Professional Documents

Culture Documents

Job Procedure For Hot Insulation Work of Piping & Equipment1

Uploaded by

ravi00098Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Procedure For Hot Insulation Work of Piping & Equipment1

Uploaded by

ravi00098Copyright:

Available Formats

JOB PROCEDURE FOR HOT INSULATION

WORK OF PIPING & EQUIPMENT

DOC.NO:

PR/2247/J-INS/01

CLIENT : RELIENCE

REV NO:00

AFCONS INFRASTRUCTURE LTD.

RPL, JAMNAGAR

Contract No: 3612153

PROJECT : JAMNAGAR EXPORT REFINERY

AF

C

O

NS

IN

FR

AS

TR

UC

TU

RE

LT

D.

PR

OJ

EC

T:

J.E

.R.

P

RP

L,

JA

M

NA

GA

R

JO

B

PR

OC

ED

UR

E

FO

R

HO

T

IN

SU

LA

TI

ON

W

OR

K

OF

PIP

IN

G

&

EQ

UI

PM

EN

T

DH

DT

&

HG

U

D

O

C

.

N

O

:

P

R

/

2

2

4

4

/

I

N

S

/

0

0

1

R

E

V

N

O

:

0

0

CONTRACTOR

AFCONS INFRASTRUCTURE LIMITED

JOB NO.

25194

PROJECT

J.E.R.P, R.P.L.

Page 1 of 13

AFCONS INFRASTRUCTURE LTD.

RPL, JAMNAGAR

Contract No: 3612153

JOB PROCEDURE FOR HOT INSULATION

WORK OF PIPING & EQUIPMENT

DOC.NO:

PR/2247/J-INS/01

CLIENT : RELIENCE

REV NO:00

PROJECT : JAMNAGAR EXPORT REFINERY

AF

C

O

NS

IN

FR

AS

TR

UC

TU

RE

LT

D.

PR

OJ

EC

T:

J.E

.R.

P

RP

L,

JA

M

NA

GA

R

JO

B

PR

OC

ED

UR

E

FO

R

HO

T

IN

SU

LA

TI

ON

W

OR

K

OF

PIP

IN

G

&

EQ

UI

PM

EN

T

DH

DT

&

HG

U

D

O

C

.

N

O

:

P

R

/

2

2

4

4

/

I

N

S

/

0

0

1

R

E

V

N

O

:

0

0

JAMNAGAR

NAME OF UNITS :

JETTY MODIFICATION

SECTION

JETTY

OWNER

RELIANCE

Page 2 of 13

AFCONS INFRASTRUCTURE LTD.

RPL, JAMNAGAR

Contract No: 3612153

JOB PROCEDURE FOR HOT INSULATION

WORK OF PIPING & EQUIPMENT

DOC.NO:

PR/2247/J-INS/01

CLIENT : RELIENCE

REV NO:00

PROJECT : JAMNAGAR EXPORT REFINERY

AF

C

O

NS

IN

FR

AS

TR

UC

TU

RE

LT

D.

PR

OJ

EC

T:

J.E

.R.

P

RP

L,

JA

M

NA

GA

R

JO

B

PR

OC

ED

UR

E

FO

R

HO

T

IN

SU

LA

TI

ON

W

OR

K

OF

PIP

IN

G

&

EQ

UI

PM

EN

T

DH

DT

&

HG

U

D

O

C

.

N

O

:

P

R

/

2

2

4

4

/

I

N

S

/

0

0

1

R

E

V

N

O

:

0

0

Page 3 of 13

JOB PROCEDURE FOR HOT INSULATION

WORK OF PIPING & EQUIPMENT

DOC.NO:

PR/2247/J-INS/01

CLIENT : RELIENCE

REV NO:00

AFCONS INFRASTRUCTURE LTD.

RPL, JAMNAGAR

Contract No: 3612153

PROJECT : JAMNAGAR EXPORT REFINERY

AF

C

O

NS

IN

FR

AS

TR

UC

TU

RE

LT

D.

PR

OJ

EC

T:

J.E

.R.

