Professional Documents

Culture Documents

Manual Oil Cooler Bloksma

Uploaded by

api-3774519Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Oil Cooler Bloksma

Uploaded by

api-3774519Copyright:

Available Formats

TABLE OF CONTENTS Glossary

Page

Glossary 1 Refer to the figure(s) in the paragraph "Assembling and

disassembling of the heat exchanger" for an explanation

1 Introduction 2 of the designation of parts of the heat exchanger in the text.

1.1 Remarks 2

1.2 Guarantee and liability 2 Conditioned circuit

1.3 Environment 2 Closed circuit with a non-corrosive medium.

1.4 Safety 2

1.5 Inhibitors 2 Unconditioned circuit

Open circuit (for instance seawater) or a closed circuit with a

2 Installation and start-up 2 corrosive medium.

2.1 Receipt 2

2.2 Installation 2 Coating

2.3 Start-up 3 Layer protecting the coated material against corrosion. The

coating separates the coated part from the corrosive medium.

3 Maintenance 3

3.1 Cleaning and inspection intervals 3 Inhibitor

3.2 Anodic protection 3 Additive to a medium flowing through the heat exchanger

3.3 Cleaning of the heat exchanger 3 which –expressly tailored to that medium- reduces the

3.3.1 Mechanical cleaning of the tubeside 3 quickness of chemical reactions like corrosion.

3.3.2 Chemichal cleaning of the shell-/tubeside 3

3.4 Shut down periods 3 Anodes / anodic protection

3.5 Assembling and disassembling of the heat exchanger 3 Introducing a base metal to a more precious metal (on purpose)

3.6 Instructions for gaskets and bolting 5 in order to protect this metal. The part serving as anode is being

3.6.1 Gaskets 5 sacrificed.

3.6.2 Bolting 5

4 Trouble shooting & repairs 5

4.1 Thermal performance too low 5

4.2 Leaking tubes / tube-tubesheet-connection 5

4.3 Leaking gaskets 5

5 Spare parts & tools 5

Appendix A: Instructions for conservation 6

Appendix B: Adresses 6

Appendix C: Constructional directions for entering a 6

P-type heat exchanger in a piping design

The P-type heat exchanger can be subdivided into four sizes:

P10, P13, P20 and P28.

The number indicates the shell size in centimeters. The construc-

tion of the P10 is slightly different from the others. When neces-

sary this manual has special texts (indicated with: "For P10

only:") which apply to the P10 only.

There are two models (P10 only in MV): the IV (Industrial Version)

and the MV (Marine Version). Main difference is the anodes in

the tubeside circuit of the MV. It is pointed out in the text when

there are differences between the two models.

In addition this manual applies to P-heat exchangers with plain

tubes as well as PF heat exchangers with bundles with fins.

P.02.02 1 Manual Bloksma P-type Heat Exchanger

1 Introduction 2 Installation and start-up

1.1 Remarks 2.1 Receipt

* Read this instruction manual before proceeding. At receipt check the packaging and the heat exchanger:

* Important documents besides this instruction manual are * report any damage to Bloksma

the order confirmation, the specification sheet, the * compare the data on the nameplate, confirmation of the

drawing(s) and the sheet with constructional directions order and on the drawing

(appendix C). In the specification sheet the design pressures * check whether or not the correct instruction manual is

and temperatures are listed that must of course not be present by comparing the article number on the cover sheet

exceeded. with the article number of the instruction manual on the

confirmation of order

1.2 Guarantee and liability

The "General conditions of Bloksma B.V." are applicable. Also Always store the heat exchanger in a dry room, free of large

refer to the confirmation of the order for possible additions. temperature changes. When the heat exchanger is not being put

into operation immediately after receipt, follow the "Instructions

Not covered by the guarantee are loss of performance and/or for conservation" (Appendix A).

damage to the heat exchanger as a result of:

* not following the instructions in this manual 2.2 Installation

* replacement with non-original parts Warning: Beware of any rust preventive layers (see "Instructions

for conservation") that might still be present in the heat exchan-

1.3 Environment ger before proceeding.

* The environmental laws and rules of the area where the heat * Remove all protective plugs and covers from the connecting

exchanger is installed, always have to be respected. flanges prior to installation of the heat exchanger.

* Always be on the alert to the possibility of leakage. * A 1- or 3-pass model (tubeside) has to be mounted in such a

* When disposing of the unit at the end of its lifespan, see to it way that shell- and tubeside will be in counterflow.

that this takes place according to the then applicable * Check whether the positions of the vent and drain

regulations. connections on the heat exchanger correspond with the

mounting position of the heat exchanger.

