Professional Documents

Culture Documents

Question Bank

Question Bank

Uploaded by

Amal GeorgeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Question Bank

Question Bank

Uploaded by

Amal GeorgeCopyright:

Available Formats

Boothroyd Chapter-2 Problems 1-13, page 104-107:

1. In an orthogonal cutting test on mild steel, the following results were obtained:

Cutting force F

c

= 900 N

Thrust force F

t

= 40 N

!ncut chi" thic#ness a

c

= 0.$ mm

Chi" thic#ness a

0

= 0.% mm

&idth of cut a

w

= $.0 mm

'ength of contact between chi" and tool l

f

= 0. mm

&or#ing normal ra#e

ne

= 0 deg.

a. Calculate the mean angle of friction on the tool face .

b. Calculate the mean shear strength of the wor# material

s

.

c. Calculate the mean frictional stress

f

.

$. In an orthogonal cutting test the following conditions were noted:

&idth of chi" (width of cut) = $. mm

!ndeformed chi" thic#ness = 0.$ mm

Chi" thic#ness = 1.0 mm

&or#ing normal ra#e = * deg

Cutting force = 900 N

Thrust force = 900 N

a. Calculate the shear angle

b. Calculate the mean shear strength of the wor# material.

+. In an e,"erimental turning o"eration where low*carbon steel was being machined using a

carbide tool, the following data were obtained:

Cutting force F

c

= 1 #N

Thrust force F

t

= 0. #N

&or#ing normal ra#e

ne

= $0 deg.

-eed f = 0.141 mm

&or#ing ma.or cutting*edge angle

r

= 4 deg.

/e"th of cut (bac# engagement) a

p

= mm

Cutting s"eed v = $ m0s

Cutting ratio r

c

= 0.$

&or#"iece diameter d

w

= 100 mm

&or#"iece machined length l

w

= +00 mm.

1stimate from the abo2e date:

a. The s"ecific cutting energ3 of the wor# material p

s

.

b. The "ower re4uired for machining P

m

.

c. The undeformed chi" thic#ness a

c

.

d. The width of cut a

w

.

e. The shear angle .

f. The mean angle of friction on the tool face .

g. The time ta#en to com"lete the machining o"eration.

4. 5how that in metal cutting when the wor#ing normal ra#e is 6ero, the ratio of the shear

strength of the wor# material

s

to the s"ecific cutting energ3 p

s

is gi2en b3

$

1

1

s c

s c

r

p r

=

+

. In an orthogonal machining o"eration with a ra#e angle of deg. and an undeformed chi"

thic#ness of 1 mm, the chi" thic#ness is found to be + mm. &hat will the chi" thic#ness

be if the ra#e angle is increased to 1 deg assuming 1rnst and 7erchant8s first theor3

holds, that is, $9 : ; * <

ne

= =0$. >ssume the friction coefficient is not influenced b3

changes in ra#e angle.

?. /eri2e an e,"ression for the s"ecific cutting energ3 p

s

in terms of the shear angle 9 and

the mean shear strength of the wor# material

s

in orthogonal cutting. >ssume that the

shear*angle relationshi" of 1rnst and 7erchant a""lies, that is $9 : ; * <

ne

= =0$

%. >ssuming that the shear angle theor3 of 'ee and 5haffer a""lies, namel3 9 : ; * <

ne

=

=04, show that the s"ecific cutting energ3 p

s

will be gi2en b3

p

s

=

s

(1:cot 9 )

where

s

is the mean shear strength of the wor# material.

@. -or the orthogonal cutting of a "articular wor# material, it is found that the length of

chi"*tool contact is alwa3s e4ual to the chi" thic#ness a

c

and that the mean shear stress at

the chi"*tool interface is e4ual to the mean shear stress on the shear "lane. 5how that,

under these circumstances, the mean co*efficient of friction on the tool face A must be

e4ual to or less than 40+ and that when it is e4ual to unit3, the shear angle 9 is e4ual to

the wor#ing normal ra#e

ne

.