P

RP

L,

JA

M

NA

GA

R

JO

B

PR

OC

ED

UR

E

FO

R

HO

T

IN

SU

LA

TI

ON

W

OR

K

OF

PIP

IN

G

&

EQ

UI

PM

EN

T

DH

DT

&

HG

U

D

O

C

.

N

O

:

P

R

/

2

2

4

4

/

I

N

S

/

0

0

1

R

E

V

N

O

:

0

0

PR/2247/J-INS/001

26.09.06

For Approval /

00

T.R.SAHA

S.MUKHERJEE

M.JAYARAM

PROC. NO.

DATE

ISSUED FOR/

REV. NO.

PREPD BY

AFCONS

CHKD BY

AFCONS

APPD BY

AFCONS

Page 4 of 13

APPD BY

CLIENT / TPI

AFCONS INFRASTRUCTURE LTD.

RPL, JAMNAGAR

Contract No: 3612153

JOB PROCEDURE FOR HOT INSULATION

WORK OF PIPING & EQUIPMENT

DOC.NO:

PR/2247/J-INS/01

CLIENT : RELIENCE

REV NO:00

PROJECT : JAMNAGAR EXPORT REFINERY

AF

C

O

NS

IN

FR

AS

TR

UC

TU

RE

LT

D.

PR

OJ

EC

T:

J.E

.R.

P

RP

L,

JA

M

NA

GA

R

JO

B

PR

OC

ED

UR

E

FO

R

HO

T

IN

SU

LA

TI

ON

W

OR

K

OF

PIP

IN

G

&

EQ

UI

PM

EN

T

DH

DT

&

HG

U

D

O

C

.

N

O

:

P

R

/

2

2

4

4

/

I

N

S

/

0

0

1

R

E

V

N

O

:

0

0

CONTENTS

1. SCOPE.

2.REFERENCE.

Page 5 of 13

AFCONS INFRASTRUCTURE LTD.

RPL, JAMNAGAR

Contract No: 3612153

JOB PROCEDURE FOR HOT INSULATION

WORK OF PIPING & EQUIPMENT

DOC.NO:

PR/2247/J-INS/01

CLIENT : RELIENCE

REV NO:00

PROJECT : JAMNAGAR EXPORT REFINERY

AF

C

O

NS

IN

FR

AS

TR

UC

TU

RE

LT

D.

PR

OJ

EC

T:

J.E

.R.

P

RP

L,

JA

M

NA

GA

R

JO

B

PR

OC

ED

UR

E

FO

R

HO

T

IN

SU

LA

TI

ON

W

OR

K

OF

PIP

IN

G

&

EQ

UI

PM

EN

T

DH

DT

&

HG

U

D

O

C

.

N

O

:

P

R

/

2

2

4

4

/

I

N

S

/

0

0

1

R

E

V

N

O

:

0

0

3.MATERIALS.

4.STORAGE OF MATERIALS.

5. PROTECTION FOR PARTIALY COMPLETED JOB.

6.APPLICATIONS.

7. QC RECORDS.

Page 6 of 13

JOB PROCEDURE FOR HOT INSULATION

WORK OF PIPING & EQUIPMENT

DOC.NO:

PR/2247/J-INS/01

CLIENT : RELIENCE

REV NO:00

AFCONS INFRASTRUCTURE LTD.

RPL, JAMNAGAR

Contract No: 3612153

PROJECT : JAMNAGAR EXPORT REFINERY

AF

C

O

NS

IN

FR

AS

TR

UC

TU

RE

LT

D.

PR

OJ

EC

T:

J.E

.R.

P

RP

L,

JA

M

NA

GA

R

JO

B

PR

OC

ED

UR

E

FO

R

HO

T

IN

SU

LA

TI

ON

W

OR

K

OF

PIP

IN

G

&

EQ

UI

PM

EN

T

DH

DT

&

HG

U

D

O

C

.

N

O

:

P

R

/

2

2

4

4

/

I

N

S

/

0

0

1

R

E

V

N

O

:

0

0

8.ATTACHMENT.