1.4 Safety * Mount the heat exchanger level and square on a flat surface

Some symbols are used in the text to underline safety aspects: in order for the pipe connections to be made without forcing.

* Do not weld anything to the heat exchanger.

* Mount one support in a fixed position, while the other one is

mounted in such a way that it is able to slide in the direction

of the longitudinal axis of the heat exchanger. The heat

Pay attention: depending on the application the heat exchanger exchanger will thus be able to expand under thermal stress.

will be hot during operation * When installing types bigger than P10 vertically, the

waterbox at which the position of the tubesheet is fixedº ,

has to be located on top.

* Before connecting piping to the heat exchanger flanges,

make sure that the gasket surface is clean and free from

scratches and other defects. Always use new gaskets, of the

Maintenance and repair: depressurize both circuits of the heat correct type and tighten the bolts crosswise.

exchanger and let them cool down to ambient temperature. * Take care when lifting the heat exchanger. Use at least two hoops

around the shell of the heat exchanger for lifting purposes.

In connection with safety every Bloksma heat exchanger is * Check for the presence and correct positions of drain/vent

tested under higher pressure than the design pressure before it connections in both circuits.

leaves the factory. This applies to heat exchangers that are not * Install the heat exchanger and the piping in such a manner

tested by a certification agency. that there is still enough room to disassemble (part of) the

heat exchanger (tubebundle, drain plugs, etc.).

1.5 Inhibitors

There can be reasons to add an inhibitor to one of the circuits of ºOn a 2-pass model the side of the heat exchanger at which the

the heat exchanger. Contact a specialised company, which can position of the tubesheet is fixed is always the side where the

also check for harmfulness of the inhibitor to the materials of tubeside medium enters and exits the heat exchanger. On 1-pass

the heat exchanger (see specification sheet). Follow the instruc- models this is the side on which fixation plates are are bolted

tions of the supplier for use of the inhibitor. between waterbox and shell (on the other side distance rings are

bolted between shell and waterbox). Furthermore the side of the

heat exchanger where the serialnumber is, is also the side with

the fixed tubesheet.

P.02.02 2 Manual Bloksma P-type Heat Exchanger

2.3 Start-up chemical solution through the heat exchanger. Another possibility

Do not exceed the design temperatures and design pressures as is disassembling of the heat exchanger and submerging the

stated on the nameplate and specification sheet. Avoid abrupt tubebundle in a tank filled with a chemical solution. Remove any

temperature fluctuations; these can cause leaking of tube-to- plastic partitions (on 2- or 3-pass heat exchangers to divide the

tubesheet or other connections. tubeside circuit) from the tubesheet(s) first.

* Make sure that the cold medium circulation is established There are several international companies (example in Appendix

first, followed by the gradual introduction of the hot medium. B) which supply equipment and fluids for chemical cleaning of

* Vent both circuits. heat exchangers. Their specialized cleaning centres, situated at

* Vent both circuits again when the operating temperatures ports all over the world, are able to give you a cleaning advise or

and pressures are reached. to clean the heat exchanger for you. To give an idea of the

* Check for leakage. possibilities, an example of a cleaning procedure is given below.

Do not deviate from the flows as stated on the specification Please note: The cleaning advice below is just an example.

sheet. Higher or lower velocities can cause erosion or corrosion Cleaning methods and procedures, as well as fluids for cleaning

respectively. will differ depending on the materials of the heat exchanger (see

specification sheet) and the application.

Avoid standstill: at non-conditioned circuits this may cause corrosion.

In case of standstill follow the instructions for shut down periods. This cleaning advise is meant for waterheaters/coolers.

If the heat exchanger is equipped with anodic protection (see Descalant NF (inhibited cleaning agent)

specification sheet) you will have to inspect the anodes (or part * Submerge the tubebundle (time is dependend on the degree

that functions as anode) when you are starting up the heat of fouling) in a tank with dissolved cleaning agent

exchanger after a shut down period. * After cleaning neutralize the tubebundle and the cleaning

agent with a special neutralizing fluid

3 Maintenance * Flush the tubebundle with fresh water

* Dry the tubebundle

If necessary refer to "Assembling and disassembling of the heat

exchanger" for (dis-)assembling instructions. 3.4 Shut down periods

During shut down periods longer than a week the heat exchanger

3.1 Cleaning and inspection intervals has to be drained completely and dried by means of preheated

Preventive maintenance of the heat exchanger is a user responsi- compressed air. In fact this also has to be done during short shut

bility. The tubeside circuit is usually the more fouling side of the down periods (longer than a day) when there is risk of freezing,

heat exchanger. Because the degree of fouling strongly depends and it also applies when a corrosive medium is used in the heat

on the operating conditions we recommend the following: exchanger. After draining a corrosive medium, the heat exchanger

