Professional Documents

Culture Documents

Fundamentals of Cutting: Chapter-20

Fundamentals of Cutting: Chapter-20

Uploaded by

George CamachoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fundamentals of Cutting: Chapter-20

Fundamentals of Cutting: Chapter-20

Uploaded by

George CamachoCopyright:

Available Formats

Chapter-20

Fundamentals of cutting

Introduction

Mechanics of chip formation

Types of chips produced in meta cutting

Mechanics of oblique cutting

Cutting forces and power

Temperature in cutting

Tool life : Wear and failure

Surface finish and integrity

Machinability

TOPICS

Fundamentals of cutting

Fig 20.3 Schematic illustration of a two-

dimensional cutting process,also called

orthogonal cutting.Note that the tool shape

and its angles,depth of cut,to,and the cutting

speed are all independent variables.

Fig 20.1 Examples of cutting process

Fig 20.2 Basic principle of turning operation

Introduction :

Cutting process : Remove material from the surface of

the work piece by producing chips

Turning operation : the work piece is rotated an a

cutting tool removes a layer of material as it moves to

the left

Cutting off: Cutting tool moves radially inwards and

separated the right piece from the back of the blank.

Slab-milling rotating cutting tool removes a layer of

material from the surface of the work piece

End-milling rotating cutter travels along a certain

depth in the work piece and produces a cavity

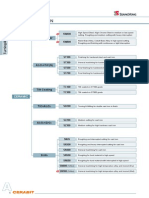

Factors influencing cutting process

Parameter Influence and interrelationship

Cutting speed depth of

cut,feed,cutting fluids.

Tool angles

Continuous chip

Built-up-edge chip

Discontinuous chip

Temperature rise.

Tool wear

Machinability

Forces power,temperature rise,tool life,type of chips,surface

finish.

As above;influence on chip flow direction;resistance to tool

chipping.

Good surface finish;steady cutting forces;undesirable in

automated machinery.

Poor surface finish,thin stable edge can product tool surface.

Desirable for ease of chip disposal;fluctuating cutting

forces;can affect surface finish and cause vibration and

chatters.

Influences surface finish,dimensional accuracy,temperature

rise,forces and power.

Influences surface finish,dimensional accuracy,temperature

rise,forces and power.

Related to tool life,surface finish,forces and power

Mechanics of chip formation :

Orthogonal cutting

Rake angle Alpha

Relief angle ( clearance angle)

Shear angle ( Pi)

Thickness of a chip Tc

Depth of cut- T0

Cutting ratio r = To / Tc

= Sin Pi / Cos ( pi- Alpha )

Mechanism of chip formation

Fig 20.4 (a) Schematic illustration of the basic mechanism of chip formation in metal

cutting. (b) Velocity diagram in the cutting zone.

Mechanism of chip formation

Chip compression ratio = 1 / r

Always > unity

On the basis of fig 20.4-a

Shear strain gama

Gama = AB/OC = AO/OC + OB/OC

Gama = Cot Pi + tan ( Pi Alpha )

Note : for actual cutting operation shear

strain > 5

Mechanism of chip formation

Shear angle adjusts itself to minimize

cutting force

Shear plane is the plane of maximum shear

stress

Pi = 45 + Alpha / 2 Beta / 2

Beta : Friction angle

Mu coefficient of friction

Mu = tan beta

Mechanism of chip formation

Mass continuity has to be maintained

So , we have

V To = Vc Tc

Vc = Vr

Vc = V Sin pi / Cos ( pi Alpha )

Vc : Velocity of a chip

V : Cutting Speed

Vs : Velocity of shearing

From trigonometric relation

V / cos ( pi Alpha ) = Vs / Cos ( Alpha ) = Vc /

Sin ( pi )

Types of chips

Continuous

Built up edge

Serrated or segmented

Discontinuous

Fig20.5 Basic types of chips and their photomicrographs produced in metal cutting (a) continuous ship

with a narrow,straight primary shear zone; (b) secondary shear zone at the chip tool interface;(c)

continuous chip with large primary shear zone; (d) continuous chip with built-up-edge;(e)

segmented or nonhomogeneous chip and (f) discontinuous chips

Continuous chips

Fig :20.6 (a) Hardness distribution in the cutting

zone for 3115 steel.Note that some regions in

the built-up edge are as mach as three times

harder than the bulk metal

(b) Surface finish in turning 5130 steel with a

built-up edge

(c) Surface finish on 1018 steel in face milling

Continuous chips are usually formed at high

rake angles and/or high cutting speeds.

