Professional Documents

Culture Documents

Ball Mill Optimization

Ball Mill Optimization

Uploaded by

satishflsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ball Mill Optimization

Ball Mill Optimization

Uploaded by

satishflsCopyright:

Available Formats

Ball mill optimization

Dhaka, Bangladesh

21 March 2010

1

Introduction

Mr.Peramas Wajananawat

Experience: 13 Years (2 y in engineering,11 y in production)

Engineering department Kiln and Burning system

Siam Cement (Ta Luang) Kiln system, Raw material grinding and Coal grinding

Siam Cement (Lampang) Cement grinding and Packing plant

The Siam Cement (Thung Song) Co,Ltd

Production Engineer

Cement grinding 7 lines

2 x Conventional mill 150 t/h (OPC) KHD

2 x Pre-grinding 100 t/h (OPC) Fuller

2 x Semi-finish grinding 270 t/h (OPC) KHD

1 x VRM 120 t/h Loesche (LM46.2 +2C)

Cement bag dispatching

Contact e-mail: peramasw@scg.co.th

2

Contents

1. Objective of Ball mill optimization

2. Mill performance test

3. Air flow and diaphragm

4. Separator performance test

3

Objective

1. Audit performance of grinding system

2. Show the key areas for optimization the ball

mill system

3. Provide the basic information for changes or

modifications within grinding system

4. Reduce power consumption, Quality

improvement or Production improvement

4

Ball mill optimization

5

Ball mill optimization

Mill charge Air flow & Diaphragm Separator

1. Mill sampling test

2. Charge distribution

3. Regular top-ups

1. Mill ventilation

2. Water injection

3. Diaphragms

1. Tromp curve

2. Separator air flow

3. Separator sealing

When: Do optimization

1. In some period (1 month, 1 Quarter, 1 Year or ???)

2. To assess the reason/cause of disturbance

When abnormal operation

Poor performance of grinding system

Low mill output or poor quality product

High operation or maintenance costs

3. Keep operation in a good efficiency

6

Conventional grinding system

To Cement Silo

Cement Mill

Clinker Gypsum Limestone

Main Machine

1. Feeding system

2. Tube mill

3. Dynamic separator

4. Dedusting (BF/EP)

5. Transport equip.

7

Mill charge optimization

To Cement Silo

Cement Mill

Clinker Gypsum Limestone

8

What is function of mill?

9

M

Size reduction along the mill

-Coarse grinding 1

st

compartment

Normal feed size 5% residue 25 mm.

Max feed size 0.5% residue 35 mm.

-Fine grinding 2

nd

compartment

Piece weight (or knocking weight)

Average weight/piece of grinding

media in each compartment

(g/piece)

Piece weight Impact force

Specific surface

Average surface area of (ball)

grinding media in each compartment

(m2/t)

Specific surface Attrition force

10

Coarse material grinding Coarse material grinding Fine material grinding Fine material grinding

Need large ball size

Need small ball size

Calculation (for steel ball)

Piece weight : i = [3.143/6] x d

3

x 7.8 ;g/pcs.

Specific surface : o = 123 / i

(1/3)

; m

2

/ton

Note : d = size of ball (cm)

Ball charge composition

11

Ball charge composition

Check piece weight and specific surface

Compartment

1

Charge calculation

Fraction Weight, W weight Piece weight, I no., n

Specific surface,

o

Surface, O

(mm), d (t) % (g) pcs. (m2/t) (m2)

90 5.0 9% 2,989 1,673 8.5 43

80 11.0 21% 2,099 5,240 9.6 106

70 13.6 26% 1,406 9,671 11.0 149

60 15.3 29% 886 17,277 12.8 196

50 5.6 11% 512 10,927 15.4 86

40 2.5 5% 262 9,528 19.2 48

Total #1 53.0 100% 976 54,317 11.8 628

Compartment

2

Charge calculation

Fraction Weight, W weight Piece weight, I no., n

Specific surface,

o

Surface, O

(mm), d (t) % (g) pcs. (m2/t) (m2)

50 0.0 0% 512 0 15.4 0

40 0.0 0% 262 0 19.2 0

30 5.0 4% 111 45,170 25.6 128

25 48.0 35% 64 749,309 30.7 1,476

20 37.5 27% 33

1,143,35

4

38.4 1,441

17 46.5 34% 20

2,308,58

5

45.2 2,102

Total #1 137.0 100% 32

4,246,41

7

37.6 5,147

Piece weight: 976 g/piece

Specific surface: 11.8 m2/t

Piece weight: 32 g/piece

Specific surface: 37.6 m2/t

12

Ball charge composition

General we use (Product Blaine 4,500 cm2/g) for Conventional

Cpt.1 : Piece weight 1,500-1,600 g./piece

Cpt 2 : Specific surface 30-35 m2/t

For Pre-grinding system R/P + Conventional

Cpt.1: PW ~1,100-1200 g/pc

Cpt.2: SS ~35-40 m2/t

**depend on product fineness!!

13

Maximum steel ball size (Bond equation)

B=36 x (F

80

)

1/2

x [(S

g

xW

i

)/(100xC

s

xD

e

1/2

)]

1/3

Where

B : Maximum ball size (mm.)

F

80

: Feed material size for 80% pass (m)

W

i

: Bond work index (kWh/t)

C

s

: N/Nc (normally ~ 0.7-0.75)

S

g

: Specific gravity of raw material (t/m3)

D

e

: Effective diameter of mill (m.)

F

80

= log [(0.20)

size residue(mm.)

]/log(%residue)

Example;

Given

Feed size = 5% res. 25 mm.

