Professional Documents

Culture Documents

DC-DC Boost Converter Design Asmarashid Ponniran 2009

DC-DC Boost Converter Design Asmarashid Ponniran 2009

Uploaded by

Sigit Kurniawan0 ratings0% found this document useful (0 votes)

10 views6 pagesOriginal Title

Dc-dc Boost Converter Design Asmarashid Ponniran 2009

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views6 pagesDC-DC Boost Converter Design Asmarashid Ponniran 2009

DC-DC Boost Converter Design Asmarashid Ponniran 2009

Uploaded by

Sigit KurniawanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

DC-DC BOOST CONVERTER DESIGN FOR

SOLAR ELECTRIC SYSTEM

ASMARASHID PONNIRAN

ABDUL FATAH MAT SAID

INTERNATIONAL CONFERENCE ON

INSTRUMENTATION, CONTROL & AUTOMATION

ICA 2009

20-22 OCTOBER 2009

BANDUNG INDONESIA

International Conference on Instrumentation, Control & Automation

ICA2009

DC-DC Boost Converter Design for Solar Electric System

Asmarashi d Ponni ran , Abdul Fatah Mat Said

Faculty of Electrical and Electronic Engi neeri ng

Universiti Tun Hussei n Onn Mal aysi a

86400 Parit Raja, Batu Pahat, J ohor, MAL AY SI A

E-mai l : asmar@uthm.edu.my

Abstract

The main focus of this project is to design and construct a

DC to DC converter (boost type) which is one of the main

parts in solar electric system. Besides, to ensure that the

output voltage will be step up from 12 V to 24 V. The 12 V

input voltage is from the battery storage equipment and the

24 V output voltage will be the input of the inverter in solar

electric system. In designing process, the switching

frequency,/is set at 20 kHz and the duty cycle, D is 50%.

The tool that been used for circuits simulation and

validation are National Instrument Multisim software and

OrCAD software. Then, all the parameter values that

obtained from the hardware measurement are compared

with the calculation estimation and the circuit simulation

for validation purposes. Output of the project, 24 V

regulated DC voltage is successfully met the requirement.

1 Introduction

This project is generally about a solar electric system for

electrical appliances. Figure 1 shows the block diagram of

the solar electric system. The main concern of this project is

to design and construct a DC to DC converter which is one

of the main module in the solar electric system that shown

in Figure 1. The main idea of the DC to DC converter is

based on boost type. The purpose of the project is to

develop DC to DC converter (boost type) that converts the

unregulated DC input to a controlled DC output with

desired voltage level. The main objectives of this project

are designing and constructing a DC to DC converter (boost

type) circuit practically with input voltage, 12 V and the

output voltage, 24 V.

Photovoltaic-

Thermal (PV/T)

Module

Solar Charge

Controller

Battery -

Electric Energy

Storage

DC to DC

Converter -

BOOST

DC Load

AC Load

DC to AC

Converter

Figure 1: Block diagram of Solar Electric System

2 Desi gn Concept and Project Devel opment

The main part of this project is DC to DC converter (boost

type). This project consists of three main approaches of

development process and that are design, simulate and

construct. Figure 2 shows the flow of process in this project.

Table 1 shows parameters involved in development of DC

to DC converter (boost type).

Designing of Simulation of Constructing of

Boost Boost Boost

Figure 2: The flow of the development process

Table 1: Parameters involved in designing the boost

converter

Parameter Value Unit

Input voltage, V

s

12 V

Output voltage, V

0

24 V

Switching frequency, f 20 k Hertz

Duty cycle, D 50 %

The inductor current, I

L

2.4 Ampere

Maximum inductor current, I

L ma x 4.28 Ampere

Minimum inductor current, I

L mi n 0.52 Ampere

Ripple, r 0.025 -

2009 ICA, ISBN 978-979-8861-05-5 210

October 20-22, 2009, Bandung, Indonesia

International Conference on Instrumentation, Control & Automation

ICA2009

October 20-22, 2009, Bandung, Indonesia

I

If

VtM2

V20

rt> * o <

TF Is

0

Figure 3: The boost converter circuit design

Simulation Results

The circuit designed is simulated in National Instrument

Multisim Power Pro Edition version 10 software or OrCAD

versions 10.3 software. The designed that is simulated is

the basic DC to DC converter (boos type). The inductor

voltage and current output waveform for DC to DC

converter (boost type) based on theory is shows in Figure 4.

