Professional Documents

Culture Documents

EX Wiring Methods

EX Wiring Methods

Uploaded by

musarraf172Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EX Wiring Methods

EX Wiring Methods

Uploaded by

musarraf172Copyright:

Available Formats

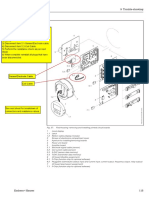

Session13 EXWiringMethods

EXInstallationMethods

ConduitorCableGlands...

IndirectEntryviaEExe

gland & enclosure

DirectEntryviaEExd

conduit

DirectEntryviaEExdgland

gland&enclosure

conduit

TypicalWiringMethods

RigidConduit

Unarmored

bl Cable

Armored

Cable

IECCableTypesandConstruction

UnarmoredCablesimilartoUSTCtypecablesbutwithfullyextrudedfillers.ArmoredCablesimilarin

concepttoIEEE45TypePmarineshipboardcableandcontinuouscorrugatedaluminumarmorcable.

TypeSWA SteelWireArmor

l TypeSTA SteelTapeArmor

TypeSWB SteelWireBraid

Cable/ConductorRequirementsinZone

applications

ThefollowingmainrequirementsarelistedintheEN60079standardforcablesandconductors:

useonlyinsulatedcablesandconductors(testvoltage500VAC),

inspecialcasesearththerequiredscreeningonlyonceattheendofthenonexplosiveenvironment,

protect intrinsically safe circuits against external electrical or magnetic fields through the maintenance of protectintrinsicallysafecircuitsagainstexternalelectricalormagneticfieldsthroughthemaintenanceof

adequatedistances,screeningand/orcoretwisting,isolateintrinsicallysafecablesandconductorsfromnon

intrinsicallysafecablesandconductorsor,protectagainstmechanicaldamageor,protectthroughmetal

housing,orscreeningofthecablesandconductorsdonotcombineconductorsofintrinsicallysafeandnon

intrinsically

safecircuits

preventthefrayingoffinewiredconductorsthroughtheuseofcablesleeves,forexample:

keeptominimumdiameterof0.1mm,

isolateintrinsicallysafeandnonintrinsicallysafecircuitsincablebundlesorductsviainsulationspaceroran

earthed metal spacer (not required with screening or sheathing) earthedmetalspacer(notrequiredwithscreeningorsheathing),

identify(i.e.lightblue)thecablesandconductorsofintrinsicallysafecircuits(notrequiredwithshieldingor

metalsheathing)

Cable/ConductorRequirementsinZone

applications

Whenselectingcablesandconductors,onlyusethosewhichcanwithstandtheexpected

mechanical,chemicalandthermalinfluences.Cablesandconductorswiththermoplasticsheath,

duroplasticsheath,elastomersheathormineralinsulationwithmetalsheathmaybeusedforfixed

i C bl b h li l i h h i f h d routing.Cablebranchlinesmustcomplywiththerequirementsforhazardousareas.

Thecablesandconductorsmustbeconnectedtotheelectricalequipmentinlinewiththedirectives

fortheassociatedtypeofprotection.Unusedopeningsondevicesandequipmentmustbeclosed.

Whencablesandconductorsareinstalledthroughopeningsintononhazardousareas,caremustbe g p g ,

takentoprovideanadequatesealattheopenings(e.g.sandfilling,mortar)topreventcarryingover

ofthezone.Atparticularly

hazardouspoints,cablesandconductorsmustbeprotectedagainstthermal,mechanicalorchemical

stressby,forexample,conduits,tubingorcovers.Theflameretardanceofcablesandconductorsfor

fixed routing must be proven in accordance with IEC 60332 1 fixedroutingmustbeproveninaccordancewithIEC603321.

IECCableTypesandConstruction

Ingeneral,SWAcablehasbeenthecableofchoiceintheUKfor

onshoreinstallations.Itissomewhatflexible,readilyavailable

andhasgoodbendingcapabilities.

SWBcablehasbecomethechoiceforinstallationsoffshorewith

variousarmormaterialsincludingtinnedcopper,bronzeand

othermaterials.Veryflexibleyetdurableunderverydemanding

conditions.Manydifferentjackettypesavailable.

STAismoreofanonshoretypecableandiswidelyusedin

onshoreapplicationsincontinentalEurope,especiallyforpower

applications.ClientshavestartedtoshyawayfromSTAasitis

generallyregardedasslightlymoredifficulttoterminatethan ge e a y ega ded as s g y o e d cu o e a e a

eitherSWAorSWB.

Onevariationcommonlyusedfordirectburyapplicationsisa

Leadsheathedarmorcable.Leadprovidesaverygood

i l ti d t i l t d i ti l l i t t insulationduetocorrosiveelementsandisparticularlyresistant

torodentsandants.Cableglandsforleadsheathedcable

typicallyneedanadditionalcomponenttoseattheleadportion

ofthecable.

DesignationsonglandsistomarkaXZforbraidandtape,witha

Wforwirearmorforfieldinstallation.

IECCableTypesandConstruction

BFOU & RFOU instrumentation cables are manufactured with either overall or individual screens the BFOU&RFOUinstrumentationcablesaremanufacturedwitheitheroverallorindividualscreens,the

coresareeitherlaidupaspairsortriples.Idealforsignalandinstrumentationcircuitswherethefire

performanceandLowSmokeZeroHalogenpropertiesareincreasinglybeingrequiredwithinpublic

buildingsandpowerstations,aswellastraditionalPetro/Chemindustries.Thecableisdesignedto

carryonworkingforaperiodof3hourswhenexposedtofire,accordingtoIEC60331testprocedure.

l ff d d l f ( ) BFOUalsooffersgoodscreeningproperties,reducingElectroMagneticInterference(EMI).