W

i

= 13.0 kWh/t

C

s

= 0.7

S

g

= 3.0 t/m

3

D

e

= 4.0 m.

F

80

= log(0.20)

25

/log(0.05)

F

80

= 13.4 mm.

Find : Maximum ball size

B = 36x(13.4)

1/2

x[(3x13)/(100x0.7x4

1/2

)]

1/3

Maximum ball size = 86 mm.

14

Maximum steel ball size

0

20

40

60

80

100

120

140

160

180

2 5 10 15 20 25 30

M

a

x

B

a

l

l

S

i

z

e

(

m

m

.

)

Feed Size (mm.), F80

Maximum ball size (mm.) : Clinker Wi 13.0 kWh/t, Cs 0.7, Sg 3

** Typical fresh clinker : 5% residue 25 mm. or F

80

= 13.4 mm.

15

Example

Given

Feed size = 5% res. 20 mm.

W

i

= 12.0 kWh/t

C

s

= 0.7

S

g

= 3.0 t/m

3

D

e

= 2.5 m.

Find: required maximum ball size

F

80

Maximum ball size (mm.)

16

Mill performance test

Steps

1. Recording of related operational data

2. Air flow measurement

3. Crash stop and visual inspection in mill

4. Sampling in mill

5. Evaluation of test

17

1. Recording of related operational data

Tube Mill

Feed rate, Return, Grinding aids, Water injection, Mill drive

power (kW)

Static separator

Vane position

Mill ventilation fan

Damper position, Air flow rate (if have instrument), Pressure

Fan drive power

18

2. Air flow measurement

Air flow measurement

Air flow rate

Temperature

Static pressure

To Cement Silo

Cement Mill

Clinker Gypsum Limestone

19

Mill ventilation air

Mill ventilation air

Purpose

Forward movement of the material retention time

Take out fine particles and so diminish the risk of coating

Cooling of the material in mill Diminish coating / dehydration

of gypsum

Usual ranges of ventilation:

Air speed in mill

Open circuit : 0.8 to 1.2 m/sec

Closed circuit : 1.2 to 1.5 m/sec

20

M

m/sec

**Min 0.5 m/s tend to result inefficient over grinding and excessive

heat generation with possible coating problem.

**Max > 1.4 m/s drag particle out of mill before they have been

sufficiency ground.

Agglomeration and ball coating

Cause:

Temperature too high tendency of the

material forming agglomerates/coating on

grinding media and liner plates

Grinding efficiency will be reduce

Temperature outlet mill range 110-120 C.

21

Test 2

Mill dimension

Inside diameter 3 m.

Degree of filling 28% in both compartment

Mill ventilation check

Flow 22,000 m3/h

Check Air ventilation speed in mill ?

22

M

m/sec

3. Crash stop and visual inspection

Stable operation before crash stop

Emergency stop or Crash stop

Tube mill / All auxiliary equipment

Mill Ventilation

Disconnect main circuit breaker (Safety !)

Preparation of sampling equipment (shovel, scoop, plastic bag, meter,

lighting etc.)

23

Preparation of sampling equipment

Lighting

Shovel

Scoop

Meter

Meter

Plastic bag

Lock switch

PPE

Crash stop

24

3. Crash stop and visual inspection

Visual inspection

Liner and Diaphragm condition wear, block

Ball size distribution along the mill classify liner

Water spray nozzle condition clogging

Foreign material ?

Ball charge condition agglomeration, coating

Clogging

Liner

Ball charge

Diaphragm

Clean block slot

25

3. Crash stop and visual inspection

Material level in compartment #1 and #2

M

26

3. Crash stop and visual inspection

Ball charge quantity (Filling degree)

Measurement by free height

Measure average internal diameter, Di

Measure height, h, in three different points along axis for each grinding

compartment

M

Inside diameter, Di

Free height, h

Effective length, L

27

Ball charge quantity (Filling degree)

0.0

10.0

20.0

30.0

40.0

50.0

60.0

0.000 0.100 0.200 0.300 0.400 0.500

D

e

g

r

e

e

o

f

f

i

l

l

i

n

g

(

%

)

h/De

h

H

De

Meter

Normal range 28-32%

Ball level

h = H- (D

e

/2)

28

4. Sampling inside mill (mill test)

Sampling of material

Take ~1 kg sample every 1 m along mill axis

Each sample collected from 3 point in the same cross section

Removed some balls and taken sample

First and last sample in each compartment should be taken

from 0.5 m off the wall or diaphragms

1m 0.5 0.5 0.5 1m 1m 1m 1m 1m 0.5 1m

1.1

1m 1m

1.2 1.3 1.4

2.1

2.2

2.3

2.4 2.5

2.6

2.7

1.1 1.2 1.3 1.4

Deep 20 cm.

Take sampling

Material sampling point in mill

29

1m 0.5 0.5 0.5 1m 1m 1m 1m 1m 0.5 1m

1.1

1m 1m

1.2 1.3 1.4

2.1

2.2

2.3

2.4 2.5

2.6

2.7

1.1

1.2

1.3 1.4

Top view

1

1

1

0.5 m.

2

2

2

3

3

3

4

4

4

5

5

5

6

6

6

7

7

7

8

8

8

9

9

9

1

0

1

0

1

0

1

1

1

1

1

1

0.5 m.