The inductor current output waveform that obtained from

the simulation is similar with the theoretical waveform.

The output waveform that obtained is continuous

conduction mode (CCM) which is the inductor current

value greater than zero. Figure 6 shows the inductor current

output waveform from simulation.

Figure 6: Inductor current output waveform from

simulation

Figure 7 is the combination between inductor voltage and

inductor current waveform. The waveform shows clearly

the switching process.

Figure 7: The combination of inductor voltage and

current output waveform

Figure 4: The inductor voltage and current waveform

for boost converter (theory)

For the simulation results of DC to DC converter (boost

type) that designed, the inductor voltage output waveform

from simulation is shown in Figure 5.

Figure 5: Inductor voltage output waveform from

simulation

j 1;;

i

1

i'

1 1 ' i

[ ;

!

:

i

1

| ;

1

' ' 1

1

:

i i

jl

r i i

i i: j

iai

'ill

. : ! ,

h

Figure 8: The output waveform of boost converter

circuit from simulation

Figure 8 shows the output waveform of the boost converter.

The waveform is constant at 24.350 V.

Voltage regulator part in the practical circuit

A voltage regulator is an electrical regulator designed to

automatically maintain constantly voltage level. The

maximum voltage from the battery is 13.8 V. The DC to

DC converter (boost type) is step up from 12 V to 24 V. To

2009 ICA, ISBN 978-979-8861-05-5

3 Resul t and Anal ysi s

Circuit Design

In designing process, the first thing need to be considered is

analyzing the characteristic of the critical parameters.

Figure 3 shows the circuit designed of DC to DC converter

(boost type).

Internati onal Conference on Inst rument at i on, Control & Aut omat i on

ICA2009

October 20-22, 2009, Bandung, Indonesi a

Constructing of Practical Circuit

In developing and constructing process, the practical circuit

that shows in Figure 11 is develops and construct.

w

utnmt

- V1

- 1 4 V

Figure 9: The practical circuit for voltage regulator

part

For the simulation, the input voltage is 14V and the output

voltage that obtained is 11.960 V nearly to 12V. Figure 10

shows the output voltage waveform of the voltage regulator

from the simulation process.

Figure 11: The practical circuit for DC to DC converter

(boost type)

The photograph of the hardware experimental setup is

shown on Figure 12.

tMkjiomijnv : M,j Wv -(<ai , jji rav IB*. ITj yr" >j j:

Figure 10: The voltage regulator output waveform from

simulation

Table 2 shows the comparison parameter values between

the calculation value and the simulation value.

Table 2: Comparison between calculation values with

the simulation values

No Parameter

Calculation

value

Simulation

value

1 3.75 A 3.8558 A

2 -3.75 A -3.8558 A

3 Output voltage, V

0 24 V 24.350 V

4 Inductor current, I

L

2.4 A 3.4151 A

5

Max. inductor

current, I

L m a x

4.28 A 4.4361 A

6

Min. inductor

current, I

L mi n

0.52 A 0.562 A

7 Min. inductor, L

r a i n 75 uH 80 uH

8 Ripple, r 0.03

Figure 12: Hardware experimental setup Practical DC

to DC Converter Testing and Calculation

Input and Output Voltage

Figure 13 shows the input voltage waveform from the DC

to DC converter (boost type) by the DL1620 digital

oscilloscope and Figure 14 shows the output voltage

waveform.

: K mi

AMD

zi.yit

Figure 13: The input voltage waveform from the

oscillation process

2009 ICA, ISBN 978-979-8861-05-5

212

ensure that the input voltage for the converter is always at

12 V the voltage regulator is added. Figure 9 shows the

practical circuit for the voltage regulator part.

