Professional Documents

Culture Documents

Bolts

Uploaded by

Anonymous YgEKXgWCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bolts

Uploaded by

Anonymous YgEKXgWCopyright:

Available Formats

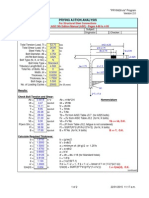

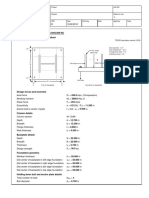

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

INPUT DATA & DESIGN SUMMARY

BOLT DIAMETER f = 0.875 in ( 7/8 in)

BOLT MATERIAL (A307, A325, A490) ASTM = A325

HOLE TYPE (STD, SSLT, SSLP, OVS, LSLP, LSLT) LSLT

STD = Standard Hole

SSLT = Short-Slotted Hole oriented transverse to the line of force

SSLP = Short-Slotted Hole oriented parallel to the line of force

OVS = Oversize Hole

LSLP = Long-Slotted Hole oriented parallel to the line of force

LSLT = Long-Slotted Hole oriented transverse to the line of force

LOADING (S=single shear,D=double shear) D

CONNECTION TYPE (SC-1, SC-2, N, X) SC-1

SC-1 = Slip-Critical Connection, slip is a serviceability limit-state 1.25

SC-2 = Slip-Critical Connection, slip is a strength limit-state

N = Bearing-Type Connection with threads included in the shear plane

X = Bearing-type connection with threads excluded from the shear plane

PLATE THICKNESS t

1

= 1 in

PLATE YIELD STRESS F

y

= 36 ksi

PLATE TENSILE STRENGTH (58, 65) F

u

= 58 ksi

NUMBER OF ROWS = > 3

NUMBER OF BOLTS / ROW = > 3 P

allowable

= 130 kips

BOLT SPACING s = 3 in

EDGE DISTANCE e = 1.25 in

ANALYSIS

MIN.THICKNESS OF SIDE PLATES t

2

= 0.5 in

PLATE WIDTH REQUIRED D = 8.50 in

Bolt f P (kips)

CHECK MIDDLE PLATE FOR SHEAR (AISC Table 7-1, 7-3, 7-4) 0.875 14.40 130

CHECK MIDDLE PLATE FOR BEARING DUE TO BOLT SPACING (AISC Table 7-5) 0.875 50.80 457

CHECK MIDDLE PLATE FOR BEARING DUE TO EDGE DISTANCE (AISC Table 7-6) 0.875 22.7 204

CHECK MIDDLE PLATE TENSION CAPACITY F

y

A

g

/ W

t

= 183 F

u

U A

n

/ W

t

= 160 <=gov 160

kips / bolt

Bolts Connection Design Based on AISC Manual 13th Edition

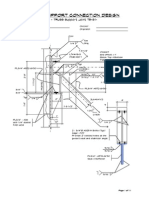

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

INPUT DATA & DESIGN SUMMARY

BOLT DIAMETER f = 0.75 in ( 3/4 in)

BOLT MATERIAL (A307, A325, A490) ASTM = A325

TOTAL NUMBER OF BOLTS n = 6

DISTANCE FROM BOLT CENTERLINE TO EDGE a = 1.778 in

DISTANCE FROM BOLT CENTERLINE TO STEM FACE b = 1.792 in

SMALLER THICKNESS OF FLANGES t = 0.695 in

LENGTH OF FLANGE TRIBUTARY TO EACH BOLT S = 4.5 in

YIELD STRENGTH OF THE FLANGE MATERIAL F

y

= 50 ksi

P

allowable

= 94.8 kips

ANALYSIS

d' = f + 1/16 = 0.813 in B = 19.9 kips / bolt, (AISC Manual 13th, Table 7-2)

b' = b - 0.5 f = 1.417 in

a' = a + 0.5 f = 2.153 in 0.819

1.001

0.790

15.8 kips / bolt, (AISC Manual 9th, Page 4-89 to 4-95)

Hanger-Type Bolts Connection Design Based on AISC Manual 13th Edition

'

8

c

y

Bb

t

SF

'

1

d

S

2

'

'

'

1

1

1

c t

t

b

a

a

2

'

2

' '

'

1 , 1

1 , 0 1

, 0

c

allow

c

t

B for

t

t

T B for

t

B for

a a

a

You might also like

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument2 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryAhmed Ben HmidaNo ratings yet

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument8 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design Summarychristian abogadoNo ratings yet

- Beam Connection of Conventional Configuration Based On AISC 360-10Document4 pagesBeam Connection of Conventional Configuration Based On AISC 360-10sushilkumarNo ratings yet

- Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionDocument3 pagesCapacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionShanoor ASNo ratings yet

