Professional Documents

Culture Documents

Production Part Approval Process (PPAP) Flow Chart

Uploaded by

Anbu KannanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production Part Approval Process (PPAP) Flow Chart

Uploaded by

Anbu KannanCopyright:

Available Formats

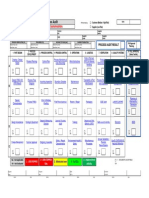

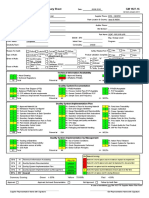

Production Part Approval Process (PPAP) Flow Chart

Identi fy PPAP

Requi rements at

APQP/Customer

Purchase Order

Fai l Safe

Update IML Tool s SO

to Inform Shi ppi ng of

Requi rements

(QA Tech)

ID Components

Requi ri ng PPAP

Ini ti ate Tracki ng

Li st

(QA Tech)

Forward Info.

Copy to

QA & Eng.

Managers

Forward Tracki ng

Li st & PO to Insp.

Component Work

Orders ID PPAP

(Eng Cl erk)

Produce Parts

& Inspect (PROD-106)

In-Process Insp.

Procedure

Rel ease Work

Order to

Manufacturi ng

Move Parts to

Inspecti on

Di mensi onal

Layout to

Numbered

Drawi ng

Contact

Engi neeri ng on

Probl em Areas

Forward

Di mensi onal

Resul ts to

QA Tech

QA Tech

Revi ews for

Accuracy and

Compl eteness

Transpose Resul ts to

Proper Document

& Match Materi al

Certs

Ini ti ate Warrant

Documentati on

(QA Manager)

Assembl e PPAP i .e..

Warrant, Mat. Cert.,

Drawi ngs,

Di m. Resul ts, Control

Pl an, Fl ow Charts,

FMEA, Gage R & R's

etc.

Make Copi es

Forward Ori gi nal

to Shi ppi ng/

Customer

Mai ntai n Copy

i n Qual i ty Fi l e

You might also like

- Ppap, R&R, MsaDocument8 pagesPpap, R&R, MsaArun SaigalNo ratings yet

- Process AuditDocument15 pagesProcess Auditdesurkarb100% (2)

- Apqp PpapDocument50 pagesApqp PpapEvandro Ribeiro50% (2)

- Production Part Approval Process PPAPDocument4 pagesProduction Part Approval Process PPAPtintucinNo ratings yet

- Production Part Approval Process (PPAP)Document3 pagesProduction Part Approval Process (PPAP)psathishthevanNo ratings yet

- Introduction To Production Part Approval Process (PPAP)Document7 pagesIntroduction To Production Part Approval Process (PPAP)VigneshNo ratings yet

- APQPDocument2 pagesAPQPRenata Codruta100% (1)

- PAPP Checklists and FormsDocument27 pagesPAPP Checklists and FormsFazal AhmedNo ratings yet

- PAPP Checklists and FormsDocument4 pagesPAPP Checklists and FormsA M100% (1)

- Turtle Diagram QMSDocument5 pagesTurtle Diagram QMSNumpetch Somsw100% (6)

- Customer Input Requirement For APQPDocument1 pageCustomer Input Requirement For APQP36hallsteveNo ratings yet

- Production Process Audit ChecklistDocument2 pagesProduction Process Audit Checklistprofmlocampo100% (5)

- GM 1927-16 PCPA ChecksheetDocument4 pagesGM 1927-16 PCPA Checksheetrahul100% (1)

- List of PPAP DocsDocument4 pagesList of PPAP DocsSunilNo ratings yet

- 1 Production Part Approval ProcessDocument42 pages1 Production Part Approval ProcessVinod Kaul100% (1)

- Tender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Document26 pagesTender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Hamza ShujaNo ratings yet

- Control Systems Engineer at FluorDocument36 pagesControl Systems Engineer at FluorMarvin Garcia Oliva100% (2)