Page 7 of 13

JOB PROCEDURE FOR HOT INSULATION WORK

OF PIPING & EQUIPMENT

AFCONS INFRASTRUCTURE

LTD. RPL, JAMNAGAR

CLIENT RELIENCE

Contract No: 3612153

PROJECT: JAMNAGAR EXPORT REFINERY

DOC.NO:

PR/2247/J-INS/01

REV NO:00

JOB PROCEDURE FOR HOT INSULATION WORK OF

PIPING & EQUIPMENT

1.

SCOPE

The scope of this procedure is to establish methods of application for various hot

insulation materials on piping & equipments

2.

REFERENCE

Project specification 22960/3PS/GAW/006

3.

MATERIALS:

Material consists of Insulation materials, cladding materials & ancillary materials. All

materials shall conform to above 22960/3PS/GAW/006 specification. .

4.

STORAGE OF MATERIALS:

Insulation materials shall be stored in such a place that should be protected against

weather. It must be ensured that insulation material shall not be stacked directly on

ground.

5.

PROTECTION FOR PARTIALY COMPLETED JOB:

Every precaution should be taken to ensure that each days of work is weather proofed

immediately after laying & before the days work is over to prevent exposure & entry

of water into the materials.

6.

APPLICATIONS:

a.

Prior to Insulation:

Before using insulation material, receiving inspection shall be done. All items to be

insulated shall be mechanically cleared, pressure tested including steam tracing. The

surfaces shall be cleaned manually for dust, rust, foreign particles, etc. All insulation

material must be free from corrosive agents & presence of water.

Page 8 of 13

JOB PROCEDURE FOR HOT INSULATION WORK

OF PIPING & EQUIPMENT

AFCONS INFRASTRUCTURE

LTD. RPL, JAMNAGAR

CLIENT RELIENCE

Contract No: 3612153

PROJECT: JAMNAGAR EXPORT REFINERY

DOC.NO:

PR/2247/J-INS/01

REV NO:00

Heat resistant aluminum paint shall be applied on carbon steel & low alloy steel

surfaces for operating temperature unto 1250C. For operating temperature above

4500C, stainless steel surface shall be painted with two coats of Heat Resistant

Silicone Aluminum paint. Stainless steel surfaces shall be covered with 0.19mm thick

aluminum foil for operating temperature unto 4500C prior to insulation

b.

During Insulation:

Insulation thickness & type of insulation to be applied shall be as per

equipment data sheet/ line schedule (for piping) & standard specification

Double layer insulation shall be done for insulation thickness greater than

75mm. exposed surfaces operating temperature above 650C & located within

600mm horizontally on 2100mm vertically of a normal access way/ walkway

on work area shall be insulated for personnel protecting only where heat loss

is desired

For securing insulation, aluminum bands/ wires shall be applied as per ASTMB209 alloy 3003 H16 or IS: 737 designation 3100 (Old NS3) condition H3.

For securing fibrous insulation on piping, 24SWG x 12 wide, aluminum bands

shall be used.

For securing fibrous insulation on equipment, 24SWG x 20 wide, aluminum

bands shall be used.

For securing fibrous material on vertical storage tank, galvanized steel 40mm

wide x 3mm thick flat shall be used.

For securing cladding on insulation on piping, aluminum band 12mm(min) x

24 SWG thick shall be used.

For securing cladding on insulation on equipment, aluminum band 20mm

wide x 24 SWG shall be used.

For securing cladding on insulation for vertical storage tanks stainless steel

band 25mm wide x 24SWG shall be used.

Preformed pipe sections shall be used pipe dia. unto 8 for insulation thickness

maximum 100mm, otherwise blankets to be used.

Page 9 of 13

JOB PROCEDURE FOR HOT INSULATION WORK

OF PIPING & EQUIPMENT

AFCONS INFRASTRUCTURE

LTD. RPL, JAMNAGAR

CLIENT RELIENCE

Contract No: 3612153

PROJECT: JAMNAGAR EXPORT REFINERY

DOC.NO:

PR/2247/J-INS/01

REV NO:00

Rivets required for metal jacket securement shall be the expanding aluminum

POP blind eye type, 9.5mm Lg., 5mm dial.