- Beam ConnectionDocument1 pageBeam ConnectionLam TranNo ratings yet

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument15 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryAthar YogaNo ratings yet

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument2 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryRayodcNo ratings yet

- MOMENT EndplateDocument8 pagesMOMENT Endplatemoseslugtu6324No ratings yet

- Ocbf IbcDocument3 pagesOcbf IbcNikki RobertsNo ratings yet

- BeamSplice DESIGNDocument1 pageBeamSplice DESIGNcecastaNo ratings yet

- Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionDocument1 pageCapacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionThiha KyawNo ratings yet

- Prying Action Analysis: Input DataDocument2 pagesPrying Action Analysis: Input Datarodriguez.gaytanNo ratings yet

- Drawings of Steel Members ConnectionsDocument7 pagesDrawings of Steel Members ConnectionsHanniel MadramootooNo ratings yet

- Daniel T. Li: Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th Edition FDocument2 pagesDaniel T. Li: Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th Edition FvtalexNo ratings yet

- PRYING9 - AISC 9th ED. PRYING ACTION ANALYSIS PROGRAMDocument5 pagesPRYING9 - AISC 9th ED. PRYING ACTION ANALYSIS PROGRAMCarlos Valverde PortillaNo ratings yet

- Truss Support Connection Design T5-S1Document11 pagesTruss Support Connection Design T5-S1rajedmaglinteNo ratings yet

- Bolts ConnectionDocument3 pagesBolts Connectionrizwanjawaid.meenaNo ratings yet

- Example: Truss/post End Connection: Joint Shear ResistanceDocument8 pagesExample: Truss/post End Connection: Joint Shear ResistanceRulli RanastraNo ratings yet

- Base Plate and Blot Design-UploadDocument6 pagesBase Plate and Blot Design-UploadygguptaNo ratings yet

- Espct - Tba Ensamble Total Monobore 3k Acording With Kom 3-1-8 3k Forging Anda Part NumberDocument1 pageEspct - Tba Ensamble Total Monobore 3k Acording With Kom 3-1-8 3k Forging Anda Part NumberJeaneth HerreraNo ratings yet

- F9001 Plano Facet para ConstrucciónDocument2 pagesF9001 Plano Facet para ConstrucciónWermer Melgar GutierrezNo ratings yet

- Uplift With Moment CalculationDocument4 pagesUplift With Moment CalculationdennykvgNo ratings yet

- Base Plate Anchor Bolt DesignDocument8 pagesBase Plate Anchor Bolt DesignVivek AnandanNo ratings yet

- Hss WF Moment Conn 2.0 Final 1Document402 pagesHss WF Moment Conn 2.0 Final 1amachmouchiNo ratings yet

- "Endplmc9" - End Plate Moment Connections: Program DescriptionDocument21 pages"Endplmc9" - End Plate Moment Connections: Program DescriptionMartin Cristobal CupitayNo ratings yet

- Api 579Document22 pagesApi 579dandiar1No ratings yet

- End Plate-Splice ConnectionDocument76 pagesEnd Plate-Splice ConnectionHemant Ramesh Narkar100% (6)

- Prying ActionDocument8 pagesPrying ActionjoseherreramogollonNo ratings yet

- Line 6 Low Down Studio 110 SMDocument80 pagesLine 6 Low Down Studio 110 SMAnonymous 3VGDAHNo ratings yet

- Anchor Bolt DesignDocument1 pageAnchor Bolt Designnishant131No ratings yet

- "Baseplt9" - Steel Column Base Plate Analysis: Program DescriptionDocument7 pages"Baseplt9" - Steel Column Base Plate Analysis: Program Descriptionsivasan10006098No ratings yet

- Check of Shear Plate Bolted Connection According AISC360-05 (LRFD)Document12 pagesCheck of Shear Plate Bolted Connection According AISC360-05 (LRFD)cataiceNo ratings yet

- "Bracket13" - Bracket Plate Stress Analysis ProgramDocument7 pages"Bracket13" - Bracket Plate Stress Analysis ProgramFarid TataNo ratings yet

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliNo ratings yet

- Bracing ConnectionDocument10 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Raccordi A Inserto Forgiato PDFDocument3 pagesRaccordi A Inserto Forgiato PDFpeppino di capriNo ratings yet

- JB ScheduleDocument42 pagesJB ScheduleJagadeesan ShanmugamNo ratings yet

- Bearing Design Method BDocument38 pagesBearing Design Method BxyztaaNo ratings yet

- Composite Floor BeamDocument6 pagesComposite Floor BeamAhmed Ben Hmida50% (2)

- Connection Design For Column Above Beam, Based On AISC Manual & AISC 360-05Document1 pageConnection Design For Column Above Beam, Based On AISC Manual & AISC 360-05RayodcNo ratings yet

