7.7 lmp. qts)

(b) Install the radiator cap.

(c) Start the engine, and bleed the cooling system.

(d) Refill the reservoir with coolant until it reaches the

FULL line.

3. CHECK ENGINE COOLANT FOR LEAKS

CO08L-02

- COOLING WATER PUMP

CO-3

1416 Author : Date :

1997 SUPRA (RM502U)

WATER PUMP

COMPONENTS

CO-4

- COOLING WATER PUMP

1417 Author : Date :

1997 SUPRA (RM502U)

B01771

Air Cleaner and MAF Meter Assembly

No.1 Air Hose

Air Cleaner Duct

Upper Radiator Support

Radiator Assembly

Radiator Reservoir Hose

Electric Cooling

Fan Connector

ECT Switch

Connector

No.2 Fan Shroud

No.2 Air Tube

Lower

Radiator

Support

Hose Clamp

Oil Cooler Tube

Engine Under Cover

Drive Belt

A/T

x 16

Battery

Insulator

Water Pump Pulley

Fan and Fluid Coupling Assembly

PS Pump Pulley

Battery Tray

Battery

MAF Meter Connector

Hold-Down

Clamp

2JZ-GTE

- COOLING WATER PUMP

CO-5

1418 Author : Date :

1997 SUPRA (RM502U)

B01432

No.2 Timing Belt Cover

Drive Belt Tensioner

No.1 Timing Belt Cover

Crankshaft Pulley

Oil Filler Cap

x 10

Timing Belt

Timing Belt Guide

No.2 Water Bypass Pipe

L

Idler Pulley

Gasket

Drain Hose

Water Pump

x 5

Dust Boot

z Gasket

z O-Ring

z O-Ring

z Gasket

Thermostat

Timing Belt Tensioner

Generator Connector

Generator Wire

Generator

Bracket (A/T)

Water Inlet and Lower

Radiator Hose Assembly

LPrecoated part

zNon-reusable part

6 x

2JZ-GTE

Gasket

Water Outlet

ECT Sender

Gauge Connector

ECT Sensor Connector

Turbo Water Hose

Drive Belt

Tension Damper

No.3 Timing Belt Cover

No.3 Turbo Water Hose

z Gasket

No.1 Water Bypass Pipe

M/T

CO-6

- COOLING WATER PUMP

1419 Author : Date :

1997 SUPRA (RM502U)

CO08M-02

P12278

P12300

Turn

- COOLING WATER PUMP

CO-7

1420 Author : Date :

1997 SUPRA (RM502U)

REMOVAL

1. 2JZ-GTE:

REMOVE NO.1 AIR HOSE

2. 2JZ-GE:

REMOVE AIR CLEANER, MAF METER AND INTAKE

AIR CONNECTOR PIPE ASSEMBLY

(See page EM-57 )

3. 2JZ-GTE:

REMOVE AIR CLEANER AND MAF METER

ASSEMBLY (See page EM-58 )

4. REMOVE RADIATOR ASSEMBLY

(See page CO-22 )

5. 2JZ-GTE M/T:

REMOVE DRIVE BELT TENSIONER DAMPER

(See page EM-15 )

6. REMOVE DRIVE BELT, FAN, FLUID COUPLING

ASSEMBLY AND WATER PUMP PULLEY

(a) Loosen the 4 nuts holding the fluid coupling to the water

pump.

(b) Loosen the drive belt tension by turning the drive belt ten-

sioner clockwise, and remove the drive belt.

(c) Remove the 4 nuts, the fan, fluid coupling assembly and

water pump pulley.

7. REMOVE WATER INLET, LOWER RADIATOR HOSE

ASSEMBLY AND THERMOSTAT

(See page CO-14 )

8. REMOVE TIMING BELT

(2JZ-GE: See page EM-13 )

(2JZ-GTE: See page EM-15 )

9. REMOVE IDLER PULLEY

(2JZ-GE: See page EM-13 )

(2JZ-GTE: See page EM-15 )

10. 2JZ-GTE:

DISCONNECT TURBO WATER HOSES FROM

WATER OUTLET

Z16746

O-Ring

Water Bypass Outlet

NO.1 Water

Bypass Pipe

2JZ-GE

Z16764

2JZ-GTE

Z16745

2JZ-GE

Z16930

2JZ-GE

No.2 Water Bypass Pipe

2JZ-GTE

No.2 Water Bypass Pipe

No.3 Turbo Water Hose

CO-8

- COOLING WATER PUMP

1421 Author : Date :

1997 SUPRA (RM502U)

11. 2JZ-GE:

REMOVE WATER BYPASS OUTLET AND NO.1

WATER BYPASS PIPE

(a) Remove the 2 bolts, water bypass outlet and No.1 water

bypass pipe.

(b) Remove the 3 O-rings from the water bypass outlet and

No.1 water bypass pipe.

12. 2JZ-GTE:

REMOVE WATER OUTLET AND NO.1 WATER

BYPASS PIPE

(a) Disconnect the ECT sensor and sender gauge connec-

tors.

(b) Remove the 2 bolts, water outlet and gasket.

(c) Remove the No.1 water bypass pipe and 2 O-rings.

13. REMOVE WATER PUMP

(a) Loosen the nut and remove the bolt, and slightly slide the

generator from the water pump.

(b) 2JZ-GE:

Remove the bolt, and disconnect the clamp bracket.

(c) 2JZ-GE:

Remove the bolt, and disconnect the connector bracket

(for crankshaft position sensor connector).

(d) Remove the 2 nuts, and disconnect the No.2 water by-

pass pipe from the water pump.