Construction

Tinnedstrandedcopperconductor,MICAtape,EPRinsulation,overallscreenofCopperbacked pp , p , , pp

Polyestertapewithastrandedcopperdrainwire0.75mm,innersheathofHalogenFreeThermoset

Elastomer,tinnedcopperwirebraidandanoutersheathofHalogenFreeThermosetElastomer.The

individuallyscreenedversionhasaCopperbackedPolyestertapewithastrandedcopperdrainwire

0.75mm aroundeachpairortriple.

Corecolors

Pairs - Light blue, black

Triples - Light blue, black and brown

Each pair or triple is identified by a numbered tape.

CableTypes

IECCableTypesandConstruction

ThemostcommonsheathmaterialfordatacablinginuseintheUKisPVC.Formanyenvironments,

PVCistheidealmaterial,havingsuperiormechanicalcharacteristicsandhighreliability.However,in

afire,PVCemitsheavyblacksmokemixedwith

hydrochloric acid thus reducing vision immediately impairing breathing and additionally initiating hydrochloricacid,thusreducingvision,immediatelyimpairingbreathing,andadditionallyinitiating

corrosionofallequipmentexposedtothefumes.Forimprovedfireperformance,itiscommonfor

LSZHLowSmokeZeroHalogen(usuallymeetingIEC61034,IEC607542andIEC603323)cable

sheathstobeusedwithinEurope.

Fire Performance Standards FirePerformanceStandards

ThemajorStandardsincommonuseare

showninthetable.

CablesmeetingIEC603323havebetterfireperformancecharacteristicsthanthosemeeting

IEC603321:Theyuseeitherathickercablesheathoramoreexpensivesheathmaterialand

thereforethecableismorecostly.

IECCableTestsforFireApplications

TypicalIECCableTests

FireResistantTest IEC6033121Underlongfire

exposure,thecablemustmaintainthepower

supplyforvitalsafetyequipment(emergency

lighting,alarm,systems&firepumps,etc.) g g, , y p p , )

SmokeDensityTest IEC610341/2The

smokedensitytestevaluatesthesmoke

emissionsofthecableandthejacket

construction.

Testunderfirecondition IEC603323

Flameretardanttestsimulatingcables

installedinbunchonaverticalladder

underfireconditions.

IEC6033212Singlewireorcable

A test on a single length of cable

600mm long held between 2 clamps.

The flame is applied for a

predetermined amount of time based

on the weight of the cable.

To pass the test there should not be

any visible damage or charring within

50mm of the lower edge of the top

l (E l t 425 hi h th clamp (Equal to 425mm higher than

the flame source) once all

combustion has stopped.

This test replaces IEC60332 1 BS4066 This test replaces IEC603321, BS4066

pt 1 & BS EN 5026521.

IEC603323Theladdertest

The IEC603323 ranges of tests are conducted on

bunches of cables and are much closer to a real life

installation. 3.5m Lengths of cables are bunched g

onto a cable ladder in a chimney simulating a building

riser.

The volume of cable on the ladder is determined in

litres of combustible material to offer a balanced

view of performance across a cable range.

A flame is applied 500mm from the base of the

ladder for a predetermined time. When the burner

has extinguished a one hour afterburn period is

allowed then the cables are checked for performance.

T th t t th bl h ld t b ff t d b To pass the tests the cables should not be affected by

the flame 2.5m above the flame source.

BS EN 50266 is the BS standard for the same test

procedure procedure

IEC603323categories

Test Qtyofmaterial Flameapplication Supersedes

60332322 Cat A 7 0 litres 40 minutes IEC603323A 60332 3 22CatA 7.0litres 40minutes IEC60332 3A

BS4066pt3A

60332323CatB 3.5litres 40minutes IEC603323B

BS4066 pt 3B BS4066pt3B

IEC60332324CatC 1.5litres 20minutes IEC603323C

BS4066pt3C

IEC60332 3 25 Cat D 0 5 litres 20 minutes IEC60332325CatD 0.5litres 20minutes

60332321CatAF/R UsedforlargeO.Dcablesinsteadof322CatA.Thecablesare

mountedonthefrontandbackoftheladder

Allthesetestsaretobeconductedoncompletecables.

CompoundsalonecannotbetestedtoIEC60332

FireResistantTesting

bl b l f l d f l f d A cables ability to continue operating safely during a fire. Also referred to as circuit integrity.

Widely used in commercial/public buildings & MOG applications to control fire alarm/monitoring systems,

emergency lighting, fire shutters and emergency evacuation equipment.

EuropeanFireStandards

Standard Ref. Performancerequirement

IEC60331 Cables0.6/1kV. 3hoursat750C(1970edition)

IEC6033121 Cables0.6/1kV 90minutes@750C(unlessalt.statedinthecablespec)

IEC6033123 Datacables 90minutes@750C

IEC6033125 Opticalfibre 90minutes@750C

IEC6033131 Cables0.6/1kV 120minutes@830Cwithvibration

VDE0472 FE180 ThistestisequaltoIEC60331(1970edition) q ( )

DIN4102 E30 Completesystemintegrityfor30minutes

DIN4102 E90 Completesystemintegrityfor90minutes p y g y

EN50200PH30,PH60,PH120 BS8434wasdevelopedandenhancedfromthisstandard.

