Professional Documents

Culture Documents

Batteries & Battery Chargers

Uploaded by

hajimak0 ratings0% found this document useful (0 votes)

202 views90 pagesThis document provides information on selecting batteries and battery chargers for use in Saudi Aramco applications. It discusses the main factors to consider when choosing a battery type, including load type and duration, temperature, life expectancy, maintenance needs, and cost. The most common types for Saudi Aramco are lead-acid and nickel-cadmium batteries. The document then provides details on lead-acid battery construction and different lead-acid battery plate designs. It also references Saudi Aramco standards and procedures for sizing batteries and chargers.

Original Description:

Its an Saudi Aramco Standards & Specifications and Regulations

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information on selecting batteries and battery chargers for use in Saudi Aramco applications. It discusses the main factors to consider when choosing a battery type, including load type and duration, temperature, life expectancy, maintenance needs, and cost. The most common types for Saudi Aramco are lead-acid and nickel-cadmium batteries. The document then provides details on lead-acid battery construction and different lead-acid battery plate designs. It also references Saudi Aramco standards and procedures for sizing batteries and chargers.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

202 views90 pagesBatteries & Battery Chargers

Uploaded by

hajimakThis document provides information on selecting batteries and battery chargers for use in Saudi Aramco applications. It discusses the main factors to consider when choosing a battery type, including load type and duration, temperature, life expectancy, maintenance needs, and cost. The most common types for Saudi Aramco are lead-acid and nickel-cadmium batteries. The document then provides details on lead-acid battery construction and different lead-acid battery plate designs. It also references Saudi Aramco standards and procedures for sizing batteries and chargers.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 90

Note: The source of the technical material in this volume is the Professional

Engineering Development Program (PEDP) of Engineering Services.

Warning: The material contained in this document was developed for Saudi

Aramco and is intended for the exclusive use of Saudi Aramcos

employees. Any material contained in this document which is not

already in the public domain may not be copied, reproduced, sold, given,

or disclosed to third parties, or otherwise used in whole, or in part,

without the written permission of the Vice President, Engineering

Services, Saudi Aramco.

Chapter : Electrical For additional information on this subject, contact

File Reference: EEX21102 W.A. Roussel on 874-1320

Engineering Encyclopedia

Saudi Aramco DeskTop Standards

Batteries And Battery Chargers

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards

CONTENTS PAGE

DETERMINING TYPES OF BATTERIES FOR USE IN TYPICAL

SAUDI ARAMCO APPLICATIONS ................................................................................... 1

DETERMINING BATTERY SIZE FOR USE IN TYPICAL SAUDI

ARAMCO APPLICATIONS .............................................................................................. 34

DETERMINING BATTERY CHARGER SIZE FOR USE IN TYPICAL

SAUDI ARAMCO APPLICATIONS ................................................................................. 57

WORK AID 1: PROCEDURE AND TECHNICAL AND ECONOMIC

REQUIREMENTS FROM SADP-P-103 AND

ESTABLISHED ENGINEERING PRACTICES FOR

DETERMINING THE TYPE OF BATTERY FOR USE IN

TYPICAL SAUDI ARAMCO APPLICATIONS...................................... 71

WORK AID 2: PROCEDURE AND TECHNICAL REQUIREMENTS

FROM SADP-P-103 AND ESTABLISHED

ENGINEERING PRACTICES FOR DETERMINING THE

SIZE OF BATTERY FOR USE IN TYPICAL SAUDI

ARAMCO APPLICATIONS .................................................................... 73

WORK AID 3: PROCEDURE, TECHNICAL REQUIREMENTS, AND

FORMULAS FROM SADP-P-103 AND ESTABLISHED

ENGINEERING PRACTICES FOR DETERMINING THE

SIZE OF A BATTERY CHARGER FOR USE IN

TYPICAL SAUDI ARAMCO APPLICATIONS...................................... 85

GLOSSARY........................................................................................................................ 88

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 1

DETERMINING TYPES OF BATTERIES FOR USE IN TYPICAL SAUDI ARAMCO

APPLICATIONS

The process of determining the type of battery for use in a given application requires an

evaluation of factors such as the following:

The type and the duration of the connected load.

The anticipated frequency and depth of discharge.

The ambient temperature at the installation site.

The planned life of the installation.

The frequency of maintenance.

Space limitations.

Life cycle cost.

Seismic requirements.

The two general types of storage batteries that can be used in Saudi Aramco installations are

lead-acid batteries and nickel-cadmium batteries. Each of these general types offers certain

advantages and disadvantages in regard to the previously listed factors. In addition, a number

of individual designs exist within each general type. These individual designs offer further

advantages and disadvantages in regard to the previously listed factors.

Because no single battery design can provide the optimum performance that is associated with

each of the previously listed factors, the factors must be weighted as to their importance in

each given installation. The actual battery type is then determined based on the weighted

factors to provide the best available compromise between desirable characteristics and

undesirable characteristics.

This section of the Module will provide information on the following topics that are pertinent

to determining the type of battery for use in typical Saudi Aramco applications:

Lead-Acid Batteries

Nickel-Cadmium Batteries

Operational Characteristics

Battery Applications

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 2

Lead-Acid Batteries

The lead-acid battery is a group of electrochemical cells that are connected in series to

generate a nominal dc voltage that would supply power to a suitably connected electrical load.

The number of cells that are connected in series determines the nominal voltage rating of the

battery. The amount of active material that is contained in an individual cell is the factor that

determines the discharge capacity rating of the cell; the rated capacity of the individual cells is

the rated capacity of the entire battery. Connecting the individual cells in series does not

increase the capacity rating of the battery.

The electrochemical couple that is used to form lead-acid cells is configured through

placement of a lead active material in a dilute sulfuric acid electrolyte. This electrochemical

couple produces a nominal cell voltage of approximately two volts.

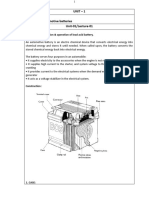

All lead-acid cells are constructed through use of the following basic components that are

shown in Figure 1:

Element

Cell jar

Cell cover

Electrolyte

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 3

Basic Components of a Lead-Acid Cell

Figure 1

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 4

Figure 2 shows an exploded view of the battery element. The battery element is the key

component of the cell, and it consists of an assembly of positive and negative plates that are

insulated from each other through use of separators. The interaction that occurs between the

battery element and the electrolyte determines the cell's performance characteristics.

Each of the plates consists of a rigid lead alloy that provides physical support for the

relatively porous active materials. The positive and the negative plates are sandwiched

together in an alternating pattern (e.g., negative-positive-negative-positive-negative) with a

negative plate at each end of the assembly. Each positive plate is separated from its

neighboring negative plate by an insulating material. The insulating material typically is a

thin sheet of microporous rubber or plastic that is ribbed on the side that faces the positive

plate.

Battery Element

Figure 2

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 5

The cell jar, which was shown in Figure 1, is usually made of a transparent impact-resistant

plastic material. The cell jar must be large enough to enclose the element and still provide

sufficient reservoir space above and below the element. The upper reservoir space is needed

to allow for the gradual lowering of the electrolyte level that occurs during normal operation

of the battery. The lower reservoir space serves as a collection basin for the sediment that is

shed from the plates during the expected life of the battery. This sediment must be kept away

from the element to prevent short-circuiting of the positive and the negative plates.