(e) 2JZ-GTE:

Disconnect the No.3 turbo water hose from the water

pump.

P25846

Drain Hose

- COOLING WATER PUMP

CO-9

1422 Author : Date :

1997 SUPRA (RM502U)

(f) Remove the 6 bolts, water pump and gasket.

(g) Remove the drain hose.

(h) Remove the O-ring from the cylinder block.

P02321

CO08N-02

P10717

P10878

CO-10

- COOLING WATER PUMP

1423 Author : Date :

1997 SUPRA (RM502U)

INSPECTION

1. INSPECT WATER PUMP

(a) Turn the pulley seat, and check that the water pump bear-

ing is not rough or noisy.

If necessary, replace the water pump.

(b) Visually check the air hole and drain hose for coolant leak-

age.

If leakage is found, replace the water pump.

2. INSPECT FLUID COUPLING

(a) Remove the 4 nuts and fan from the fluid coupling.

(b) Check that the fluid coupling is not damaged and that no

silicon oil leaks.

If necessary, replace the fluid coupling.

(c) Reinstall the fan to the fluid coupling with the 4 nuts.

Torque: 7.4 Nm (75 kgfcm, 65 in.lbf)

CO08O-01

P03945

New

O-Ring

P02574

New Gasket

S00913

A

B

A

B

A

B

B

B

- COOLING WATER PUMP

CO-1 1

1424 Author : Date :

1997 SUPRA (RM502U)

INSTALLATION

1. INSTALL WATER PUMP

(a) Install a new O-ring to the cylinder block.

(b) Install the drain hose.

(c) Install a new gasket to the water pump.

(d) Connect the water pump to the water bypass pipe. Do not

install the nut yet.

(e) Install the water pump with the 2 bolts (A) and 4 bolts (B).

Torque: 21 Nm (210 kgfcm, 15 ftlbf)

HINT:

Hand tighten the (A) bolts first.

(f) Install the 2 nuts holding the No.2 water bypass pipe to

the water pump.

Torque: 21 Nm (210 kgfcm, 15 ftlbf)

(g) 2JZ-GTE:

Connect the No.3 turbo water hose to the water pump.

(h) 2JZ-GE:

Install the connector bracket (for crankshaft position sen-

sor connector) with the bolt.

(i) 2JZ-GE:

Install the engine clamp bracket with the bolt.

(j) Install the generator with the bolt and nut.

Torque: 40 Nm (400 kgfcm, 30 ftlbf)

2. 2JZ-GE:

INSTALL NO.1 WATER BYPASS PIPE AND

WATER BYPASS OUTLET

(a) Install 2 new O-rings to the No.1 water bypass pipe.

(b) Install a new O-ring and the water bypass outlet with the

2 bolts.

Torque: 9.0 Nm (90 kgfcm, 80 in.lbf)

3. 2JZ-GTE:

INSTALL NO.1 WATER BYPASS PIPE AND

WATER OUTLET

(a) Install 2 new O-rings to the No.1 water bypass pipe.

(b) Apply soapy water to the O-rings.

(c) Install the No.1 water bypass pipe to the water pump.

P02583

Matchmarks

CO-12

- COOLING WATER PUMP

1425 Author : Date :

1997 SUPRA (RM502U)

(d) Install a new gasket and the water outlet with the 2 bolts.

Torque: 21 Nm (210 kgfcm, 15 ftlbf)

(e) Connect the ECT sensor and sender gauge connectors.

4. 2JZ-GTE:

CONNECT TURBO WATER HOSES TO WATER

OUTLET

5. INSTALL IDLER PULLEY AND TIMING BELT

(2JZ-GE: See page EM-19 )

(2JZ-GTE: See page EM-21 )

6. INSTALL WATER INLET AND LOWER RADIATOR

HOSE ASSEMBLY (See page CO-16 )

7. INSTALL WATER PUMP PULLEY, FAN, FLUID

COUPLING ASSEMBLY AND DRIVE BELT

(a) Align the matchmarks, and install the water pump pulley,

the fan and fluid coupling assembly with the 4 nuts.

(b) Install the drive belt by turning the drive belt tensioner

clockwise.

(c) Stretch the belt tight, and tighten the 4 nuts.

Torque: 16 Nm (165 kgfcm, 12 ftlbf)

8. 2JZ-GTE M/T:

INSTALL DRIVE BELT TENSIONER DAMPER

9. INSTALL RADIATOR ASSEMBLY

(See page CO-28 )

10. 2JZ-GE:

INSTALL AIR CLEANER, MAF METER AND INTAKE

AIR CONNECTOR PIPE ASSEMBLY

11. 2JZ-GTE:

INSTALL AIR CLEANER AND MAF METER

ASSEMBLY

12. 2JZ-GTE:

INSTALL NO.1 AIR HOSE

13. ROAD TEST

Check for abnormal noise, shock, slippage, correct shift points

and smooth operation.

CO08P-02

Z16933

2JZ-GE

Thermostat

Water Inlet

L Gasket

Hose Assembly

Lower radiator

Water Inlet and

Engine Under Cover

L Gasket

L Non reusable part

Thermostat

2JZ-GTE

x16

- COOLING THERMOSTAT

CO-13

1426 Author : Date :

1997 SUPRA (RM502U)

THERMOSTAT

COMPONENTS

CO08Q-01

Z16744

2JZ-GE

Z16763

2JZ-GTE

CO-14

- COOLING THERMOSTAT

1427 Author : Date :

1997 SUPRA (RM502U)

REMOVAL

HINT:

Removal of the thermostat would have an adverse effect, caus-

ing a lowering of cooling efficiency. Do not remove the thermo-

stat, even if the engine tends to overheat.