* Inspect the tubeside at least quarterly. has to be rinsed with fresh water. Stopping of the flows, cooling

* Inspect the shellside at least twice a year. down and draining of the heat exchanger has to be done in a

With the results of these inspections you will be able to manner to minimize thermal stresses on the heat exchanger.

determine the required cleaning intervals. Always keep

performing regular inspections. Never stop one of the flows of the heat exchanger while the

other one stays in operation, because of the risk of boiling.

3.2 Anodic protection

Not applicable for IV models. 3.5 Assembling and disassembling of the heat exchanger

The MV models of P-type heat exchangers are fitted with anodic The circumferences of the tubesheets are fitted with three

protection: the tubeside circuit is provided with anodes. When grooves. The two outer grooves carry O-rings (sealing between

inspecting the tubeside of the heat exchanger also inspect the shell- and tubeside). At one of the tubesheets the middle groove

state of the anodes (always drain the tubeside circuit before is for the fixation of the position of the tubebundle by means of

removing the anodes). ‘fixationplates’ (this tubesheet is called the fixed tubesheet).

3.3 Cleaning of the heat exchanger

3.3.1 Mechanical cleaning of the tubeside

The tubes can be cleaned with a tube brush. Use original Bloksma

brushes only; these have the correct dimensions and are of a suitable

material. Other brushes may damage the protective layer that is

in the normal course of events present on the tubewalls.

3.3.2 Chemichal cleaning of the shell-/tubeside

Warning: Chemical cleaning may damage the heat exchanger.

Make sure your supplier of a cleaning agent verifies and

confirms the compatibility of his product with the materials of

the heat exchanger (see specification sheet).

Cleaning of the shellside will normally be necessary seldom.

The shell- as well as the tubeside can be cleaned by circulating a

P.02.02 3 Manual Bloksma P-type Heat Exchanger

In case the heat exchanger is placed vertical, disassemble the

upper waterbox first. This is the side with the fixationplates.

Fasten the fixationplates immediately with the nuts before pro-

ceeding. For P10 only: A vertically placed P10 will always have to

be disassembled completely because the the tubebundle does

not stay in position.

* remove the waterboxes by untightening the nuts

(the fixationplates come loose as well)

* 2- or 3-pass heat exchangers have plastic partitions on the

tubesheet(s) for dividing the tubeside circuit; mark their

position and remove them

* mount the fixationplates again with the nuts (not necessary

when the tubebundle is going to be removed (see step 2))

* remove the first O-ring from both tubesheets

* only for a pressure test: pressurize the shellside again.

Depressurize the shellside again after the pressure test. For P10

only: Remember that the tubebundle is not fixated!

1 2 3 4 5

Step 2: Removing the tubebundle

* drain the shellside circuit, by opening the drain in the lowest

1 Tubesheet 4 Shell point and the vent in the highest point

2 O-ring 5 Tubes * mark the position of the tubebundle

3 Fixationplate * move the tubebundle to one side until the second O-ring

shows (do not move the tubebundle further than necessary)

Figure 1: Schematic drawing of tubesheet construction and remove this O-ring

* move the tubebundle to the other side and remove the

For P10 only: Instead of fixationplates the P10 has a metal spring second O-ring on this side as well

ring in the middle groove of the tubesheet. As soon as the bolts * carefully pull the tubebundle from the shell

are untightened the position of the tubebundle is no longer * support the tubebundle at the baffles when lifting it, but be

fixated. Tubeside inspection or cleaning remains possible, careful not to bend the baffles (this will affect the thermal

but extra attention is required because the tubebundle is not performance of the heat exchanger)

fixed anymore. Except when performinge a pressure test, we

recommend to drain both circuits. Step 3: Assembling

* assemble the heat exchanger in reversed order

For tubeside inspection, shellside pressure testing or (pay attention to the earlier made marks):

cleaning of the tubes with a tubebrush, only the tube- Mounting of the tubebundle (only in case it was removed):

side connections and the waterboxes (these are the * push the tubebundle in the shell (let it stick out of the shell

parts on both ends of the shell, on which the tubeside a little bit)

connections are made) need to be removed (follow step 1 and 3). * mount the inner O-ring on the first tubesheet

Pay attention: when the nuts are untightened the fixationplates * move the tubebundle further and let it stick out a little bit

are also untightened, so the tubebundle comes loose. In order to on the other side of the shell

fixate the tubebundle temporarily, fasten the fixationplates with * mount the inner O-ring on the second tubesheet

the nuts.