Screw required for metal Jacket securement shall be cadmium plated steel self

tapping screw type A No. 8, 12mm Lg. with neoprene washer.

All projection, such as lifting lugs, trunion, support lugs, support cleats shall

be insulated to the same extent that of equipment or piping.

Inspection windows shall be provided at critical locations on equipment and

piping for future inspection.

Cleats used for supporting of insulation shall not project outside insulation.

Insulation shall not be applied to the following unless specifically asked otherwise:

i.

ii.

iii.

iv.

v.

vi.

vii.

viii.

ix.

x.

xi.

Valves, including control valves, flanges in process lines (Safety insulation shall be

provided wherein required).

Pipe union fittings.

Steam traps, sight flow indicators.

Pumps with operating temp below 2000 C.

Fans, compressors, blower or other rotating or reciprocating equipment.

Internally insulated or refractory line equipment.

Turbine seal caps, shaft bearing housing, throttle valves, governors and supports.

Exchanger channel and covers, shell and channel flanges and expansion joints.

Nozzles, manholes and handholds and flanges of equipment.

Surfaces of coolers and condensers.

Thermo well bosses and pressure tapping.

a) Support skirts of vertical vessels and columns 1200mm dia. & above shall be

insulated both from inside and outside to a minimum distance of 600mm from bottom

tangent line. The insulation must terminate at minimum 300mm above support

concrete or steel work. For below 1200mm dia. support skirts shall be insulated

externally only.

b) Spacer strip with the help of Z stays shall be provided for supporting of cladding

material. The height shall be same of insulation thickness. Blanket shall be secured

with wide steel strapping not more than 300mm equal distance.

c) Vapor barrier shall be applied on all the vessels and equipment for services upto

1250C.

Page 10 of 13

JOB PROCEDURE FOR HOT INSULATION WORK

OF PIPING & EQUIPMENT

AFCONS INFRASTRUCTURE

LTD. RPL, JAMNAGAR

CLIENT RELIENCE

Contract No: 3612153

PROJECT: JAMNAGAR EXPORT REFINERY

DOC.NO:

PR/2247/J-INS/01

REV NO:00

d) Expansion joints shall be provided in all direction wherever required. For expansion

joints, gap shall be filled with loose insulation material of same density.

e) Valve & flange pairs, manhole, if necessary, shall be insulated with removable covers

& it should terminated in such a way that during maintenance bolts can be easily

removed without affecting insulation.

c.

Finishing After Insulation:

a) All insulated items shall be finished with metal jacketing as per specification. But

before installation of metal sheet one coat of bituminous anti corrosive paints to be

used.

b) The sheeting shall be fixed with self tapping screws of size No. 8 @ 150mm

distance.

c) Jacketing over valves & flanges shall be prefabricated in half section & shall be

secured in place by means of bands with quick release clips. Before fixing of boxes,

in inside, the same insulation shall be fixed with the help of strips & rivets.

d) For vessel heads with a large dia. shall be made in segmental form.

e) To ensure perfect water proofing, all cladding joints shall be packed with sealing

materials (Silicon Sealant). Minimum overlap in sheet metal at joints shall be 50mm

both circumferentially & longitudinally.

7.

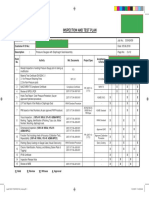

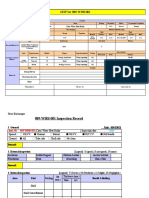

QC RECORD

8. ATTACHMENT.

ATTACHMENT -1

Page 11 of 13

DOC.NO:

JOB PROCEDURE FOR HOT INSULATION WORK

OF PIPING & EQUIPMENT

AFCONS INFRASTRUCTURE

LTD. RPL, JAMNAGAR

CLIENT RELIENCE

Contract No: 3612153

PROJECT: JAMNAGAR EXPORT REFINERY

PR/2247/J-INS/01

REV NO:00

Insulation thickness (in mm) for hot insulation

Pipe Size

N.B (mm)

Up to 100

15

25

20

25

25

25

32

25

40

25

50

25

65

25

80

25

100

25

125

25

150

25

200

25

250

25

300

25

350

25

400

25

450

25

500

25

550

25

600

25

>600& Equipment

25

flat surface

Temperature (Deg. C)