CurrentlyEN50200isinferiortoBS8434asitdoesnot

includethewaterspraytest.

SmokeEmission&ToxicGas

Obscuration of vision and toxic gas are the main threat to people during a fire leading to disorientation

and chocking from fumes Death is normally caused by choking rather than flames Reducing smoke & and chocking from fumes. Death is normally caused by . choking rather than flames. Reducing smoke &

fume emissions is vital to enable safe evacuation.

Equipment damage is caused by HCl gases mixing with moisture from the sprinkler systems and creates

acid rain leading to long term component failure even if the equipment does not look damaged acid rain leading to long term component failure even if the equipment does not look damaged.

Notallmaterialsthatarelowsmokearehalogenfree,examples:

LSPVC(LimitedSmokePVCtoUL1685)

Fluorocarbons (PTFE FEP etc ) Fluorocarbons(PTFE,FEPetc.)

TypeBCSPtoBS6883(1991)

EuropeanSmokeTesting

IEC 610342: A one meter sample of cable (or a bundle of

cables depending on the outer diameter) is placed in a 3m

cube and subjected to combustion by an alcohol produced cube and subjected to combustion by an alcohol produced

flame for 20 minutes. The light transmission through the

cube should not fall below 60% during the test (at peak or

total)

Measurement method :

100W halogen light source sensed by a photoelectric cell

positioned on the opposite side of the smoke cube.

IEC610342 is the most popular test used for cable in

Europe.

IEC610341 covers the apparatus required and test

procedure.

ToxicGasEvolutionIEC60754

IEC607541 (BS EN 50267 pt1) measures the amount of hydrochloric acid (HCl) evolved during

burning The result is normally expressed as a percentage of the sample weight There is no burning. The result is normally expressed as a percentage of the sample weight. There is no

pass/fail criteria.

This method is not suitable for testing cables classed as Zero Halogen and compounds

containing less than 5mg/g (5%) containing less than 5mg/g (5%)

IEC607542 (BS EN 50267 pt2) measures the corrosiveness of the evolved gas in terms of

acidity (pH) and conductivity. IEC 607542 recommended values are :

pH > 4.3. & Conductivity of combustion gases < 10 mS/mm

PanelWiringtoIECrequirements

MostofEuropeabidesbyIEC(InternationalElectrotechnical Commission)wiringcolorcodesforAC

branchcircuits.Theoldercolorcodesinthetablereflectthepreviousstylewhichdidnotaccountfor

properphaserotation.Theprotectivegroundwire(listedasgreenyellow)isgreenwithyellowstripe.

Function Label CurrentColorIEC OldColorIEC

ProtectiveEarth PE GreenYellow GreenYellow

Neutral N Blue Blue

Line,singlePhase L Brown Brown orBlack

Line 3 phase L1 Brown Brown or Black Line,3phase L1 Brown Brown orBlack

Line,3phase L2 Black BrownorBlack

Line,3phase L3 Grey BrownorBlack

The United Kingdom now follows the IEC AC wiring color codes The table below lists these TheUnitedKingdomnowfollowstheIECACwiringcolorcodes.Thetablebelowliststhese

alongwiththeobsoletedomesticcolorcodes.

Function Label CurrentColorUK OldColorUK

ProtectiveEarth PE GreenYellow GreenYellow o ec e a G ee e o G ee e o

Neutral N Blue Black

Line,singlePhase L Brown Red

Line,3phase L1 Brown Red

Line,3phase L2 Black Yellow

Li 3 h L3 G Bl Line,3phase L3 Grey Blue

ExampleofoldUKwiringcolors

Theuseofcolorcodedferrulesorsleevesistypicallyleftuptotheclient/userpreference.

EitherpracticeisacceptabletorelevantIECstandards.

CableGlandSelectionCriteria

Cableglandsusedinenclosuresintendedforuseina

hazardousareamustmeetwiththe

samecriteriaastheenclosuretowhichtheyare y

connected.Forexample,cableglandsusedon

anEExeenclosuremustmeettherequirementsforthe

enclosuresoftheEExe

standardi.e.mustbecapableofwithstandinga7Nm

impact and capable of maintaining an impactandcapableofmaintainingan

ingressprotectionofatleastIP54.

Ifaplasticornonmetalliccableglandisuseditmustbe

capableofpassingthesetestsafter

havingundergoneanacceleratedconditioningperiod.

Mostreputablecableglandmanufacturershavetheir

productsapprovedbyasuitablynotified

body and will carry the certification markings on the body bodyandwillcarrythecertificationmarkingsonthebody

ofthegland.Cableglandsareaveryimportantelementin

theprotectionofelectricalequipmentandshouldnotbe

underestimated.Thereareavastarrayofdifferentcables

inusetodayanditisimportantthatadviceissoughtfrom

bl l d f di l i acableglandmanufacturerregardingselection.