9. In the cutting e,"eriments using a shar" tool with 6ero ra#e, it was found that the chi"*

tool contact length was e4ual to the chi" thic#ness a

0

. It was also found that the shear

stress along the tool face was constant and was a constant "ro"ortion R of the shear

strength of the wor# material on the shear "lane.

a. /eri2e an e,"ression for the cutting force F

c

in terms of a

c

, a

w

,

s

, R and 9 .

b. /ifferentiate the e,"ression to obtain the 2alue of 9 to gi2e minimum F

c

.

10. >ssume that in an orthogonal cutting o"eration, the frictional force -f on the tool face is

gi2en b3 K

s

A

0

where K is a constant,

s

is the a""arent shear strength of the wor#

material, and A

0

is the cross*sectional area of the chi". 5how that the following

relationshi" e,ists between the mean coefficient of friction A on the tool face, the shear

angle 9, and the wor#ing normal ra#e

ne

$

cos ( )

sin( ) cos( ) 1

e

e e

n

n n

K

K

=

+

11. -or the machining of a "articular wor# material, it is found that the shear angle 9 is

alwa3s e4ual to wor#ing normal ra#e

ne

. >ssuming that the shear strength of the wor#

material in the stic#ing friction region on the tool face is the same as the shear strength

s

of the material on the shear "lane and that the length of the stic#ing region is e4ual to the

chi" thic#ness a

0

, deri2e e,"ressions for the cutting force F

c

and the thrust force F

t

in

terms of

s

,

ne

and the cross*sectional area of the uncut chi" A

c

. >lso calculate the 2alue

of

ne

for which F

t

= 0. Neglect the forces in the sliding*region on the tool face.

1$. In machining test it was found that for a "articular material the following relation a""lied:

$9 : ; * <

ne

= =0$. >lso, when the rac# angle <

ne

was $0 deg, the coefficient of friction

was 1.$.

a. &hat would the chi" thic#ness be if in a turning o"eration, the feed was 0. mm and

the ma.or cutting angle was ?0 degB

b. If the cutting force is limited to + #N and the s"ecific cutting energ3 of the material $

CD0m

+

, what ma,imum de"th of cut can be ta#enB

1+. >ssuming the in an orthogonal machining the distribution along the normal stress is

along tool ra#e face is linear, becoming ma,imum at the cutting edge and reducing to

6ero at the end of chi" tool contact length, dri2e an e,"ression for the mean coefficient of

friction A between the tool and the chi" and tool in terms of: the ma,imum normal stress

E

m

, normal stress E

0

at which real and a""arent areas of contact become e4ual, and the

coefficient of friction region A

s

.

Solved Examples rom !hosh a"d #all$% (chapter 4; page no. 195 onwards)

1. /uring orthogonal machining with a cutting tool ha2ing a 10 ra#e angle, the chi"

thic#ness is measured to be 0.4mm, the uncut chi" thic#ness being 0.1mm. /etermine

the shear "lane angle and also the magnitude of the shear strain.

$. /uring an orthogonal machining o"eration on mild steel, the results obtained are t

1

=

0.$mm, t

2

= 0.%mm, w= $.mm, 0 = , F

C

= 90N, F

T

=4%N. (i)/etermine the

coefficient of friction between the tool and the chi". (ii)/etermine the ultimate shear

stress

5

of the wor# material.

+. 7ild steel is being machined at a cutting s"eed of $00 m0min with a tool of ra#e angle

10 . The width of cut and the uncut thic#ness are $mm and 0.$mm, res"ecti2el3. If the

a2erage 2alue of the coefficient of friction between the tool and the chi" is 0. and the

shear stress

5

of the wor# material is 400 N0mm

$

, determine (i) the shear angle and (ii)

the cutting and the thrust com"onents of the machining forces.

4. -ind out the order of magnitude of the cutting com"onent of the machining force during

orthogonal machining of machining of mild steel with an uncut thic#ness of 0.$mm, the

width of cut being $.mm.

&"solved Examples rom !hosh a"d #all$% (chapter 4; page no. 282

onwards)

1. The chi"s from an orthogonal cutting o"eration with an uncut thic#ness of 0.$mm for

2arious ra#e angles are

1 10 0

t

2

0.4 0. 0.?+ 1.1+

Calculate, for each chi", the corres"onding shear angle and shear strain and "lot them

against

.