1. 2JZ-GTE:

REMOVE ENGINE UNDER COVER

2. DRAIN ENGINE COOLANT

3. 2JZ-GE:

DISCONNECT WATER INLET FROM WATER PUMP,

AND REMOVE THERMOSTAT

(a) Remove the 2 nuts holding the water inlet to the water

pump, and disconnect the water inlet from the water

pump.

(b) Remove the thermostat.

(c) Remove the gasket from the thermostat.

4. 2JZ-GTE:

REMOVE WATER INLET, LOWER RADIATOR HOSE

ASSEMBLY AND THERMOSTAT

(a) Disconnect the lower radiator hose from the radiator.

(b) Remove the 2 nuts holding the water inlet to the water

pump, and disconnect the water inlet and lower radiator

hose from the water pump.

(c) Remove the thermostat.

(d) Remove the gasket from the thermostat.

CO08R-01

P11116

CO0601

P03242

Valve

Lift

- COOLING THERMOSTAT

CO-15

1428 Author : Date :

1997 SUPRA (RM502U)

INSPECTION

INSPECT THERMOSTAT

HINT:

The thermostat is numbered with the valve opening tempera-

ture.

(a) Immerse the thermostat in water and gradually heat the

water.

(b) Check the valve opening temperature.

Valve opening temperature:

80 - 84C (176 - 183F)

If the valve opening temperature is not as specified, replace the

thermostat.

(c) Check the valve lift.

Valve lift: 8.5 mm (0.335 in.) or more at 95C (203F)

If the valve lift is not as specified, replace the thermostat.

(d) Check that the valve is closed when the thermostat is at

low temperatures (below 40C (104F)).

If not closed, replace the thermostat.

CO08S-01

P11770

Jiggle Valve

Protrusion

2JZ-GE

2JZ-GTE

CO-16

- COOLING THERMOSTAT

1429 Author : Date :

1997 SUPRA (RM502U)

INSTALLATION

1. PLACE THERMOSTAT IN WATER INLET

(a) Install a new gasket to the thermostat.

(b) Align the jiggle valve of the thermostat with the protrusion

of the water inlet.

2. INSTALL WATER INLET

(a) Install the water inlet with the 2 nuts.

Torque:

2JZ-GE 8.8 Nm (90 kgfcm, 78 in.lbf)

2JZ-GTE 21 Nm (210 kgfcm, 15 ftlbf)

(b) 2JZ-GTE:

Connect the lower radiator hose to the radiator.

3. 2JZ-GTE:

INSTALL ENGINE UNDER COVER

4. FILL WITH ENGINE COOLANT

5. START ENGINE AND CHECK FOR COOLANT

LEAKS

CO08T-01

- COOLING RADIATOR

CO-17

1430 Author : Date :

1997 SUPRA (RM502U)

RADIATOR

ON-VEHICLE CLEANING

Using water or a steam cleaner, remove any mud and dirt from the radiator core.

NOTICE:

If using a high pressure type cleaner, be careful not to deform the fins of the radiator core. (i. e. Main-

tain a distance between the cleaner nozzle and radiator core.)

Z00570

Radiator Cap Tester

30 or More

Radiator Cap

P11504

CO08U-01

CO-18

- COOLING RADIATOR

1431 Author : Date :

1997 SUPRA (RM502U)

ON-VEHICLE INSPECTION

1. REMOVE RADIATOR CAP

CAUTION:

To avoid the danger of being burned, do not remove the ra-

diator cap while the engine and radiator are still hot, as fluid

and steam can be blown out under pressure.

2. INSPECT RADIATOR CAP

NOTICE:

L If the radiator cap has contaminations, always rinse

it with water.

L When performing steps (a) and (b) below, keep the ra-

diator pump tester at an angle of over 30 above the

horizontal.

(a) Before using a radiator cap tester, wet the relief valve and

pressure valve with engine coolant or water.

(b) Using a radiator cap tester, slowly pump the tester and

check that air is coming from the vacuum valve.

Pump speed: 1 push/ (3 seconds or more)

NOTICE:

Push the pump at a constant speed.

If air is not coming from the vacuum valve, replace the radiator

cap.

(c) Pump the tester and measure the relief valve opening

pressure.

Pump speed: 1 push within 1 second

NOTICE:

This pump speed is for the first pump only (in order to close

the vacuum valve). After this, the pump speed can be re-

duced.

Standard opening pressure:

93 - 123 kPa (0.95 - 1.25 kgf/cm

2

, 13.5 - 17.8 psi)

Minimum opening pressure:

78 kPa (0.8 kgf/cm

2

, 11.4 psi)

HINT:

Use the testers maximum reading as the opening pressure.

If the opening pressure is less than minimum, replace the radia-

tor cap.

3. INSPECT COOLING SYSTEM FOR LEAKS

(a) Fill the radiator with coolant, and attach a radiator cap tes-

ter.

(b) Warm up the engine.

(c) Pump it to 147 kPa (1.5 kgf/cm

2

, 21.3 psi), and check that

the pressure does not drop.

If the pressure drops, check the hoses, radiator or water pump

for leaks.

If no external leaks are found, check the heater core, cylinder

block and cylinder head.

