Professional Documents

Culture Documents

Construction Safety Guidelines No. 11b Gas Welding & Cutting

Uploaded by

Juju Ferns0 ratings0% found this document useful (0 votes)

23 views1 pageHSE IGC

Original Title

Gl11bgaswelding&Cutting

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHSE IGC

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views1 pageConstruction Safety Guidelines No. 11b Gas Welding & Cutting

Uploaded by

Juju FernsHSE IGC

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

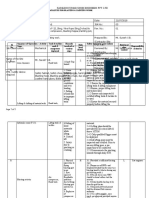

Construction Safety Guidelines No.

11b Gas Welding & Cutting

EHS/GL#11b/Rev-01 February 2010 Page 1 of 1

LOCATION OF WORK

& TROLLEY

HOTWORK PERMIT

FLASH BACK ARRESTOR,

HOSE PIPES & PRESSURE GAUGES

Keep the flammable storage

away from the gas welding &

cutting operation.

Keep & store the gas

cylinders away from the

source of heat.

Always keep the gas

cylinders vertical in a trolley

& tied with chain.

Do not lift gas trolley with

crane.

Obtain Hot work Permit from the

area supervisor & to be closed

daily.

Cordon off the area & display the

permit where welding & cutting

work is carried out.

Operations shall be shielded by

non-combustible or flameproof

screens to protect people working

in the close vicinity.

Flammable containers shall be

drained, washed, dried thoroughly

& purged with inert gas.

Ensure that Flash back arrestors

are provided on both the

cylinders.

Provide RED colour hose pipe

for Acetylene cylinder &

GREEN for Oxygen cylinder.

Hose pipes must be connected

with proper clamps.

Maintain pressure gauges in

working condition.

Torch should be kept free from

molten metal slag.

FIRE FIGHTING EQUIPMENT

& USE OF PPE

STORING GAS CYLINDERS TRAINING & FIRE WATCH

Provide appropriate fire

fighting equipment as

prescribed by the Civil

Defense.

Workers shall be protected by

suitable eye, face, hand, body,

foot & respiratory protective

equipment.

Provide adequate mechanical fume

extraction & / or forced ventilation

whenever work is not carried out in

the open air.

Gas cylinders shall be stored in a

well ventilated shed made up of

non flammable material.

Keep the valve caps in place.

Contactors shall instruct

workers in the safe means of

arc welding and cutting.

Provide fire watch for at least

an hour after completion of

welding or cutting work.

You might also like

- SMC Material Safety Data Sheet MethanolDocument9 pagesSMC Material Safety Data Sheet Methanolanand.srajuNo ratings yet

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Jsa SMDB Maintenence...Document3 pagesJsa SMDB Maintenence...ASLAM MULANINo ratings yet

- Jha Bridge Work - RomoDocument8 pagesJha Bridge Work - Romoalexander pimentel jrNo ratings yet

- Warehouse Job Hazard AssessmentDocument2 pagesWarehouse Job Hazard AssessmentAnonymous cuHV7lTNo ratings yet

- Excavaten Work PermitDocument1 pageExcavaten Work Permitasem sawalmehNo ratings yet

- Working at HeightDocument2 pagesWorking at HeightMohammed KadhimNo ratings yet

- Maintenance ProcduresDocument12 pagesMaintenance ProcduresashutoshNo ratings yet

- Safety Alert Finger PinchDocument1 pageSafety Alert Finger PinchAadil HaroonNo ratings yet

- Hot Work Procedure, WHSPRO-010 CMDocument3 pagesHot Work Procedure, WHSPRO-010 CMmyo lwinNo ratings yet

- SWP Air CompressorDocument2 pagesSWP Air Compressormyn maliQueNo ratings yet

- AttachmentDocument12 pagesAttachmentChung TrịnhNo ratings yet

- SWP 01 - Delivery, Unloading, Storage and Transferring of MaterialsDocument3 pagesSWP 01 - Delivery, Unloading, Storage and Transferring of MaterialsGerald Wong Ntt100% (1)

- Safety Plan HSDDocument110 pagesSafety Plan HSDvijayNo ratings yet

- Visitors HSES InductionDocument30 pagesVisitors HSES InductionPradeep KunduNo ratings yet

- Inspection Procedure: Grillon LanyardDocument5 pagesInspection Procedure: Grillon LanyardUlviyye ElesgerovaNo ratings yet

- H&S Meeting Minutes - TemplateDocument5 pagesH&S Meeting Minutes - TemplategrantNo ratings yet

- Aerial Lift Safety: Weekly ES&H Toolbox TalkDocument1 pageAerial Lift Safety: Weekly ES&H Toolbox TalkrjlafortezaNo ratings yet