Hint: when it is difficult to move the tubebundle through the

For shellside inspection (for instance), the tubebundle shell because the already mounted O-ring is hard to

has to be removed completely (follow step 1, 2 and 3), compress, you can use a strip between tubesheet and

and both circuits have to be drained. waterbox and then tighten two of the four bolts and nuts

* move the tubebundle in its final position

When assembling as well as disassembling follow the

"Instructions for gaskets and bolting". Tubeside assembly:

* mount the outer O-rings on both sides

Step 1: Tubeside disassembling * mount the plastic partitions on the tubesheets of 2- or 3-pass

models

* mount the fixationplates (for P10 only: mount the metal

spring ring)

* mount the waterboxes and all connections

* depressurize both circuits * start-up the heat exchanger again:

* let both circuits cool down to ambient temperature * make sure that the cold medium circulation is established

* drain the tubeside circuit, by opening the drain in the lowest first, followed by the gradual introduction of the hot medium

point and the vent in the highest point * vent both circuits

* mark the position of all parts that will be disassembled, so

they can be mounted in the correct position later on

P.02.02 4 Manual Bloksma P-type Heat Exchanger

* vent both circuits again when the operating temperatures of 2- or 3-pass heat exchangers; the position of the

and pressures are reached tubebundle (this might accidentally be mounted rotated 180°

* check for leakage around its axis))

3.6 Instructions for gaskets and bolting 4.2 Leaking tubes / tube-to-tubesheet connection

It is often very hard to determine whether leakage occurs because

3.6.1 Gaskets of a leaking tube or because of a leaking tube-to-tubesheet con-

Two types of gaskets are being used in this heat exchanger: nection. The shellside of the heat exchanger can be hydrotested,

after disassembling the tubeside. Follow the instructions in

O-rings: After disassembling the heat exchanger never use the "Assembling and disassembling of the heat exchanger".

old O-rings again. Replace them with original Bloksma O-rings. Subsequently pressurize the shellside. After hydrotesting depres-

surize and drain the shellside again. Assemble the heat exchan-

Warning: The O-rings have to be lubricated with a special O-ring ger again.

lubricant (O-ring silicone paste or Parker O-lube) for easy assembly

and a good sealing capacity. Lubricants not suited for O-rings can The tubes are roller expanded into the tubesheet. It is either not

affect the sealing capacity of the O-ring (for instance do never possible (finned tubebundles) or relatively complicated (unfin-

use vaseline). Any warranty claim will be rejected when unsuited ned tubebundles) to replace a leaking tube, but it can be plug-

lubricants are used. ged with soft copper Bloksma plugs (other materials are too

hard and may cause leakage of the adjacent tube-to-tubesheet

Soft metal rings: After disassembly of the heast exchanger never connections) in both tube ends. A maximum of approximately

use the old soft metal rings again. Replace them with new ones 10% plugged tubes will not influence the thermal performance

for good sealing. of the heat exchanger too much. Contact Bloksma when more

than 10% of the tubes is plugged.

3.6.2 Bolting

Check bolts and nuts for damages. Tighten the bolts crosswise 4.3 Leaking gaskets

(see figure 2). This also applies to connecting piping to the heat * Check the gasket surfaces.

exchanger. Make sure the gasket surface is clean (remove dirt * Remove dirt or corrosion residues

and any corrosion residues) and undamaged. * Mount new gaskets

It is possible to determine which of the O-rings is leaking, by

3 1 determining the medium that is leaking from the heat exchanger.

5 Spare parts & tools

Available spare parts and tools for P-type heat exchangers:

* Set of gaskets (four O-rings)

* Soft copper plugs

* Nylon tube brush

* Bolts / nuts

* Complete tubebundle

2 4 * For P10 only: Metal spring ring

* Fixationplates (for types > P10)

* Plastic partitions (not for 1-pass heat exchangers)

Figure 2: (Un-)bolting sequence * Water box

* Cover

4 Trouble shooting & repairs * Anode

When ordering spare parts, please refer to the Bloksma drawing

number (listed on name plate).