4. REINSTALL RADIATOR CAP

CO08V-02

- COOLING RADIATOR

CO-19

1432 Author : Date :

1997 SUPRA (RM502U)

COMPONENTS

S04927

Air Cleaner Duct

Upper Radiator Hose

Hold-Down

Clamp

Radiator

Cap

Battery Insulator

Battery

Lower Radiator Hose

Oil Cooler Hose (A/T)

Upper Radiator

Support

Radiator

Assembly

L O-Ring

No.2 Fan Shroud

Battery Tray

Engine Under Cover

x 16

Electric Cooling

Fan Connector

Drain Plug

Radiator Reservoir

Hose

No.5 Air Hose

No.2 Air Tube

ECT Switch (for Electric

Cooling Fan) Connector

Radiator

LNon-reusable part

No.1 Fan Shroud

Clip

Lower

Radiator

Support

2JZ-GTE

Drain Hose

ECT Switch (for Electric Cooling Fan)

L O-Ring

Electric Cooling Fan

LH Headlight Beam Angle Gauge

CO-20

- COOLING RADIATOR

1433 Author : Date :

1997 SUPRA (RM502U)

P12141

Upper Tank

L O-Ring

Cushion

Lower Tank

Oil Cooler

Radiator Cap

Core

Lower Tank

Inlet Pipe

Drain Plug

L O-Ring

A / T

L O-Ring

L O-Ring

L Non-reusable part

- COOLING RADIATOR

CO-21

1434 Author : Date :

1997 SUPRA (RM502U)

CO0ZZ-01

P12769

Pry

Clip

Pull

Disconnect

P12217

P13162

(2)

(1)

P11646

Plug

(4)

(3)

CO-22

- COOLING RADIATOR

1435 Author : Date :

1997 SUPRA (RM502U)

REMOVAL

1. REMOVE ENGINE UNDER COVER

HINT:

Start the engine, and check for coolant and A/T fluid leaks.

2. REMOVE BATTERY AND BATTERY TRAY

3. DRAIN ENGINE COOLANT

4. 2JZ-GTE:

REMOVE NO.2 AIR TUBE

5. REMOVE NO.2 FAN SHROUD

(a) Remove the 2 clips.

(b) Disconnect the claw of the No.2 fan shroud from the hook

of the No.1 fan shroud, and remove the No.2 fan shroud.

6. REMOVE AIR CLEANER DUCT

7. 2JZ-GTE:

REMOVE NO.5 AIR HOSE

8. REMOVE LH HEADLIGHT BEAM ANGLE GAUGE

Remove the screw and beam angle gauge.

9. DISCONNECT HOSES FROM RADIATOR

Disconnect these hoses from the radiator:

(1) Reservoir inlet hose

(2) Upper radiator hose

(3) Lower radiator hose

(4) A/T (2 oil cooler hoses):

Plug the hose ends.

HINT:

At the time of installation, please refer to the following items.

Check the A/T fluid level.

P11908

(A)

Z16741

Drain

Hose

ECT Switch (2JZ-GTE)

S05171

- COOLING RADIATOR

CO-23

1436 Author : Date :

1997 SUPRA (RM502U)

10. REMOVE RADIATOR ASSEMBLY

(a) 2JZ-GTE:

Disconnect the ECT switch (for electric cooling fan con-

nector) and wire harness.

(b) 2JZ-GTE:

Disconnect the 2 electric cooling fan connectors and wire

harness.

(c) Remove the bolt and upper radiator support. Remove the

2 upper radiator supports.

HINT:

At the time of installation, please refer to the following items.

Check that the rubber cushion (A) of the support is not de-

pressed.

Torque: 15 Nm (155 kgfcm, 11 ftlbf)

(d) Lift out the radiator assembly.

(e) Remove the 2 lower radiator supports.

11. REMOVE DRAIN HOSE FROM RADIATOR

12. 2JZ-GTE:

REMOVE ENGINE COOLANT TEMPERATURE (ECT)

SWITCH FROM RADIATOR

(a) Remove the ECT switch.

HINT:

At the time of installation, please refer to the following item.

Apply soapy water to the O-ring, and install the ECT switch.

Torque: 7.4 Nm (75 kgfcm, 65 in.lbf)

(b) Remove the O-ring from the ECT switch.

HINT:

At the time of installation, please refer to the following item.

Use a new O-ring.

13. REMOVE NO.1 FAN SHROUD FROM RADIATOR

(a) 2JZ-GE:

Remove the 4 bolts and No.1 fan shroud.

(b) 2JZ-GTE:

Remove the 5 bolts and No.1 fan shroud.

P02651

Stopper Bolt

SST

Lock

Plate

CO1205

Overhaul Handle

Dimension B

SST

Part A

Claw

Stopper Bolt

CO08X-01

P11773

Lightly

Tap

Z16737

Inlet Pipe

A/T

CO-24

- COOLING RADIATOR

1437 Author : Date :

1997 SUPRA (RM502U)

DISASSEMBLY

1. REMOVE CUSHIONS FROM RADIATOR

2. ASSEMBLE SST

SST 09230-01010

(a) Install the claw to the overhaul handle, inserting it in the

hole in part A as shown in the installation.

(b) While gripping the handle, adjust the stopper bolt so that

dimension B shown in the diagram is 0.2 - 0.5 mm

(0.008 - 0.020 in.).

NOTICE:

If this adjustment is not done, the claw may be damaged.

3. UNCAULK LOCK PLATES

Using SST to release the caulking, squeeze the handle until

stopped by the stopper bolt.

SST 09230-01010

4. REMOVE TANKS AND O-RINGS

(a) Lightly tap the radiator hose inlet (or outlet) with a soft-

faced hammer and remove the tank.

(b) Remove the O-ring.

5. A/T:

REMOVE OIL COOLER FROM LOWER TANK

(a) Remove the inlet pipes.

HINT:

Make a note of the direction to face the pipes.

(b) Remove the nuts, plate washers and oil cooler.

(c) Remove the O-rings from the oil cooler.