Internati onal Conference on Instrumentati on, Control & Aut omat i on

ICA2009

October 20-22, 2009, Bandung, Indonesi a

r~. f-~. n

' AKUT

STENT> S3 SAE&U

Figure 14: The output voltage waveform from the

oscillation process

* ru.il K.JWKW rmi r G.S

BNSCCLI ft *.TJ*'

Figure 16: The PWM from pin 10 and pin 8

Table 3 shows the comparison parameter values between

the calculations, simulation and practical output values.

Table 4 shows the comparison parameter values between

the calculations, simulation and practical output values.

Table 3: Comparison between calculations, simulation

and practical output values (using DL1620 digital

oscilloscope)

No Parameter

Calculation

value

Simulation

value

Hardware

value

1

Input

voltage, V

s

12 V 12 V 12.9167 V

2

Output

voltage, V

0

24 V 24.350 V 24.5833 V

Pulse Width Modulation (PWM)

Figure 15 shows the diagram of integrated circuit (IC1

TDA2004).

+ Vs Bootstrap 1

Positive Input 1 1

Negative Input 1 2

Negative Input2 4

Positive Input 2 5

10 Output 1

8 Output 2

Ground Bootstrap 2

Figure 15: IC1 TDA 2004 diagram

Based on Figure 15, pin 10 is output 1 and pin 8 is output 2.

The output of pin 8 and pin 10 are a pulse width signals.

Figure 16 shows the PWM from pin 10 and pin 8 obtained

using DL1620 digital oscilloscopes.

Table 4: Comparison between calculations, simulation

and practical output values (using DL1620 digital

oscilloscope)

No Parameter

Calculation

value

Simulation

value

Hardware

value

1

Duty

Cycle, D

50% 50% 33.33 %

Voltage Regulator Part

Voltage regulator is used in this practical circuit to maintain

the voltage at 12 V from the charged battery that gives

maximum output voltage 13.8 V. Figure 17 shows the

output waveform form the voltage regulator. Table 5 shows

the comparison between simulation and hardware values.

2* W* ' * X> to46 61 :

N*S(CLF UMFTW

Figure 17: The voltage regulator output waveform

2009 ICA, ISBN 978-979-8861-05-5

213

Internati onal Conference on Instrumentati on, Control & Aut omat i on

ICA2009

October 20-22, 2009, Bandung, Indonesi a

Table 5: Comparison between simulation and hardware

values

No Parameter

Simulation

value

Hardware

value

1

Regulator Output

Voltage, V

0

.

r eB U

,

at or

11.960 V 12.292 V

Acknowledgement

The author would like to thank to Universiti Tun Hussein

Onn Malaysia, Malaysia for any technical supports and

assistance in the laboratory works.

References

The Operation of the Hardware

DC to DC converter (boost type)

The DC to DC converter (boost type) is able to stand by

itself. The output voltage is 24 V and the current range of 0

- 2.5 Ampere can be used to operate electrical appliances

that used brushless DC motor as a load such as PC fans,

blower, and DC ceiling fan.

4 Conclusions

DC to DC converter (boost type) is successfully developed

and constructed. The project is able to convert DC voltage,

12 V to regulated DC voltage 24 V. Table 6 shows the

comparison between hardware, simulation and calculation

estimation for several parameters.

Table 6: The different between practical and simulation

results

No Parameter

Calculation

value

Simulation

value

Oscillation

value

1

Input

voltage, Vs

12V 12V 12.9167 V

2

Output

voltage, V

0

24 V 24.350 V 24.5833 V

3

Duty

Cycle, D

50% 50% 33.33 %

[1] Muhammad H. Rashid (2003). "Power Electronics

Circuits, Devices, And Applications." 3rd. ed.

University of West Florida.: Pearson Prentice Hall.

166-224.

[2] Daniel W. hart (1997). "Introduction to Power

Electronics." Upper Saddle River, New J ersey. :

Prentice. 185-231.

[3] Alexander, K. and Sadiku, N.O. (2003) "Fundamental

of Electric Circuits." 2nd. Ed. New York. : McGraw

Hill. 555-598.