- SOP - Stick WeldingDocument1 pageSOP - Stick WeldingMALLADI PRADEEPNo ratings yet

- Toolboxtalk2 Housekeeping PDFDocument2 pagesToolboxtalk2 Housekeeping PDFSajid HussainNo ratings yet

- JHA For Crates-Boxes With Potential Hazardous SubstancesDocument4 pagesJHA For Crates-Boxes With Potential Hazardous SubstancesTnarg RagawNo ratings yet

- Code of Practice-OHSAS 18001Document18 pagesCode of Practice-OHSAS 18001Mudassar AdilNo ratings yet

- General Safety Inspection ChecklistDocument1 pageGeneral Safety Inspection ChecklistAyşe BalamirNo ratings yet

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilNo ratings yet

- SOP For Gas Cutting Amp WeldingDocument12 pagesSOP For Gas Cutting Amp WeldingRmr ReyesNo ratings yet

- HSE Bulletin - 41 Lifting Operation 14.06.13Document1 pageHSE Bulletin - 41 Lifting Operation 14.06.13ajeet kumar singhNo ratings yet

- Ehs Policy and ProceduresDocument12 pagesEhs Policy and ProceduresAlvin James GuintoNo ratings yet

- Common Office HazardsDocument2 pagesCommon Office HazardsbosesubrataNo ratings yet

- Job Hazard Analysis: List The Tasks To Be Performed in Sequence of Execution. #Document2 pagesJob Hazard Analysis: List The Tasks To Be Performed in Sequence of Execution. #Ajay KrishnanNo ratings yet

- HSE ALERT NO. 5-Safe Working at HeightDocument1 pageHSE ALERT NO. 5-Safe Working at HeightClark Angelo JuanNo ratings yet

- OHS PROC 113 BarricadesDocument9 pagesOHS PROC 113 BarricadesPhillip L100% (1)

- Module 2Document58 pagesModule 2Jayson frederick RaymundoNo ratings yet

- Job Safety Analysis (JSA) - Night Work DateDocument2 pagesJob Safety Analysis (JSA) - Night Work Datenabeel100% (2)

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- Award and Penalty ProcedureDocument2 pagesAward and Penalty ProcedurePanchdev KumarNo ratings yet

- Safety Campaign-Working at Height Final (May-2022)Document6 pagesSafety Campaign-Working at Height Final (May-2022)HSE99 BHDC100% (1)

- Welding and Cutting SafetyDocument22 pagesWelding and Cutting SafetyyawarhassanNo ratings yet

- Job HazardDocument2 pagesJob HazardBre WirabumiNo ratings yet

- Fes TBT Housekeeping PDFDocument1 pageFes TBT Housekeeping PDFsalem enwaijiNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- Manual Handling ChartDocument20 pagesManual Handling ChartTatak Bay Ahmed100% (1)

- Risk Assessment Green Dream - HIDD AL SAADIYAT VILLA - SP4 - 58 - V1Document29 pagesRisk Assessment Green Dream - HIDD AL SAADIYAT VILLA - SP4 - 58 - V1طارق رضوانNo ratings yet

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDocument2 pagesJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiNo ratings yet

- Hira - 01Document3 pagesHira - 01Angw BasumataryNo ratings yet

- Roof Access Permit TemplateDocument2 pagesRoof Access Permit TemplateOthelloBeneventiNo ratings yet

- HousekeepingDocument10 pagesHousekeepingdinesh100% (1)

- MachineGuardingSopTech 31Document1 pageMachineGuardingSopTech 31muthuswamy77No ratings yet

- Basics of FireDocument2 pagesBasics of FireMr. XNo ratings yet

- Subin Babu - CVDocument5 pagesSubin Babu - CVJuju FernsNo ratings yet

- Officeriskassess 260109Document1 pageOfficeriskassess 260109api-330763254No ratings yet

- Working Over WaterDocument1 pageWorking Over WaterAgnes BNo ratings yet

- Jsa of Solvent Filling in VarnishesDocument3 pagesJsa of Solvent Filling in VarnishesMuhammad AliNo ratings yet

- 2018 Electrical Toolbox Talk #3 Power Lines Live WorkDocument1 page2018 Electrical Toolbox Talk #3 Power Lines Live WorkEsmatullah FarahmandNo ratings yet

- Picture of Task/equipment: Task: Name of Shop or Dept: Job Title(s) : Analyzed By: Date: Required PPEDocument2 pagesPicture of Task/equipment: Task: Name of Shop or Dept: Job Title(s) : Analyzed By: Date: Required PPEArif RachmanNo ratings yet