CO08Y-02

Z16734

A/T

(1)

(2)

(4)

(3)

(5)

(6)

Z16738

A/T

(6)

CO1267

Lock Plate

Lock Plate

Core

CO0317

O-Ring

O Normal

X Twisted

X Twisted

P10899

CORRECT

Tank

WRONG

Lock

Plate

- COOLING RADIATOR

CO-25

1438 Author : Date :

1997 SUPRA (RM502U)

REASSEMBLY

1. A/T:

INSTALL OIL COOLER TO LOWER TANK

(a) Clean the O-ring contact surface of the lower tank and oil

cooler.

(b) Install new O-rings (1) to the oil cooler (2).

(c) Install the oil cooler (2) to the lower tank (3).

(d) Install the plate washers (4), and nuts (5).

Torque: 8.3 Nm (85 kgfcm, 74 in.lbf)

(e) Install the inlet pipes (6).

Torque: 15 Nm (150 kgfcm, 11 ftlbf)

HINT:

Face the inlet pipes in the same direction they were before dis-

assembly.

2. INSPECT LOCK PLATE

Inspect the lock plate for damage.

HINT:

L If the sides of the lock plate groove are deformed, reas-

sembly of the tank will be impossible.

L Therefore, first correct any deformation with pliers or simi-

lar object. Water leakage will result if the bottom of the

lock plate groove is damaged or dented. Therefore, repair

or replace if necessary.

NOTICE:

The radiator can only be recaulked 2 times.

After the 2nd time, the radiator core must be replaced.

3. INSTALL NEW O-RINGS AND TANKS

(a) After checking that there are no foreign objects in the lock

plate groove, install the new O-ring without twisting it.

HINT:

When cleaning the lock plate groove, lightly rub it with sand pa-

per without scratching it.

(b) Install the tank without damaging the O-ring.

(c) Tap the lock plate with a soft-faced hammer so that there

is no gap between it and the tank.

CO1206

Overhaul Handle

Dimension B

SST

Part A

Punch Assembly

Stopper Bolt

Z09523

1

SST

Tank

Lock

Plate

Stopper Bolt

5 8

6

4 3

7 2

P11771

Bracket

Tank Rib

Pipe

P11772

CO-26

- COOLING RADIATOR

1439 Author : Date :

1997 SUPRA (RM502U)

4. ASSEMBLE SST

SST 09230-01010, 09231-14010

(a) Install the punch assembly to the overhaul handle, insert-

ing it in the hole in part A as shown in the illustration.

(b) While gripping the handle, adjust the stopper bolt so that

dimension B shown in the diagram.

Dimension B:

8.4 mm (0.34 in)

5. CAULK LOCK PLATE

(a) Lightly press SST against the lock plate in the order

shown in the illustration. After repeating this a few times,

fully caulk the lock plate by squeezing the handle until

stopped by the stopper plate.

SST 09230-01010

HINT:

L Do not stake the areas protruding around the pipes,

brackets or tank ribs.

L The points shown in the rib sides and oil cooler near here

cannot be staked with SST. Use a plier or similar object

and be careful not to damage the core plates.

P02648

H

P04580

SST

B02745

Clearance

Lock

Plate

O-Ring

- COOLING RADIATOR

CO-27

1440 Author : Date :

1997 SUPRA (RM502U)

(b) Check the lock plate height (H) after completing the caulk-

ing.

Plate height:

7.40 - 7.80 mm (0.2959 - 0.3119 in)

If not within the specified height, adjust the stopper bolt of the

handle again and caulk again.

6. INSPECT FOR WATER LEAKS

(a) Tighten the drain plug.

(b) Plug the inlet and outlet pipes of the radiator with SST.

SST 09230-01010

(c) Using a radiator cap tester, apply pressure to the radiator.

Test pressure:

177 kPa (1.8 kgf/cm

2

, 26 psi)

(d) Inspect for water leaks.

HINT:

On radiators with resin tanks, there is a clearance between the

tank and lock plate where a minute amount of air will remain,

giving the appearance of an air leak when the radiator is sub-

merged in water. Therefore, before doing the water leak test,

move the radiator around in the water until all air bubbles disap-

pear.

7. INSTALL CUSHIONS TO RADIATOR

S04468

Stop

Below 91C

S04469

Below 91C

ECT Switch

Connector

Disconnect

CO090-01

S04470

Above 100C

Rotate

Thermometer

S04471

Ammeter

Battery

Fan Connector

2.5 - 4.5 A

- COOLING ELECTRIC COOLING FAN (2JZ-GTE)

CO-29

1442 Author : Date :

1997 SUPRA (RM502U)

ELECTRIC COOLING FAN

(2JZ-GTE)

ON-VEHICLE INSPECTION

1. CHECK COOLING FAN OPERATION WITH LOW

TEMPERATURE (Below 91C (196F))

(a) Turn the ignition switch ON.

(b) Check that the cooling fan stops.

If not, check the cooling fan relay and ECT switch, and check

for a separated connector or severed wire between the No.1 ra-

diator fan relay and ECT switch.

(c) Disconnect the ECT switch connector.

(d) Check that the cooling fan rotates.

If not, check the No.1 radiator relay, No.2 radiator fan relay,

cooling fan, fuses, and check for short circuit between the No.1

radiator fan relay and ECT switch.

(e) Reconnect the ECT switch connector.

2. CHECK COOLING FAN OPERATION WITH HIGH

TEMPERATURE (Above 100C (212F))

(a) Start the engine, and raise coolant temperature to above

100C (212F).

(b) Check that the cooling fan rotates.

If not, replace the ECT switch.

3. INSPECT COOLING FAN

(a) Disconnect the fan connector.