After the element has been lowered into the empty jar, the cell cover is placed over the top of

the jar and is sealed. The terminal posts that are connected to the element protrude through

holes that are in the top of the cell cover. The cell cover also is fitted with a flame arrestor

vent that allows gases to escape from inside of the cell but that prevents entry of sparks or

flames.

The electrolyte that is used in lead-acid batteries is a dilute solution of sulfuric acid and water.

The ratio of acid weight to water is measured as specific gravity. Pure water has a specific

gravity of 1.000. A typical nominal specific gravity for a lead-acid storage battery is 1.215 at

25

o

C (77

o

F). The specific gravity of the electrolyte gradually drops as a cell is discharged.

When the battery charger recharges the cell, the specific gravity gradually rises back to the

nominal value.

If a battery is to be operated at temperatures that exceed 29

o

C (85

o

F) for more than 30 days

per year, a tropical (low) specific gravity electrolyte could be used to increase the life of the

battery. A medium or a high specific gravity electrolyte is also available for special

applications such as UPS systems that, in some cases, will reduce the overall battery size that

is required.

As previously stated, all lead-acid batteries contain the same basic components. The major

difference between the various types of lead-acid batteries is the design of the positive plates

that are used in the battery element. The remainder of this section provides information on

the following specific types of lead-acid batteries:

Plante

Lead calcium

Lead antimony

Sealed

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 6

Plante

The Plante lead-acid battery is named after Raymond Gaston Plante, who was the inventor of

the first practical lead-acid storage battery. The original Plante cell was constructed of two

long strips of lead foil and intermediate layers of coarse cloth that were spirally wound and

immersed in a 10% solution of sulfuric acid. Because the amount of stored energy of the

early Plante cells depended on the corrosion of one lead foil to form lead dioxide, which is the

active material of the positive plate, the early Plante cells had little capacity. However, the

capacity of the early Plante cells did increase after repeated cycling because the cycling

resulted in corrosion of the substrate foil. Such corrosion created more active material and an

increased surface area.

Today, the name "Plante" refers to all lead-acid storage batteries in which the active material

of the positive plates is electro-chemically developed from pure metallic lead. Modern Plante

lead-acid batteries are available with two types of positive plate constructions: traditional and

Manchester. Both types of plates are shown in Figure 3.

Positive Plates Used in Plante Lead-Acid Batteries

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 7

Figure 3

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 8

The traditional positive plate starts off as a blank (slab) of pure metallic lead. Grooves are

then cut into the surface of the lead blank through use of a combing process. The grooves

increase the surface area of the plate, which increases the capacity of the cell.

The Manchester plate is the most common type of plate that is used in Plante lead-acid

batteries. The Manchester plate is constructed of a heavy antimony alloy grid that is cast with

circular holes. Heavy corrugated strips of high purity lead are then rolled into spiral buttons

or "rosettes" that are forced into the holes that are cast in the grid. Each of the lead buttons

exposes approximately five times more surface area to the electrolyte than a comparable area

on a pasted plate battery. The lead buttons also help to prolong the life of the cell by

providing a reserve supply of unformed lead that is gradually converted to active material

during operation of the cell.

The negative plates of Plante lead-acid batteries are pasted or "flat" plates with a heavy alloy

grid. The construction of these plates will be discussed in more detail in the next section of

this Module.

The following are the major advantages and disadvantages of Plante lead-acid batteries:

Advantages Disadvantages

Long service life (20 to 25 years) High cost

Smallest amount of positive plate growth

of all lead-acid cells

Poor energy density and poor power

density

Very high reliability Moderate self-discharge rates (3%/month)

Plante lead-acid batteries have the highest capital cost of all types of lead-acid batteries. The

cost of Plante lead-acid cells is approximately 3 to 3-1/2 times that of a comparable lead

antimony cell and approximately 2-1/2 to 3 times that of a comparable lead calcium cell.

However, in some applications, the high initial capital cost may be justified by the long (25

year) service life.

The cyclic performance and cycle life of Plante lead-acid batteries, as is the case with all

stationary lead-acid storage batteries, can only be discussed in relative terms. Stationary lead-

acid storage batteries are designed to provide a relatively long calendar service life (more than

ten years) when they are operated under float charge conditions rather than a Lead-Acid

Batteries (Cont'd)

long cycle life. Stationary lead-acid storage batteries are normally not rated or guaranteed to

deliver a specific number of equivalent full charge cycles.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 9

When any stationary lead-acid storage battery is subjected to deep and frequent discharges, its

calendar service life will be reduced; however, because of the number of variables that are

involved, the specific amount of calendar service life reduction cannot easily be quantified.

For this reason, the cyclic performance of one type of lead-acid storage battery is generally

only discussed in terms of comparison with another type of stationary lead-acid storage

battery.

The cyclic performance (e.g., the ability to withstand frequent and/or deep discharges) of

Plante lead-acid batteries is far superior to the cyclic performance of lead calcium batteries

and is approximately equivalent to the cyclic performance of lead antimony batteries. Plante

lead-acid batteries are capable of withstanding a moderate amount of cycling with a minimum

loss of calendar service life.

Lead Calcium

The positive and the negative plates of lead calcium batteries are pasted plates. Pasted plates

are constructed by forcing a thick slurry of active material (e.g., a combination of lead oxides

and sulfuric acid) into an open lattice grid. A typical pasted plate grid is shown in Figure 4.

The open lattice grid is cast from an alloy of pure lead and calcium. The addition of the

calcium alloying agent is necessary to increase the mechanical strength of the plate.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 10

Typical Pasted Plate Grid

Figure 4

After the active material is "pasted" on the open lattice grid, the plates are dried and formed

(activated) by an electrochemical process. The completed plate is porous so that the sulfuric

acid electrolyte can circulate through the active material. The porous construction greatly

increases the surface area of active material that is in contact with the electrolyte, which

increases the capacity of a given sized cell.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 11

The following are the major advantages and disadvantages of lead calcium batteries:

Advantages Disadvantages

Medium service life (12-15 years). Subject to excessive positive plate grid

growth.

Better energy density and power Not suitable for deep or density than Plante

batteries.frequent discharges

Low self-discharge rates (1%/month).

Low water consumption.

Medium cost.

The cost of lead calcium batteries is more than the cost of lead antimony batteries but is

considerably less than the cost of Plante batteries. On a cursory examination, this medium

range cost, when coupled with the other advantages of lead calcium batteries, make this

battery appear to be more attractive for most applications than the Plante battery. However, a

close look at the disadvantages of the lead calcium battery shows that this battery is only more

attractive in non-cycling applications.

The cyclic performance of lead calcium batteries is extremely poor. Of the three major types

of stationary lead acid storage batteries (Plante, lead calcium, and lead antimony), the lead

calcium battery suffers the greatest loss of calendar service life when it is subjected to cyclic

service. This battery should only be used in float charge, shallow cycle applications.