A good surface finish is generally produced.

continuous chips are not always desirable,

particularly in automated machine tools,

tend to get tangled around the tool

operation has to be stopped to clear away

the chips.

Continuous chips

Built-up edges chips

BUE consists of layers of material from the

workpiece that are gradually deposited on the tool.

BUE then becomes unstable and eventually breaks up

BUE material is carried away on the tool side of the

chip

the rest is deposited randomly on the workpiece

surface.

BUE results in poor surface finish

reduced by increasing the rake angle and therefore

decreasing the depth of cut.

Discontinuous chips

Discontinuous chips consist of segments that may be

firmly or loosely attached to each other

These chips occur when machining hard brittle

materials such as cast iron.

Brittle failure takes place along the shear plane

before any tangible plastic flow occurs

Discontinuous chips will form in brittle materials at

low rake angles (large depths of cut).

Serrated chips

Figure :20.5e

Segmented chips or non-

homogeneous chips

Semi continuous chips with

zones low and high shear

strain

Low thermal conductivity and

strength metals exhibit this

behavior

Fig 20.5 (e)segmented or

nonhomogeneous chip and

Chip Breakers

Long continuous chip

are undesirable

Chip breaker is a piece

of metal clamped to the

rake surface of the tool

which bends the chip

and breaks it

Chips can also be broken

by changing the tool

geometry,thereby

controlling the chip flow

Fig 20.7 (a) Schematic illustration of the action of

a chip breaker .(b) Chip breaker clamped on

the rake of a cutting tool. (c) Grooves in

cutting tools acting as chip breakers

Chip Breakers

Fig:Various chips produced in turning: a)tightly curled chip b)chip hits workpiece

and breaks c)continuous chip moving away from workpiece;and d)chip hits tool

shank and breaks off

Chip Formation in Nonmetallic Materials

Fig: a) cutting with an oblique tool b) Top view showing the inclination angle, i.

c) Types of chips produced with different inclination

Mechanism of Oblique Cutting

The cutting edge is at an angle i, called inclination angle.

The chip movement is in lateral direction

Fig: a)right hand cutting tool.Although these tools have traditionally been produced

from solids tool-steel bars,they have been largely replaced by carbide or other inserts

of various shapes and sizes,as shownin b).The vcarious angles on these tools and

their effects on machining are described

Temperature In Cutting

Fig:Typical temperature distribution

in the cutting zone.

Fig:Percentage of the heat generated in

cutting going into the workpiece,tool,and

chip,as a function of cutting speed.

Temperature Distributions

Fig:Temperatures developed in turning 52100 steel: a) flank temperature

distribution;and b)tool-chip interface temperature distribution

Tool Life: Wear and Failure

1. Flank wear :It occurs

on the relief face of

the tool and the side

relief angle.

2. Crater wear:It occurs

on the rake face of the

tool.

3. Chipping :Breaking

away of a small piece

from the cutting edge

of the tool .

Fig (a) Flank and crater wear in a cutting tool.tool

moves to the left. (b) View of the rake of a

turning tool,showing nose radius R and crater

wear pattern on the rake face of the tool

c)View of the flank face of a turning

tool,sowing the average flank wear land VB

and the depth-of-cut line (wear notch)

Wear and Tool Failures: Crater wear

Fig (a) Schematic illustrations of types of wear observed on various types of cutting tools .(b)

Schematic illustrations of catastrophic tool failures.A study of the types and mechanism of

tool wear and failure is essential to the development of better tool materials

Forces acting in 2-Dimensional cutting

Fig :Forces acting on a cutting tool in a two

dimensional cutting .Note that the resultant

force,R,must be collinear to balance the

forces

Cutting forces can be

measured by using suitable

dynamometers or force

transducers mounted on the

machine tool

They can also be calculated

from the amount of power

consumption,that occurs

during cutting.