Take 1 sample

Get total 11 collected

samples along the mill

1 kg per sample

Side view

Front view

30

4. Sampling inside mill (mill test) cont.

After work inside the mill

Calculation quantity of ball charge and filling degree

Sample sieve analysis

1st compartment

Sieve : 16 , 10 , 6 , 2 , 1.25 , 0.5 , 0.2 mm

2nd compartment

Sieve : 1.25 , 0.5 , 0.2 , 0.12 , 0.09 , 0.06 mm., Blaine Fineness

Plot size reduction chart (graph)

31

Sieve test equipment

32

Results: Sieve and Fineness analysis from mill test

Sample Location % residue on sieve (by weight)

Blaine 32 16 8 4 2 1 0.50 0.20 0.09

Position m.

cm2/g

mm mm mm mm mm mm mm mm mm

Compt 1 pt.1 0.5 7.00 18.00 34.00 47.00 57.00 64.00 71.00 81.00 90.50

1.0 9.00 21.00 36.00 45.00 52.00 60.00 69.00 79.00 89.00

2.0 3.00 7.00 13.00 18.00 20.50 31.00 48.00 67.00 83.00

3.0 0.50 1.00 3.00 5.50 8.00 19.50 29.50 52.00 71.00

pt.2 4.0 0.10 3.00 5.00 7.00 8.00 10.50 22.00 46.00 65.00

pt.3 4.5 0.05 4.00 7.50 9.00 10.50 12.50 28.00 48.50 68.00

Partition **

Compt 2 pt.1 0.5 940 1.00 8.00 32.00 56.00

pt.2 1.0 1080 2.00 9.00 33.00 59.00

2.0 1260 0.50 7.00 24.00 50.00

3.0 1300 0.01 4.00 18.00 42.00

4.0 1500 0.00 1.50 12.00 39.00

5.0 1600 0.00 1.00 9.00 32.00

6.0 1700 0.00 0.50 5.00 27.00

pt.3 7.0 1880 0.00 0.22 4.00 21.00

pt.4 8.0 2000 0.00 0.01 3.00 19.50

9.0 2120 0.00 0.01 1.50 18.50

pt.5 9.5 0.00 0.00 2.00 19.00

33

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

0

10

20

30

40

50

60

70

80

90

100

0.5 1.0 2.0 3.0 4.0 4.5 ** 0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 9.5

B

l

a

i

n

e

(

c

m

^

2

/

g

)

%

R

e

s

i

d

u

e

o

n

s

i

e

v

e

Length (m.)

Size Reduction Progress

32.000 mm

16.000 mm

8.000 mm

4.000 mm

2.000 mm

1.000 mm

0.500 mm

0.200 mm

0.090 mm

Blaine cm2/g

Comp. 1 Comp. 2

0.5

4 4.

5

3

2 1

0.

5

4 5 3 2 1 6 9.5 9 8 7

0.5 m 0.5 m

Typical grinding diagram : OPC 3000 cm

2

/g

34

5. Evaluation of performance test

Grinding efficiency

Data for evaluation

Result from visual inspection inside tube mill

Sample analysis from longitudinal sampling inside tube mill Size

reduction graph

Cement Mill Cement Mill

35

Evaluation of mill test standard reference

Size reduction along mill axis

Sieve residues and Blaine value in front of the diaphragms

Compartme

nt

Particle size FLSmidth Holderbank Slegten

First comp.

+0.5 mm. 15-25% 12-25% -

+0.6 mm. 10-20% - -

+1.0 mm. 7-14% - -

+2.0 mm. Max 4% Max 3%

Max 5% (at 2.5

mm.)

Second comp.

+0.2 mm. 20-30% 20-30%

15-25% (at 0.1

mm.)

+0.5 mm. Max 5% Max 5% -

Blaine

(cm2/g)

- 2,100 -

36

Evaluation of mill test

Compartm

ent

Particle

size

FLSmidth

Holderban

k

Slegten Mill test Result OK?

First comp.

+0.5 mm. 15-25% 12-25% - 28%

Little much

coarse

particle size

from

compartmen

t 1

+0.6 mm. 10-20% - - -

+1.0 mm. 7-14% - - 12.5%

+2.0 mm. Max 4% Max 3%

Max 5% (at 2.5

mm.)

10.5%

Second

comp.

+0.2 mm. 20-30% 20-30%

15-25% (at 0.1

mm.)

2%

Good!

+0.5 mm. Max 5% Max 5% - 0%

Blaine

(cm2/g)

- 2,100 - 2,120

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

0

10

20

30

40

50

60

70

80

90

100

0.5 1.0 2.0 3.0 4.0 4.5 ** 0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 9.5

B

l

a

i

n

e

(

c

m

^

2

/

g

)

%

R

e

s

i

d

u

e

o

n

s

i

e

v

e

Length (m.)

Size Reduction Progress

32.000 mm

16.000 mm

8. 000 mm

4. 000 mm

2. 000 mm

1. 000 mm

0. 500 mm

0. 200 mm

0. 090 mm

Blaine cm2/g

Comp. 1 Comp. 2

37

Evaluation of mill test

Test result : provide information to

Improvement of ball charge composition

Maximum ball size and composition

Charge composition (PW and SS)

Modification/Replace inside grinding compartment

Liners

Diaphragms

Operation

Mill ventilation

Clear diaphragm slot

38

39

Bad condition step liner

Broken liner

Good condition liner

Slot blockage

Inspection

Common problems!

Compartment Result Ball charge

Liner/Diaphragm

Operation Mill vent.

First comp.

Over limit of

particle size in

front of diaphragm

1

st

comp.

-Increase impact

force in 1

st

comp.

-Revise ball

charge and need

larger ball size

(piece weight)

-Low lifting

efficiency (visual

inspection)

-Clean block at

diaphragm (nib)

-Feed too much

(visual

inspection)

-Too high velocity

(check air flow)

Second comp.

Over limit of

particle size in

front of diaphragm

2

nd

comp.

-Wait for revise

charge in 1

st

comp.