[4] Fujisawa, T. and Tani, T. (1997). "Binary Utilization

of Solar Energy with Photovoitaic-Thermal Hybrid

Collector." Solar World Congress, pp. 1-8.

[5] Mirzaei, R. and Ramanarayanan, V. (2005).

"Polyphase Boost Converter for Automotive and UPF

Applications." 1-9.

[6] David, K. and Cheng, W. (2000). "Steady-State

Analysis of an Interleaved Boost Converter with

Coupled Inductors." Transactions on Industrial

Electronics. 4. 1-9.

[7] Gurunathan, R. (2001). "ZVT Boost Converter Using

a ZCS Auxiliary Circuit." Transaction on Aerospace

and Electronics. 3. 1-9.

[8] J aycar Electronics References Data Sheet (2001).

"DC-DC Converter: A Primer."

[9] Bosanac, N. and Katie, I. (2003).

"Photovoltaic/Thermal Solar Collectors and Their

Potential in Denmark." Final Report EFP project

1713/00-0014.

2009 ICA, ISBN 978-979-8861-05-5

214

You might also like

- Electronics Explained: Fundamentals for Engineers, Technicians, and MakersFrom EverandElectronics Explained: Fundamentals for Engineers, Technicians, and MakersRating: 5 out of 5 stars5/5 (5)

- Design and Construction of Single Phase Pure Sine Wave Inverter For Photo Voltaic ApplicationDocument4 pagesDesign and Construction of Single Phase Pure Sine Wave Inverter For Photo Voltaic ApplicationRafid Haider ShantonuNo ratings yet

- ECEN 2270 CU Boulder 2013, Electronics Design Lab, Lab2, WIPDocument8 pagesECEN 2270 CU Boulder 2013, Electronics Design Lab, Lab2, WIPNunjaNo ratings yet

- Ussd Money TransferDocument4 pagesUssd Money TransfermadrasNo ratings yet

- Companies Oil Drilling.Document103 pagesCompanies Oil Drilling.figo999990% (10)

- DC-DC Voltage ConverterDocument14 pagesDC-DC Voltage ConverterasifNo ratings yet

- Three-Phase Rectifier Using A Sepic DC-DC Converter in Continuous Conduction Mode For Power Factor CorrectionDocument7 pagesThree-Phase Rectifier Using A Sepic DC-DC Converter in Continuous Conduction Mode For Power Factor CorrectionuakragunathanNo ratings yet

- Simulation and Design of Low Cost Single Phase Solar InverterDocument7 pagesSimulation and Design of Low Cost Single Phase Solar InverterAnjana VaranasiNo ratings yet

- The International Conference On Renewable Energies: "ICRE-2010"Document30 pagesThe International Conference On Renewable Energies: "ICRE-2010"M VetriselviNo ratings yet

- Analysis and Characterization of Various Current Mirror Topologies in 90 NM TechnologyDocument6 pagesAnalysis and Characterization of Various Current Mirror Topologies in 90 NM TechnologyGurinder Pal SinghNo ratings yet

- Lab Innovation Project DC DCDocument15 pagesLab Innovation Project DC DCAyush MittalNo ratings yet

- 2011 Important PDFDocument6 pages2011 Important PDFShaheer DurraniNo ratings yet

- Group3 ExperimentNo.2Document11 pagesGroup3 ExperimentNo.2odrhey hernandezNo ratings yet

- Ec1355 Esd EceDocument31 pagesEc1355 Esd EceSenthil KumarNo ratings yet

- 23D AdvanceDocument8 pages23D AdvancePATEL SWAPNEELNo ratings yet

- Design High Gain DC-DC Boost Converter With Coupling Inductor and Simulation in PsimDocument8 pagesDesign High Gain DC-DC Boost Converter With Coupling Inductor and Simulation in PsimInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Analysis of Boost Converter Using PI Control AlgorithmsDocument3 pagesAnalysis of Boost Converter Using PI Control AlgorithmsTrương Văn TrọngNo ratings yet