101 to 150

151 to 200

201 to 250

25

40

50

25

40

50

25

40

50

30

40

60

30

40

60

30

50

60

30

50

60

40

50

70

40

50

70

40

60

70

40

60

80

40

60

80

40

60

80

40

60

90

40

60

90

40

70

90

40

70

90

40

70

90

50

70

90

50

70

90

50

70

90

251 to 310

60

60

70

70

70

80

80

80

90

90

100

100

110

110

110

120

120

120

120

120

120

Insulation thickness given in above table has been calculated based on the following

parameters.

Ambient Temperature

Surface temperature

Wind velocity

Emissive

material

Page 12 of 13

35C

50C

0 m/s

0.60(for GI cladding)

Mineral wool Mats. 150 Kg/m

JOB PROCEDURE FOR HOT INSULATION WORK

OF PIPING & EQUIPMENT

AFCONS INFRASTRUCTURE

LTD. RPL, JAMNAGAR

CLIENT RELIENCE

Contract No: 3612153

PROJECT: JAMNAGAR EXPORT REFINERY

Page 13 of 13

DOC.NO:

PR/2247/J-INS/01

REV NO:00

You might also like

- Piping & Equipt Insulation - RevDocument7 pagesPiping & Equipt Insulation - RevLuis Gabriel BautistaNo ratings yet

- Paint DefectsDocument129 pagesPaint Defectsmohammad100% (6)

- Blyton Enid Noddy 5 Well Done Noddy! 1952Document71 pagesBlyton Enid Noddy 5 Well Done Noddy! 1952carlosathinopolos75% (12)

- Impact TestingDocument27 pagesImpact Testingapi-3764139100% (2)

- InsulationDocument63 pagesInsulationSH1961No ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- Classification of Cables SlidesDocument19 pagesClassification of Cables Slidessaravan1891100% (4)

- NRP QapDocument10 pagesNRP QapKevin Mathew100% (1)

- Askeland Science and Engineering 7e ISM Chapter 08Document24 pagesAskeland Science and Engineering 7e ISM Chapter 08Ian Gabriel Cañas Fernández100% (4)

- ME Lab 1 Exp 7 Bomb CalorimeterDocument18 pagesME Lab 1 Exp 7 Bomb CalorimeterJAMAL HALIBAYNo ratings yet

- Jacobs: Equipment Inspection Code: ADocument2 pagesJacobs: Equipment Inspection Code: ASigit BintanNo ratings yet

- Coating Faults AADocument82 pagesCoating Faults AAAbrianto Akuan100% (5)

- Blasting & Painting ReportDocument2 pagesBlasting & Painting ReportSanjay KumarNo ratings yet

- JNK Heaters Co - LTD: Ferrite Test ReportDocument1 pageJNK Heaters Co - LTD: Ferrite Test ReportUzorNo ratings yet

- WPS PqrchecklistDocument1 pageWPS PqrchecklistrodofgodNo ratings yet

- Specification For 3 Layer Polyethylene CoatingDocument34 pagesSpecification For 3 Layer Polyethylene CoatingYogesh BaraskarNo ratings yet

- ESAB Puls Mig Welding Hand BookDocument20 pagesESAB Puls Mig Welding Hand BookLeonardo De La HudiNo ratings yet

- Inspection and Test Plan for Pressure GaugesDocument1 pageInspection and Test Plan for Pressure GaugesVenkatesh PethurajNo ratings yet

- Fundamentals of Professional WeldingDocument213 pagesFundamentals of Professional Weldingapi-3856939No ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- Process Design of TurboexpanderDocument55 pagesProcess Design of TurboexpanderSaidFerdjallahNo ratings yet

- Daily piping fit-up reportDocument2 pagesDaily piping fit-up reportnguyenquanghiepNo ratings yet

- Kittel Solutions AKDocument79 pagesKittel Solutions AKAra Martínez-Olguín100% (5)

- Tank Seam Testing EvaluationDocument1 pageTank Seam Testing EvaluationMark Kevin Bechayda100% (1)