-Wait for improve

liner in 1

st

comp.

1

st

comp. OK but

2

nd

comp. over

limit of particle size

in front of

diaphragm

-Revise ball

charge and may

need to increase

specific surface

or Piece weight

-Check ball

charge

distribution along

the mill

-Classifier liner

efficiency

-Clean block at

diaphragm

-Feed too much

(visual

inspection)

-Too high velocity

(check air flow)

40

Case mill test, CM6 STS (Aug,2008)

1,487

1,626

1,739

1,927

1,807

2,058

2,333

2,314

0

500

1000

1500

2000

2500

0.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

80.0

0 2 4 6 8 10 12 14

5.6 mm. 2 mm. 0.5 mm. 0.212 mm. 0.09 mm. 0.075 mm. 0.045 mm. blaine

D

i

a

p

h

r

a

g

m

D

i

a

p

h

r

a

g

m

%

r

e

s

i

d

u

e

B

l

a

i

n

e

(

c

m

2

/

g

)

abnormal

41

Evaluate and correction

Compartme

nt

Particle

size

FLSmidth

Holderba

nk

Slegten

Mill

test

Result OK?

First comp.

+0.5 mm. 15-25% 12-25% - 31%

Abnormal size reduction

(in front of diaphragm),

should clear blockage

diaphragm slot

+0.6 mm. 10-20% - - -

+1.0 mm. 7-14% - - -

+2.0 mm. Max 4% Max 3%

Max 5%

(at 2.5 mm.)

23%

Second

comp.

+0.2 mm. 20-30% 20-30%

15-25%

(at 0.1 mm.)

52%

Abnormal size reduction

(in front of diaphragm),

should clear blockage

diaphragm slot

+0.5 mm. Max 5% Max 5% - 51%

Blaine

(cm2/g)

- 2,100 - 2,314

Reference standard

42

Case Mill test from : VDZ congress 2009

43

Cement plant in Europe

Chamber 1 : good size reduction efficiency

Chamber 2 : 45 micron shown results that grinding has

stopped midway through the 2

nd

chamber

Evaluate and correction

44

Average ball size in chamber 2 is too small (average 16 mm, PW 17 g.)

Take charge distribution more coarse to increase PW and average ball

size diameter (to 42 g. and 22 mm.)

Separator performance test

To Cement Silo

Cement Mill

Clinker Gypsum Limestone

45

What is separator?

46

Advantage of grinding system

with separator

Reduce the number of fine particle to

be ground in mill

Increase production capacity and

Reduce mill power consumption

Increase % of Active particle in fine

particle of Cement

Advantage of grinding system with separator

47

Maximized separator performance Maximized power saving

Separator performance test

Steps

1. Recording of related operational data

2. Air flow measurement

3. Sampling within grinding system

4. Evaluation of test

48

1. Recording of related operational data

Tube Mill

Feed rate, Return, Grinding aids, Water injection, Mill drive

power (kW)

Dynamic separator

Rotor speed, Damper/vane position

Separator drive power (kW)

Separator circulating fan & Separator ventilation

Flow rate (if have instrument), Damper position

Separator fan power (kW)

49

2. Air flow measurement

Air flow measurement

Air flow rate

Temperature

Static pressure

To Cement Silo

Cement Mill

Clinker Gypsum Limestone

Separator circulating air

50

Dynamic Separator circulating air

Purpose

Distribute and disperse cement dust

Classify cement dust at rotor

Take out fine particle from separator to be product

Usual ranges of circulating air

Depend on separator feed and production rate

Separator load 1.8-2.5 kg feed / m

3

= Separator feed / Circulating air

Dust load (fine) less than 0.75-0.8 kg fine / m

3

= Fine product / Circulating air

Circulating air

flow (m/h)

Separator feed

(t/h)

Return

Fine

product

(t/h)

51

3. Sampling within grinding system

Operation period

Determined suitable sampling point

Stable operation

6-12 hours duration of performance test

Taking samples every ~1 hour

52

Sampling plan (stable operation period)

To Cement Silo

Cement Mill

Clinker Gypsum Limestone

Sampling

1

2

3

53

Sampling point in process

Separator feed

or mill output

Return (reject) Fine product

Scoop

54

Sampling test

Point

Sampling point Weight Required sieve analysis

1 Separator feed m 0.5 kg PSD Laser test, Blaine (cm2/g)

2 Separator return g 0.5 kg PSD Laser test, Blaine (cm2/g)

3 Separator fine f 0.5 kg PSD Laser test, Blaine (cm2/g)

55

PSD analysis equipment

Particle size distribution analysis

56

ThungSong Plant

Result: from Laser analysis

-Range 1.8-350 um

-Test time <5 mins/sampling

57

Particle Size Distribution (PSD)

Rm Rf Rg

Size (um)

Feed

%residue

Fines

%residue

Rejects

%residue

1 96.4 95.1 98.1

2 93.9 91.7 96.5

4 89.0 85.3 93.7

8 81.5 74.6 89.9

16 68.8 55.1 85.6

24 60.3 41.2 83.9

32 52.2 28.9 80.9

48 39.4 13.0 71.9

64 32.3 7.4 62.9

96 18.2 0.0 40.5

200 4.9 0.0 11.0

TOTAL: 636.9 492.3 814.9

0

10

20

30

40

50

60

70

80

90

100

1 10 100 1000

%

R

e

s

i

d

u

e

Sieve size (um)

Feed %residue Fines %residue Rejects %residue

58

Meaning sieve size 32 um

52.2% of separator feed

residue on sieve size 32 um

80.9% of reject residue on

sieve size 32 um

Rm Rf Rg

Size (um)