Lead Antimony

The positive and the negative plates of lead antimony batteries are also pasted plates. The

only real difference between the construction of lead antimony batteries and the construction

of lead calcium batteries is the addition of an antimony alloying material to the grid rather

than a calcium alloying material. The antimony alloying material, which is similar to the

calcium alloying material, is added to increase the mechanical strength of the plate.

The amount of antimony that is used in the grid varies from about 1.5% to 12% antimony by

weight. The percentage of antimony that is used affects the characteristics of the battery.

High antimony content provides greater grid strength; however, it also results in higher float

current requirements, an increase in water usage, and an increase in the frequency of

equalizing chargers towards the end of the battery's service life. Low antimony content

provides more desirable operating characteristics but at the sacrifice of grid strength.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 12

If the antimony content is less than 4%, small amounts of other elements such as selenium

must be added to maintain sufficient grid strength. Saudi Aramco does not allow the use of

lead antimony batteries that contain more than 3% antimony.

The following are the major advantages and disadvantages of lead antimony batteries:

Advantages Disadvantages

Low cost. High self-discharge rates (7%/month).

Better energy density and power density

than Plante batteries.

Short service life (10-12 years).

Can be used in cycling service. High water consumption.

Lead antimony batteries have the least capital cost of all lead-acid batteries. The low capital

cost makes this battery an attractive choice for cycling service applications in which the high

water usage is acceptable.

The cyclic performance of lead antimony batteries is approximately equivalent to the cyclic

performance of Plante batteries. Lead antimony batteries are capable of withstanding a

moderate amount of cycling with a minimum loss of calendar service life.

Sealed

Two different versions of sealed lead-acid batteries are available: the gelled electrolyte

version and the absorbed glass mat (AGM) version. The basic technology of both versions of

sealed lead-acid batteries is identical in that they are both recombinant-type batteries that have

positive limited plate groups that operate in the oxygen cycle.

In all types of lead-acid batteries, a lead oxide positive plate and a sponge lead negative plate

are placed in a dilute mixture of sulfuric acid. The voltage difference that is produced by this

electrochemical couple causes electrons to flow from one plate to the other plate when the

plates are connected. This electron flow causes a chemical reaction inside of the battery. The

chemical reaction will be discussed in more detail later in this section. When a lead acid

battery is discharged, much of the sulfuric acid electrolyte is changed to water and both of the

plates are reduced to lead sulfate. When a lead-acid battery is subsequently charged by

forcing electrons to flow in the opposite direction, all of the chemical reactions are reversed.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 13

During recharge, oxygen is released at the positive plate, and, when the negative plate is fully

charged, it releases hydrogen. These gases are formed from the decomposition of the water

that is mixed with the sulfuric acid. The gases must be vented out of the battery room, and

they must be properly dispersed because of the explosive nature of hydrogen. In flooded

lead-acid batteries, this water loss must be replaced on a regular basis to prevent the plate

from drying out.

In sealed lead-acid batteries, the negative plate is designed to be what is known in the industry

as "positive limited" because the chemical reaction of discharging is stopped when the

positive plate is exhausted. When a sealed lead-acid battery is recharged, the negative plate

never reaches its full charge condition; therefore, hydrogen gas is not released. The oxygen

that is released at the positive plate travels through the void paths that are in the separator to

the negative plate. At the negative plate, the oxygen combines with the lead in the negative

plate to form lead dioxide. The lead dioxide reacts with the sulfuric acid that is in the

electrolyte to form lead sulfate and water. This water replaces the water that was consumed at

the positive plate to make the oxygen; therefore, water never needs to be added to the battery

and the case can be sealed.

The oxygen that is generated at the positive plate creates a positive pressure inside of the

battery that is two to three pounds above the ambient pressure. Because of this positive

pressure, sealed lead-acid batteries must contain a relief valve to prevent overpressurization of

the battery in the event of a malfunction such as a runaway charger. The relief valves are

designed to automatically reseal once the pressure returns to normal.

The construction of the gelled electrolyte version of sealed lead-acid batteries is similar to the

construction of flooded lead-acid batteries with a few key differences. In the gelled

electrolyte version, the dilute sulfuric acid mixture is blended with silica to form a gel or a

paste-like substance. This gelled electrolyte is then used with a pasted plate element that is

complete with a microporous separator. The primary difference between a pasted plate

element for a flooded lead-acid battery and the pasted plate element for sealed lead acid

battery is that the element that is used in the sealed lead-acid battery is positive limited. The

other key difference is that the sealed lead-acid battery is constructed with a relief valve rather

than with a flash arrestor.

In the AGM version, the positive limited element is constructed without the microporous

separator. Instead, the positive plates are separated from the adjoining negative plates by a

fiberglass mat. The fiberglass mat absorbs the liquid electrolyte so that no free liquid exists

inside of the battery. The very fine micro fiber construction of the mat and its relatively thin

(approximately 1/8 inch) construction results in a very low internal cell impedance. Because

of the AGM version's construction, it is generally smaller, lighter, and more energy-efficient

for short discharge periods than the gelled electrolyte version. However, the AGM version is

more prone to plate shorting as a result of small lead filaments bridging the thin glass mat

separator.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 14

The following are the major advantages and disadvantages of sealed lead-acid batteries:

Advantages Disadvantages

Long service life (15 to 20 years) in float

service.

High cost.

No maintenance. Short service life (< 10 years) in cycling

service.

Reduced battery room/ventilation

requirements.

Moderate self-discharge rates (3%/month).

Vertical or horizontal mounting. Not suitable for deep or frequent

discharges.

The development of sealed lead-acid batteries for large stationary storage applications is a

relatively recent (within the last ten years) technology and, as such, these batteries are more

expensive than their lead calcium and lead antimony flooded cell counterparts. The cost of

sealed lead-acid batteries is similar to the cost of Plante lead-acid batteries.

Because most sealed lead-acid batteries for stationary storage applications use a lead calcium

grid, their cyclic performance is similar to the cyclic performance of the flooded lead calcium

batteries that were previously discussed. Sealed lead acid batteries do not perform well in

frequent or deep cycle application; these batteries should only be used in float charge, shallow

cycle applications.

Nickel-Cadmium Batteries

The nickel-cadmium battery also is a group of electrochemical cells that are connected in

series to generate a nominal dc voltage that would supply power to a suitably connected

electrical load. The number of cells that are connected in series determines the nominal

voltage rating of the battery. The amount of active material that is contained in an

individual cell is the factor that determines the discharge capacity rating of the cell; the rated

capacity of the individual cells is the rated capacity of the entire battery. Connecting the

individual cells in series does not increase the capacity rating of the battery.