4.1 Thermal performance too low

Check:

* whether all connections have been made according to the

drawing

* whether the heat exchanger and the system have been

properly vented

* whether the flows are according to the specification (check

all valves, lines and pumps, as well as the flow directions)

* whether the shell- as well as the tubeside have been cleaned

recently (fouling can cause a drop in performance and an

increased pressure loss; an increased pressure drop is a good

indication that cleaning is necessary)

* whether the heat exchanger has been reassembled properly

after disassembly (the plastic partitions on the tubesheet(s)

P.02.02 5 Manual Bloksma P-type Heat Exchanger

Appendix A: Instructions for conservation Appendix C: Constructional directions for

including a P-type heat exchanger in a

Standard conservation (controlled conditions) piping design.

All heat exchangers supplied by Bloksma are treated with a rust

preventive layer (on both shell- and tubeside). This layer will pro- Pay attention to the following points:

tect the heat exchanger when it is stored at controlled condi- * Level and square mounting possibility.

tions, i.e. inside, in a dry room at constant temperature. When * Bends in the piping have to be located at a distance of at

these conditions are met, the heat exchanger can be stored wit- least three times the nominal diameter of the pipe from the

hout special treatment for a longer period (up till 24 months). inlet of the heat exchanger.

The rust preventive layer can be removed with a mineral solvent * When a vaporizing cryogenic medium is used, the heat

(petroleum). exchanger has to be placed under an angle of 3° - 10°, in order

for the vapor to be able to exit the heat exchanger, helped by

Advise for conservation (uncontrolled conditions) natural circulation.

When the above mentioned storage conditions are not met, you * Check if vent and drain connections are present in both

will have to fill the heat exchanger with an inert gas and all ope- circuits of the heat exchanger (when not on the heat

nings have to be closed airtight (additionally silica gel can be exchanger then make them in the piping).

added to absorb liquids). Alternatively, the heat exchanger can * Put a filter (with a permeability of 3 mm.) before the inlet of

be treated with a rust preventive liquid of a type suited for long both circuits of the heat exchanger.

term conservation. * Stress- and vibration free mounting possibility of the

When necessary contact a specialised company. Take the materi- connections and the supports (fit expansion bellows and/or

als of the heat exchanger (see specification sheet) into conside- silencer blocks when necessary).

ration. Be aware that in uncontrolled storage conditions large * Disassembling possibility of the tubebundle (and other parts

amounts of water can accumulate in the heat exchanger as a like drain and vent plugs).

result of condensation. * Expansion possibility of lockable liquid circuits.

* Danger of freezing of liquid circuits.

Appendix B: Adresses * The design data of the heat exchanger on the specifiation-

sheet and the drawing. For instance the flows: deviating

Chemichal cleaning and products for chemichal cleaning from them can cause unacceptable high or low velocities.

A (temporary) lower flow is acceptable when caused by a

Ashland Chemical Nederland B.V. controlsystem and a conditioned circuit is involved. Avoid

standstill (unless the heat exchanger is drained and flushed

Drew Marine Division with fresh water).

Malledijk 20 * When adding an inhibitor to one of the fluids in the heat

3208 LA Spijkenisse exchanger, always check whether this inhibitor can be

The Netherlands harmful for the materials of the heat exchanger

Telephone : + 31 (0)181-457074 (see specification sheet).

Telefax : + 31 (0)181-625792 * Make sure that in case of flow control (with conditioned

Internet: www.ashchem.com circuits only) this is done gradually (no ‘on-off-control’).

* Although this will almost never occur in practice, Bloksma

reserves the right (according to TEMA RGP-RCB-2) to plug a

maximum of 1% of the tubes.

* Always check whether both fluids are compatible with the

materials of the heat exchanger; Bloksma chooses the

materials judging on the fluids specified by the customer,

but is often not well informed about possible

contaminations, higher or lower than normal degrees of

acidity and other for the choice of materials important

proprties.