- Confined Space Entrant Attendant Form PDFDocument2 pagesConfined Space Entrant Attendant Form PDFgkmlalNo ratings yet

- Compounding Building: Incident / Accident Closeout FormDocument2 pagesCompounding Building: Incident / Accident Closeout FormKiran ChenchalaNo ratings yet

- Safety Data Sheet: ARDROX 907PB AerosolDocument11 pagesSafety Data Sheet: ARDROX 907PB Aerosolabdulbaset alselwi100% (1)

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- Theme Based Safety Discussion (TBT) For Manual Grinding OperationDocument3 pagesTheme Based Safety Discussion (TBT) For Manual Grinding OperationMr. XNo ratings yet

- Welding and Cutting InstructionDocument2 pagesWelding and Cutting InstructioncaptaincadenaNo ratings yet

- How Does Electricity WorkDocument15 pagesHow Does Electricity WorkJuju FernsNo ratings yet

- ZB - 02 - Suspension TraumaDocument10 pagesZB - 02 - Suspension TraumaJuju FernsNo ratings yet

- BitLocker Recovery Key 8AABD40C A56C 440D B10D 123305DF1122Document1 pageBitLocker Recovery Key 8AABD40C A56C 440D B10D 123305DF1122MuhammadKhalidNo ratings yet

- Downloaded FromDocument2 pagesDownloaded FromDuzzysNo ratings yet

- Sanitaryware CatalogueDocument40 pagesSanitaryware CatalogueJuju FernsNo ratings yet

- Texting and Driving Safety PresentationDocument19 pagesTexting and Driving Safety PresentationJuju Ferns100% (1)

- Downloaded From WWW - ETTV.tvDocument1 pageDownloaded From WWW - ETTV.tvJuju FernsNo ratings yet

- Aam Aadmi Series 5Document16 pagesAam Aadmi Series 5Deepak SharmaNo ratings yet

- PLOT NO. 2 - Ground Floor Plan (2781 SQFT)Document1 pagePLOT NO. 2 - Ground Floor Plan (2781 SQFT)Juju FernsNo ratings yet

- SOP08 Occupational Health Plan LUS HSE SP2 446 004 00Document17 pagesSOP08 Occupational Health Plan LUS HSE SP2 446 004 00Juju FernsNo ratings yet

- AlertDocument1 pageAlertJuju FernsNo ratings yet

- ETA Group - HRP031 - Exit AdministrationDocument4 pagesETA Group - HRP031 - Exit AdministrationJuju FernsNo ratings yet

- Emergency Evacuation Layout: Jerry Al Samur Development ProjectDocument1 pageEmergency Evacuation Layout: Jerry Al Samur Development ProjectRichu PaliNo ratings yet

- HGFYGYDocument1 pageHGFYGYJuju FernsNo ratings yet

- Material Safety Data Sheet: Galva Brite AerosolDocument6 pagesMaterial Safety Data Sheet: Galva Brite AerosolJuju FernsNo ratings yet

- TYGF12Document1 pageTYGF12Juju FernsNo ratings yet

- ETA Group - HRP029 - Notice Period PolicyDocument3 pagesETA Group - HRP029 - Notice Period PolicyJuju FernsNo ratings yet

- TYGF12Document1 pageTYGF12Juju FernsNo ratings yet

- TYGF12Document1 pageTYGF12Juju FernsNo ratings yet

- Dhinesh Nebosh Completed Cv-1Document4 pagesDhinesh Nebosh Completed Cv-1Juju FernsNo ratings yet

- 5025-11 - Minutes of MEP Weekly Progress Meeting No. 39 PDFDocument24 pages5025-11 - Minutes of MEP Weekly Progress Meeting No. 39 PDFJuju FernsNo ratings yet

- Scaffold Inspection Log Nos Location/Scaffolding Scaffolding Parts Caster Wheelstoe Board Guard RailDocument2 pagesScaffold Inspection Log Nos Location/Scaffolding Scaffolding Parts Caster Wheelstoe Board Guard RailJuju FernsNo ratings yet

- HSE Risk Consultant RequiredDocument1 pageHSE Risk Consultant RequiredJuju FernsNo ratings yet

- DohaDocument1 pageDohaJuju FernsNo ratings yet

- Approved Form AF 2Document1 pageApproved Form AF 2Juju FernsNo ratings yet

- GFRTDocument2 pagesGFRTJuju FernsNo ratings yet

- JojojoDocument1 pageJojojoJuju FernsNo ratings yet

- QatarDocument1 pageQatarJuju FernsNo ratings yet

- 125Document2 pages125Juju FernsNo ratings yet