The electrochemical couple that is used to form nickel-cadmium cells is configured through

placement of a nickel hydroxide positive electrode and a metallic cadmium negative electrode

in a dilute potassium hydroxide electrolyte. This electrochemical couple produces a nominal

cell voltage of approximately 1.2 volts.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 15

The following types of nickel-cadmium stationary storage batteries will be discussed in this

section:

Pocket Plate

Sintered Plate

Pocket Plate

Pocket plate nickel-cadmium batteries get their name from the "pocket" strip that holds the

active material of the plates. The pockets are made from very thin, finely perforated strips of

steel that are formed into shallow "U" channels as shown in Figure 5. The positive active

material, which consists of hydrates of nickel oxide and graphite, and the negative active

material, which consists of cadmium oxide and a small amount of iron oxide, are placed into

the open "U" channel. The open "U" channel is then covered with a similar strip of perforated

steel and the two strips are crimped together to form a perforated pocket.

A number of these perforated pockets are interlocked edge-to-edge and then cut to the

approximate finished plate width. The interlocked pockets are then rolled to compress the

active material and to form longitudinal indentations in the plate. Each plate group is then

bolted or welded together. The two (positive and negative) plate groups are interleaved and

insulated with plastic rod or mat separators that are inserted into the longitudinal grooves of

the plates. The insulated plate group or element is then inserted into a plastic container or jar.

After the mechanical assembly is complete, the cells are put through an electrochemical

formation process to convert the active materials to their charged condition.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 16

Pocket Plate Construction

Figure 5

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 17

Figure 6 shows a cutaway view of a typical pocket plate nickel-cadmium battery. The

following components are identified in Figure 6:

Vent Cap/Flame Arrestor

Cell Container or Jar

Plate Tab

Plate Group Bus

Separating Grids

Plate Frame

Plate

Typical Pocket Plate Nickel-Cadmium Battery

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 18

Figure 6

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 19

The vent cap/flame arrestor allows the gases that are generated during normal charging and

discharging to escape from the battery, but it prevents the entry of sparks and foreign

material. The vent cap/flame arrestor can be removed to allow access to the interior of the

cell.

The cell container or jar is made out of translucent polypropylene. The cell container or jar is

the enclosure that holds the individual components of the cell and that contains the liquid

potassium hydroxide (KOH) electrolyte.

The plate tabs are spot welded to the plate frame and to the upper edge or the pocket plates.

The plate tabs provide the electrical connection between the plates and the plate group bus.

The plate group bus connects the plate tabs to the terminal posts of the battery. The plate tabs

and the terminal posts are welded to opposite sides of the plate group bus.

The separating grids separate the plates and insulate the plate frames from each other. The

separating grids are porous, and they allow the free circulation of the KOH electrolyte

between the plates.

The plate frames seal the plate pockets, and they serve as current collectors. The plates in this

particular battery have horizontal pockets of double-perforated steel strips.

Most manufacturers make three general pocket plate designs: thin plates, medium plates, and

thick plates. The thin plate design has a low internal resistance, and it is used in high rate,

short duration (less than 30 minutes) discharge cells. The medium plate design has an internal

resistance that is similar to the internal resistance of general purpose lead-acid cells. This

plate design is used in median rate, median duration (from 30 minutes to 2 hours) discharge

cells. The thick plate design has a high internal resistance, and it is used in very low rate,

long duration (more than two hours) discharge cells.

All vented nickel-cadmium batteries have several general advantages over their flooded lead

acid counterparts. One of these advantages stems from the KOH electrolyte that is used in

nickel-cadmium batteries. The freezing point of KOH electrolyte with a typical specific

gravity of 1.190 is -32

o

C (-25

o

F). Because the specific gravity of the electrolyte in a nickel-

cadmium battery remains relatively constant from the fully charged state to the fully

discharged state, the freezing point also remains relatively constant. In contrast, the freezing

point of a fully discharged lead-acid battery essentially is the same as the freezing point of

water or 0

o

C (32

o

F); therefore, lead acid batteries are much more likely to freeze than nickel-

cadmium batteries. Nickel-cadmium batteries also make a significantly higher percentage of

their current available at lower temperatures than lead-acid batteries.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 20

Another general advantage of nickel-cadmium batteries is that they require much less

maintenance than flooded lead-acid batteries. Nickel-cadmium batteries can go years without

being watered, and they will not deteriorate when they are left in a discharged condition.

Nickel-cadmium batteries have successfully been returned to service after being left "on-the-

shelf" for 10 to 15 years.

The other general advantages of nickel-cadmium batteries include a more rugged and durable

construction (i.e., relatively immune to vibration, shock, and overcharge currents), a long

cycle life, and minimal gas generation on charge and discharge. Also, the gaseous vapors that

are emitted from nickel-cadmium batteries are not corrosive to ferrous metals.

The only general disadvantage of nickel-cadmium batteries to flooded lead-acid batteries is

the high cost of nickel-cadmium batteries. The cost (dollars/kilowatt-hour) of nickel-

cadmium batteries is four to ten times the cost of flooded lead-acid batteries. Also, because

cadmium is more difficult and expensive to recycle and/or dispose of than lead, the disposal

cost of expended nickel-cadmium batteries is higher than it is for expended lead-acid

batteries. In North America, large nickel-cadmium storage batteries are actually being phased

out of production as a result of the disposal issues that surround cadmium.

The advantages of pocket plate nickel-cadmium batteries over sintered-plate nickel-cadmium

batteries are that pocket plate nickel-cadmium batteries have a lower cost, they have a long

cycle life, and they do not suffer a "memory" effect on shallow discharges. The major

disadvantage of pocket plate nickel-cadmium batteries is that they only have about 50% of the

energy density of sintered-plate nickel-cadmium batteries.

In contrast to flooded stationary lead-acid batteries, pocket plate nickel-cadmium batteries

have a long cycle life in addition to a long calendar life. Under normal operating conditions,

pocket plate nickel-cadmium batteries can deliver as many as 2000 equivalent full charge

cycles. The calendar life of pocket plate nickel-cadmium batteries ranges from 15 to 25

years. Because of the large number of cycles that this battery can withstand (more than 80

equivalent full charge cycles per year over a 25 year calendar service life), cycling has little or

no effect on the calendar service life of pocket plate nickel-cadmium batteries.

Sintered-Plate

Because Saudi Aramco does not permit the use of sintered-plate nickel-cadmium batteries,

this section is intended only for general information purposes. The primary applications of

sintered-plate nickel-cadmium batteries are those that require high-power discharge service in

a lightweight compact package such as aircraft turbine engine starting circuits.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 21

Sintered-plate nickel-cadmium batteries are constructed similarly to pocket plate nickel-

cadmium batteries. The major difference between the two batteries is the way in which the

electrodes (positive and negative plates) are designed. In the sintered-plate design, the active

materials are impregnated into a porous nickel coating that is applied to an iron grid or charge

collector.

Sintered-plate nickel-cadmium batteries have nickel oxyhydroxide positive plates and

cadmium hydroxide negative plates. The plates are separated by non-conductive, porous

materials that act as a gas barrier and an electrical separator. The electrolyte is a dilute KOH

solution, and it completely covers the plates and separators.

