Professional Documents

Culture Documents

Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design Summary

Uploaded by

RayodcOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design Summary

Uploaded by

RayodcCopyright:

Available Formats

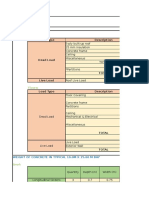

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

Bolts Connection Design Based on AISC Manual 13th Edition

INPUT DATA & DESIGN SUMMARY

BOLT DIAMETER f = 0.875 in ( 7/8 in)

BOLT MATERIAL (A307, A325, A490) ASTM = A325

HOLE TYPE (STD, SSLT, SSLP, OVS, LSLP, LSLT) LSLT

STD = Standard Hole

SSLT = Short-Slotted Hole oriented transverse to the line of force

SSLP = Short-Slotted Hole oriented parallel to the line of force

OVS = Oversize Hole

LSLP = Long-Slotted Hole oriented parallel to the line of force

LSLT = Long-Slotted Hole oriented transverse to the line of force

LOADING (S=single shear,D=double shear) D

CONNECTION TYPE (SC-1, SC-2, N, X) SC-1

SC-1 = Slip-Critical Connection, slip is a serviceability limit-state 1.25

SC-2 = Slip-Critical Connection, slip is a strength limit-state

N = Bearing-Type Connection with threads included in the shear plane

X = Bearing-type connection with threads excluded from the shear plane

PLATE THICKNESS t1 = 1 in

PLATE YIELD STRESS Fy = 36 ksi

PLATE TENSILE STRENGTH (58, 65) Fu = 58 ksi

NUMBER OF ROWS => 3

NUMBER OF BOLTS / ROW => 3 Pallowable = 130 kips

BOLT SPACING s = 3 in

EDGE DISTANCE e = 1.25 in

ANALYSIS

MIN.THICKNESS OF SIDE PLATES t2 = 0.5 in

PLATE WIDTH REQUIRED D = 8.50 in

Bolt f kips / bolt P (kips)

CHECK MIDDLE PLATE FOR SHEAR (AISC Table 7-1, 7-3, 7-4) 0.875 14.40 130

CHECK MIDDLE PLATE FOR BEARING DUE TO BOLT SPACING (AISC Table 7-5) 0.875 50.80 457

CHECK MIDDLE PLATE FOR BEARING DUE TO EDGE DISTANCE (AISC Table 7-6) 0.875 22.7 204

CHECK MIDDLE PLATE TENSION CAPACITY Fy Ag / Wt = 183 Fu U An / Wt = 160 <=gov 160

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

Hanger-Type Bolts Connection Design Based on AISC Manual 13th Edition

INPUT DATA & DESIGN SUMMARY

BOLT DIAMETER f = 0.75 in ( 3/4 in)

BOLT MATERIAL (A307, A325, A490) ASTM = A325

TOTAL NUMBER OF BOLTS n= 6

DISTANCE FROM BOLT CENTERLINE TO EDGE a= 1.778 in

DISTANCE FROM BOLT CENTERLINE TO STEM FACE b= 1.792 in

SMALLER THICKNESS OF FLANGES t= 0.695 in

LENGTH OF FLANGE TRIBUTARY TO EACH BOLT S= 4.5 in

YIELD STRENGTH OF THE FLANGE MATERIAL Fy = 50 ksi

Pallowable = 94.8 kips

ANALYSIS

d' = f + 1/16 = 0.813 in B= 19.9 kips / bolt, (AISC Manual 13th, Table 7-2)

b' = b - 0.5 f = 1.417 in '

a' = a + 0.5 f = 2.153 in 1 d 0.819

S

8 Bb ' 1.001

tc 1 t c 2

SF y 1

'

0.790

'

t

1 b '

a

t 2

B 1 , for ' 1

tc

2

t

T allow B 1 ' , for 0 ' 1 15.8 kips / bolt, (AISC Manual 9th, Page 4-89 to 4-95)

tc

B , for 0

'

You might also like

- Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16Document4 pagesMoment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16gyanwapiNo ratings yet

- Equal angle steel profiles data sheetDocument2 pagesEqual angle steel profiles data sheetGalih PutraNo ratings yet

- Material Properties:: Main Builtup Girder Flexural CheckDocument22 pagesMaterial Properties:: Main Builtup Girder Flexural CheckDipak BorsaikiaNo ratings yet

- Bolt Design & Development LengthDocument3 pagesBolt Design & Development LengthShamik ChowdhuryNo ratings yet

- Calculation of Steel PlateDocument2 pagesCalculation of Steel PlateChan Kin CheungNo ratings yet

- Seismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameDocument34 pagesSeismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameEmmanuel LazoNo ratings yet

- Pipe Support2of 5Document1 pagePipe Support2of 5Anonymous fLgaidVBhz100% (1)

- Design of Steel ColumnDocument7 pagesDesign of Steel ColumnKim Javier EstaNo ratings yet

- Dimensional Solutions Mat3DDocument69 pagesDimensional Solutions Mat3DTimothy HancockNo ratings yet