* Check whether the materials of the connecting piping are

compatible with the materials of the heat exchanger (when

the materials of the bundle are, from a corrosion point of

view, weak in comparison with the materials of the piping,

the bundle will corrode faster than expected).

www.bloksma.net

P.02.02 6 Manual Bloksma P-type Heat Exchanger

You might also like

- Asm. ManualDocument236 pagesAsm. Manualapi-3774519No ratings yet

- Wartsila Vasa 32 Project GuideDocument125 pagesWartsila Vasa 32 Project Guidepauliusdabar100% (1)

- Heatpac EHM Electric Heater: Component DescriptionDocument32 pagesHeatpac EHM Electric Heater: Component DescriptionCarlos Eduardo Galvão75% (4)

- Maintenance MAK M43CDocument309 pagesMaintenance MAK M43Ctruc80% (10)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- SEE00553.01 BFC BFCF Comp VA Maintenance ManualDocument74 pagesSEE00553.01 BFC BFCF Comp VA Maintenance Manualapi-377451950% (2)

- Starbucks Cleaning Program TransitionDocument1 pageStarbucks Cleaning Program TransitionzorthogNo ratings yet

- Alfa Laval Moatti: Compatible Spare Parts For Fuel-And Lube Oil FilterDocument10 pagesAlfa Laval Moatti: Compatible Spare Parts For Fuel-And Lube Oil FilterMintomo IrawanNo ratings yet

- Chris Marine Surface Grinder Type CPLDocument22 pagesChris Marine Surface Grinder Type CPLSamer SalibaNo ratings yet

- Tech. Info M 25Document34 pagesTech. Info M 25abuzer1981No ratings yet

- Service Manual Air Starter A17.G01Document26 pagesService Manual Air Starter A17.G01abuzer1981100% (3)

- Drew Catalog 2009 7th EdDocument47 pagesDrew Catalog 2009 7th EdbuDurovQ1Aq100% (1)

- Type Approval Certificate: Schneider Electric Industries S.A.SDocument3 pagesType Approval Certificate: Schneider Electric Industries S.A.SSreegith Chelatt100% (1)

- Boxcooler ManualDocument18 pagesBoxcooler Manualhpss77No ratings yet

- Aura Marine Feeder UnitDocument447 pagesAura Marine Feeder UnitImmorthalNo ratings yet

- General MenuDocument23 pagesGeneral Menuapi-3774519No ratings yet

- ASTM D 3359-23 Rating Adhesion by Tape Test (X-Cut)Document5 pagesASTM D 3359-23 Rating Adhesion by Tape Test (X-Cut)z6ytg7mcrjNo ratings yet

- Oil Cooler BloksmaDocument1 pageOil Cooler Bloksmaapi-3774519100% (1)

- Luzhou Mineral Oil Separator PDFDocument12 pagesLuzhou Mineral Oil Separator PDFOrlando GalvanNo ratings yet

- W8L20 - Engine AttachmentsDocument348 pagesW8L20 - Engine AttachmentsTuan Linh VoNo ratings yet

- Manual Mak 8M20 Parte C ExternaDocument1,115 pagesManual Mak 8M20 Parte C Externaartemio Cardoso100% (1)

- Pick-Up Turbo - Jaquet Dse 1210.02 AHZDocument2 pagesPick-Up Turbo - Jaquet Dse 1210.02 AHZjuanjo100% (1)

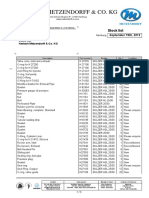

- Herbert Metzendorff & Co. KGDocument3 pagesHerbert Metzendorff & Co. KGbeu catalin0% (2)

- S35MC-C9 2 PDFDocument312 pagesS35MC-C9 2 PDFKHairil AdZharNo ratings yet

- Welding Refrig Catalog 8th EditionDocument48 pagesWelding Refrig Catalog 8th Editionnguyenvanhai19031981100% (1)

- Scana Volda CPP DiagramDocument66 pagesScana Volda CPP DiagramAlejandro BautistaNo ratings yet

- 5 PDFDocument40 pages5 PDFSantiago Dellacha100% (1)

- Ac Compressor Model - 5h66Document32 pagesAc Compressor Model - 5h66sting12345100% (2)

- k90mc CDocument279 pagesk90mc CfaintaresNo ratings yet

- 2 Maintenance BDocument324 pages2 Maintenance BPranav Shekhar100% (1)

- Rotor PDFDocument68 pagesRotor PDFAerox neoNo ratings yet

- Volvo Tamd163aDocument163 pagesVolvo Tamd163aParAldNo ratings yet

- Service Information M20Document72 pagesService Information M20Alexander100% (1)

- Fuel Pump and Fuel Valve Grinding MachineDocument43 pagesFuel Pump and Fuel Valve Grinding MachineSamer SalibaNo ratings yet