(b) Connect battery and ammeter to the cooling fan connec-

tor.

(c) Check that the cooling fan rotates smoothly, and check

the reading on the ammeter.

Standard amperage: 2.5 - 4.5 A

(d) Reconnect the fan connector.

CO091-02

S04927

Air Cleaner Duct

Upper Radiator Hose

Lower Radiator Hose

Radiator

Cap

Radiator Reservoir

Hose

No.5 Air Hose

Battery

Battery Tray

Radiator

Assembly

Hold-Down

Clamp

Battery Insulator

Oil Cooler Hose (A/T)

Upper Radiator

Support

Electric Cooling

Fan Connector

No.2 Air Tube

Drain Plug

No.2 Fan Shroud

Clip

ECT Switch (for Electric

Cooling Fan) Connector

Lower

Radiator

Support

L O-Ring

Electric Cooling Fan

Radiator

No.1 Fan Shroud

Engine Under Cover

x16

2JZ-GTE

L O-Ring

ECT Switch (for Electric Cooling Fan)

Drain Hose

L Non-reusable part

LH Headlight Beam Angle Gauge

CO-30

- COOLING ELECTRIC COOLING FAN (2JZ-GTE)

1443 Author : Date :

1997 SUPRA (RM502U)

COMPONENTS

CO092-02

S04950

- COOLING ELECTRIC COOLING FAN (2JZ-GTE)

CO-31

1444 Author : Date :

1997 SUPRA (RM502U)

REMOVAL

1. REMOVE RADIATOR (See page CO-22 )

2. REMOVE FAN

Remove the 6 screws and 2 fans.

3. REMOVE FAN MOTOR

(a) Disconnect the 2 connectors from the fan shroud.

(b) Remove the 6 screws and 2 fan motors.

NOTICE:

Install the fan motor so that its water drainage hole faces

downward.

Torque: 3.9 Nm (40 kgfcm, 35 in.lbf)

4. REASSEMBLY IS IN THE REVERSE ORDER OF RE-

MOVAL (See step 3)

P01924

Ohmmeter

P13220

CO094-01

- COOLING ENGINE COOLANT TEMPERATURE (ECT) SWITCH

CO-33

1446 Author : Date :

1997 SUPRA (RM502U)

ENGINE COOLANT

TEMPERATURE (ECT) SWITCH

(2JZ-GTE)

INSPECTION

1. REMOVE ENGINE UNDER COVER

2. DRAIN ENGINE COOLANT

3. REMOVE ECT SWITCH

(a) Disconnect the ECT switch connector.

(b) Remove the ECT switch.

(c) Remove the O-ring from the ECT switch.

4. INSPECT ECT SWITCH

(a) Using an ohmmeter, check that there is no continuity be-

tween the terminals when the coolant temperature is

above 100C (212F).

If there is continuity, replace the switch.

(b) Using an ohmmeter, check that there is continuity be-

tween the terminals when the coolant temperature is be-

low 91C (196F).

If there is no continuity, replace the switch.

5. REINSTALL ECT SWITCH

(a) Install a new O-ring to the ECT switch.

(b) Apply soapy water to the O-ring.

(c) Install the ECT switch.

Torque: 7.4 Nm (75 kgfcm, 65 in.lbf)

(d) Connect the ECT switch connector.

6. REFILL WITH ENGINE COOLANT

7. START ENGINE AND CHECK FOR LEAKS

8. REINSTALL ENGINE UNDER COVER

P12291

No.1 Radiator

Fan Relay

CO095-01

P11929

Ohmmeter

No Continuity

Continuity

1

2

4

3

Ohmmeter

P11928

Ohmmeter

Continuity

1

2

4

3

Battery

P12292

No.2 Radiator

Fan Relay

P12133

No Continuity

Continuity

1

2

5

3

Ohmmeter

Ohmmeter

Ohmmeter

Continuity

6

CO-34

- COOLING RADIATOR FAN RELAY

1447 Author : Date :

1997 SUPRA (RM502U)

RADIATOR FAN RELAY (2JZ-GTE)

INSPECTION

1. w/ Auto Spoiler:

REMOVE LH HEADLIGHT

2. w/o Auto Spoiler:

REMOVE ENGINE UNDER COVER

3. INSPECT NO.1 RADIATOR FAN RELAY

(a) Remove the No.1 radiator fan relay. (Marking: RADIA-

TOR FAN RELAY)

(b) Inspect the No.1 radiator fan relay continuity.

(1) Using an ohmmeter, check that there is continuity

between terminals 3 and 4.

If there is no continuity, replace the relay.

(2) Check that there is no continuity between terminals

1 and 2.

If there is continuity, replace the relay.

(c) Inspect the No.1 radiator fan relay operation.

(1) Apply battery positive voltage across terminals 3

and 4.

(2) Using an ohmmeter, check that there is continuity

between terminals 1 and 2.

If there is no continuity, replace the relay.

(d) Reinstall the No.1 radiator fan relay

4. INSPECT NO.2 RADIATOR FAN RELAY

(a) Remove the No.2 radiator fan relay. (Marking:

A.B.S.(TRAC) RELAY)

(b) Inspect the No. 2 radiator fan relay continuity.

(1) Using an ohmmeter, check that there is continuity

between terminals 1 and 6.

If there is no continuity, replace the relay.

(2) Check that there is continuity between terminals 3

and 5.

If there is no continuity, replace the relay.

(c) Check that there is no continuity between terminals 2 and

5.

If there is continuity, replace the relay.

(d) Inspect the No.2 radiator fan relay operation.

(e) Apply battery positive voltage across terminals 1 and 6.