Feed

%residue

Fines

%residue

Rejects

%residue

1 96.4 95.1 98.1

2 93.9 91.7 96.5

4 89.0 85.3 93.7

8 81.5 74.6 89.9

16 68.8 55.1 85.6

24 60.3 41.2 83.9

32 52.2 28.9 80.9

48 39.4 13.0 71.9

64 32.3 7.4 62.9

96 18.2 0.0 40.5

200 4.9 0.0 11.0

TOTAL: 636.9 492.3 814.9

59

4. Evaluation of performance test

Separator efficiency

Data for evaluation

Particles size analysis of sample within grinding system

- Separator feed R

m

- Separator fine R

f

- Separator tailing or Reject R

g

Tromp curve or Fractional recovery

The tromp curve shows what fraction of particles of different sizes in the

feed material is going in to the coarse fraction (often called Return or

Tailing)

Separator specific loads / Dust Load

60

Tromp curve

Calculation

Circulation factor (CF)

CF = (R

f

- R

g

)/(R

m

- R

g

)

where

R

f

= % residue on sieve of fine

R

g

= % residue on sieve of coarse

R

m

= % residue on sieve of feed

In this case (size 48 um)

Circulation Factor = 1.81

61

Tromp curve

Calculation

Tromp value

Tromp (range d1,d2) = [(R

g1

-R

g2

)/(R

m1

-R

m2

)]x[1-(1/CF)]x100

where

Tromp (range d1,d2) : Fraction of particles size between d1 and d2

R

g

= % residue on sieve of coarse (return/reject)

R

m

= % residue on sieve of separator feed

In this case

Tromp value (32-48 um) = 31.5%

62

Example

Find Circulation factor (CF) of

particle size 32 um and 48 um

CF = (R

f

- R

g

)/(R

m

- R

g

)

where

R

f

= % residue on sieve of fine

R

g

= % residue on sieve of coarse

R

m

= % residue on sieve of feed

Find Tromp value of size in range

32-48 um

Tr (d1,d2)=[(R

g1

-R

g2

)/(R

m1

-R

m2

)]x[1-

(1/CF)]x100

where

Tromp (range d1,d2) : Fraction of particles size

between d1 and d2

R

g

= % residue on sieve of coarse (return/reject)

R

m

= % residue on sieve of separator feed

Rm Rf Rg

Size (um)

Feed

%residue

Fines

%residue

Rejects

%residue

1 96.4 95.1 98.1

2 93.9 91.7 96.5

4 89.0 85.3 93.7

8 81.5 74.6 89.9

16 68.8 55.1 85.6

24 60.3 41.2 83.9

32 52.2 28.9 80.9

48 39.4 13.0 71.9

64 32.3 7.4 62.9

96 18.2 0.0 40.5

200 4.9 0.0 11.0

TOTAL: 636.9 492.3 814.9

63

Tromp value meaning Tromp value (32-48 um) = 31.5%

For separator feed size between 32-48 um = 100 %

Separator feed

Separator

31.5%to coarse fraction

Reject/Return

68.5% to fine fraction

Fine product

64

Tromp value Plot Tromp curve

65

Rm Rf Rg

Size (um)

Feed

%residue

Fines

%residue

Rejects

%residue

CF

Size avg

(um)

Tromp

value

1 96.4 95.1 98.1 1.76 0.5 22.9

2 93.9 91.7 96.5 1.85 1.5 29.3

4 89.0 85.3 93.7 1.79 3 25.2

8 81.5 74.6 89.9 1.82 6 22.8

16 68.8 55.1 85.6 1.82 12 15.2

24 60.3 41.2 83.9 1.81 20 8.9

32 52.2 28.9 80.9 1.81 28 16.6

48 39.4 13.0 71.9 1.81 40 31.5

64 32.3 7.4 62.9 1.81 56 56.9

96 18.2 0.0 40.5 1.82 80 71.4

200 4.9 0.0 11.0 1.80 148 98.8

TOTAL: 636.9 492.3 814.9 1.81 TOTAL:

0

10

20

30

40

50

60

70

80

90

100

1 10 100 1000

%

r

e

c

o

v

e

r

y

t

o

r

e

t

u

r

n

(

r

e

j

e

c

t

)

Sieve size (um)

Plot Tromp curve

Particle size in range 32-48 um

-31.5% go to be Return

-68.5% go to be Fine product

Particle size in range 8-16 um

-15.2% go to be Return

-84.8% go to be Fine product

Particle size in range 2-4 um

-25.2% go to be Return

-74.8% go to be Fine product

66

Tromp curve of Ideal and Actual separator

Ideal separator

No coarse in product and No fine in

return/reject

Actual separator

Have some coarse in product and Have

some fine in return/reject

0

10

20

30

40

50

60

70

80

90

100

1

%

r

e

c

o

v

e

r

y

t

o

r

e

t

u

r

n

(

r

e

j

e

c

t

)

Sieve size (um)

Ideal separator

Actual separator

67

0

10

20

30

40

50

60

70

80

90

100

1 10 100 1000

%

r

e

c

o

v

e

r

y

t

o

r

e

t

u

r

n

(

r

e

j

e

c

t

)

Sieve size (um)

Tromp curve

d50

Cut size : d50 = 60 um

The cut size of the separation

being made is the particle size

where the tromp value is 50%

Meaning : Size 60 um has an

equal chance to go either to

product or to rejects

68

Tromp value meaning Cut size (d50)

For separator feed size between 48-64 um = 100 %

Separator feed

Separator

50%to coarse fraction

Reject/Return

50% to fine fraction

Fine product

Size ~ 60 um: equal chance to go

either to product or to rejects

69

0

10

20

30

40

50

60

70

80

90

100

1 10 100 1000

%

r

e

c

o

v

e

r

y

t

o

r

e

t

u

r

n

(

r

e

j

e

c

t

)

Sieve size (um)

Tromp curve

d75

Sharpness = d25/d75

Sharpness = 0.38

Steeper tromp curve, the better

the separation

Ideal separator sharpness = 1

d25

70

0

10

20

30

40

50

60

70

80

90

100

1 10 100 1000

%

r

e

c

o

v

e

r

y

t

o

r

e

t

u

r

n

(

r

e

j

e

c

t

)

Sieve size (um)

Tromp curve

Minimum value

Bypass = 8.9%

Meaning : Bypass is an

indication of the amount of

material that essentially

bypasses the separator.