- Mobile Phone Charger ReportDocument16 pagesMobile Phone Charger ReportVarun Khanna100% (3)

- Development of A Step-Up Converter For A PV System: (Elec5510 - Practical Laboratory Session 1)Document23 pagesDevelopment of A Step-Up Converter For A PV System: (Elec5510 - Practical Laboratory Session 1)oopeoluwa_1No ratings yet

- Digital Object Counter Using MicrocontrollerDocument60 pagesDigital Object Counter Using MicrocontrollerKishan Amara82% (22)

- Statcp, XdsadsadsadasasdsadsadsadsadsadsadsadDocument6 pagesStatcp, Xdsadsadsadasasdsadsadsadsadsadsadsadrathorsumit2006No ratings yet

- Analysis of A D-Statcom in A 25 KV Power Distribution System Using Simulink-193Document9 pagesAnalysis of A D-Statcom in A 25 KV Power Distribution System Using Simulink-193Anshik BansalNo ratings yet

- Design Cicuit Power Electronic by PSIMDocument14 pagesDesign Cicuit Power Electronic by PSIMTrương Văn TrọngNo ratings yet

- Buck Converter SimulinkDocument6 pagesBuck Converter SimulinkfrankersinatNo ratings yet

- Digital Laboratory Power SupplyDocument5 pagesDigital Laboratory Power SupplyKishore CkNo ratings yet

- Solar PV CellDocument4 pagesSolar PV CellSumit Kumar Singh RajputNo ratings yet

- Experiment 2: Weerasinghe D.A.P 201939070011 E.E.ADocument10 pagesExperiment 2: Weerasinghe D.A.P 201939070011 E.E.AkamalNo ratings yet

- Modelling and Simulation of High Step Up DC To AC Converter For Microsource ApplicationDocument5 pagesModelling and Simulation of High Step Up DC To AC Converter For Microsource ApplicationtheijesNo ratings yet

- DSP Based Real Time Implementation of AC-DC-AC Converter Using SPWM TechniqueDocument18 pagesDSP Based Real Time Implementation of AC-DC-AC Converter Using SPWM Techniquebalamurugan041992No ratings yet

- Microcontroller-Based Boost ConverterDocument10 pagesMicrocontroller-Based Boost ConverterDevendra DwivdiNo ratings yet

- 9-Level Trinary DC Source Inverter Using Embedded ControllerDocument6 pages9-Level Trinary DC Source Inverter Using Embedded ControllerIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- 9.mohamed Ezzat - Final PaperDocument12 pages9.mohamed Ezzat - Final PaperiisteNo ratings yet

- Syllignakis J. Et AlDocument14 pagesSyllignakis J. Et Alali ghalibNo ratings yet

- Microcontrollers ApplicationDocument7 pagesMicrocontrollers Applicationer_ravi5No ratings yet

- 10 11648 J Se 20180602 11 PDFDocument10 pages10 11648 J Se 20180602 11 PDFSyed Zain BukhariNo ratings yet

- Design of A Solar Powered Battery Charger: Ke Liu, Member IEEE, and John Makaran, Member, IEEEDocument5 pagesDesign of A Solar Powered Battery Charger: Ke Liu, Member IEEE, and John Makaran, Member, IEEEtinhmaixatoi2006No ratings yet

- DC DC ConvertersDocument4 pagesDC DC Convertersmurthy237No ratings yet

- Simulation Model of Single Phase PWM Inverter by Using MatlabDocument6 pagesSimulation Model of Single Phase PWM Inverter by Using Matlabnikhilrathod704No ratings yet

- App - Note - Easily - Test - DC-DC - Converters - Using - The - Keysight - DC - Power - AnalyzerDocument8 pagesApp - Note - Easily - Test - DC-DC - Converters - Using - The - Keysight - DC - Power - Analyzerarnd.popp2No ratings yet

- Design of Transformer-Less DC To AC Converter Using PWM TechniqueDocument6 pagesDesign of Transformer-Less DC To AC Converter Using PWM TechniqueHariesh WaranNo ratings yet