- List Certificates of Werder QualificationDocument2 pagesList Certificates of Werder QualificationMuhammad FajarNo ratings yet

- Procedure for Fireproofing InstallationDocument13 pagesProcedure for Fireproofing InstallationRodelio RemoNo ratings yet

- Material Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureDocument1 pageMaterial Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureMohamed RaafatNo ratings yet

- Subjective and Objective Questions With Answers of Chemical Equilibrium For PracticeDocument21 pagesSubjective and Objective Questions With Answers of Chemical Equilibrium For PracticehappyNo ratings yet

- Construction Steel Erection PlansDocument10 pagesConstruction Steel Erection PlansTran KhuynhNo ratings yet

- 20 Welding RevisedDocument104 pages20 Welding Revisedravi00098No ratings yet

- 20 Welding RevisedDocument104 pages20 Welding Revisedravi00098No ratings yet

- Line History SheetDocument46 pagesLine History SheetBhanu Pratap Choudhury33% (3)

- Daily structural concrete reportDocument2 pagesDaily structural concrete reportAli RazaNo ratings yet

- F07-Visual Inspection Report NEWDocument1 pageF07-Visual Inspection Report NEWmohd as shahiddin jafriNo ratings yet

- Systems de Levage Des Réservoirs Par VérinsDocument17 pagesSystems de Levage Des Réservoirs Par VérinsAziz ELNo ratings yet

- SEIP for Claus Waste Heat Boiler InspectionDocument6 pagesSEIP for Claus Waste Heat Boiler InspectionThinh NguyenNo ratings yet

- Hotel Sales Strategies To Effectively Increase RevenueDocument38 pagesHotel Sales Strategies To Effectively Increase Revenueravi00098No ratings yet

- Valves and PipingDocument118 pagesValves and PipingMahdi Daly100% (1)

- Rhourde El Baguel LPG Extraction Plant Feed Planning Rev 0 PDFDocument3 pagesRhourde El Baguel LPG Extraction Plant Feed Planning Rev 0 PDFZakari LOUNISNo ratings yet

- Tank Settlement Record T-05Document8 pagesTank Settlement Record T-05Marvan Audy BurikoNo ratings yet

- Node-Design of Baseplate For ColumnsDocument7 pagesNode-Design of Baseplate For ColumnsTusharNo ratings yet

- Kou2003 PDFDocument6 pagesKou2003 PDFGe EffgenNo ratings yet

- Nanorobotics: The Future of Medical SciencesDocument21 pagesNanorobotics: The Future of Medical Sciencesvinamra m singh100% (1)

- Coating Failure Presentation 01 PDFDocument32 pagesCoating Failure Presentation 01 PDFravi00098No ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- Comments Resolution Sheet For Commented QAPDocument10 pagesComments Resolution Sheet For Commented QAPSuraj ShettyNo ratings yet

- Welding HISTORY SHEETDocument9 pagesWelding HISTORY SHEETAhmedNo ratings yet

- Hydro Test Loop File Index FormatDocument22 pagesHydro Test Loop File Index FormatHema NandhNo ratings yet

- Test package flow logDocument2 pagesTest package flow logsyedahmad39No ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFRadhakrishna VachaNo ratings yet

- Electrode Brand Name and Class MirfaDocument13 pagesElectrode Brand Name and Class MirfaAnonymous rYZyQQot55No ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- Checklist For Fabrication & Erection of Structural Steel WorkDocument1 pageChecklist For Fabrication & Erection of Structural Steel Workbetelehem hailuNo ratings yet

- 57 PQRDocument13 pages57 PQRAbdul Tri Hamdani HamdaniNo ratings yet

- StandardsDocument4 pagesStandardsrania hammamiNo ratings yet

- Lish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFDocument1 pageLish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFliving goodNo ratings yet

- Maintaining ExperienceDocument5 pagesMaintaining ExperienceIvan KryskoNo ratings yet

- 10624-Master Index For Pipe SupportsDocument36 pages10624-Master Index For Pipe SupportsSARFRASNo ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- Certificate of Origin Form F For China-Chile FTADocument2 pagesCertificate of Origin Form F For China-Chile FTAinspectormetNo ratings yet