(1) Using an ohmmeter, check that there is no continu-

ity between terminals 3 and 5.

(2) If there is continuity, replace the relay.

(3) Check that there is continuity between terminals 2

and 5.

You might also like

- Manual Refrigeracio Toyota2cDocument14 pagesManual Refrigeracio Toyota2cDeivit Utah BastidasNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 2AZ FE CoolingDocument35 pages2AZ FE CoolingLuks Fernandez50% (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Engine Mechanical ECHO 2002Document85 pagesEngine Mechanical ECHO 2002Tomas Dominguez100% (1)

- 2GR FE CoolingDocument36 pages2GR FE CoolingLuks FernandezNo ratings yet

- CoolingDocument32 pagesCoolingapi-3833108No ratings yet

- TOYOTA 1CD-FTV D4D Cooling SystemDocument28 pagesTOYOTA 1CD-FTV D4D Cooling SystemLuis Daniel CortesNo ratings yet

- Remove Cylinder Head AssemblyDocument2 pagesRemove Cylinder Head AssemblyUriel MFNo ratings yet

- Toyota Truck Pickup 2WD L4 2.4L SOHC 22R 1987Document8 pagesToyota Truck Pickup 2WD L4 2.4L SOHC 22R 1987Rick ZNo ratings yet

- Water Pump: ComponentsDocument4 pagesWater Pump: ComponentsvixentdNo ratings yet

- Engine Mechanical PDFDocument115 pagesEngine Mechanical PDFAndrey GladyshevNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Valve BodyDocument5 pagesValve BodyPablo MontesNo ratings yet

- CarburetorDocument23 pagesCarburetorKarina Leyva GuerreroNo ratings yet

- Instalacion 3rz-FeDocument5 pagesInstalacion 3rz-FeAngel Lira100% (3)

- Cooling System (2Az-Fe) : On-Vehicle InspectionDocument27 pagesCooling System (2Az-Fe) : On-Vehicle InspectionTung NguyenNo ratings yet

- Ec (2jz-Gte) PDFDocument12 pagesEc (2jz-Gte) PDFAshokNo ratings yet

- 2GR-FE Emission ControlDocument23 pages2GR-FE Emission ControlLuks FernandezNo ratings yet

- Yamaha T135 Service Manual CoolingDocument10 pagesYamaha T135 Service Manual CoolingRaditya Erlangga100% (2)

- Emission ControlDocument26 pagesEmission ControllogammicNo ratings yet

- 2007 Honda Civic Hybrid - Engine CoolingDocument19 pages2007 Honda Civic Hybrid - Engine Coolingangelvalladares100% (1)

- Karbala Refinary Project: Preparing Fatima Ali MahdiDocument28 pagesKarbala Refinary Project: Preparing Fatima Ali Mahdiضياء محمدNo ratings yet

- 2001 Toyota Prius L4-1.5L (1NZ-FXE) Hybrid: Timing Chain: Service and RepairDocument13 pages2001 Toyota Prius L4-1.5L (1NZ-FXE) Hybrid: Timing Chain: Service and Repairfernando ortizNo ratings yet

- 2010 Toyota Prius Repair Manual - Maintenance - EGRDocument17 pages2010 Toyota Prius Repair Manual - Maintenance - EGRspam4lotNo ratings yet

- 10 - Engine Control SystemDocument13 pages10 - Engine Control SystemZee ShanNo ratings yet

- Replacement: 1. Remove Battery 2. Remove Battery TrayDocument2 pagesReplacement: 1. Remove Battery 2. Remove Battery TraydiemnganNo ratings yet

- Motor ProboxDocument12 pagesMotor ProboxrufuruNo ratings yet

- Removal Refitting Variable Geometry Turbocharger GARETTDocument6 pagesRemoval Refitting Variable Geometry Turbocharger GARETTiliecNo ratings yet

- Disassembly Cylinder Head 920 Wheel LoaderDocument7 pagesDisassembly Cylinder Head 920 Wheel LoaderAmir Bambang YudhoyonoNo ratings yet

- Cylinder Head - Install: Desmontagem e MontagemDocument10 pagesCylinder Head - Install: Desmontagem e MontagemTatiano BrolloNo ratings yet

- Culata Motor 3406Document3 pagesCulata Motor 3406Julio GuillenNo ratings yet

- Montagem C7.1 Engine 320D2 L ExcavatorDocument9 pagesMontagem C7.1 Engine 320D2 L ExcavatorRafa SantosNo ratings yet

- Patg Pamg Turbo PartsDocument12 pagesPatg Pamg Turbo Parts1luckywolf0% (1)

- 2AZ-FE Emission ControlDocument25 pages2AZ-FE Emission ControlLuks FernandezNo ratings yet

- Idle Air Control (Iac) Valve: On-Vehicle InspectionDocument12 pagesIdle Air Control (Iac) Valve: On-Vehicle InspectionhazchuenNo ratings yet

- 03-01C Engine, 4.0L V-66ford 4.0 Repair ManualDocument206 pages03-01C Engine, 4.0L V-66ford 4.0 Repair ManualMike GunionNo ratings yet

- (TM) Toyota Manual de Motor Toyota Yaris Verso 2001 en InglesDocument11 pages(TM) Toyota Manual de Motor Toyota Yaris Verso 2001 en Inglesjonathan matusNo ratings yet

- Hyundai Eon Bomba de AguaDocument3 pagesHyundai Eon Bomba de AguaEduardo TorresNo ratings yet

- Co2 Ee-00100-Co2-002Document56 pagesCo2 Ee-00100-Co2-002anbarasusivaprakasam100% (2)