- CUK ConverterDocument10 pagesCUK ConverterMohd FakhriNo ratings yet

- Photovoltaic Powered DC-DC Boost Converter Based oDocument12 pagesPhotovoltaic Powered DC-DC Boost Converter Based oMeryouma LarbNo ratings yet

- Performance Analysis and Comparison of Conventional and Interleaved DC/DC Boost Converter Using MULTISMDocument10 pagesPerformance Analysis and Comparison of Conventional and Interleaved DC/DC Boost Converter Using MULTISMIam AbdiwaliNo ratings yet

- Design and Simulation of PI Control For Positive Output Triple Lift Luo ConverterDocument3 pagesDesign and Simulation of PI Control For Positive Output Triple Lift Luo ConverterIJMERNo ratings yet

- Solar Powered Simplified Multilevel InverterDocument8 pagesSolar Powered Simplified Multilevel InverterAnney RevathiNo ratings yet

- 1405 0087v1 PDFDocument18 pages1405 0087v1 PDFSteve TranNo ratings yet

- DC Ripple Current Reduction On A Single-Phase PWM Voltage-Source RectifierDocument11 pagesDC Ripple Current Reduction On A Single-Phase PWM Voltage-Source RectifierRajni YadavNo ratings yet

- Analysis, Modelling and Simulation of A Multiphase Interleaved Buck DC/DC Converter For PV ApplicationsDocument7 pagesAnalysis, Modelling and Simulation of A Multiphase Interleaved Buck DC/DC Converter For PV ApplicationsInnovative Research PublicationsNo ratings yet

- Methodology HifiDocument6 pagesMethodology HifikrcdewanewNo ratings yet

- Buck Boost ConverterDocument17 pagesBuck Boost Converteramohdzah100% (2)

- PE Lab 08Document4 pagesPE Lab 08Haseeb BalochNo ratings yet

- Materials and Methodology: IntrductionDocument15 pagesMaterials and Methodology: Intrductionmosub fudolNo ratings yet

- Sowparnika 8Document8 pagesSowparnika 8ulaganathanNo ratings yet

- Expt No. 1 Design of Regulated Power SupplyDocument6 pagesExpt No. 1 Design of Regulated Power Supplyrani kumarNo ratings yet

- Automaticclutch and Braking SystemDocument23 pagesAutomaticclutch and Braking SystemStartechnico TechnocratsNo ratings yet

- A Closed Loop Control Strategy of Transformer-Less Buck-Boost Converter With PID ControllerDocument7 pagesA Closed Loop Control Strategy of Transformer-Less Buck-Boost Converter With PID Controllerbhawna guptaNo ratings yet

- Proposal of Innovative Work BbeeDocument3 pagesProposal of Innovative Work BbeeAaryaveerNo ratings yet

- 2002apr08 Icd Amd Pow TacDocument9 pages2002apr08 Icd Amd Pow TacMihaela CaciumarciucNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Modern Control of DC-Based Power Systems: A Problem-Based ApproachFrom EverandModern Control of DC-Based Power Systems: A Problem-Based ApproachNo ratings yet

- Power Systems-On-Chip: Practical Aspects of DesignFrom EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

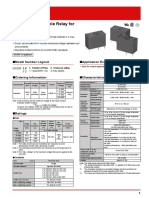

- Compact Single-Pole Relay For Switching 5 ADocument3 pagesCompact Single-Pole Relay For Switching 5 ASigit KurniawanNo ratings yet

- Fuente Step Up 1 30vDocument4 pagesFuente Step Up 1 30vSigit KurniawanNo ratings yet

- Discharge ModelDocument186 pagesDischarge ModelSigit KurniawanNo ratings yet

- Lecture 6: Random WalksDocument20 pagesLecture 6: Random WalksSigit KurniawanNo ratings yet

- TQMA70E1-5 Bayard-Alpert Pirani Gauge 720 Short Operating InstructionsDocument47 pagesTQMA70E1-5 Bayard-Alpert Pirani Gauge 720 Short Operating InstructionsSigit KurniawanNo ratings yet