- Form Data TankDocument8 pagesForm Data TankYayan LesmanaNo ratings yet

- HSS Flange Plate Moment Connection - Temporary SteelDocument9 pagesHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNo ratings yet

- BASEPLT9Document27 pagesBASEPLT9Homero Silva100% (3)

- Ebf CBCDocument6 pagesEbf CBCNikki RobertsNo ratings yet

- Formulas 2010Document13 pagesFormulas 2010Camilo García0% (1)

- AISC360-05 LRFD Shear Bolted Connection CheckDocument12 pagesAISC360-05 LRFD Shear Bolted Connection CheckMario FeghaliNo ratings yet

- Casing DesignDocument49 pagesCasing DesignAmar BenAmar100% (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Pressure Vessel1Document1 pagePressure Vessel1Anonymous YgEKXgWNo ratings yet

- 11.4 Formulas For at Plates With Straight Boundaries and Constant ThicknessDocument1 page11.4 Formulas For at Plates With Straight Boundaries and Constant ThicknessAnonymous YgEKXgWNo ratings yet

- Tandard: Detail A Detail BDocument1 pageTandard: Detail A Detail BAnonymous YgEKXgWNo ratings yet

- Boat L EnergyDocument1 pageBoat L EnergyAnonymous YgEKXgWNo ratings yet

- 11.4 Formulas For at Plates With Straight Boundaries and Constant ThicknessDocument1 page11.4 Formulas For at Plates With Straight Boundaries and Constant ThicknessAnonymous YgEKXgWNo ratings yet

- Steel Connection 1Document1 pageSteel Connection 1Anonymous YgEKXgWNo ratings yet

- BLDocument1 pageBLAnonymous YgEKXgWNo ratings yet

- AISC Cheat SheetDocument4 pagesAISC Cheat SheetLaura Sophia Icaza Estrada100% (1)

- Reinforcement Basic Training: Productversion 13.1 May 2008Document1 pageReinforcement Basic Training: Productversion 13.1 May 2008Anonymous YgEKXgWNo ratings yet

- Saddle 1Document1 pageSaddle 1Anonymous YgEKXgWNo ratings yet

- dofxo G Dvvhpeodjh 3Rxwuh3Rxwuh Sodwlqh G DerxwDocument1 pagedofxo G Dvvhpeodjh 3Rxwuh3Rxwuh Sodwlqh G DerxwAnonymous YgEKXgWNo ratings yet

- Company Document Identification Owner Document Identification Validity Status Revisi On #Sheet of SheetsDocument1 pageCompany Document Identification Owner Document Identification Validity Status Revisi On #Sheet of SheetsAnonymous YgEKXgWNo ratings yet

- © 2008 Tekla Corporation and Its Licensors. All Rights ReservedDocument1 page© 2008 Tekla Corporation and Its Licensors. All Rights ReservedAnonymous YgEKXgWNo ratings yet

- Pages de Calcul de Coffrage-4Document1 pagePages de Calcul de Coffrage-4Anonymous YgEKXgWNo ratings yet

- Annexe 04 Trap DWG Bravo Rev0Document1 pageAnnexe 04 Trap DWG Bravo Rev0Anonymous YgEKXgWNo ratings yet

- Pages de Calcul de Coffrage6Document1 pagePages de Calcul de Coffrage6Anonymous YgEKXgWNo ratings yet

- Pages de Calcul de Coffrage2Document1 pagePages de Calcul de Coffrage2Anonymous YgEKXgWNo ratings yet

- Pages de Calcul de Coffrage1Document1 pagePages de Calcul de Coffrage1Anonymous YgEKXgWNo ratings yet

- BoltsDocument2 pagesBoltsAnonymous YgEKXgWNo ratings yet

- Schema de Calcul PDFDocument1 pageSchema de Calcul PDFAnonymous YgEKXgWNo ratings yet

- Pages de Calcul de Coffrage1Document1 pagePages de Calcul de Coffrage1Anonymous YgEKXgWNo ratings yet

- Assem ExistantDocument1 pageAssem ExistantAnonymous YgEKXgWNo ratings yet

- Example Ed5Document40 pagesExample Ed5Anonymous YgEKXgWNo ratings yet

- Example E.2dDocument1 pageExample E.2dAnonymous YgEKXgWNo ratings yet

- Pages de Mechanics of MaterialsDocument1 pagePages de Mechanics of MaterialsAnonymous YgEKXgWNo ratings yet

- Pages de Mechanics of Materials-2Document1 pagePages de Mechanics of Materials-2Anonymous YgEKXgWNo ratings yet

- Example E4dDocument1 pageExample E4dAnonymous YgEKXgWNo ratings yet

- Example E.1dDocument1 pageExample E.1dAnonymous YgEKXgWNo ratings yet