Figure 7 shows the construction of a typical sintered-plate nickel-cadmium battery. The

battery consists of a plate pack that contains the positive plates, the negative plates, and the

separators. A terminal comb is placed over the negative plate tabs to connect the negative

plates. A separate terminal comb is placed over the positive plate tabs to connect the positive

plates. The assembled plate pack is then placed in the cell container. A cell cover is placed

on top of the cell container, and it is sealed to the container. A terminal is connected to the

positive terminal comb and to the negative terminal comb. The terminals are used to connect

the battery to the external load. The removable vent cap allows excess gases to escape and a

means to add electrolyte.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 22

Typical Sintered-Plate Nickel-Cadmium Battery

Figure 7

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 23

The advantages and disadvantages of sintered-plate nickel-cadmium batteries are shown in

Figure 8.

Advantages and Disadvantages of Sintered-Plate Nickel-Cadmium Batteries

Figure 8

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 24

As was noted in Figure 8, the sintered-plate nickel-cadmium battery is more expensive than

the vented pocket plate battery and many times more expensive than the sealed lead-acid

battery.

The average calendar life of a sintered-plate nickel-cadmium battery ranges from three to ten

years, and the cycle life ranges from 500 to 2000 equivalent full charge cycles. The cycle life

and calendar life are strongly influenced by the method of operation, the ambient temperature

conditions, and the depth of discharge. The best battery life performance is obtained from

operation at normal temperatures and at moderate (50% average) discharge depths. The life

of sintered-plate nickel-cadmium batteries drops when the battery is subjected to frequent

deep or shallow discharges.

Operational Characteristics

Each type (lead-acid or nickel-cadmium) of battery has a unique set of operational

characteristics that are based on the construction and configuration of the electrochemical

couple that is used in the battery. The following operational characteristics of batteries will be

discussed in this section:

Electrochemical Reaction

Charge Discharge Characteristics

Effects of Temperature on Battery Life and Capacity

Electrochemical Reaction

The electrical energy that secondary batteries are capable of delivering is derived from the

electrochemical reaction that occurs between two electrically dissimilar metals or metallic

compounds. In the case of lead-acid batteries, the electrolyte also takes part in the

electrochemical reaction. The electrochemical reaction is essentially reversible and electrical

energy is consumed to restore the battery to a charged condition. The sections that follow

provide an explanation of the electrochemical reactions that occur during the discharge and

charge of the following types of secondary storage batteries:

Lead-Acid

Nickel-Cadmium

Lead-Acid - In a fully charged lead-acid battery, the positive electrode material is lead dioxide

(PbO

2

), the negative electrode material is pure sponge lead (Pb), and the electrolyte is a

mixture of sulfuric acid (H

2

SO

4

) and water (H

2

O). As the battery is discharged, both of the

electrodes are converted to lead sulfate (PbSO

4

) and the electrolyte is consumed, which

produces water; the process reverses when the battery is charged. This electrochemical

reaction is called the "double-sulfate" reaction.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 25

Figure 9 shows the discharge electrochemical reaction that occurs in a lead-acid battery. The

initial reaction that occurs on discharge is an ionization process. The 2H

2

SO

4

breaks down

into 2SO

2-

4

and 4H

+

through the ionization process. The PbO

2

breaks down to 4OH

-

and

Pb

4+

. After the ionization process, the current producing process begins to produce usable

electric current. The Pb of the negative electrode reacts with the SO

2-

4

ions that are in the

electrolyte. The product of this reaction is Pb

2+

and 2e; the Pb

2+

then combines with the

SO

2-

4

ions to produce PbSO

4

. PbSO

4

is the discharged composition of the negative

electrode.

At the positive electrode, the Pb

4+

combines with the SO

2-

4

ions that are in the electrolyte

and with 2e from the load to produce PbSO

4

. PbSO

4

also is the discharged composition of

the positive electrode. The 4OH

-

ions from the positive electrode combine with the 4H

+

ions

that are in the electrolyte to produce 4H

2

O. This discharge reaction continues until the active

materials are effectively depleted.

Discharge Electrochemical Reaction

Figure 9

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 26

After the battery is discharged, a reverse polarity electric current must be applied to the

battery to reverse the electrochemical reaction, which restores the battery to a charged

condition. Figure 10 shows a graphical representation of the electrochemical reaction

that occurs inside of a lead-acid cell during a battery charge.

When a reverse polarity current is applied to the electrodes, the PbSO

4

that comprises

both electrodes ionizes to form Pb

2+

ions and SO

2-

4

ions. Also, the water (4H

2

O)

that is in the electrolyte ionizes to form 4H

+

ions and 4OH

-

ions. After ionization

occurs, the Pb

2+

ions of the negative electrode absorb 2e, which converts the negative

electrode back to Pb. The SO

2-

4

ions from both of the electrodes combine with the

4H

+

ions that are in the electrolyte, which forms 2H

2

SO

4

. The Pb

2+

ions of the

positive electrode combine with the 4OH

-

ions that are in the electrolyte, which

converts the positive electrode back to PbO

2

and forms 2H

2

O. This charge reaction

continues until the previously depleted active materials are returned to their original

composition. The following is the overall discharge/charge equilibrium equation for

lead-acid batteries:

Pb + PbO

2

+ 2H

2

SO

4

_ 2PbSO

4

+ 2H

2

O + 2e

Electrochemical Reaction During a Battery Charge

Figure 10

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 27

When a lead-acid battery approaches its full charge condition, the majority of the

PbSO

4

has been converted to Pb or PbO

2

, which causes the battery voltage on charge

to rise above the gassing voltage. The overcharge reactions then begin. The

overcharge reactions result in the production of hydrogen and oxygen (i.e., gassing)

and the resultant loss of water. The following are the equations for the overcharge

reactions:

Negative Electrode Reaction: 2H

+

+ 2e _ H

2

Positive Electrode Reaction: H

2

O - 2e _ 1/2O

2

+ 2H

+

Overall Reaction: H

2

O _ H

2

+ 1/2O

2

In sealed lead-acid batteries, the above reactions are controlled by design to prevent

hydrogen evolution and the loss of water through recombination of the evolved

oxygen with the negative plate.

Nickel-Cadmium- In a fully charged nickel-cadmium battery, the positive electrode

material is nickel oxyhydroxide (NiOOH), the negative electrode material is cadmium

(Cd), and the electrolyte is a mixture of potassium hydroxide (KOH) and water. When

nickel-cadmium batteries are discharged, the active materials that are contained in the

electrodes change in oxidation with no deterioration in the physical state. The active

materials are present only as solids that are highly insoluble in the KOH electrolyte.

Also, the KOH electrolyte does not participate in the electrochemical reaction; the

electrolyte only acts as a current carrying medium.