TestingProceduresforCable

Glands Glands

IP66Testing 100litersofwaterfor3minutesfrom

2.5to3meters

Continuity Testing of Armor Gland is heated and cooled ContinuityTestingofArmor Glandisheatedandcooled

overtimeandresistivityshouldnotchangemorethan

10%

TorkTest Multiplespannerstoprescribedtension

with no damage on disassembly withnodamageondisassembly

TestingProceduresforCable

Glands

Load Test Unarmored cable gland with mandrel to

Glands

LoadTest Unarmoredcableglandwithmandrelto

notslipmorethan6mmover6hrs.

ImpactTest Ikgfallingfrom70cmor7joules.No

damagetogland

PressureTest Minimumof450psiwithoutleakage

forExd,2000psiforUL2225requirements

WiringMethods

WiringconceptsOffshorefollowtheestablished&prevailingMarinestandards,

e.g.IEC60092352

ll ( l d ) h ll b h d ff l h Metallicparts(includingarmour)shallbeearthedeffectivelytopreventthem

frombecominglive.

CableArmour/Braidprovidesameansofgoodearthcontinuityaswellas

mechanicalprotection.

Normalpracticehasbeentouseexternalgroundingasthemostdirectrouteto

earth.

Thisiseasilyachievedwithmetalliccableglandsinnonmetallicenclosuresby

the use of an earth tag theuseofanearthtag

Shroudshavebeenfoundtobeanineffectivemeansofkeepingwateroutof

enclosuresandglandsaretypicallynotusedforNorthSeaapplicationsany

more

WiringMethods ShieldingEMI

Protection

TwoformsofEMI/RFItoconsider

ConductedEmissions(Generated&Susceptibility)

AScreenedCableenteringshieldedenclosure

AssistsinprotectionagainstRadiatedEmissions

RadiatedEmissions(Generated&Susceptibility)

Metallicglandsareanessentialpartofthesystem

designinrespectofElectromagnetprotection.

360

o

Cableshieldingprovidesoptimumperformance

forEMCasopposedtopigtailtechniques.

Nonmetallicglandscreatetheweaklinkinthe

systembetweenshieldedcableandenclosure.

TypicalEExd&earmoredcablegland

ComponentsofTypicalEExe&dcablegland.

FrontEnd

DelugeSeal

ArmorCone

ClampingRing BackEnd

OuterSeal

InnerSeal

Inner & Outer Seals

InstallationofEExedgland

Inner&OuterSeals

Locknut

EExd&EExe

Requirement for EEx d cable glands for equipment < 2 litres RequirementforEExdcableglandsforequipment<2litres

Screwedentrythreadsmustmaintainflamepath

Innersealmustbeexplosionproofandgastight

TrendistousedualcertifiedExd&Exe

RequirementsforEExecableglands

Impactstrength 7NmMinimum

MinimumI.P.rating IP54gas/vapour IP64dust

Single(outer)sealasaminimum

Trend is to use a double (inner/outer) seal Trendistouseadouble(inner/outer)seal

NotunusualtousetheidenticalglandforbothEExdandEExeapplicationsforlessconfusionininstallation

inthefield.

InstallationofEExdbarrier

gland

Flame Path

Sealrequired

towithstand

apressureof

450 PSI (31 bar)

FlamePath

Exhaust

Routes

450PSI(31bar)

for2minutes

Pressure essu e

Flame

HotGases

EpoxyResin

Compound

FlamePath

Compound

DirectEntryintoZone1,EExdenclosureover2litersvolume

WithArcingSparkingDevices

Which type is suitable for use with Flameproof Ex d equipment

SampleofCableTypes

WhichtypeissuitableforusewithFlameproofExdequipment

usingaglandwithanELASTOMERIC seal?

CableA CableB CableC

IncorrectShape,

CablesShould

b d

beRound

NoInnerSheath,

ExtrudedBedding

orSuitableFillers

CorrectCable,

e.g.hasan

extruded

inner bedding innerbedding

CableD CableE

WiringMethods TypicalNorwegian

InstallationPractice

IEC6007915CableGlandSelectionChart

Ingeneral,about90%oftheapplicationforhazardouslocationcable

glandscanbefulfilledwiththeuseofanonbarriercompoundgland

WiringMethods TypicalNorwegian

InstallationPractice

DirectandIndirectEntryEExe&EExd

Enclosures

DirectEntry,GlandTypeEEx

dBarrierTypeifvolume>2

litres

IgnitionSource

IndirectEntry,GlandTypeEExe

orDualCertifiedEExe/EExd

gland gland

DirectEntryEExnREquipment

GlandTypeEExDBarrierType

providinggastightBiDirectional

seal

GlandTypeEExd/EExeincorporatinginternal

sealthatprovidesBiDirectionalGastightseal.

DiaphragmSealsorcompressionsealsnot

recommended

Duetothis

WiringMethods CableGlandusageUK

Equipment

MarketSector

EExe95%

UKOffshore

HazardousAreas

Equipment

Cable

EExd5%

BraidArmor

98%

Unarmored

2%

Brass"Armored"

EExd/EExe

C bl Gl d

Brass"Armored"

EExdCompound

B i Gl d

98%

Brass"Unarmored"

EExd/EExe

C bl Gl d

"Unarmored"

PlasticEExe

C bl Gl d

2%

Cable Glands

CableGland

99%

BarrierGland

1%

CableGland

99%

CableGland

1%

CableGlands

ThreadInformationand

Accessories

ThestandardizationofthreadtypeintheIECworldistypicallyaroundthe

Metricstraightthread.However,otherthreadtypesdoexistintheIECworld

andifnotMetricoravariationof,areaPG,BSPorBSTthreadtype.