- APQP - Customer Input Requirement - Ver2Document3 pagesAPQP - Customer Input Requirement - Ver236hallsteveNo ratings yet

- Production Part Approval ProcessDocument6 pagesProduction Part Approval ProcessleonardoNo ratings yet

- Turtle Diagrams - IATF - 16949 - 2016Document8 pagesTurtle Diagrams - IATF - 16949 - 2016Sathyaprakash Hs100% (1)

- Turtle Diagram - R & DDocument2 pagesTurtle Diagram - R & Dabdelmutalab100% (5)

- PPAPDocument2 pagesPPAPPrasad K Nagarajaiah100% (1)

- Configuration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingFrom EverandConfiguration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingNo ratings yet

- BMC Control-M 7: A Journey from Traditional Batch Scheduling to Workload AutomationFrom EverandBMC Control-M 7: A Journey from Traditional Batch Scheduling to Workload AutomationNo ratings yet

- Aqp Flow FmeaDocument2 pagesAqp Flow FmeaqmsnorthNo ratings yet

- Purified Water DOCUMENTATION: S.No. Name of Document Full FormDocument34 pagesPurified Water DOCUMENTATION: S.No. Name of Document Full FormMulayam Singh Yadav100% (1)

- Design Process TurtleDocument2 pagesDesign Process TurtleBAlaNo ratings yet

- Why Perform Production Part Approval Process (PPAP)Document6 pagesWhy Perform Production Part Approval Process (PPAP)Sourabh Patil100% (1)

- NPI ChecklistDocument11 pagesNPI ChecklistMaria CruzNo ratings yet

- PPAPDocument7 pagesPPAPsunnysunsationNo ratings yet

- Pass Through CharacteristicsDocument10 pagesPass Through CharacteristicsmirosekNo ratings yet

- Sudhan Ppap (Sem)Document15 pagesSudhan Ppap (Sem)sudhans029No ratings yet

- Prepared byDocument11 pagesPrepared byaboemadaldeenNo ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- Softhub ERPDocument28 pagesSofthub ERPSofthub TecNo ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- R. Praveen: Email@Document3 pagesR. Praveen: Email@Harini DossNo ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- Supplier Quality Manual: Honda Company PrincipleDocument5 pagesSupplier Quality Manual: Honda Company PrincipleMemin1970No ratings yet

- Job Quality Assurance Plan Presentation by AbbDocument28 pagesJob Quality Assurance Plan Presentation by AbbChandrakant ThakurNo ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- DocumetsDocument11 pagesDocumetsaboemadaldeenNo ratings yet

- Safari - 7:03 CH, Ngày 4 THG 1, 2022Document1 pageSafari - 7:03 CH, Ngày 4 THG 1, 2022ghhgNo ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- RGBSI PPAP 101 Whitepaper 2020Document11 pagesRGBSI PPAP 101 Whitepaper 2020Rajesh GhoshNo ratings yet

- SD Sales Planning: Basic DataDocument2 pagesSD Sales Planning: Basic Datamayur_lanjewarNo ratings yet

- DocumetsDocument11 pagesDocumetsaboemadaldeenNo ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- F1021 PPAP Check List Instructions 04JN18Document9 pagesF1021 PPAP Check List Instructions 04JN18Sharmad TamhaneNo ratings yet

- Prepared byDocument12 pagesPrepared byaboemadaldeenNo ratings yet

- PPAP IV Edition TrainingDocument38 pagesPPAP IV Edition Trainingshariq warsi100% (1)

- QAF-080 Supplier Requirement Manual 03-20-09 Rev PDocument38 pagesQAF-080 Supplier Requirement Manual 03-20-09 Rev PJesus SanchezNo ratings yet

- Venkatesh GDocument2 pagesVenkatesh GArunanandNo ratings yet

- DocumetsDocument11 pagesDocumetsaboemadaldeenNo ratings yet