- Assassin Kill AllDocument4 pagesAssassin Kill AllHưngNo ratings yet

- Freshers CVDocument2 pagesFreshers CVsalalakulaNo ratings yet

- Data Mining For Business Intelligence - Concepts, Techniques, and Applications in Microsoft Office Excel With XLMiner (Shmueli, Patel & Bruce 2010-10-26)Document12 pagesData Mining For Business Intelligence - Concepts, Techniques, and Applications in Microsoft Office Excel With XLMiner (Shmueli, Patel & Bruce 2010-10-26)Mohit OstwalNo ratings yet

- User Manual Roller Shutter FM RSH-201-T-01Document1 pageUser Manual Roller Shutter FM RSH-201-T-01Victor AsogwaNo ratings yet

- Inverter Power SocketsDocument2 pagesInverter Power SocketsrandelmacocoNo ratings yet

- CA Technologies DatasheetDocument4 pagesCA Technologies DatasheetsaothiencodenNo ratings yet

- Waukesha Gas EngineDocument2 pagesWaukesha Gas Enginepolaris44No ratings yet

- Business Heads DetailsDocument2 pagesBusiness Heads DetailsaneesgazalNo ratings yet

- GSQ-004 - Supplier Corrective Action - enDocument14 pagesGSQ-004 - Supplier Corrective Action - enbhaskar100% (1)

- Selection in HRMDocument7 pagesSelection in HRMN C Abhijith100% (5)

- Diwakar File 40Document40 pagesDiwakar File 40komalpreetdhirNo ratings yet

- mf6500 Series-PcDocument70 pagesmf6500 Series-PcsashkovichNo ratings yet

- Automation, Prouction Systems and CIM MP GROOVER CHAPTER 3 SolutionDocument7 pagesAutomation, Prouction Systems and CIM MP GROOVER CHAPTER 3 SolutionMuhammad Adeel Ahsen100% (1)

- PBL Review - PPT - 1535638001816Document12 pagesPBL Review - PPT - 1535638001816Nehal PanchalNo ratings yet

- ARMOR Catalogue 2020 - CustomerDocument60 pagesARMOR Catalogue 2020 - CustomerTony ThooNo ratings yet

- Nema Vs IPDocument1 pageNema Vs IPTamer Ahmed SalemNo ratings yet

- Ducts Pressure Losses Board: Project: SITE: Al Madinah Duct Name: Serving: (MT) General DataDocument1 pageDucts Pressure Losses Board: Project: SITE: Al Madinah Duct Name: Serving: (MT) General DataahmedNo ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Template of My Lesson Plan in PhysicsDocument6 pagesTemplate of My Lesson Plan in Physicsapi-3749101No ratings yet

- Dubai IslamicDocument8 pagesDubai IslamicAsif JavaidNo ratings yet

- Introduction To Game Theory: Matigakis ManolisDocument46 pagesIntroduction To Game Theory: Matigakis ManolisArmoha AramohaNo ratings yet

- Hps2016 SDGDocument16 pagesHps2016 SDGhh rickyNo ratings yet

- FLSL (Flare3D Layer Shader Language)Document4 pagesFLSL (Flare3D Layer Shader Language)Vasile MarinNo ratings yet

- From The Telegraph To The Digital Divide in Uganda, Kenya and TanzaniaDocument288 pagesFrom The Telegraph To The Digital Divide in Uganda, Kenya and TanzaniaRupert Brown100% (32)

- Control of Doubly-Fed Induction Machines As An Adjustable Speed Motor/GeneratorDocument4 pagesControl of Doubly-Fed Induction Machines As An Adjustable Speed Motor/GeneratorRadu BabauNo ratings yet

- ME2041-Advanced IC EnginesDocument7 pagesME2041-Advanced IC EnginesMonishSachin100% (1)

- Learn Bench India - Best Project Center in ChennaiDocument25 pagesLearn Bench India - Best Project Center in Chennailearn bench india-best project center in chennaiNo ratings yet

- Boiler Alarms ListDocument2 pagesBoiler Alarms ListCatalin SevastianNo ratings yet