During a discharge, the cadmium metal of the negative electrode oxidizes to cadmium

hydroxide (Cd(OH)

2

) and releases electrons to the external circuit. This portion of the

electrochemical reaction is shown in the following equation:

Cd + 2OH

-

_ Cd(OH)

2

+ 2e

At the positive electrode, the NiOOH is reduced to the lower valence state of nickel

hydroxide (Ni(OH)

2

) by accepting electrons from the external circuit. This portion of

the electrochemical reaction is shown in the following equation:

2NiOOH + 2H

2

O + 2e _ 2Ni(OH)

2

+ 2OH

-

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 28

After the battery is discharged, a reverse polarity electric current must be applied to the

battery to reverse the electrochemical reaction, which restores the battery to a charged

condition. When a reverse polarity current is applied to the electrodes, the Cd(OH)

2

of the negative plate accepts electrons and returns to its original state as shown by the

following equation:

Cd(OH)

2

+ 2e _ Cd + 2OH

-

At the positive electrode, the 2Ni(OH)

2

is oxidized back to the its original higher

valence state of NiOOH as shown by the following equation:

2Ni(OH)

2

+ 2OH

-

_ NiOOH + 2H

2

O + 2e

The following is the overall discharge/charge equilibrium equation for nickel-cadmium

batteries:

Cd + 2NiOOH + 2H

2

O _ Cd(OH)

2

+ 2Ni(OH)

2

Charge/Discharge Characteristics

Figure 11 shows the way in which the following lead-acid battery characteristics change

during a constant current discharge and subsequent charge:

Specific gravity

Ampere-hours discharged/charged

Volts per cell

When a lead-acid battery is discharged at a constant, the specific gravity linearly decreases in

proportion to the number of ampere-hours that are discharged. In contrast, the volts per cell

remain relatively constant at the beginning of the discharge and then the volts per cell

decrease at an increased rate as the voltage approaches the end voltage of 1.75 volts. When

the battery reaches its end voltage, the discharge should be stopped and the battery should be

recharged.

When a lead-acid battery is placed on a constant rate (current) charge, the volts per cell have

an initial step jump increase, and then the volts per cell gradually rise and level off toward the

end of the charge. The specific gravity increase during the battery charge is not linear and it

lags behind the number of ampere-hours charged. The reason that the specific gravity

increase lags the number of ampere-hours charged is because complete mixing of the

electrolyte does not occur until gassing begins. Once gassing begins, the specific gravity

quickly rises to its full charge level.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 29

Lead-Acid Battery Charge/Discharge Characteristic Curves

Figure 11

Figure 12 shows a typical charge/discharge characteristic curve for a vented nickel-cadmium

battery. When a constant current discharge is placed on a fully charged nickel-cadmium

battery, the battery voltage initially drops as it begins to supply current to the load. After the

initial drop in voltage, the voltage remains essentially constant until about 90% to 95% of the

ampere-hours have been discharged. At this point, the volts per cell quickly drop to the final

voltage of 1.1 volts. When the battery reaches its end voltage, the discharge should be

stopped and the battery should be recharged.

When a vented nickel-cadmium battery is charged at a constant rate, the volts per cell have an

initial step jump increase and then gradually rise and level off toward the end of the charge.

The charge curve for a vented nickel-cadmium battery is similar to the charge curve for a

lead-acid battery except that the volts per cell values are lower.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 30

Because the specific gravity of a nickel-cadmium battery remains essentially constant from

fully charged to fully discharged, the curve for the specific gravity of a nickel-cadmium

battery is not shown in Figure 12.

Nickel-Cadmium Battery Charge/Discharge Characteristic Curves

Figure 12

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 31

Effects of Temperature on Battery Capacity and Service Life

The temperature at which a lead-acid battery is operated has a definite effect on its capacity

and its service life. Figure 13 shows the effects of temperature on the capacity of a lead-acid

battery at several different discharge rates. For each discharge rate that is shown (3 to 8 hour

rate, 0.5 to 3 hour rate, and 0.5 hour rate), the battery delivers its rated capacity (100%) at an

electrolyte temperature of 25

o

C, which is the optimum operating temperature for a lead-acid

storage battery. As the operating temperature drops below 25

o

C, the % rated capacity of the

battery also decreases. The decrease is due to reduced chemical activity and to increased

internal resistance.

As the operating temperature rises above 25

o

C, the % rated capacity of the battery also

increases; however, such operation should be avoided as the high temperatures also cause a

severe reduction in service life. Operation of a lead-acid storage at an electrolyte temperature

of 35

o

C reduces the service life by 50%.

Effect of Temperature on Lead-Acid Battery Capacity

Figure 13

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 32

High and/or low electrolyte temperatures have a much smaller effect on nickel-cadmium

batteries than they do on lead-acid batteries. Pocket plate nickel-cadmium storage batteries

that contain standard electrolyte concentrations can be used at temperatures as low as -20

o

C

with little loss of capacity. Batteries that contain concentrated electrolyte can be used at

temperatures as low as -50

o

C.

Pocket plate nickel-cadmium storage batteries can also be continuously operated at elevated

temperatures with little or no loss of service life. Generally, these batteries can operate with

electrolyte temperatures that range from 45 to 50

o

C with no long term detrimental effects.

Battery Applications

A number of factors must be considered to select the best battery for a particular application.

No single battery provides optimum performance under all operating conditions. The

characteristics of each available battery must be weighed against the total equipment

requirements, and the battery that is selected must best fill these requirements. Generally, the

following factors are considered in the selection process:

Ambient temperature

Life cycle cost

Required ampere-hour capacity and duty cycle

Frequency of required maintenance

Available space

Because of the effects of electrolyte temperature on the capacity and the life of lead-acid

batteries, the ambient temperature of the battery installation site must be considered in the

battery selection process. If the battery will be required to operate in low ambient

temperatures, a lead-acid battery may still be satisfactory; however, a larger cell size would be

required to make up for the decreased ampere-hour capacity of lead-acid batteries at low

temperatures. If the battery will be required to operate in high ambient temperatures, a nickel-

cadmium battery may be the only acceptable choice because of the severe service life

reduction that is suffered by lead-acid batteries when they are operated in high ambient

temperatures.

The life cycle cost of the different batteries that could be used in a given installation must be

determined to realistically compare the cost of different battery types. The life cycle cost of a

given battery is the initial capital cost of the battery plus the anticipated cost of maintenance

over the battery's anticipated service life, divided by the anticipated calendar service life or

number of equivalent full charge cycles, whichever is applicable.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 33

The required ampere-hour capacity and duty cycle must be known to determine the required

cell size for the application. This topic is discussed in more detail in the next section of this

Module ("Determining Battery Size for use in Typical Saudi Aramco Applications").

The frequency of required maintenance must be considered from the standpoint of both cost

and practicality. If a battery is going to be installed in a remote, unmanned location, a high

capital cost battery that requires minimal maintenance may have a lower overall cost and be

more practical than a low capital cost, high maintenance battery.

The amount of space that is available must be considered to ensure that the chosen battery

will fit in the installation. If the installation space is limited, the additional cost of a compact,

high-performance battery is justified.

The following are typical examples of applications in which each type of battery might be

used:

Plante lead-acid batteries are used for UPS installations that have air

conditioned battery rooms. This is one of the few applications in which

the long service life of the Plante battery justifies its cost.

Lead calcium batteries are used in air conditioned applications in which

the battery is only expected to be subjected to infrequent and shallow

discharges. Lead calcium batteries are not suitable for frequent and/or

deep discharge services. Lead-calcium batteries are suitable for many

UPS installations, emergency lighting installations, and telephone

exchanges.

Lead antimony batteries are used in air conditioned applications in

which the battery is expected to be subjected to frequent and/or deep

discharges but also in which the high cost of Plante batteries cannot be

justified.