- Protect Industrial Chemical Tanks Under 40 CharactersDocument16 pagesProtect Industrial Chemical Tanks Under 40 CharactersChonTicha'100% (1)

- TATA Painting Specification 43Document1 pageTATA Painting Specification 43Suleman KhanNo ratings yet

- Esab, OK Autrod 12.22 (1222252800)Document1 pageEsab, OK Autrod 12.22 (1222252800)RodrigoNo ratings yet

- Hydrotest - 333 AG FW 0001 - Rev03 PDFDocument26 pagesHydrotest - 333 AG FW 0001 - Rev03 PDFIhsan IchwansyahNo ratings yet

- Inspection Report For Pipeline Route Survey Sign Copy and Blank FormatDocument1 pageInspection Report For Pipeline Route Survey Sign Copy and Blank FormatVishvjeet Prakash TiwariNo ratings yet

- INSPECTION REPORT TITLEDocument7 pagesINSPECTION REPORT TITLEABEC Trombay siteNo ratings yet

- F-035 (Valve Erection Format)Document1 pageF-035 (Valve Erection Format)Rajeev Kumar100% (1)

- CV of Engineer MD Sazid Alam1Document8 pagesCV of Engineer MD Sazid Alam1Alam MD SazidNo ratings yet

- Epilux 610 HBLD Primer Coating: Resistance Guide Product DataDocument2 pagesEpilux 610 HBLD Primer Coating: Resistance Guide Product DataBijaya RaulaNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- Pttep Painitng of Offshore FacilitiesDocument66 pagesPttep Painitng of Offshore FacilitiesSufianNo ratings yet

- Ug PipingDocument1 pageUg PipingVinoth KumarNo ratings yet

- Switch GearDocument7 pagesSwitch GearpanduranganraghuramaNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Section 2 QAP, Cable TrayDocument3 pagesSection 2 QAP, Cable TrayveerendraNo ratings yet

- Painting ReportDocument29 pagesPainting ReportDimas Afiefan AmirNo ratings yet

- Tool Fab - WorkshopDocument347 pagesTool Fab - Workshophrdsby100% (1)

- DVS 2207-3Document12 pagesDVS 2207-3gura9054No ratings yet

- Dimensional Check-Form 3TDocument3 pagesDimensional Check-Form 3Tlempeng durianNo ratings yet

- Kaiflex Specification DomesticDocument5 pagesKaiflex Specification Domesticnaseema1No ratings yet

- Con AirDocument156 pagesCon Airravi00098No ratings yet

- Barbara Delinsky-The Wedding Night PDFDocument217 pagesBarbara Delinsky-The Wedding Night PDFravi00098No ratings yet

- 009 The Great Airport MysteryDocument67 pages009 The Great Airport Mysteryomar omarNo ratings yet

- NDT Radio Graphy Notes PDFDocument18 pagesNDT Radio Graphy Notes PDFravi00098No ratings yet

- Practices PipeDocument4 pagesPractices PipeParag Naik100% (2)

- RadioGraph Book 1Document33 pagesRadioGraph Book 1Vicky SinghNo ratings yet

- Stainless Pocket GuideDocument36 pagesStainless Pocket GuidePukhraj DagaNo ratings yet

- Weld Chart 1Document4 pagesWeld Chart 1ravi00098No ratings yet

- An Introduction To RadiographyDocument52 pagesAn Introduction To RadiographyAmit PalaliyaNo ratings yet

- Welding of Duplex SSDocument20 pagesWelding of Duplex SSHermansyah PutraNo ratings yet

- Welding Reference To Sec-IXDocument22 pagesWelding Reference To Sec-IXVijayananda AnandaNo ratings yet

- W Section 2 Tig Welding Saf Fro General Catalogue3005009245853932523Document18 pagesW Section 2 Tig Welding Saf Fro General Catalogue3005009245853932523ravi00098No ratings yet

- PaintCure PDFDocument8 pagesPaintCure PDFmahendraNo ratings yet

- Measure Optical Density of X-Ray FilmsDocument2 pagesMeasure Optical Density of X-Ray FilmsthisisghostactualNo ratings yet