The lower the bypass, the more

efficiency the separation.

3

rd

generation bypass < 15%

71

Evaluation of separator performance test

Item Units Typical range Result Evaluate

Circulation factor - 2-3 1.81 little less

Cut size(d50) micron

depend on rotor speed

and fineness level

60 micron seems high

Sharpness (d25/d75) - 0.5 0.38 little less

Bypass % 5-15% 8.90% OK

Separator load kg/m

3

1.8-2.5 1.7 OK

Product load kg/m

3

0.75 0.6 OK

Action :

1. Increase circulation factor (CF) Separator load has available

2. Need to increase speed of rotor (due to higher CF coarser separator feed)

3. Tromp curve move to finer side and d50 change to be less than 60 um.

4. Bypass slightly increase

5. Power consumption of mill went down.

72

0

10

20

30

40

50

60

70

80

90

100

1 10 100 1000

%

r

e

c

o

v

e

r

y

t

o

r

e

t

u

r

n

(

r

e

j

e

c

t

)

Sieve size (um)

Improvement Tromp curve

1. Improve product: Reduce cut size

-Increase circulation factor to 2-3

-Increase rotor rotation speed

-%Bypass may slightly increase OK

-Check separator load and dust load ?

Result:

-Better active particle size of product

-Strength improve

Ideal separator

Actual separator

1

73

0

10

20

30

40

50

60

70

80

90

100

1 10 100 1000

%

r

e

c

o

v

e

r

y

t

o

r

e

t

u

r

n

(

r

e

j

e

c

t

)

Sieve size (um)

Improvement Tromp curve

2. Improve production rate: Reduce

%bypass

-Improve separator feed distribution

-Check separator load and dust load ?

-Separator ventilation flow

-Check mechanical seal or leak

-Check guide vane and rotor blade ?

Result:

-Increase production rate

-Reduce power consumption

Ideal separator

Actual separator

2

74

Test result : provide information to :

Adjustment of separator settings

Circulation load

Separating air flow, fan speed ,etc

Modification inside separator

Mechanical adjustment ,etc

Mechanical seal

Dispersion plate

Guide vane and rotor

75

General separator improvement

Separator feed chute

o 100% feed on dispersion plate

(over the rotor) good distribution

76

Feed point and dispersion plate

General separator improvement

Make sure symmetry feed on rotor

good distribution

77

KHD Sepmaster and Fuller O-Sepa

General separator improvement

Adjust guide vane good air flow

distribution to rotor

78

Guide vane

General separator improvement

Check rotor blade condition (wear and

deform)normal classification

79

Rotor blade condition

General separator improvement

Upper and Lower seal condition good

classification

Grinding aids good

classification/reduce bypass

80

Summary

81

Ball mill optimization

Mill charge Air flow & Diaphragm Separator

1. Mill sampling test

2. Charge distribution

3. Regular top-ups

1. Mill ventilation

2. Water injection

3. Diaphragms

1. Tromp curve

2. Separator air flow

3. Separator sealing

1. Every 6 months

2. Every 1 Year

3. 1,000 hours

1. Check and maintain

2. 1,000 hours check

3. 1,000 hours check

1. Every 3 months

2. Optimized and maintain

3. Every 3 months

Q & A

Performance test

Mill test and Separator test

Evaluation

Visual inspection

Size reduction graph and Tromp curve

Improvement

Charge composition, Operation, ect.

Results

Energy saving, Quality improvement

82

You might also like

- Optimization of Vertical Raw Mill OperationDocument32 pagesOptimization of Vertical Raw Mill OperationNael93% (40)

- Kiln Heat and Mass Balance September 2010Document20 pagesKiln Heat and Mass Balance September 2010samuel libsework50% (2)

- Ericsson KPI CountersDocument4 pagesEricsson KPI Counterspankajjangra4100% (2)

- VP - 10 - Ball Cement Mill Monitoring, Inspection & EvaluationDocument41 pagesVP - 10 - Ball Cement Mill Monitoring, Inspection & Evaluationrecai92% (13)

- Ball Mill PresentationDocument34 pagesBall Mill PresentationISLAM I. Fekry100% (18)

- 1 Ball Mills 1Document106 pages1 Ball Mills 1BharaniChirsabesan100% (3)

- Factors Influencing The Grinding EfficiencyDocument27 pagesFactors Influencing The Grinding Efficiencynoelbaba71100% (2)

- Ball Mill Audit and OptimizationDocument82 pagesBall Mill Audit and Optimizationanrulo100% (4)

- VRM PresentationDocument49 pagesVRM PresentationMKPashaPasha100% (4)

- 03 Ball Mill EDMDocument47 pages03 Ball Mill EDMVishnu Vardhan . C92% (13)

- Mill Testing Optimisation and TargetingDocument134 pagesMill Testing Optimisation and TargetingArtemMirra90% (10)