Sealed lead-acid batteries are used in applications that require no

maintenance or that require the battery to be installed in other than a

horizontal configuration.

Because nickel-cadmium batteries are generally more expensive than a

comparable lead-acid battery, they should not be used in air conditioned

spaces. Because the temperature has only a small effect on the nickel-

cadmium battery's life and capacity, the nickel-cadmium battery is ideal

for installation in high temperature, remote locations.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 34

DETERMINING BATTERY SIZE FOR USE IN TYPICAL SAUDI ARAMCO

APPLICATIONS

After a specific type of battery is selected for a particular application, the size of the battery

must be determined. Determination of the proper size will ensure that the battery can supply

power to the connected load for the specified duration of time. This section provides

information on the following topics that are pertinent to determining the correct battery size:

Load Criteria

Duty Cycle

Battery Voltage

Determining Battery Capacity

Load Criteria

Accurate specification of battery size depends on an accurate definition of the system's load.

The following data must be considered for each item of connected electrical equipment to

accurately define the system's load:

Voltage Range (Window)

Current or kW Draw

Load Classification (Duration of Operation)

Frequency of Use

Voltage Range (Window)

Stationary battery systems can be designed to meet almost any desired voltage rating. Most

dc-powered electrical equipment falls within one of the following major dc voltage groups:

6/12 volts (emergency lighting units)

24 volts (alarm systems, engine cranking, communications systems)

32 volts (emergency lighting systems, engine cranking, electric clock

systems)

48 volts (switchgear systems, telephone systems, microwave systems,

engine cranking)

120 volts (switchgear systems, emergency lighting systems, boiler flame

control, communication systems, telemetering, supervisory control

systems, fire alarm systems, UPS systems, large engine cranking)

240 volts (switchgear systems, UPS systems, large engine cranking)

Higher voltages (UPS systems)

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 35

The battery system voltage is based on the number of cells that are connected in series and the

nominal voltage of each cell; however, battery systems are normally maintained at voltages

that are higher than the nominal voltage of the system. For example, a battery system that has

a nominal system voltage of 120 volts is normally operated at 130 to 135 volts. This higher

voltage is due to the fact that most battery systems are always operated in a float charge

condition, and the float charge voltage is always higher than the nominal system voltage.

Most dc-powered equipment items are designed to operate on a fairly broad range of dc

supply voltages for the following reasons:

To accommodate the gradual decline of battery voltage as the battery

discharges.

To accommodate the voltage increases that occur when the battery is on

charge.

The minimum and the maximum voltage that is permissible for each item of connected

electrical equipment must be known to properly size the battery in terms of voltage. The

actual determination of battery voltage is discussed in more detail later in this module.

Current or kW Draw

Each item of electrical equipment is assigned a nominal current rating (ampere rating) or a

kW rating by its manufacturer. If the equipment is assigned a nominal current rating, this

rating can be used as the equipment's contribution to the overall load on the battery for the

period of time that the equipment operates. If the equipment is assigned a nominal kW rating,

this rating must be divided by the battery system voltage to determine the equipment's

contribution to the overall load on the battery for the period of time that the equipment

operates. When making this calculation, the engineer must note that, as the battery voltage

decreases during the discharge, the current load must increase to maintain the same kW.

In addition to the normal ampere rating, some electrical equipment has another current factor

that is seldom rated by the manufacturer but that is vitally important to battery size. This

factor is the temporary high ampere demand or inrush current that is imposed on the power

source (battery) when equipment such as electric motors are started. Inrush demands must be

determined or estimated on the high side to ensure that the battery voltage does not drop

below its specified minimum value during the inrush.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 36

Load Classification (Duration of Operation)

For Saudi Aramco installations, the individual dc loads that are supplied by a battery are

classified as follows:

Continuous loads

Essential loads

Momentary loads

Continuous loads are indicating lights, alarm systems, and other devices that are necessary for

personnel safety. The following are the minimum continuous load durations that must be

provided:

Twelve hours for the continuous loads that are located in attended

substations or other similar locations.

Eighteen hours for the continuous loads that are located in unattended

substations in on-shore locations.

Twenty-four hours for the continuous loads that are located in

unattended off-shore locations.

Essential loads are critical motors, emergency lighting, selected communication equipment,

emergency shutdown systems (ESD), and any loads that are determined to be life critical by

the Loss Prevention Department. Regardless of the location of the load, the minimum

essential load duration that must be provided is three hours.

Momentary loads are random, short duration loads that are considered coincident with the

highest load requirement. Generally, momentary loads provide close or trip power for

switchgear and generator field flashing. UPS systems may also require a momentary load at

the end of the discharge to furnish power for ESD systems to energize motor operated valves.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 37

The design duration of momentary loads is different for lead-acid and nickel-cadmium

batteries. Because of the time that is required for the battery to respond to an abrupt load

change, the momentary loads for lead-acid batteries system have a design duration of one

minute. The design duration for nickel-cadmium batteries is one second. The faster response

of nickel-cadmium batteries can result in smaller ampere-hour ratings.

The loads that are included in the three listed categories are not a comprehensive list of all the

possible dc loads at a given installation. The Electrical Engineer must carefully analyze each

system to be sure that all possible loads and load variations have been included.

Frequency of Use

Because some of the electrical equipment that is supplied by the battery may be energized

more than once during the battery discharge, the anticipated frequency of such usage must be

specified. If the frequency of use varies dependent on equipment positions or status when the

battery discharge begins, the maximum number of possible operations should instead be

specified. Such a specification is necessary to ensure that the battery will have sufficient

capacity to handle a worst-case situation.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 38

Duty Cycle

The duty cycle of a battery is defined as the load currents that a battery is expected to supply

for specified periods of time. Accurate information about the anticipated duty cycle of a new

battery is needed to properly size the battery.

Selection of the proper size of battery depends not only on the nominal current rating or the

kW draw and the duration of each load (i.e., the duty cycle), but it also depends on the

sequence in which the load are energized. Careful scheduling of the load sequence in the

duty cycle helps keep the required cell size to a minimum and reduces the cost of the

installation.

Most stationary battery installations are multi-load systems rather than single-load systems.

When a variety of loads are connected to a battery, sudden increases and decreases in current

demands are imposed on the battery. If the high-current loads can be scheduled to energize at

the beginning of the duty cycle rather than at the end of the duty cycle, a smaller sized battery

can be used. However, if the load is random in nature and could occur at any time during the

duty cycle, the best practice is to assume that the load will energize at the most limiting point

in the duty cycle when its effect will be the most severe.

A duty cycle diagram is a tool that aids in the analysis of the duty cycle and in the

determination of the required battery capacity. A duty cycle diagram shows the total required

battery current at any given time in the duty cycle. To prepare such a diagram, all of the loads

that are expected during the duty cycle are tabulated along with their anticipated start and stop

times.

The loads that have known start and stop times are plotted on the duty cycle diagram as they

would occur. The remainder of the loads should be plotted through use of the following

guidelines:

If the start time for a load is known but the stop time is indefinate, the

load is assumed to be continuous for the remainder of the duty cycle.