$. The cutting and the thrust com"onents of the machining force during orthogonal

machining of aluminum with a ra#e angle of 10 are found to be +1$N and 1@N,

res"ecti2el3. (i) 1stimate the coefficient of friction between the tool and the chi" (ii) If

the ra#e angle is reduced to 0 , #ee"ing all the other "arameters the same, and if the

coefficient of friction also remains unchanged, estimate the new 2alues of -

C

and -

T

,

using 7erchant8s first solution.

+. /uring orthogonal machining with a ra#e angle 10 and an uncut thic#ness 0.1$mm, the

2alues of -

C

and -

T

are found to be 1%N and $1%N, res"ecti2el3. The a2erage is also

measure and found to be 0.4+mm. 12aluate the machining constant for the wor# material.

4. &hen the ra#e angle is 6ero during orthogonal cutting, show that

$

(1 )

1

s

c

r r

U r

=

+

. /uring an orthogonal cutting test, the obser2ations made are

t

1

= 0.$ mm t

2

= 1.$ mm w = $. mm F = 0 F

c

= 900 F

r

= @10

Calculate the mean shear strength of the wor# material.

?. 1stimate the cutting com"onent of the machining force during the orthogonal machining

of aluminum allo3 with an uncut thic#ness of 0.1mm, the width of cut being $.mm.

%. > metal is being cut orthogonall3 with a tool with 6ero ra#e angle. 5how that the rate of

heat generation in the shear "lane can be e,"ressed as

(1 )

C

F r

.

You might also like

- Encyclopedia of Music in The 20th Century (PDFDrive)Document801 pagesEncyclopedia of Music in The 20th Century (PDFDrive)Petros Karatsolis100% (6)

- How To Hack Instagram Followers Ebook 2017 PDFDocument18 pagesHow To Hack Instagram Followers Ebook 2017 PDFBAKROLIYA'S Bak Bak100% (2)

- DinoGenics RulebookDocument16 pagesDinoGenics RulebookstetsonNo ratings yet

- How To Compute Tonnage Requirements in Hydraulic PressDocument2 pagesHow To Compute Tonnage Requirements in Hydraulic PressRahul KhoslaNo ratings yet

- CHAPTER - 44 Design of Riveted Joints Design of Riveted Joints Design of Riveted Joints Design of Riveted JointsDocument41 pagesCHAPTER - 44 Design of Riveted Joints Design of Riveted Joints Design of Riveted Joints Design of Riveted JointsVarshaNo ratings yet

- Milling Tech Info FormulasDocument5 pagesMilling Tech Info Formulasசிலம்பரசன் செல்வராஜ்No ratings yet

- Servo Motors: Product DataDocument52 pagesServo Motors: Product DataAnoj Pahathkumbura100% (1)

- Lista DocumentatiiDocument188 pagesLista DocumentatiiSteffyAnghelNo ratings yet

- United Nations Brundtland Report: Venn Diagram of Economic SustainabilityDocument3 pagesUnited Nations Brundtland Report: Venn Diagram of Economic SustainabilityMousumi MajumdarNo ratings yet

- Assignments 15 16Document2 pagesAssignments 15 16Mazhar3633% (3)

- HW 1 DSVDocument3 pagesHW 1 DSVAnonymous 2xjDjAcZNo ratings yet

- Assignment 1Document2 pagesAssignment 1ayushagarwal.techfestNo ratings yet

- Merchant's Circle NotsDocument5 pagesMerchant's Circle NotsSaravanan MathiNo ratings yet

- Mechanics of Metal Cutting: Tool EngineeringDocument26 pagesMechanics of Metal Cutting: Tool EngineeringChen WANYINGNo ratings yet

- Tutorial Sheet: 1 Manufacturing Science and Technology-IIDocument2 pagesTutorial Sheet: 1 Manufacturing Science and Technology-IIDeepam ShyamNo ratings yet

- ME 338 Manufacturing Processes II HW#1Document3 pagesME 338 Manufacturing Processes II HW#1jambu99No ratings yet

