Professional Documents

Culture Documents

1103 The Facility Files

Uploaded by

sajuhereOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1103 The Facility Files

Uploaded by

sajuhereCopyright:

Available Formats

30 Engi neer ed Syst ems March 2011

BY AMANDA MCKEW

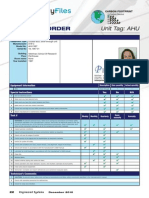

CHILLER WORKORDER Unit Tag Ch-1

TheFacilityFiles

CARBON FOOTPRINT

Carbon Neutral

Equipment Type

Manufacturer

Model No.

Serial No

Building

Floor

Room name

Year installed

Chiller

X-Y-Z

CCH

11101028

Commercial ofce building

Mechanical penthouse

N/A

1976

McKew is a senior project engineer with

InterPro Solutions. Reach her at amckew@

interprosoft.com.

Equipment Information

Description Item quantity Actual quantity

Chiller 1

Special Instructions Yes No N/A

1 Turn on electrical power.

2 Make sure you have any needed special tools.

3 Take care in handling refrigerants and documentation

4 Make sure you have the correct lubricants.

5 Follow lock-out/tag-out and safety procedures and follow safety procedures.

6 Attach manufacturer's maintenance checklist.

Task #

Weekly Monthly Quarterly

Semi-

annually

Annually

1

WARNING: To prevent personal injury, follow lock-out/tag-out procedures and follow safety

procedures identied in the manufacturer's manual. Disconnect all electrical power to the unit

to prior to performing any of the following maintenance procedures. Read, understand, and

follow all the instruction warnings in all of the component instruction manuals.

2

Inspect and record stats for customers records:

Unit starts Unit run hours Logged faults

3 Tighten internal electrical connections.

4

Perform electronic refrigeration leak check of all internal compressors. Check operation of

makeup valve components.

5 Manually check the operations of inlet guide vanes.

6 Check calibration of suction and discharge pressure sensor.

7 Check calibration of suction and discharge temperature sensor.

8 Check that amperages are per the design.

9 Check that communication cables are secure.

10 Check that there are no signs of physical damage/discoloration on printed circuitboards.

11 Check that all mounting bolts are secure.

12 Check for refrigerant leaks.

13 Check for mechanical damage.

14 Check operating temperatures and pressures.

15 Check for water leaks at chiller bundles.

16 Clean condenser water and evaporator.

17 Workorder complete and report deciencies and corrective measures taken.

Technician's Comments

1 Additional PM requirements associated with replacement of chiller compressor retrots (www.SouthernAirInc.com).

You might also like

- 1106 The Facility FilesDocument1 page1106 The Facility FilessajuhereNo ratings yet

- Cooling Tower Maintenance ChecklistDocument1 pageCooling Tower Maintenance ChecklistsajuhereNo ratings yet

- 1012 The Facility FilesDocument1 page1012 The Facility FilessajuhereNo ratings yet

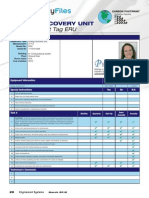

- TITLE Energy Recovery Unit Maintenance ChecklistDocument1 pageTITLE Energy Recovery Unit Maintenance ChecklistsajuhereNo ratings yet

- Condensing Boiler Maintenance ChecklistDocument1 pageCondensing Boiler Maintenance ChecklistsajuhereNo ratings yet

- Appendix C2-Preventive Maintenance ChecklistDocument10 pagesAppendix C2-Preventive Maintenance Checklisteeit_nizamNo ratings yet

- Central AHU PM Workorder TasksDocument1 pageCentral AHU PM Workorder TaskssajuhereNo ratings yet

- TRANE IOM Air Cooled Scroll - Cgap CgahDocument31 pagesTRANE IOM Air Cooled Scroll - Cgap Cgahari_arista100% (2)

- EWWD380-C11BJYNN D-KIMWC00311-09 en Installation Manuals EnglishDocument32 pagesEWWD380-C11BJYNN D-KIMWC00311-09 en Installation Manuals Englishshazil shaikNo ratings yet