- 1996 Subaru Legacy Intake Manifold Service ProcedureDocument11 pages1996 Subaru Legacy Intake Manifold Service ProcedureJohn CubineNo ratings yet

- Multi Zone Outdoors Service ManualDocument56 pagesMulti Zone Outdoors Service Manualcmorley505775% (4)

- Throttle BodyDocument8 pagesThrottle BodyHugo Armando Garcia LepeNo ratings yet

- Maintenance Operations: Engine Cold Engine OperationsDocument18 pagesMaintenance Operations: Engine Cold Engine OperationsJorgeAlbuquerqueNo ratings yet

- Riello RG5D Burner ManualDocument11 pagesRiello RG5D Burner ManualjadetorresNo ratings yet

- BB. Docking Indent (Repair) Pioneer. 13th Feb.20Document11 pagesBB. Docking Indent (Repair) Pioneer. 13th Feb.20Thiet PhamNo ratings yet

- Kia Venga Audio Remote ControlDocument12 pagesKia Venga Audio Remote ControlffurlanutNo ratings yet

- Sicnronización de Motor Hyundai, Kia, G4LC PDFDocument18 pagesSicnronización de Motor Hyundai, Kia, G4LC PDFJorge Cedeno100% (3)

- 2010 Toyota Prius Repair Manual - Exhaust Heat RecirculationDocument10 pages2010 Toyota Prius Repair Manual - Exhaust Heat RecirculationMuhammad Imran Aftab100% (1)

- Hyundai Santa Fé 2.7L 2008 - Cabeçote - Remoção Recolocação PDFDocument31 pagesHyundai Santa Fé 2.7L 2008 - Cabeçote - Remoção Recolocação PDFLeonardo Limberger0% (1)

- Instruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaDocument14 pagesInstruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaAlexandre EmmerickNo ratings yet

- Manual de Motor Elantra-Tiburón 1998 G4GRDocument6 pagesManual de Motor Elantra-Tiburón 1998 G4GRRodolfo SilvaNo ratings yet

- Component Code AJ: Printed in Japan (02) 1Document5 pagesComponent Code AJ: Printed in Japan (02) 1PepeTRBKNo ratings yet

- EGR Cooler Removal (4JJ1 Without DPD) : 1. Component ViewsDocument46 pagesEGR Cooler Removal (4JJ1 Without DPD) : 1. Component ViewsPatricio ValenciaNo ratings yet

- How To Start Combined Cycle Power PlantDocument37 pagesHow To Start Combined Cycle Power PlantBv Rao100% (1)

- Installer GT GTFDocument8 pagesInstaller GT GTFElektroNiNo ratings yet

- Cylinder Head: Components For Removal and InstallationDocument40 pagesCylinder Head: Components For Removal and InstallationTeo CovaNo ratings yet

- 2010 Toyota Prius Repair Manual - ThermostatDocument4 pages2010 Toyota Prius Repair Manual - ThermostatBilal al zeitawiNo ratings yet

- Water-Heater Manual Ss4200Document19 pagesWater-Heater Manual Ss4200Aiman NasirNo ratings yet

- Integrated Vehicle Thermal Management - Combining Fluid Loops in Electric Drive VehiclesDocument32 pagesIntegrated Vehicle Thermal Management - Combining Fluid Loops in Electric Drive VehiclesAiman NasirNo ratings yet

- Air-Conditioning System For Electric Vehicles (I-Miev) : Sae Automotive Refrigerant & System Efficiency Symposium 2010Document20 pagesAir-Conditioning System For Electric Vehicles (I-Miev) : Sae Automotive Refrigerant & System Efficiency Symposium 2010Aiman NasirNo ratings yet

- vss046 Rugh 2011 oDocument28 pagesvss046 Rugh 2011 oAiman NasirNo ratings yet

- View Content 1Document43 pagesView Content 1Aiman NasirNo ratings yet

- View ContentDocument8 pagesView ContentAiman NasirNo ratings yet

- Valeo Systemes Thermiques Sas - Frederic LadrechDocument15 pagesValeo Systemes Thermiques Sas - Frederic LadrechAiman Nasir100% (1)

- Outline: Hybrid Powertrains Part 2 Component ModelingDocument5 pagesOutline: Hybrid Powertrains Part 2 Component ModelingAiman NasirNo ratings yet

- How Cooling System WorksDocument32 pagesHow Cooling System WorksAiman NasirNo ratings yet

- 3.1 (Version 1.1)Document27 pages3.1 (Version 1.1)Aiman NasirNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Electric Motor Control: DC, AC, and BLDC MotorsFrom EverandElectric Motor Control: DC, AC, and BLDC MotorsRating: 4.5 out of 5 stars4.5/5 (19)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingFrom EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNo ratings yet

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceFrom EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNo ratings yet

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningFrom EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningRating: 5 out of 5 stars5/5 (4)

- Renewable Energy Finance: Theory and PracticeFrom EverandRenewable Energy Finance: Theory and PracticeRating: 4 out of 5 stars4/5 (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Nigerian Public Discourse: The Interplay of Empirical Evidence and HyperboleFrom EverandNigerian Public Discourse: The Interplay of Empirical Evidence and HyperboleNo ratings yet

- Thermal Power Plant: Design and OperationFrom EverandThermal Power Plant: Design and OperationRating: 4.5 out of 5 stars4.5/5 (23)

- Electric Motors and Drives: Fundamentals, Types and ApplicationsFrom EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsRating: 4.5 out of 5 stars4.5/5 (12)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- The Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadFrom EverandThe Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadRating: 4.5 out of 5 stars4.5/5 (10)

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsFrom EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNo ratings yet