- Manual EVK SealDocument18 pagesManual EVK Sealpanamajack26No ratings yet

- Herbert Metzendorff & Co. KGDocument2 pagesHerbert Metzendorff & Co. KGAymen BriniNo ratings yet

- Evac Stainless Steel Vacuum ToiletDocument19 pagesEvac Stainless Steel Vacuum ToiletTayfun SezişNo ratings yet

- Valve Seat Grinding Machine Type MSDDocument57 pagesValve Seat Grinding Machine Type MSDSamer SalibaNo ratings yet

- Wartsila Spare PartsDocument1 pageWartsila Spare PartsMaan MohammedNo ratings yet

- W8L20 - Spare PartsDocument2 pagesW8L20 - Spare PartsTuan Linh VoNo ratings yet

- Woodward UG ActuatorDocument4 pagesWoodward UG ActuatorИгорь100% (2)

- Imo Screw Pumps ACG-UCG 7Document12 pagesImo Screw Pumps ACG-UCG 7Chhoan NhunNo ratings yet

- +description and Operating Instructions For Back-Flushing Filter Type 6.46Document32 pages+description and Operating Instructions For Back-Flushing Filter Type 6.46phoenix a703100% (1)

- Esd5500E Series Speed Control Unit: Product Technical Information PTI 1002EDocument7 pagesEsd5500E Series Speed Control Unit: Product Technical Information PTI 1002EalstomNo ratings yet

- MIB 303S - Spare Parts CDocument46 pagesMIB 303S - Spare Parts CECO Green and BlueNo ratings yet

- SW280 SW28 Cylinder Head OverviewDocument2 pagesSW280 SW28 Cylinder Head OverviewD.Poljachihin100% (1)

- Ktms - 2007 Yanmar Stock ListDocument123 pagesKtms - 2007 Yanmar Stock ListhanifNo ratings yet

- G300 Parts Catalogue (New) 2Document10 pagesG300 Parts Catalogue (New) 2Operations gtllogisticsNo ratings yet

- Jets Products GW TKDocument1 pageJets Products GW TKВладимир БNo ratings yet

- W8L20 - Safety Spare Parts RecommendationDocument8 pagesW8L20 - Safety Spare Parts RecommendationTuan Linh VoNo ratings yet

- Duplex Filter 2.04.5 en BOLLFILTER PDFDocument2 pagesDuplex Filter 2.04.5 en BOLLFILTER PDFTroller TallNo ratings yet

- Engine Performance Data: Safety Precautions Special ToolsDocument184 pagesEngine Performance Data: Safety Precautions Special ToolsHtooThar AungNo ratings yet

- Governor Test StandDocument76 pagesGovernor Test StandPj Easton100% (1)

- FORM - CYL HD O HL W32 W34SG ws12v009 - 02gb (1) (Right Form)Document2 pagesFORM - CYL HD O HL W32 W34SG ws12v009 - 02gb (1) (Right Form)tomiNo ratings yet

- External MAKDocument424 pagesExternal MAKGiovanniJara100% (1)

- Product Guide GB 2018 LowDocument268 pagesProduct Guide GB 2018 LowFahri AzhieNo ratings yet

- AQ-8.10 Instructie ManualDocument22 pagesAQ-8.10 Instructie ManualJan MaarschalkerweerdNo ratings yet

- Daihatsu DL 22Document10 pagesDaihatsu DL 22prakash buddhdev100% (1)

- Imo Pump Ace PDFDocument4 pagesImo Pump Ace PDFpetrakou aglaia100% (1)

- Charge Air CoolerDocument15 pagesCharge Air CoolerMYO WIN0% (1)

- Manual BoxcoolerDocument24 pagesManual BoxcoolerdenysNo ratings yet

- Iom Swing Check ValveDocument11 pagesIom Swing Check ValveMohamadIbnuHassanNo ratings yet

- HLS-220 D 750.23.5.028 (031033036043) - EnglischDocument13 pagesHLS-220 D 750.23.5.028 (031033036043) - EnglischRainNo ratings yet

- Specification For Cold InsulationDocument21 pagesSpecification For Cold InsulationSagarBabuNo ratings yet

- Diesel Engine NoiseDocument10 pagesDiesel Engine Noisehpss77No ratings yet

- Maintenance Planning and SchedulingDocument74 pagesMaintenance Planning and Schedulingapi-3732848100% (16)

- Lean MaintenanceDocument55 pagesLean Maintenanceapi-3732848No ratings yet

- Folad Mobarake-Mohamad Ali ShiraziDocument4 pagesFolad Mobarake-Mohamad Ali Shiraziapi-3774519No ratings yet