- TheFacilityFiles6 10Document1 pageTheFacilityFiles6 10sajuhereNo ratings yet

- Mounting and Operating Manual for Water Chiller BL 008-02Document28 pagesMounting and Operating Manual for Water Chiller BL 008-02Riccardo De RubeisNo ratings yet

- Contoil vzfIIDocument48 pagesContoil vzfIIMuhammad ZainNo ratings yet

- Heatline Caprizplus 24-28Document52 pagesHeatline Caprizplus 24-28opel1997No ratings yet

- Operational Manual Air Cooled Screw Nov 2010Document20 pagesOperational Manual Air Cooled Screw Nov 2010Chinh Viet HoangNo ratings yet

- Electrical Preventive Maintenance and ChecklistDocument8 pagesElectrical Preventive Maintenance and ChecklistEdmund Yoong100% (4)

- User & Technical Manual: NE050, NE060, & NE080 SeriesDocument26 pagesUser & Technical Manual: NE050, NE060, & NE080 Seriesusamakhan205No ratings yet

- Halliburton: Power Pack Hydraulic Quick Disconnect Skid S12A Suggested Interval: 120 DAYSDocument4 pagesHalliburton: Power Pack Hydraulic Quick Disconnect Skid S12A Suggested Interval: 120 DAYSKhalfan Al HabsiNo ratings yet

- Annual Inspection: Container RefrigerationDocument30 pagesAnnual Inspection: Container RefrigerationJuan Pablo Muñoz CortezNo ratings yet

- FM-PT-05-00 Electrical Pre-Com Check List 01Document23 pagesFM-PT-05-00 Electrical Pre-Com Check List 01Niko GunnNo ratings yet

- Prevent Electrical FailuresDocument11 pagesPrevent Electrical FailuresSelvn SubramanianNo ratings yet

- PUHY P200 250YREM A Service HandbookDocument124 pagesPUHY P200 250YREM A Service HandbookGingubaNo ratings yet

- MS Mercure Hotel PPMDocument8 pagesMS Mercure Hotel PPM4jan1980No ratings yet

- Service & Maintenance ManualDocument44 pagesService & Maintenance ManualAnonymous 2iQ1B59No ratings yet

- Work Instructions For Rolling of PlatesDocument3 pagesWork Instructions For Rolling of PlatesPravin Patil100% (1)

- AR W CenturyDocument74 pagesAR W CenturyJoão André100% (1)

- Manual Cold PointDocument9 pagesManual Cold PointJuan Antonio Alvaro HuaynateNo ratings yet

- SOW for BF5 Annual maintenace Jobs (1) (1)Document26 pagesSOW for BF5 Annual maintenace Jobs (1) (1)Shafiulla BaigNo ratings yet

- 普通商用泳池机说明书(2)[1]Document45 pages普通商用泳池机说明书(2)[1]Jose Luis ColmenarezNo ratings yet

- SKN Jambimerang Construction Checksheet E20-A Gas Turbine: InformationDocument1 pageSKN Jambimerang Construction Checksheet E20-A Gas Turbine: InformationsuparnaNo ratings yet

- RTWB Iom E4 - 1003Document40 pagesRTWB Iom E4 - 1003nairam2003100% (1)

- Install Air Conditioning SystemsDocument16 pagesInstall Air Conditioning SystemsuddinnadeemNo ratings yet

- Midmark M9/M11 Tabletop Sterilizer: Repair and PM: MD Expo Conference April, 2019Document39 pagesMidmark M9/M11 Tabletop Sterilizer: Repair and PM: MD Expo Conference April, 2019andrea lizeth martinez camachoNo ratings yet

- Seedorff AMCE Preventative Maintenance for Resistance WeldersDocument4 pagesSeedorff AMCE Preventative Maintenance for Resistance WeldersWael MansourNo ratings yet

- The Facility Files 9 11Document1 pageThe Facility Files 9 11sajuhereNo ratings yet

- Pilot Pac Industrial 7.5 11 15kw Rotary ScrewDocument28 pagesPilot Pac Industrial 7.5 11 15kw Rotary ScrewStandard PneumaticNo ratings yet