THE END

You might also like

- Rolls-Royce Core Competencies and Innovation Strategy AnalysisDocument7 pagesRolls-Royce Core Competencies and Innovation Strategy Analysisdlopes77775% (4)

- AliveDocument5 pagesAliveJesus Maury67% (3)

- Determining Punch Problems: What The Slug Can Tell YouDocument4 pagesDetermining Punch Problems: What The Slug Can Tell YouAl Engg100% (1)

- Anti-Aircraft Journal - Dec 1954Document68 pagesAnti-Aircraft Journal - Dec 1954CAP History Library100% (4)

- ch21 Fundamentals of MachiningDocument25 pagesch21 Fundamentals of MachiningBaatar Zorigt100% (1)

- Type MaterialDocument31 pagesType MaterialChristopherGunawanNo ratings yet

- Technology Ii: Industrial EngineeringDocument23 pagesTechnology Ii: Industrial EngineeringSergio Daniel Humberto Acosta SantosNo ratings yet

- Standard Milling Grade DescriptionsDocument3 pagesStandard Milling Grade DescriptionssisosamNo ratings yet

- Types of Chips in Metal CuttingDocument5 pagesTypes of Chips in Metal CuttingMUKIIBI GERALDNo ratings yet

- Die Cutting TolerancesDocument4 pagesDie Cutting TolerancesNeil LeonNo ratings yet

- Chapter-8: Advanced MachiningDocument7 pagesChapter-8: Advanced MachiningAniruddha Bartakke100% (1)

- Amity University Rajasthan: " Rico Auto Industries PVT Ltd. "Document21 pagesAmity University Rajasthan: " Rico Auto Industries PVT Ltd. "Aman SinhaNo ratings yet

- Production Technology-I Unit No. 1: Cutting ToolDocument15 pagesProduction Technology-I Unit No. 1: Cutting ToolPankaj ChhabraNo ratings yet

- Procedures For Stud WeldignDocument4 pagesProcedures For Stud WeldignJulius KulvinskasNo ratings yet

- Advances in Cutting ToolsDocument14 pagesAdvances in Cutting ToolsLe HuynhNo ratings yet

- Full-Automatic Wafer Cone Making Machine Detail Data SheetDocument4 pagesFull-Automatic Wafer Cone Making Machine Detail Data SheetSaffih KheireddineNo ratings yet

- User Manual ATC-1000Document5 pagesUser Manual ATC-1000iamdausNo ratings yet

- Probing Cycles: Workpiece Measurement With TS Touch ProbeDocument4 pagesProbing Cycles: Workpiece Measurement With TS Touch Probeemo_waggyNo ratings yet

- Report Sheet Metal Blanking 1hhDocument28 pagesReport Sheet Metal Blanking 1hhDino DanielNo ratings yet

- Sheet Metal Best PracticesDocument11 pagesSheet Metal Best PracticesAng Tiong WeeNo ratings yet

- TOPIC 7 Blanking Sheating and TrimmingDocument19 pagesTOPIC 7 Blanking Sheating and TrimmingmouliNo ratings yet

- Press Working Operations - Sheet MetalDocument16 pagesPress Working Operations - Sheet MetalIrwan Rony100% (2)

- Sinumerik OPC DA Device DriverDocument8 pagesSinumerik OPC DA Device DriverMartinNo ratings yet

- Sheet Metal Form Vinay 1226927986919169 9Document83 pagesSheet Metal Form Vinay 1226927986919169 9Nhan LeNo ratings yet

- Inserts PDFDocument6 pagesInserts PDFvigneshwarannNo ratings yet

- Chess Pieces Manufacturing Description Part2Document10 pagesChess Pieces Manufacturing Description Part2Chanel Méndez RamírezNo ratings yet

- Dies1 2Document23 pagesDies1 2Ajay BabuNo ratings yet

- Computer Numerical Control Machine: By-Er - Ved PrakashDocument28 pagesComputer Numerical Control Machine: By-Er - Ved Prakashyogesh borseNo ratings yet

- End Mill Training Website PDFDocument64 pagesEnd Mill Training Website PDFDejan Jovanovic100% (1)

- AMT-Forming (Compatibility Mode)Document15 pagesAMT-Forming (Compatibility Mode)Abdulhmeed MutalatNo ratings yet

- Mt1 Unit 4 NotesDocument11 pagesMt1 Unit 4 Notesvelavansu100% (1)