Accessoriesthatarecommonlyusedare:

CableShrouds Becomingincreasinglylessusedastheyhaveatendencyto

holdwaterinandcoveruppotentialcorrosionwithglands.

EarthTags OtherwiseknownasBanjosorFryingPans.Usedtoprovide

ameanstogroundthecableglandtypicallywhenusedinnonmetallic

enclosures.

L k t T i ll d t th bl l d t th l Locknuts Typicallyusedtosecurethecableglandtotheenclosure.

ThreadInformationand

Accessories(Cont.)

Withthevariousthreadsused,threadadaptorsandreducers

areacommonaccessorywidelyused.Onekeypointisthatitis

notallowedtoreduceareducer

ShakerWashers Typicallyusedbetweenthelocknutand

insideofanenclosure,shakerwashersareusedtoprovidea

meanstokeepvibrationsfromlooseningthecableglandtothe

enclosure.

IPwashers Asthenameimplies,IPwashershelpmaintainthe

IPratingbetweenthecableglandandtheenclosure

Ifyouhaveacableglandinaclearancehole,youhaveametal you a e a cab e g a d a c ea a ce o e, you a e a e a

tometal(orplastic)surfacethatprovidesnobetterthanIP54

protection.IPwashersgobetweenthefaceoftheglandand

theoutsideoftheenclosure.

D i EE d i th t ll d ti t d i f th Drains EExedrainsthatallowcondensationtodrainfromthe

insideofenclosuresduetomoisturebuildupduringthenormal

heatingandcoolingprocessduringthedayandnight.

Cableglandspacingonenclosures

Cableglandsclearanceholesneedtobeconsideredwhendeterminingnumberandsizesofglandsinstalled

inenclosures.Alwaysconfirmglandcrosscornerclearancewithmanufacturerandtemplatesizeof

enclosuretoconfirmwhetherenoughspaceexistsforglandentries

Cableglandspacingonenclosures

TraditionaluseofcableglandsenteringintoanExeenclosureneedasignificant

amountofexcessspacetoallowfortheuseofaspannerorwrenchtotightenthe

gland.TheuseofcabinetsealscertifiedtoExecanreducethefootprintofthe

enclosurerequiredbyasmuchas50%orallowadoublingofcablestoenterinthe

same space as traditional cable glands samespaceastraditionalcableglands.

ExdSealsandConduitSystems

ConduitSealsarecommonlyusedwithconduitsystemsfor

directentryintoEExdenclosures.Themaximumallowed

distancefromenclosureis450mm.LiketheUS,installations

alsorequiresealfittingsatboundaries.

Conduitsystemshaveaslightlydifferentrequirementinthat

countriestypicallymandatemax.fill.Inthecaseofmostof

thesouthernEuropeancountries,amax.fillof60%is

allowed This differs with US regulations of typically 40% allowed.ThisdifferswithUSregulationsoftypically40%

maximumconduitfill.Conduitsystemsareusuallylimited

to3000Vorless.Above3000V,cablesystemsarerequired

TypicalWiringPracticeswithConduit

Allswitchingmechanismsshouldbeomnipolarwheretheneutralwireisalwayscut

MINIMUMallowedwiresizes: AuxiliaryCircuits(Controls)1.5mm/sq. Power

Circuits2.5mm/sq.

Cablesshouldbe3000Vmin.andflameretardanttype

CablesMUSTprotectedagainstinsulationdamagegenerallydueto:

Impactdamage

Heatsourcesthatcoulddamagecablesinsulation

Chemicalsubstancesthatcouldcauseinsulationcablescorrosion Chemical substances that could cause insulation cables corrosion

Inordertocomplywithabovementionedrequirements,aproperchoiceofcablesand

cableroutingisveryimportant.

If C bl P f f l ith i k f i id t l d IfCablesPassfarawayfromanyplacewithriskofcorrosionoraccidentaldamage

(i.e.cablesforceilingmountedlightingfixtures)astandardPVCinsulatedcablesin

propercabletraysareallowed.Whencablescomedowntoworkingareas,orpass

besidetovalvesorotherequipmentthatmightreleaseheatorcorrosivesubstances

thatmightdamagecablesinsulation,itisrecommendedtopassrelevantcablesinside

agalvanizedsteelpipes.Ifcablesgotovibratingmachines(example:electricalmotors)

pipesshouldbeflexiblehoses,forthelast500mmapprox.connectedtospecialcable

glandswithfemalethreadedheadwhichallowforflexiblehosesdirectconnectionto

theglandnut,withoutleavinganypartofcablesuncovered.

ThisisverysimilartoUSinstallationswherebytheuseofconduitactsasameansof

mechanicalprotection.

TypicalWiringPracticeswithConduit

FlexibleConduitforvibrationand

mechanicalprotection

Conduitformechanical

protection

TypicalWiringPracticeswithConduit

IEC61386isthenewEuropeanstandardgoverningtheperformanceofflexible

conduit(andrigid)systemsinelectricalinstallations.

TensiletestforIEC61386.