- Vertical Mill CalculationsDocument11 pagesVertical Mill CalculationsSai Sricharan Reddy84% (19)

- The Selection and Design of Mill LinersDocument11 pagesThe Selection and Design of Mill Linersluis martinezNo ratings yet

- IESNA LM-80-08 Guide To Evaluating LED Lumen MaintenanceDocument2 pagesIESNA LM-80-08 Guide To Evaluating LED Lumen MaintenanceAlex SantiagoNo ratings yet

- GATE UsersGuide - v5.0.0 PDFDocument225 pagesGATE UsersGuide - v5.0.0 PDFAlejandraGomezNo ratings yet

- Auto Full Vehicle Durability Using Abaqus Standard 11Document4 pagesAuto Full Vehicle Durability Using Abaqus Standard 11TimNo ratings yet

- Ball Mill Testingjune99Document29 pagesBall Mill Testingjune99Shakil Ahmad83% (6)

- Ball Mill Optimization PDFDocument82 pagesBall Mill Optimization PDFJackson Vu100% (2)

- Ball Mill Checking (Compatibility Mode)Document33 pagesBall Mill Checking (Compatibility Mode)Nael100% (9)

- Grinding Course: Ball Charge Design MethodsDocument12 pagesGrinding Course: Ball Charge Design MethodsVishnu Vardhan . C100% (12)

- Process Train Ball MillDocument28 pagesProcess Train Ball MillvvijaybhanNo ratings yet

- 8 - 9 - Mill Optimisation Part 1 and 2Document82 pages8 - 9 - Mill Optimisation Part 1 and 2bulentbulutNo ratings yet

- 3 - Ball Mill GrindingDocument78 pages3 - Ball Mill GrindingMega Purnama Zainal91% (11)

- Grinding TechnologiesDocument41 pagesGrinding TechnologiesJoseph Leveque100% (10)

- D3 2 100701 Kiln Mec Behav Patroller PDFDocument30 pagesD3 2 100701 Kiln Mec Behav Patroller PDFbulentbulut100% (3)

- Ball Charge in Ball MillDocument11 pagesBall Charge in Ball MillRanu Yadav0% (1)

- Ball Mill OptimizationDocument7 pagesBall Mill OptimizationWael Fanous100% (1)

- 41 Vertical Mills - V2-0Document56 pages41 Vertical Mills - V2-0Sai Sricharan Reddy86% (14)

- Blaine Vs ResiduesDocument3 pagesBlaine Vs ResiduesVisnu Sankar100% (2)

- BALL MILL - Ball Charge Composition Piece Weight & Specific SurfaceDocument1 pageBALL MILL - Ball Charge Composition Piece Weight & Specific Surfacevvijaybhan100% (2)

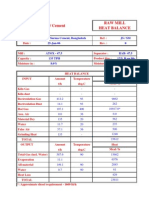

- Raw Mill Heat BalanceDocument1 pageRaw Mill Heat BalanceElwathig Bakhiet100% (1)

- Ball Charge Design - VDocument11 pagesBall Charge Design - VKaran_Agarwal_4807100% (2)

- V5 Process Technology 3Document449 pagesV5 Process Technology 3RRHH100% (1)

- Max Ball Size With Respect To Mill Feed SizeDocument3 pagesMax Ball Size With Respect To Mill Feed Sizevvijaybhan100% (1)

- 04 05 08Document55 pages04 05 08taghdirim100% (5)

- Ball MillDocument14 pagesBall MillLaxman Kumar100% (1)

- Cement Process Engineering Vade-Mecum: 3. QualityDocument22 pagesCement Process Engineering Vade-Mecum: 3. QualityRaúl Marcelo Veloz100% (1)

- KilnDocument26 pagesKilnVishnu Vardhan . C100% (4)

- Grinding Media Pattern & Charge CalcDocument1 pageGrinding Media Pattern & Charge CalcJayaram SudhakarNo ratings yet

- Ball Mill Vs VRMDocument15 pagesBall Mill Vs VRMvvananth0% (2)

- Ball Mill Grinding MediaDocument47 pagesBall Mill Grinding Mediamahreza189100% (3)

- Vertical Raw Mill Heat Balance - SolutionDocument3 pagesVertical Raw Mill Heat Balance - SolutionSai Sricharan Reddy80% (5)

- Verticalrawmill Pradeepkumar 130515030859 Phpapp02Document88 pagesVerticalrawmill Pradeepkumar 130515030859 Phpapp02Sai Sricharan Reddy50% (2)

- Grinding Mills Optimisation: Magotteaux / Slegten / Sturtevant SolutionsDocument44 pagesGrinding Mills Optimisation: Magotteaux / Slegten / Sturtevant Solutionsshani5573100% (1)

- Blaine Reference Blaine Required e KDocument4 pagesBlaine Reference Blaine Required e KNael100% (4)

- Cement Tech BooksDocument7 pagesCement Tech Booksrat12345No ratings yet

- 16 High Efficiency Separator LG 2005-02-02 DGLDocument23 pages16 High Efficiency Separator LG 2005-02-02 DGLRobson DE Freitas WerlingNo ratings yet

- Ball Mill VS VRMDocument26 pagesBall Mill VS VRMKhurram Shahzad50% (2)

- Heat Balance of Kilns and Coolers and Related Topics PDFDocument62 pagesHeat Balance of Kilns and Coolers and Related Topics PDFAli HüthütNo ratings yet

- Clinker FormationDocument120 pagesClinker FormationDragos PlaesuNo ratings yet

- V6 EngineeringDocument330 pagesV6 EngineeringRRHHNo ratings yet

- Clinker CoolersDocument74 pagesClinker CoolersMuhammed EmamiNo ratings yet

- Cement Mill NotebookDocument32 pagesCement Mill NotebookNael92% (50)