- Metal FormingDocument49 pagesMetal FormingtejasNo ratings yet

- Metal FormingDocument6 pagesMetal FormingHarish Kumar SNo ratings yet

- FMP-302 Lecture 3 4 Lathe, Types, OperationsDocument57 pagesFMP-302 Lecture 3 4 Lathe, Types, OperationsJahangir AliNo ratings yet

- 156 180Document181 pages156 180Kurnia Adi WibowoNo ratings yet

- Engineering AbbreviationsDocument4 pagesEngineering AbbreviationsnicolapellowNo ratings yet

- Jetro AssemblyDocument7 pagesJetro Assemblykhoi84cv100% (1)

- MillingDocument38 pagesMillingsamurai7_77100% (2)

- Blanking and PiercingDocument5 pagesBlanking and PiercingPratap VeerNo ratings yet

- Cutting Tool FundamentalsDocument25 pagesCutting Tool FundamentalssatenawuNo ratings yet

- Books:: Machining Technology & MetrologyDocument8 pagesBooks:: Machining Technology & MetrologyaritraNo ratings yet

- Milling: Prepared By: Dinbandhu Singh 1Document23 pagesMilling: Prepared By: Dinbandhu Singh 1Dino SinghNo ratings yet

- 2 Grade InformationDocument17 pages2 Grade InformationAndres Alejandro RoblesNo ratings yet

- 5 PPDocument48 pages5 PPPatel NikhilNo ratings yet

- Theory of Metal CuttingDocument46 pagesTheory of Metal CuttingRaju MathewNo ratings yet

- Manufacturing of Spur Gear: Aim of The ExperimentDocument5 pagesManufacturing of Spur Gear: Aim of The ExperimentParameshwara MeenaNo ratings yet

- Lecture Slide Metrology and Inspection - PPT PDFDocument30 pagesLecture Slide Metrology and Inspection - PPT PDFEdo EdgarNo ratings yet

- Presses N Press Work 1Document15 pagesPresses N Press Work 1Sankalp BhatiyaNo ratings yet

- Cam Lab ManualDocument14 pagesCam Lab Manualelangandhi0% (1)

- Edm Wire CutDocument2 pagesEdm Wire CutRedza Rabani RosliNo ratings yet

- Machining ProcessDocument51 pagesMachining ProcessSudeepNo ratings yet

- Large Model TechniquesDocument27 pagesLarge Model TechniquesMatija RepincNo ratings yet

- Advanced CAD Practical FileDocument31 pagesAdvanced CAD Practical FileJitender KumarNo ratings yet

- Lecture 03 - Bulk-Forming Processes PDFDocument22 pagesLecture 03 - Bulk-Forming Processes PDFMohamed Galal MekawyNo ratings yet

- Lean Manufacturing: ObjectiveDocument26 pagesLean Manufacturing: Objectivegokul sNo ratings yet

- Powerpoint Presentation: Cutting Tool and MaterialDocument27 pagesPowerpoint Presentation: Cutting Tool and MaterialMayank RawatNo ratings yet

- Joining Part2Document27 pagesJoining Part2Dune StarlightNo ratings yet

- AWT Maintanace ManualDocument132 pagesAWT Maintanace ManualLawrence KellyNo ratings yet

- CNC Interface Board CM101 ManualDocument17 pagesCNC Interface Board CM101 ManualZorica SolunacNo ratings yet

- Abrasive Jet Machining (AJM)Document31 pagesAbrasive Jet Machining (AJM)Abhishek KumarNo ratings yet

- Fundamentals of Cutting: Chapter-20Document26 pagesFundamentals of Cutting: Chapter-20rameshNo ratings yet

- Fundamentals of Cutting: Chapter-20Document26 pagesFundamentals of Cutting: Chapter-20Venu Gopal AnneNo ratings yet

- Basic of Cutting ToolsDocument26 pagesBasic of Cutting Toolssiva kumarNo ratings yet

- Speed Control of BLDC Motor Using DSP: 1 4 1 JNTUH Hyderabad, India 2 JNTUH Hyderabad, IndiaDocument5 pagesSpeed Control of BLDC Motor Using DSP: 1 4 1 JNTUH Hyderabad, India 2 JNTUH Hyderabad, IndiapravnkumarNo ratings yet