SupersedingthecurrentEuropeanflexibleconduitsystemsstandards,EN50086,IEC

61386 covers performance requirements for use of such products in electrical 61386coversperformancerequirementsforuseofsuchproductsinelectrical

installationapplications.Theperformancerequirementscoveredincludefatiguelife,

bendradius,operatingtemperature,nonflamepropagation,IPratings,impact

resistanceandpulloffstrength.FullimplementationofIEC61386isbeingphasedin

throughout2006,anditisexpectedthatthestandardwillfullyreplaceEN50086by

2007 2007.

Thosemanufacturersofflexibleconduitandtrunkingwhichcandemonstratefull

compliancewiththenewstandard(forexample,intheUKviaBSIandtheKitemark

scheme),especiallyifconfirmedbyindependentthirdpartycertification,willbeina ), p y y p p y ,

goodcompetitivesituationintermsofsales.Thisisbecausesuchmanufacturers'

customerswillbeabletoconfidentlyspecifyflexibleconduitsystemscomplyingwith

IEC61386forthecompleterangeofsuitableapplications,knowingthattheyhave

beenapprovedtothenewscheme.Suchcustomersoftenfacestrictcontrolsontheir

working environments and may typically include food processing healthcare workingenvironments,andmaytypicallyincludefoodprocessing,healthcare,

hazardousarea,MODandotherspecialistmarkets.

TypicalWiringPracticeswithConduit

Tests to be carried out under IEC 61386: TeststobecarriedoutunderIEC61386:

ThenewIEC61386standardrequiresanumberofteststobecarriedoutonspecimenconduitmaterials.

Theseinclude:

TheImpactStrengthTest Thisiscarriedoutonconduitsoverarangeofdifferenttemperatures.Thetestis

madeoneachspecimenusinganimpactheadwithadefinedprofile.Conventionally,fracturebehavioris

studied,butunderthistest,itisthedeformation(buckling)behaviorthatisalsodetermined.Thespecimen

passesthetestifnofractureoccursafterimpact,andthereisalsonoexcessivepermanentdeformation.

ThePeakLoadTest Undertherequirementsofthistest,carriedoutonconduitspecimensunderstandard

ambientconditions(whichisspecifiedas23Cat50%relativehumidity),theconduitisdeformedbyadefined

amountbetweentwoplates.

TheReverseBendingTest(WithSwingingMovements) Thistestisbasedonacyclicreversedbendingof

conduitsundervarioustemperatures.Undertherequirementsforthetest,conduitsaredynamicallyloaded

andevaluatedoverthetemperaturelimits.Thenumberofbendingcyclestakentofracturetheconduit

determinesitsstrength.

TheSelfExtinguishingTest Undertherequirementsforthistest,theconduitisexposedtoaflame(froma

standardburner).Thetimetoignition(ifany),theflamepropagation,andthetimetoselfextinguishingafter

flameremovalareallparametersmeasured.

TypicalWiringPracticeswithCable

Atypicalmethodofmakingfinalterminationstoenclosuresistoleaveexcesscablein

aloopconfigurationtorelieveanypotentialunduestrainonthecablegland,and

alloweasiermodificationsifequipmentneedstobereplacedorrepaired..

TypicalWiringPracticeswithCable

You might also like

- Allen-Bradley Schematic Reference GuideDocument14 pagesAllen-Bradley Schematic Reference GuideaseethepalliNo ratings yet

- Schematic Diagram t240Document6 pagesSchematic Diagram t240dany weinfeldNo ratings yet

- Pipeline Stability and Weight Coating CalculationDocument4 pagesPipeline Stability and Weight Coating CalculationAdaghara67% (3)

- Pioneer 202 Metal DetectorDocument20 pagesPioneer 202 Metal Detectorp_romero_cNo ratings yet

- Zelio Time RE1 CatalogDocument6 pagesZelio Time RE1 Cataloganthony tigerNo ratings yet

- Motor SpecificationDocument12 pagesMotor SpecificationAdeel RazaNo ratings yet

- Promag 50 53 Resistance Check PDFDocument4 pagesPromag 50 53 Resistance Check PDFAllisson MacedoNo ratings yet

- 1746-Ib16 User ManualDocument48 pages1746-Ib16 User ManualC Raziel Fdz ONo ratings yet

- Application Guide Safe BarrierDocument19 pagesApplication Guide Safe BarriernoljacNo ratings yet

- DO8P Datasheet PDFDocument10 pagesDO8P Datasheet PDFRio YuwandiNo ratings yet

- Allen Bradley SMC Flex 41391 454 01 s1fxDocument1 pageAllen Bradley SMC Flex 41391 454 01 s1fxJohn SuarezNo ratings yet

- A-72562en-026 Fanuc Servo Amplifier Βi Series DescriptionsDocument38 pagesA-72562en-026 Fanuc Servo Amplifier Βi Series DescriptionsRoberto Manzanares MtzNo ratings yet

- Wago Short Form Product Catalog 7Document24 pagesWago Short Form Product Catalog 7mhafizanNo ratings yet

- Electrical Wiring in General Refers To Insulated Conductors Used To Carry ElectricityDocument15 pagesElectrical Wiring in General Refers To Insulated Conductors Used To Carry ElectricityAsim ZargarNo ratings yet

- Installation of Distribution-to-Utilization Voltage TransformersDocument7 pagesInstallation of Distribution-to-Utilization Voltage TransformersadauNo ratings yet

- LFL Burner ControlsDocument26 pagesLFL Burner ControlsbledmikifrNo ratings yet

- VP 200 - Handbook of Electrical Hygiene & PracticesDocument28 pagesVP 200 - Handbook of Electrical Hygiene & PracticesvikramNo ratings yet