If the load can occur at random, the load is assumed to occur at the most

critical point in the duty cycle to simulate the worst-case condition. The

most critical point in the duty cycle is the point that controls the size of

the battery that is needed.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 39

Figure 14 shows an example of the duty cycle diagram that would be plotted from the

following hypothetical loads:

L

1

represents 50 amps of continouus emergency lighting load for three

hours.

L

2

represents 100 amps of momentary switchgear operations load and

250 amps of momentary motor starting load.

L

3

represents 50 amps of noncontinuous motor load for one and a half

hours.

L

4

represents 100 amps of noncontinuous load that starts after 30

minutes and stops after one hour of operation.

L

5

represents 50 amps of momentary switchgear operations load that

occurs during the last minute of the duty cycle.

L

6

represents four 25 amp random momentary loads that can occur at

any time during the duty cycle.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 40

Duty Cycle Diagram

Figure 14

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 41

Battery Voltage

The voltage at which a battery system operates is not constant; rather, it fluctuates between

minimum and maximum fixed values dependent on the state of charge. The range of voltages

that lies between the minimum system voltage and the maximum system voltage is the

voltage operating "window" for the battery system. The size (number of cells) of the battery

must be selected to ensure that the battery operates inside of the voltage window.

For batteries that supply dc systems, the minimum and the maximum battery system voltages

are based on the voltage rating of the most limiting load. The minimum system voltage is

selected to ensure that sufficient voltage is available to operate the loads at the end of the

battery duty cycle. The maximum system voltage is selected to ensure that the voltage rating

of the loads will not be exceeded when the battery is being recharged. The following are the

minimum and the maximum battery system voltages for Saudi Aramco dc systems:

Nominal System Voltage Minimum System Voltage Maximum System Voltage

12 vdc 10.5 vdc 15.5 vdc

24 vdc 21.0 vdc 30.0 vdc

48 vdc 42.0 vdc 58 vdc

120/125 vdc 105 vdc 143 vdc

240/250 vdc 210 vdc 286 vdc

360/375 vdc 315 vdc 429 vdc

For batteries that supply UPS systems, the minimum and the maximum battery system

voltages are based on the allowable dc input voltage ratings of the UPS system. The

allowable dc input voltage ratings are specified by the manufacturer of the UPS system.

For batteries that supply a combined dc and UPS system load, the minimum and the

maximum system voltages for dc systems should be used.

Because the battery system voltage is the product of the individual cell voltages and the

number of cells that are connected in series, the minimum and the maximum battery system

voltage values are used to determine the minimum and the maximum number of cells that can

be used in a battery installation. The following equation (included in Work Aid 2) can be

used to calculate the minimum number of cells that can be used in an installation:

For most applications, the final volts per cell for lead-acid batteries is 1.75, and the final volts

per cell for nickel-cadmium batteries is 1.1 volts. If justified by valid engineering and

economic reasons, other final volts per cell values could be used.

The following equation (included in Work Aid 2) can be used to calculate the maximum

number of cells that can be used in an installation:

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 42

The maximum cell voltage on charge for lead-acid batteries is the equalizing voltage that is

recommended by the manufacturer. If the manufacturer's data are not available, a value of

2.33 volts per cell can be assumed. The maximum cell voltage on charge for nickel-cadmium

batteries is the charging voltage that is recommended by the manufacturer. If the

manufacturer's data are not available, a value of 1.55 volts per cell can be assumed.

After the minimum and the maximum number of cells are known, the actual number of cells

can be specified. The actual number of cells that are specified can be any number that lies

between the minimum and the maximum number. For consistency and ease of specification,

SAES-P-103 contains the following information that lists the number of lead-acid or nickel-

cadmium cells that should be specified for various nominal battery system voltages:

Nominal Battery

System Voltage

(vdc)

Number of Cells

Lead-Acid Nickel-Cadmium

12 6 10

24 12 19

48 24 37

120/125 60 92

240/250 120 184

360/375 180 276

The equations serve as a second check to verify that the number of cells that are listed is

correct for the application.

For example, if a new lead-acid battery is needed to supply emergency power for a dc system

with a nominal voltage of 120 vdc, the number of cells that are required is determined as

follows:

From the table that is in SAES-P-103, 60 lead-acid cells are required for

a nominal battery system voltage of 120 vdc.

The number of cells that were determined from the table can be verified as follows:

The above calculations verify that 60 lead-acid cells are adequate for this installation.

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 43

Determining Battery Capacity

The capacity of a secondary storage battery is usually expressed in amperes and time. For

example, a battery capacity can be expressed as 42.5A for eight hours or 340 ampere-hours

(Ah) at the eight hour rate. Because the temperature of the electrolyte and the minimum

allowable cell voltage also affect the number of Ah's that a given battery can deliver, these

values must also be included as part of the battery's capacity rating. For example, a

completely defined battery capacity is 42.5A for eight hours at an electrolyte temperature of

25

o

C to a final cell voltage of 1.75 vdc. The following is a summary of relationships that

exist between the various elements of a battery capacity rating:

As the discharge rate (amperes) of a battery increases above the

standard rate, the length of time that elapses before the final cell voltage

is reached decreases.

As the discharge rate (amperes) of a battery decreases below the

standard rate, the length of time that elapses before the final cell voltage

is reached increases.

If the electrolyte temperature is less than the standard rated electrolyte

temperature and the battery is still discharged at its standard rate, the

final cell voltage rating will be reached before the standard rated time

elapses.

If the final cell voltage that is allowed increases, the number of amps

that the battery can deliver for the standard rated time period decreases

or the length of time that the battery can deliver its standard rated amps

decreases.

If the final cell voltage that is allowed decreases, the number of amps

that the battery can deliver for the standard rated time period increases

or the length of time that the battery can deliver its standard rated amps

increases.

Each stationary storage battery manufacturer generally designs more than one series of cell

types that vary in plate thickness and separation, in the number of plates, and in the size of the

current carrying parts. These variances result in large differences in the performance of

different cells that have similar nominal Ah capacities. For example, the following list shows

six different commercially available cells from different manufacturers:

Engineering Encyclopedia Electrical

Batteries and Battery Chargers

Saudi Aramco DeskTop Standards 44

Discharge in Amperes at 25

o

C to 1.75 v/c

(Lead-Acid) and 1.10 v/c (Nickel-Cadmium)

Ah Capacity

for 8 Hours 8 Hours 3 Hours 1 Hour 1 Minute

Plante 760 95 190 330 500

Lead-Calcium 752 94 188 369 910

Lead-Antimony 752 94 202 411 964

Nickel-Cadmium (L) 760 95 237 454 1140

Nickel-Cadmium (M) 736 92 232 540 1780

Nickel-Cadmium (H) 744 93 241 666 3180

The list shows that although all of the batteries have similar Ah capacities at the eight hour

rate, the batteries have very different ampere capabilities for shorter duration discharges. If

one of the batteries from the table was specified for a given application solely on the basis of

its Ah rating at the eight hour rate, the battery could be too small or too large for the

application by a factor of two.