- Chapter Three: FUNDAMENTALS OF CUTTING PROCESS: The Common Feature Is The Use of A Cutting Tool To FormDocument12 pagesChapter Three: FUNDAMENTALS OF CUTTING PROCESS: The Common Feature Is The Use of A Cutting Tool To FormkidusNo ratings yet

- TA202 AssignmentsDocument1 pageTA202 AssignmentsBrajesh kumarNo ratings yet

- Assignment No1Document2 pagesAssignment No1Thakur Kali DassNo ratings yet

- Oxley 1961Document11 pagesOxley 1961Carlos Heyser Villanueva RomanNo ratings yet

- Theory of Metal CuttingDocument32 pagesTheory of Metal CuttingGagandeep Bhatia100% (1)

- SHEETSDocument13 pagesSHEETSXHaMzAXNo ratings yet

- U2Metal Cutting & Tool DesignDocument32 pagesU2Metal Cutting & Tool DesignVansh puriNo ratings yet

- Production EnggDocument41 pagesProduction EnggRinne UchihaNo ratings yet

- Exp 3 Effect of Speed and Feed in Orthogonal MachiningDocument2 pagesExp 3 Effect of Speed and Feed in Orthogonal MachiningYasmin RedaNo ratings yet

- DOPT AssignmentDocument6 pagesDOPT AssignmentRabindra Kumar LakraNo ratings yet

- A Hybrid Cutting Force Model For High-Speed Milling of Titanium AlloysDocument4 pagesA Hybrid Cutting Force Model For High-Speed Milling of Titanium Alloysabdsu75No ratings yet

- 2b Week 7 Pre Test AnswersDocument9 pages2b Week 7 Pre Test AnswersKhushbu KumarNo ratings yet

- Comprehensive Simulation of Surface Texture For An End-Milling ProcessDocument8 pagesComprehensive Simulation of Surface Texture For An End-Milling Processirinuca12No ratings yet

- Tutorial - Metal Removal ProcessDocument2 pagesTutorial - Metal Removal ProcessbananaNo ratings yet

- MC&TDDocument4 pagesMC&TDGopal Krishan0% (1)

- Three Dimensional Cutting Force Analysis in End MillingDocument11 pagesThree Dimensional Cutting Force Analysis in End Millingamsubra8874No ratings yet

- Chapter-4: Metal CuttingDocument24 pagesChapter-4: Metal Cuttingbhushan wandreNo ratings yet

- M. Fontaine, A. Devillez, A. Moufki, D. DudzinskiDocument14 pagesM. Fontaine, A. Devillez, A. Moufki, D. DudzinskiOscar RamónNo ratings yet

- Metal Cutting TheoryDocument8 pagesMetal Cutting TheorySheetal SoniNo ratings yet

- Assign 1 2012Document2 pagesAssign 1 2012chiru1431No ratings yet

- Metal Cutting OperationsDocument6 pagesMetal Cutting OperationsNikhil SinghNo ratings yet

- Friction in Metal CuttingDocument18 pagesFriction in Metal Cuttingaj87_goswami71% (7)

- Real Time Drill Wear Estimation Based On Spindle Motor PowerDocument7 pagesReal Time Drill Wear Estimation Based On Spindle Motor PowerNguyen Danh TuyenNo ratings yet

- CIRP Annals - Manufacturing Technology: T. O Zel, Y. Karpat, A. SrivastavaDocument4 pagesCIRP Annals - Manufacturing Technology: T. O Zel, Y. Karpat, A. SrivastavarajeshNo ratings yet

- Time 3 Hours Max. Marks: 100 : Roll No.Document2 pagesTime 3 Hours Max. Marks: 100 : Roll No.Clash GodNo ratings yet

- Orthogonal Machining PDFDocument6 pagesOrthogonal Machining PDFManideep AnanthulaNo ratings yet

- Tutorial - Mechanics - 4 Example in The LectureDocument1 pageTutorial - Mechanics - 4 Example in The LectureChen WANYINGNo ratings yet