- Insulation Resistance TestDocument5 pagesInsulation Resistance TestS.DharanipathyNo ratings yet

- D2P1 Thurnherr SchwarzDocument81 pagesD2P1 Thurnherr SchwarzacairalexNo ratings yet

- CC-Link Remote IO Module User's Manual Ver.JDocument162 pagesCC-Link Remote IO Module User's Manual Ver.Jrammu2001100% (1)

- ABB - 1SFA898111R7000 pstx170 600 70 Softstarter - Datasheet PDFDocument3 pagesABB - 1SFA898111R7000 pstx170 600 70 Softstarter - Datasheet PDFandri putrantoNo ratings yet

- VLT 5000 PDFDocument193 pagesVLT 5000 PDFJOSUE RUIZNo ratings yet

- C-406EA Conversion GuideDocument12 pagesC-406EA Conversion GuideJorge Huachaca RodríguezNo ratings yet

- Ellis Patents Trade Pricelist 2011Document33 pagesEllis Patents Trade Pricelist 2011nicesreekanthNo ratings yet

- Level Measurement 4Document5 pagesLevel Measurement 4gsnptiNo ratings yet

- MR J2S A2 Instruction ManualDocument342 pagesMR J2S A2 Instruction ManualDiego TocancipaNo ratings yet

- EarthingDocument2 pagesEarthingAhmed MagdyNo ratings yet

- MR J3 TC E.pdf Meldas Servo MotorDocument227 pagesMR J3 TC E.pdf Meldas Servo Motorchidambaram kasiNo ratings yet

- TD01135E Metal-Oxide Surge Arresters Application GuideDocument52 pagesTD01135E Metal-Oxide Surge Arresters Application GuideAlbita PintoNo ratings yet

- PLC DVP28SV11TDocument20 pagesPLC DVP28SV11TSarah DoyleNo ratings yet

- En 50288Document3 pagesEn 50288rose chenNo ratings yet

- Types of Earthing (As Per IEC Standards) - Electrical Engineering CommunityDocument10 pagesTypes of Earthing (As Per IEC Standards) - Electrical Engineering CommunitySantosh Thapa100% (1)

- Toshiba Satellite C55-B LA-B303P r1.0 PDFDocument41 pagesToshiba Satellite C55-B LA-B303P r1.0 PDFmiltis papamiltiadouNo ratings yet

- Lightening Arrester: Substation Equipment and Its FunctionDocument8 pagesLightening Arrester: Substation Equipment and Its FunctionSunny KatariaNo ratings yet

- Instruction Manual: Welding Interface (Digital)Document181 pagesInstruction Manual: Welding Interface (Digital)ouyangxin1991No ratings yet

- Oglaend System Smart Cleat 1113Document12 pagesOglaend System Smart Cleat 1113sourcNo ratings yet

- Power Sector Overview in India - EARTHING DESIGN CALCULATIONDocument3 pagesPower Sector Overview in India - EARTHING DESIGN CALCULATIONnavneetNo ratings yet

- E200P Operation ManualDocument26 pagesE200P Operation ManualsharmasourabhNo ratings yet

- 1082 DDocument21 pages1082 DbilsaitNo ratings yet

- ABB ACS800 37 Manual PDFDocument250 pagesABB ACS800 37 Manual PDFAnonymous 6IqOdxNo ratings yet

- List of IEC StandardsDocument6 pagesList of IEC StandardsPranav BhattNo ratings yet

- Advanced Instrumentation Solutions Crafted With Highest PrecisionDocument6 pagesAdvanced Instrumentation Solutions Crafted With Highest PrecisionSandeep K Tiwari0% (1)

- B 64693en 1 01 0i F Plus Connection Manual Hardware CompressDocument160 pagesB 64693en 1 01 0i F Plus Connection Manual Hardware CompressRogerio PereiraNo ratings yet

- LabVolt MET326 LabsDocument32 pagesLabVolt MET326 LabsAnmar Shamel2No ratings yet

- Toshiba - Bs - AC Motor - Eng PDFDocument36 pagesToshiba - Bs - AC Motor - Eng PDFAleksa Milenkovic100% (1)

- FX Training ManualDocument128 pagesFX Training Manualgreystones100% (2)

- HZBB-10B Intelligent Tester of Transformer Ratio-User ManualDocument12 pagesHZBB-10B Intelligent Tester of Transformer Ratio-User ManualGio CJNo ratings yet

- 3.2transmitters Guided Wave Radar 706xxxDocument58 pages3.2transmitters Guided Wave Radar 706xxxQuy le manhNo ratings yet

- Electro PneumaticsDocument136 pagesElectro PneumaticsJaphet GabatanNo ratings yet

- Unicore Catalogue GB PDFDocument20 pagesUnicore Catalogue GB PDFSimsFreeplayNo ratings yet

- Industrial SocketsDocument38 pagesIndustrial SocketsAyman RamzyNo ratings yet

- BussBar CatDocument52 pagesBussBar CatRonald H Santos100% (1)

- Safety RelayDocument28 pagesSafety Relayeric_sauvageau1804No ratings yet

- Thermister TrainingDocument6 pagesThermister TrainingkazishahNo ratings yet

- s600 User Manual v2Document83 pagess600 User Manual v2Prakash SharmaNo ratings yet