- CMMSand EAM06Document54 pagesCMMSand EAM06api-3732848No ratings yet

- CARBOSORB NC 830 - Comelt - TDS - ENDocument1 pageCARBOSORB NC 830 - Comelt - TDS - ENilkerNo ratings yet

- ES 22 Color Coding of Piping MaterialsDocument3 pagesES 22 Color Coding of Piping MaterialsjojeecaresNo ratings yet

- PowerPoint IonsDocument11 pagesPowerPoint IonsAlly100% (1)

- Tarakky Sir First QuestionDocument7 pagesTarakky Sir First QuestionKhondokar TarakkyNo ratings yet

- B403-12 Standard Specification For Magnesium-Alloy Investment CastingsDocument4 pagesB403-12 Standard Specification For Magnesium-Alloy Investment CastingsmithileshNo ratings yet

- Seminar Topic EditedDocument2 pagesSeminar Topic Editedhitheshds1999No ratings yet

- Sikament - 600: High Range Water-Reducing Concrete AdmixtureDocument3 pagesSikament - 600: High Range Water-Reducing Concrete Admixturedeboline mitraNo ratings yet

- Kubus en PDFDocument6 pagesKubus en PDFLuis CostaNo ratings yet

- A Blacksmith Ing PrimerDocument2 pagesA Blacksmith Ing Primerstubby49No ratings yet

- Separating Mixtures PDFDocument4 pagesSeparating Mixtures PDFDenise Adriene ParanNo ratings yet

- Job Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006Document11 pagesJob Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006mahesh naikNo ratings yet

- Commercial Brochure - Uponor Ecoflex Thermo and Varia - EN - 070813 - 55750Document4 pagesCommercial Brochure - Uponor Ecoflex Thermo and Varia - EN - 070813 - 55750portocala12No ratings yet

- Opuscolo Pompeii Nov18 HiResDocument5 pagesOpuscolo Pompeii Nov18 HiResnot a bookwormNo ratings yet

- Pu-2013-Color-fixing Polyester and Preparatio1Document4 pagesPu-2013-Color-fixing Polyester and Preparatio1Syed Tawab ShahNo ratings yet

- Bray Serie 20 - 21 (Ficha Tecnica)Document4 pagesBray Serie 20 - 21 (Ficha Tecnica)Oscar Horta PolaniaNo ratings yet

- TECHNOLOGY1 Answer-1Document6 pagesTECHNOLOGY1 Answer-1JlkKumarNo ratings yet

- Medium of Visual ArtsDocument58 pagesMedium of Visual Artsfernandez ararNo ratings yet

- 2 - Defects & RemediesDocument29 pages2 - Defects & RemediesShivam Aggarwal100% (2)

- Dimensions N Weights Pipes N TubesDocument6 pagesDimensions N Weights Pipes N TubesRahul SinghNo ratings yet

- Pyrolysis of WoodDocument42 pagesPyrolysis of WoodCléo VieiraNo ratings yet

- Very-High-Performance Concrete With Ultrafine PowdersDocument5 pagesVery-High-Performance Concrete With Ultrafine PowdersYuliusRiefAlkhalyNo ratings yet

- TODO Catalogo Tecnico 2Document67 pagesTODO Catalogo Tecnico 2Abrar HussainNo ratings yet

- Influence of Calcium Addition On Calcined Brick Clay Based GeopolymersDocument10 pagesInfluence of Calcium Addition On Calcined Brick Clay Based GeopolymersJaouad El FarissiNo ratings yet

- House Construction On Plot 430 Sector 21 BDocument9 pagesHouse Construction On Plot 430 Sector 21 BP Eng Suraj SinghNo ratings yet

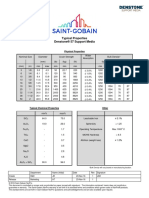

- Denstone® 57 Support Media Typical PropertiesDocument1 pageDenstone® 57 Support Media Typical PropertiesJuan Victor Sulvaran ArellanoNo ratings yet

- Sethco Bulletin 354Document10 pagesSethco Bulletin 354edgar vasquezNo ratings yet

- Machine Design Elements08 - : God BlessDocument101 pagesMachine Design Elements08 - : God BlessReynald de VeraNo ratings yet

- SKF Materials For Bearing Rings and Rolling ElementsDocument2 pagesSKF Materials For Bearing Rings and Rolling ElementsKamolwan WeerachatsakulNo ratings yet