- Tan Tan Tan : Explain Why The Cutting Force, F, Increases With Increasing Depth of Cut and Decreasing Rake Angle?Document1 pageTan Tan Tan : Explain Why The Cutting Force, F, Increases With Increasing Depth of Cut and Decreasing Rake Angle?m8bm8bm8bNo ratings yet

- Ch-2 Force & Power in Metal CuttingDocument43 pagesCh-2 Force & Power in Metal CuttingNimish JoshiNo ratings yet

- Manufacturing HW 1Document1 pageManufacturing HW 1pulkitsagarNo ratings yet

- Assignment 2Document5 pagesAssignment 2Hamlity SaintataNo ratings yet

- ME 338 Manufacturing Processes II HW#1Document3 pagesME 338 Manufacturing Processes II HW#1Aditya DaveNo ratings yet

- Machining of Metals: Fundamentals: α to the normal to theDocument1 pageMachining of Metals: Fundamentals: α to the normal to thetomica06031969No ratings yet

- 01 Fundamentals of MachiningDocument30 pages01 Fundamentals of MachiningThiraj ShanilkaNo ratings yet

- Tutorial Sheet 3Document2 pagesTutorial Sheet 3Ajay yadavNo ratings yet

- 2004-Deng-Finite Element Analysis of Effects of Ball Burnishing Parameters OnDocument6 pages2004-Deng-Finite Element Analysis of Effects of Ball Burnishing Parameters OnJesus Ismael Jimenez GarciaNo ratings yet

- Part C: Production Techniques (ME C342) Open BookDocument2 pagesPart C: Production Techniques (ME C342) Open BookpankazspamNo ratings yet

- 05 - Development of Ring Hoop Shear Test For The Mechanical Characterization of Tubular MaterialsDocument7 pages05 - Development of Ring Hoop Shear Test For The Mechanical Characterization of Tubular MaterialsAli KhalfallahNo ratings yet

- 2.2 Force, Power in Metal Cutting Q&A For StudentDocument7 pages2.2 Force, Power in Metal Cutting Q&A For StudentnikhilbathamNo ratings yet

- CH 3Document10 pagesCH 3alsltanyhasanNo ratings yet

- May 2015Document20 pagesMay 2015ManojKumar MNo ratings yet

- Chapter-1 ShavingDocument3 pagesChapter-1 ShavingNikhil PrasannaNo ratings yet

- Cutting Force Modeling and Simulation of Tee Slot MillingDocument6 pagesCutting Force Modeling and Simulation of Tee Slot MillingJing YinNo ratings yet

- Tribology International: Bikash Chandra Behera, Sudarsan Ghosh, P. Venkateswara RaoDocument13 pagesTribology International: Bikash Chandra Behera, Sudarsan Ghosh, P. Venkateswara RaoAnonymous gM6RZL5lYdNo ratings yet

- Deber 1Document15 pagesDeber 1jmgavilanes0% (1)

- Metal Forming 2Document5 pagesMetal Forming 2aksgupta24No ratings yet

- Cat 2 Ear 306Document4 pagesCat 2 Ear 306Mercy MerryNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- E Money PrototypeDocument4 pagesE Money PrototypeVishnu GuptaNo ratings yet

- Ersonal Rofile: Urriculum ItaeDocument3 pagesErsonal Rofile: Urriculum ItaeVishnu GuptaNo ratings yet

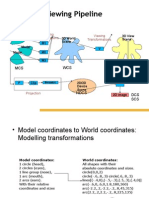

- Viewing Pipeline: Modeling Transformations Viewing TransformationsDocument14 pagesViewing Pipeline: Modeling Transformations Viewing TransformationsVishnu GuptaNo ratings yet

- Admit CardDocument1 pageAdmit CardVishnu GuptaNo ratings yet

- Syllabus of CAM LabDocument1 pageSyllabus of CAM LabVishnu GuptaNo ratings yet

- Linear Variable Differential Transformer (LVDT) : Will Bane CEE 398Document10 pagesLinear Variable Differential Transformer (LVDT) : Will Bane CEE 398Vishnu GuptaNo ratings yet