- Schubert PDFDocument66 pagesSchubert PDFdattu33No ratings yet

- Husain Al Muslim Saudi Aramco PDFDocument34 pagesHusain Al Muslim Saudi Aramco PDFravi00098No ratings yet

- Welding Power SourcesDocument6 pagesWelding Power SourcesM.IBRAHEEMNo ratings yet

- Elcometer 456 User Manual PDFDocument76 pagesElcometer 456 User Manual PDFchaparal100% (1)

- Naming Aromatic CompoundsDocument14 pagesNaming Aromatic Compoundssantosmaangelica16No ratings yet

- 2004 Modeling Wood Gasification in A Countercurrent Fixed Bed ReactorDocument14 pages2004 Modeling Wood Gasification in A Countercurrent Fixed Bed ReactorJean Carlos Gonzalez HernandezNo ratings yet

- 9700 BIOLOGY: MARK SCHEME For The October/November 2015 SeriesDocument11 pages9700 BIOLOGY: MARK SCHEME For The October/November 2015 SeriesNerminNo ratings yet

- Metabólica Review 1Document50 pagesMetabólica Review 1Eduardo Alonso Lopez OrnelasNo ratings yet

- Crystallization Vs PrecipitationDocument3 pagesCrystallization Vs Precipitationgullipalli srinivasa raoNo ratings yet

- 4 - Material Characteristics Bitumen and Mixes 5-6 - 2020Document56 pages4 - Material Characteristics Bitumen and Mixes 5-6 - 2020Venkata Harsha Vardhan KinjarapuNo ratings yet

- Mme 2203Document4 pagesMme 2203Zahida ParnisNo ratings yet

- Interactive Textbook 5 PDF Elelments 3 1Document5 pagesInteractive Textbook 5 PDF Elelments 3 1api-240094705No ratings yet

- ME468 NanotechnologyDocument2 pagesME468 NanotechnologySreehari SNo ratings yet

- No Ans Regular Assignment of Atomic Structure XI Chapter 2Document4 pagesNo Ans Regular Assignment of Atomic Structure XI Chapter 2manojwarlaniNo ratings yet

- GC Analysis Derivatization ReactionsDocument28 pagesGC Analysis Derivatization Reactionsfarkad rawiNo ratings yet

- Limestone Sourcing Study - Rev00Document146 pagesLimestone Sourcing Study - Rev00Parasuram PadmanabhanNo ratings yet

- CDU-I Monthly Yields 2017-18 UpdatedDocument44 pagesCDU-I Monthly Yields 2017-18 UpdatedPinjala AnoopNo ratings yet

- OGA - Chemical Series - Soda Ash Market Outlook 2019-2025Document20 pagesOGA - Chemical Series - Soda Ash Market Outlook 2019-2025ambarish ramNo ratings yet

- 2015 2016AP Chemistry Summer AssignmentDocument7 pages2015 2016AP Chemistry Summer AssignmentBraden FarrellNo ratings yet

- Answers - CallisterDocument6 pagesAnswers - CallisterLucas SeixasNo ratings yet

- ICAMM-2016 Conference Technical Sessions ScheduleDocument19 pagesICAMM-2016 Conference Technical Sessions SchedulePurna Suresh PedamalluNo ratings yet

- Chapter-09 - Answer Key & Explanation - CHEMISTRY Explanation Alcohol Phenol and EatherDocument11 pagesChapter-09 - Answer Key & Explanation - CHEMISTRY Explanation Alcohol Phenol and EatherAshutosh SinghNo ratings yet

- CAFAM BasicReportDocument135 pagesCAFAM BasicReportDaniel R. CC AIRESNo ratings yet

- pGBKT7 MapDocument0 pagespGBKT7 MapJuan Jose MartinezNo ratings yet

- No. 127 More About Modifications and InstrumentsDocument8 pagesNo. 127 More About Modifications and InstrumentsLisa FosterNo ratings yet

- Inv Chem 1Document24 pagesInv Chem 1Animesh kanjilalNo ratings yet