- TuttnauerManSterilizers PDFDocument10 pagesTuttnauerManSterilizers PDFspaske_No ratings yet

- 30gt 49si PDFDocument32 pages30gt 49si PDFMukhamad Ilyas SufaatNo ratings yet

- PRES-E-04 Electrical Equipment - Oil & TransformerDocument2 pagesPRES-E-04 Electrical Equipment - Oil & TransformersalamlinNo ratings yet

- Steam Generator Instruction Manual: MODEL E-404Document226 pagesSteam Generator Instruction Manual: MODEL E-404BOILER ECUADORNo ratings yet

- Pre Startup DTDocument1 pagePre Startup DTsajuhereNo ratings yet

- NTT Om PDFDocument24 pagesNTT Om PDFrpichoNo ratings yet

- Rotary-Screw Chiller SpecificationDocument11 pagesRotary-Screw Chiller Specificationadel rihanaNo ratings yet

- Chiller Service 2Document8 pagesChiller Service 2VENKATNo ratings yet

- 02250195-403 r00 - MAN - Regenerative-Heatless Dryer DHLDocument76 pages02250195-403 r00 - MAN - Regenerative-Heatless Dryer DHLJuan Ignacio Alvarez Claramunt100% (2)

- User'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerDocument67 pagesUser'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerValentin Bogdan100% (1)

- HD - Planta de PVCDocument7 pagesHD - Planta de PVCDavid LapacaNo ratings yet

- Cgah Chiller IomDocument28 pagesCgah Chiller IomLuong Dao100% (2)

- Service KlimaDocument50 pagesService Klimaspirittotti100% (1)

- Red Bag Checklist For Mechanical CompletionDocument9 pagesRed Bag Checklist For Mechanical Completionhitm357No ratings yet

- WG10-1 Instalation Manual AnDocument44 pagesWG10-1 Instalation Manual AnIsmail Ekmekci100% (4)

- Ac MaintenanaceDocument22 pagesAc Maintenanacenafis2uNo ratings yet

- Air Cooled Screw Liquid Free Cooling Chiller - YORK YVFA R134a 50Hz & 60HzDocument6 pagesAir Cooled Screw Liquid Free Cooling Chiller - YORK YVFA R134a 50Hz & 60Hzalf_haroNo ratings yet

- Syncrotrak Manual v20mDocument50 pagesSyncrotrak Manual v20mPrzemyslaw SzumnyNo ratings yet

- Water Cooled Package Service NewDocument23 pagesWater Cooled Package Service NewDiêm Công ViệtNo ratings yet

- ABB SCC-C Rev2Document28 pagesABB SCC-C Rev2Coolequipment CeeNo ratings yet

- R024138b.C9035 E1004Document270 pagesR024138b.C9035 E1004BOILER ECUADORNo ratings yet

- Air Cooled Package Units Roof Top Unit - AnnuallyDocument2 pagesAir Cooled Package Units Roof Top Unit - AnnuallyDreamlinerNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- HPAC Article On Specifying VAV BoxesDocument4 pagesHPAC Article On Specifying VAV Boxesjoejex123No ratings yet

- Sizing Exhaust System For Refrigerating Machinery Rooms - Seidl, TaylorDocument13 pagesSizing Exhaust System For Refrigerating Machinery Rooms - Seidl, Taylorforevertay2000No ratings yet

- Chapter 07Document39 pagesChapter 07kevinmathew27No ratings yet

- SandBookInterior r1Document16 pagesSandBookInterior r1sajuhereNo ratings yet

- CoolTools ProjectggDocument24 pagesCoolTools ProjectggdaveleyconsNo ratings yet

- HPAC Operable Windows - Daly PDFDocument8 pagesHPAC Operable Windows - Daly PDFsajuhereNo ratings yet

- ASHRAE Symposium SE 99-16-3 Kammerud & Hydeman CB Analysis UncertaintyDocument10 pagesASHRAE Symposium SE 99-16-3 Kammerud & Hydeman CB Analysis UncertaintysajuhereNo ratings yet