- Amity School of Engineering & Technology B. Tech (MAE), V Semester BTM 505: Microprocessor Systems Assignment 1Document1 pageAmity School of Engineering & Technology B. Tech (MAE), V Semester BTM 505: Microprocessor Systems Assignment 1Vishnu GuptaNo ratings yet

- Btech Mae All Syllabus For Amity University RajasthanDocument173 pagesBtech Mae All Syllabus For Amity University RajasthanVishnu Gupta0% (1)

- DBMS Viva QuestionsDocument4 pagesDBMS Viva QuestionsVishnu GuptaNo ratings yet

- Ipe Short Notes - SUEDocument3 pagesIpe Short Notes - SUEMunch ChiniNo ratings yet

- BT1 - Đề TADocument4 pagesBT1 - Đề TA2157011009No ratings yet

- 60092-509 - 18 1178 RVCDocument5 pages60092-509 - 18 1178 RVCNicolas150956No ratings yet

- TI BLE Vendor Specific HCI GuideDocument152 pagesTI BLE Vendor Specific HCI Guider96221029No ratings yet

- Activity 7.rizalDocument8 pagesActivity 7.rizalZia GuerreroNo ratings yet

- Illustration - 2022-02-16T110618.998Document3 pagesIllustration - 2022-02-16T110618.998mosarafNo ratings yet

- Presentation 4Document18 pagesPresentation 4Dipayan BiswasNo ratings yet

- ID Tindakan Koperasi Simpan Pinjam Yan Mengakibatkan Perbuatan Tindak PidanaDocument7 pagesID Tindakan Koperasi Simpan Pinjam Yan Mengakibatkan Perbuatan Tindak PidanaAyu Pratiwi SatriyoNo ratings yet

- Company Profile PT Samiaji Putra MandiriDocument19 pagesCompany Profile PT Samiaji Putra MandiriSkandinavia Apartment50% (2)

- East West University Presentation On Wal-Mart Course: MGT-600Document12 pagesEast West University Presentation On Wal-Mart Course: MGT-600Dipto KhanNo ratings yet

- 72 Police-Body-Cameras US StudentDocument6 pages72 Police-Body-Cameras US StudentAline ChagasNo ratings yet

- Openswitch Opx Install Guide r221Document10 pagesOpenswitch Opx Install Guide r221Ahmad WahidNo ratings yet

- HD Video Capture Box UltimateDocument12 pagesHD Video Capture Box UltimatetheMonchNo ratings yet

- Psion WOrkupDocument31 pagesPsion WOrkupRobert ShoemakeNo ratings yet

- English3am Modakirat Gen2-Unit3Document34 pagesEnglish3am Modakirat Gen2-Unit3aichaNo ratings yet

- Booking Confirmation Letter and Payment Details-41Document2 pagesBooking Confirmation Letter and Payment Details-41RAMGOPAL GUPTANo ratings yet

- Daftar Peralatan Rig #01Document4 pagesDaftar Peralatan Rig #01abel saingNo ratings yet

- Operating and Installation Instructions WasherDocument80 pagesOperating and Installation Instructions WasherSorin Ionut MoldoveanuNo ratings yet

- HP Compaq cq320 321 Inventec Villemont 2010 Intel-Uma Rev A02 SCH PDFDocument59 pagesHP Compaq cq320 321 Inventec Villemont 2010 Intel-Uma Rev A02 SCH PDFIIIkwarkaNo ratings yet

- Avkis: College of Engineering, HassanDocument2 pagesAvkis: College of Engineering, HassankiranNo ratings yet

- Adjustable Pressure Switch: Penn Commercial RefrigerationDocument3 pagesAdjustable Pressure Switch: Penn Commercial RefrigerationdungNo ratings yet

- Application To Resume Australian Citizenship: Step 1 - EligibilityDocument15 pagesApplication To Resume Australian Citizenship: Step 1 - Eligibilityulysses.carvalhoNo ratings yet

- Soal Us B Inggris 2022-2023Document8 pagesSoal Us B Inggris 2022-2023Septia AnggraeniNo ratings yet

- Emerito Ramos Vs CaDocument5 pagesEmerito Ramos Vs CaErwin BernardinoNo ratings yet