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- Cement Separator & Ball Mill OptimizationDocument29 pagesCement Separator & Ball Mill OptimizationAdelezzat OmranNo ratings yet

- 04 MillingDocument21 pages04 MillingMKPashaPasha100% (1)

- Casting Technology: DC School Text BookDocument22 pagesCasting Technology: DC School Text BookTrang Anh ToànNo ratings yet

- Chapter IDocument36 pagesChapter Ihùng nguyễnNo ratings yet

- Design and Fabrication of Mould ForDocument20 pagesDesign and Fabrication of Mould Forajaysurya9245No ratings yet

- Design and Fabrication of Mould ForDocument20 pagesDesign and Fabrication of Mould Forajaysurya9245No ratings yet

- Abrasive Jet MachiningDocument25 pagesAbrasive Jet MachiningAjay BhaleraoNo ratings yet

- Lev's Presentation, US-Russia Symposium English Only PDFDocument50 pagesLev's Presentation, US-Russia Symposium English Only PDFJulio César ChávezNo ratings yet

- Factors Influencing The Grinding EfficiencyDocument27 pagesFactors Influencing The Grinding Efficiencygrameshkreddy2013No ratings yet

- UAS Manajemen Pemasaran MembuatDocument4 pagesUAS Manajemen Pemasaran MembuatfarahNo ratings yet

- User Guide Terrameter LSDocument114 pagesUser Guide Terrameter LSJuventino Montoya GandaraNo ratings yet

- MediaDocument10 pagesMediaVusale MirzeyevaNo ratings yet

- Universal Music GroupDocument6 pagesUniversal Music GroupImad SalhaNo ratings yet

- Cjenm Ir Book 202204Document46 pagesCjenm Ir Book 202204backup tringuyenNo ratings yet

- World Buddhist Association Headquarers Objection To Las Vegas Monorail BankruptcyDocument9 pagesWorld Buddhist Association Headquarers Objection To Las Vegas Monorail BankruptcyToohoolNo ratings yet

- Recycled Aggregates Paper PresentationDocument26 pagesRecycled Aggregates Paper PresentationManoj Prince100% (2)

- Allama Iqbal Open UniversityDocument2 pagesAllama Iqbal Open UniversityNiamatNo ratings yet

- Vibrating Wire Strain GaugesDocument9 pagesVibrating Wire Strain Gaugessannan azizNo ratings yet

- Fintech, The New Era of Financial Services: Studies and ArticlesDocument11 pagesFintech, The New Era of Financial Services: Studies and ArticlesPily CorroNo ratings yet

- Sky-Remit PGL - 10m ProjectDocument9 pagesSky-Remit PGL - 10m ProjectRichie BensonNo ratings yet

- Frequency of Plumbing Fixture UseDocument30 pagesFrequency of Plumbing Fixture UseZiyad AwaliNo ratings yet

- MANIPAL 2013 - List of Roll Nos of Candidates Shortlisted For InterviewDocument14 pagesMANIPAL 2013 - List of Roll Nos of Candidates Shortlisted For InterviewBooma JegarajaNo ratings yet

- Full Operations Management 6Th Edition Test Bank Nigel Slack PDF Docx Full Chapter ChapterDocument23 pagesFull Operations Management 6Th Edition Test Bank Nigel Slack PDF Docx Full Chapter Chaptersuavefiltermyr62100% (30)

- Anu 2Document3 pagesAnu 2anuNo ratings yet

- 312 EXP 1 IntroductionDocument4 pages312 EXP 1 IntroductionSamiul TashbirNo ratings yet

- The Management Accountant-October, 2013Document124 pagesThe Management Accountant-October, 2013sundeepcwaNo ratings yet

- SVKM'S Nmims School of Distance Learning: InstructionsDocument2 pagesSVKM'S Nmims School of Distance Learning: InstructionsAnees MerchantNo ratings yet

- Financial Statements and Ratio Analysis NEWDocument108 pagesFinancial Statements and Ratio Analysis NEWDina Adel DawoodNo ratings yet

- First Phil. Intl Bank vs. CADocument2 pagesFirst Phil. Intl Bank vs. CAchaNo ratings yet

- IE 6840 Week 6 HW - 5 GY2876 PDFDocument3 pagesIE 6840 Week 6 HW - 5 GY2876 PDFBharat DarsiNo ratings yet

- The Impact of Digital Media and Technology On The Marketing MixDocument37 pagesThe Impact of Digital Media and Technology On The Marketing MixJhagantini PalaniveluNo ratings yet

- Easton, McAnally, Sommers y Zhang. Financial Statement Analysis & Valuation. Módulo 2 - Páginas 2-32 A 2-33 (C, D y E)Document2 pagesEaston, McAnally, Sommers y Zhang. Financial Statement Analysis & Valuation. Módulo 2 - Páginas 2-32 A 2-33 (C, D y E)Rafael Ernesto Ponce PérezNo ratings yet

- Inspection & Test Plan For Piping Systems: Doc. No.: Rev No.: 0Document5 pagesInspection & Test Plan For Piping Systems: Doc. No.: Rev No.: 0심판자No ratings yet

- Electronic Reservation Slip (ERS) : 6854762884 13018/ganadevta Exp AC Chair Car (CC)Document2 pagesElectronic Reservation Slip (ERS) : 6854762884 13018/ganadevta Exp AC Chair Car (CC)SYEDA MYSHA ALINo ratings yet

- 3CO02 Assessment Guidance 2022Document5 pages3CO02 Assessment Guidance 2022Gabriel ANo ratings yet