- ASHRAE-Symposium WSE in Data Centers SteinDocument9 pagesASHRAE-Symposium WSE in Data Centers SteinDiego CMNo ratings yet

- Seidl NCBC08 Paper TR CorrectedDocument10 pagesSeidl NCBC08 Paper TR CorrectedsajuhereNo ratings yet

- Contracting Business Magazine - Taking Controls in-House-FriedmanDocument2 pagesContracting Business Magazine - Taking Controls in-House-FriedmanBasil OguakaNo ratings yet

- Fan SurgingDocument10 pagesFan SurgingPrashant SrivastavaNo ratings yet

- HPAC A Fresh Look at Fans-FinalDocument10 pagesHPAC A Fresh Look at Fans-FinalsajuhereNo ratings yet

- ASHRAE Journal - Underfloor Lessons Learned-DalyDocument4 pagesASHRAE Journal - Underfloor Lessons Learned-DalysajuhereNo ratings yet

- ASHRAE Symposium HI-02!18!2 Symposium Hydeman & Webb New Chiller ModelDocument10 pagesASHRAE Symposium HI-02!18!2 Symposium Hydeman & Webb New Chiller ModelsajuhereNo ratings yet

- ASHRAE Journal - VAV Box Duct Design - TaylorDocument8 pagesASHRAE Journal - VAV Box Duct Design - TaylorsajuhereNo ratings yet

- ASHRAE Journal - Staying OnlineDocument6 pagesASHRAE Journal - Staying OnlinesajuhereNo ratings yet

- ASHRAE Journal - Retrofitting DDC Controls ASHRAE Journal June 2004Document7 pagesASHRAE Journal - Retrofitting DDC Controls ASHRAE Journal June 2004sajuhereNo ratings yet

- ASHRAE Symposis Degrading Delta-T-TaylorDocument13 pagesASHRAE Symposis Degrading Delta-T-TaylormondsbaNo ratings yet

- ASHRAE Journal - Stauffer Case StudyDocument5 pagesASHRAE Journal - Stauffer Case StudysajuhereNo ratings yet

- ASHRAE Journal - Series Fan-Powered Boxes-Taylor PDFDocument0 pagesASHRAE Journal - Series Fan-Powered Boxes-Taylor PDFsajuhereNo ratings yet

- ASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorDocument6 pagesASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorsajuhereNo ratings yet

- ASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow SystemsDocument5 pagesASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow SystemsQaz Zaq100% (1)

- ASHRAE Journal - Return Fans in VAV Systems - TaylorDocument6 pagesASHRAE Journal - Return Fans in VAV Systems - TaylorAntonio LebrunNo ratings yet

- 2014 ASHRAE - Restroom Exhaust Design PDFDocument4 pages2014 ASHRAE - Restroom Exhaust Design PDFAntonio LebrunNo ratings yet

- ASHRAE Journal - Humidity Controls in Data CentersDocument8 pagesASHRAE Journal - Humidity Controls in Data CentersAntonio LebrunNo ratings yet

- ASHRAE Journal - Return Air Systems - TaylorDocument4 pagesASHRAE Journal - Return Air Systems - TaylorKadiri Olanrewaju100% (1)

- ASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - TaylorDocument7 pagesASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - Taylorsajuhere100% (1)

- ASHRAE Journal - Optimizing Chilled Water Plant ControlsDocument12 pagesASHRAE Journal - Optimizing Chilled Water Plant ControlsAntonio LebrunNo ratings yet

- ASHRAE Journal - LEED and Standard 62.1-TaylorDocument4 pagesASHRAE Journal - LEED and Standard 62.1-TaylorNg Khanh100% (1)

- ASHRAE Journal - How To Design & Control Waterside Economizers-TaylorDocument7 pagesASHRAE Journal - How To Design & Control Waterside Economizers-TaylorsajuhereNo ratings yet

![普通商用泳池机说明书(2)[1]](https://imgv2-2-f.scribdassets.com/img/document/721156336/149x198/078b320b93/1712585568?v=1)