- MagnetismDocument8 pagesMagnetismAdesh Partap SinghNo ratings yet

- 139-Hospital Management System - SynopsisDocument6 pages139-Hospital Management System - SynopsismcaprojectsNo ratings yet

- SLMI9CT693F2S60FDocument1 pageSLMI9CT693F2S60FСергей АлексеевичNo ratings yet

- Living ThingsDocument3 pagesLiving ThingsVanessa MasanqueNo ratings yet

- Submitted To: Dr. Sherry Dahiya Submitted By: MUSKAN (309) MBA (GEN.) - 2.4Document10 pagesSubmitted To: Dr. Sherry Dahiya Submitted By: MUSKAN (309) MBA (GEN.) - 2.4DeepakNo ratings yet

- A Quantitative Evaluation of Shame Resilience TheoryDocument2 pagesA Quantitative Evaluation of Shame Resilience TheoryDanica Rose clarinNo ratings yet

- Agile 20230208 055729503Document25 pagesAgile 20230208 055729503sravani ThummalapalliNo ratings yet

- Modul 4 - Teaching DisciplinaryDocument3 pagesModul 4 - Teaching DisciplinaryDwiarko SusantoNo ratings yet

- Lec1 PDFDocument29 pagesLec1 PDFRonald JosephNo ratings yet

- Intel SSD DCT 3 0 X User GuideDocument73 pagesIntel SSD DCT 3 0 X User GuideIman Teguh PNo ratings yet

- Febrianto Prasetyo Kresnawan: Chresnafebry@yahoo - Co.idDocument1 pageFebrianto Prasetyo Kresnawan: Chresnafebry@yahoo - Co.idAji Jayanti IndahNo ratings yet

- Variable and HypothesisDocument40 pagesVariable and HypothesisDennis AleaNo ratings yet

- Ethanol Plant DetailsDocument15 pagesEthanol Plant Detailskaran avhadNo ratings yet

- Ran19.1 Kpi Reference (Bsc6900 Based) (02) (PDF) enDocument162 pagesRan19.1 Kpi Reference (Bsc6900 Based) (02) (PDF) enhekri100% (1)

- 2 B.Tech CSE R20Document235 pages2 B.Tech CSE R20Vijayakumar KNo ratings yet

- 17 - GT2011-45243-An Aerodynamic Design Methodology For Low Pressure Axial Fans WithDocument9 pages17 - GT2011-45243-An Aerodynamic Design Methodology For Low Pressure Axial Fans WithkcpatnaikNo ratings yet

- Experiment On A BirdDocument4 pagesExperiment On A BirdaunpunnNo ratings yet

- TRS501&TRS601 - Project GuidelinesDocument3 pagesTRS501&TRS601 - Project GuidelinesHoang Trung Tin (K18 HCM)No ratings yet

- BLW Geno-Brg-CoolingDocument1 pageBLW Geno-Brg-CoolingNishan MahanamaNo ratings yet

- Indicadores Economicos Ei - 200912Document2 pagesIndicadores Economicos Ei - 200912Mari Luz Hermoza MamaniNo ratings yet

- Fuel and Emissions SystemsDocument82 pagesFuel and Emissions Systemsmkisa70100% (2)

- Artificial IntelligenceDocument10 pagesArtificial IntelligenceAYUSH PRATAP 9th 'A'No ratings yet

- Past Simple and Continuous-Scary Stories and The UnexplainedDocument7 pagesPast Simple and Continuous-Scary Stories and The UnexplainedMaría Cecilia CarattoliNo ratings yet

- Fasani Through Conduit Slab Type Bolted Bonnet ValvesDocument10 pagesFasani Through Conduit Slab Type Bolted Bonnet ValvesFrancis AlmiaNo ratings yet

- Rules and Regulation For Slogan Writing CompetitionDocument2 pagesRules and Regulation For Slogan Writing Competitionbhumibhatia0506No ratings yet

- On The Usefulness of Nothingness: A Daoist-Inspired Philosophy of Music EducationDocument15 pagesOn The Usefulness of Nothingness: A Daoist-Inspired Philosophy of Music EducationPhilip David DeYoungNo ratings yet