- Catalogo de Cables de ControlDocument176 pagesCatalogo de Cables de Controlapok2040No ratings yet

- Chapter 13 EX Wiring Methods - IECDocument51 pagesChapter 13 EX Wiring Methods - IECdanishaslNo ratings yet

- Intruduction Final LV NexansDocument37 pagesIntruduction Final LV NexansDc DocNo ratings yet

- Types of Fire Testing: IEC 60331 IEC 60332 BS 6387 C, S, W & Z UL 1709Document12 pagesTypes of Fire Testing: IEC 60331 IEC 60332 BS 6387 C, S, W & Z UL 1709kevinwz1989100% (1)

- 0500 C0040 Offshore Marine EbookDocument184 pages0500 C0040 Offshore Marine EbookJorge Vasquez ChavarryNo ratings yet

- Intruduction Final LVDocument37 pagesIntruduction Final LVmealysrNo ratings yet

- Chapter 20: Technical Specification For Xlpe Cable With TerminationDocument46 pagesChapter 20: Technical Specification For Xlpe Cable With TerminationSristi MitraNo ratings yet

- Iec 6036Document3 pagesIec 6036Arun KumarNo ratings yet

- LD7890 LeadtrendDocument16 pagesLD7890 LeadtrendO6U Pharmacy RecordingsNo ratings yet

- CFD AssignmentDocument2 pagesCFD AssignmentApurba Roy0% (2)

- Rossfechten - German GuardsDocument7 pagesRossfechten - German GuardsEsgrima AntiguaNo ratings yet

- Brigada Eskwela Individual Plan 2019Document1 pageBrigada Eskwela Individual Plan 2019Arangote GlennNo ratings yet

- Facerec PythonDocument16 pagesFacerec PythonAbhishek BhandariNo ratings yet

- Arbol Navidad 1 - InstruccionDocument8 pagesArbol Navidad 1 - InstruccionEl Robert Vichop100% (1)

- 0808FT191040 - PCC - FT301Document20 pages0808FT191040 - PCC - FT301Ayush BarskerNo ratings yet

- Arta PasadoDocument20 pagesArta PasadoDanica Toledo PagoboNo ratings yet

- Strengthlifting II (Kilos)Document971 pagesStrengthlifting II (Kilos)Andrea AschiNo ratings yet

- Southern TagalogDocument12 pagesSouthern TagalogJamela Mer AlbertoNo ratings yet

- Msds Prestone BeltDocument6 pagesMsds Prestone BeltrizalramNo ratings yet

- Humoral Immunity: Dr. Beenish ZahidDocument24 pagesHumoral Immunity: Dr. Beenish ZahidayeshaNo ratings yet

- Street Fighter III: 3rd Strike Moves ListDocument21 pagesStreet Fighter III: 3rd Strike Moves ListHussain Alhaddad75% (4)

- Week 2 Branches of SocologyDocument15 pagesWeek 2 Branches of SocologyLaiba MunirNo ratings yet

- Well Completion and Stimulation - Chapter 3 Well Performance Analysis-NewDocument56 pagesWell Completion and Stimulation - Chapter 3 Well Performance Analysis-NewsouthliNo ratings yet

- ACTIVITIESDocument7 pagesACTIVITIESAnonymous irpr3uGyz2100% (2)

- 5 Reasons To Invest in Kotak Manufacture in India NFODocument2 pages5 Reasons To Invest in Kotak Manufacture in India NFOKISHOR KUMARNo ratings yet

- BASICS OF AN INSTRUMENT AIR SUPPLY SYSTEM - Instrumentation and Control EngineeringDocument4 pagesBASICS OF AN INSTRUMENT AIR SUPPLY SYSTEM - Instrumentation and Control EngineeringAhmadTaufikMuradNo ratings yet

- Savage Worlds - World of The Dead - Player's GuideDocument67 pagesSavage Worlds - World of The Dead - Player's GuideJulio100% (4)

- The Divine Secret of Nothing by Vincent MoralesDocument227 pagesThe Divine Secret of Nothing by Vincent Moralesh_vincent_m6715No ratings yet

- ENV 107L.15 Assignment 1 Analysis of The Ecological Condition of A PondDocument4 pagesENV 107L.15 Assignment 1 Analysis of The Ecological Condition of A Pondsafwan shamsNo ratings yet

- DLL Science 6 Q2 W9 1Document10 pagesDLL Science 6 Q2 W9 1Michelle Orge100% (1)

- Astronomy Unit Resources SchoolpointeDocument17 pagesAstronomy Unit Resources SchoolpointeShekel DeninoNo ratings yet

- 40 Item Test Science 6with Key To CorrectionDocument5 pages40 Item Test Science 6with Key To CorrectionvinnNo ratings yet

- DH-SD49425XB-HNR: 4MP 25x Starlight + IR PTZ AI Network CameraDocument4 pagesDH-SD49425XB-HNR: 4MP 25x Starlight + IR PTZ AI Network CameraHumberto RojasNo ratings yet

- Math WorksheetDocument20 pagesMath WorksheetSheena MangampoNo ratings yet

- Hi-Tech Projects: (An Industrial Monthly Magazine On New Project Opportunities and Industrial Technologies)Document17 pagesHi-Tech Projects: (An Industrial Monthly Magazine On New Project Opportunities and Industrial Technologies)Shridhar L MallapurNo ratings yet