- POLEFDNDocument10 pagesPOLEFDNcoolkaisyNo ratings yet

- Strength Requirement: (1) - Pile Shear CapacityDocument4 pagesStrength Requirement: (1) - Pile Shear CapacityAlma M. LaraNo ratings yet

- Metal One Corp. Connection Data SheetDocument1 pageMetal One Corp. Connection Data SheetBalkis FatihaNo ratings yet

- ACI Beam DesignDocument1 pageACI Beam DesigndantevariasNo ratings yet

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Document5 pagesEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingNo ratings yet

- Beam Design 1Document22 pagesBeam Design 1shamen amarasekaraNo ratings yet

- Tunnel LiningDocument5 pagesTunnel Liningp_ignatiusNo ratings yet

- Concrete Shear: Tank SupportDocument12 pagesConcrete Shear: Tank SupportfostbarrNo ratings yet

- Combined FootingDocument7 pagesCombined FootingMohammed ElemamNo ratings yet

- Atasehir Gardens Podium OF: Member: LocationDocument7 pagesAtasehir Gardens Podium OF: Member: LocationAlphyl BalasabasNo ratings yet

- Unit weight (γ), angle of friction (ø) and allowable bearing pressure for different soil typesDocument5 pagesUnit weight (γ), angle of friction (ø) and allowable bearing pressure for different soil typesSuraj PantNo ratings yet

- Aashto I-Beams Section PropertiesDocument45 pagesAashto I-Beams Section PropertiesAnonymous pD2ymRUguNo ratings yet

- X Y and Partners: Steel Beam DesignDocument35 pagesX Y and Partners: Steel Beam DesignAndré SantosNo ratings yet

- Base Plate DesignDocument19 pagesBase Plate DesignLeah Ann ManuelNo ratings yet

- Reinforcement: V, F: Project: Staircase Design - STC 1Document4 pagesReinforcement: V, F: Project: Staircase Design - STC 1zzweirdozzNo ratings yet

- Foundation Design: Exhaust StackDocument4 pagesFoundation Design: Exhaust StackHugoNo ratings yet

- Hinge Connection Design: A Reference CodeDocument3 pagesHinge Connection Design: A Reference CodeGaurav BhabadNo ratings yet

- Load Calc3Document43 pagesLoad Calc3Saravanan SilambanNo ratings yet

- Chequred Plate CheckDocument2 pagesChequred Plate Check_jessecaNo ratings yet

- GratingDocument2 pagesGratingAnand3101No ratings yet

- Design of Anti Flotation BlocksDocument4 pagesDesign of Anti Flotation Blocksvishnumani3011No ratings yet

- My 2 Way Slab ExcelDocument18 pagesMy 2 Way Slab ExcelURVESHKUMAR PATELNo ratings yet

- Base Plate Design SummaryDocument3 pagesBase Plate Design SummarySơn Nguyễn-LêNo ratings yet

- Z Purlin Design Span 12 SL 0.3Document1 pageZ Purlin Design Span 12 SL 0.3arman malikNo ratings yet

- Connection design shear and tension capacityDocument1 pageConnection design shear and tension capacitySuman NakarmiNo ratings yet

- Beam TabDocument19 pagesBeam Tab45k4No ratings yet

- DN400Document32 pagesDN400ersivarajNo ratings yet

- Load Calculation CS-5Document3 pagesLoad Calculation CS-5yadav04_abhishekNo ratings yet

- Span/Eff - Depth Ratio Fs Modification Ten. Factor Modification Com. Factor Actual Span/effe - Depth Allowable Span/eff. Depth Long Span FactorDocument1 pageSpan/Eff - Depth Ratio Fs Modification Ten. Factor Modification Com. Factor Actual Span/effe - Depth Allowable Span/eff. Depth Long Span Factorshamen amarasekaraNo ratings yet

- Escaltor Cantilever Beam: Load CalculationDocument6 pagesEscaltor Cantilever Beam: Load CalculationJAYASHREEBHUVANANo ratings yet

- FND BoltDocument1 pageFND BoltArunkumar RackanNo ratings yet

- Design of Shear Connector For Composite Bending ActionDocument2 pagesDesign of Shear Connector For Composite Bending ActionankitNo ratings yet

- Cantilever SlabDocument3 pagesCantilever SlabMatiur Rahman BasumNo ratings yet

- Output: Pile Cap Beam Calculation For Most Critical Zone 1Document7 pagesOutput: Pile Cap Beam Calculation For Most Critical Zone 1Prakash Singh RawalNo ratings yet

- CC RoadDocument3 pagesCC RoadRupam ChoudhuriNo ratings yet

- RCC54 Circular Column ChartingDocument13 pagesRCC54 Circular Column Chartingbunheng lonNo ratings yet

- Punch Typ C4Document10 pagesPunch Typ C4Suhail AhamedNo ratings yet

- Name of Work:-: M /sec M /sec M /sec M /sec M /sec M /sec M /secDocument9 pagesName of Work:-: M /sec M /sec M /sec M /sec M /sec M /sec M /secChauhan UjjvalNo ratings yet

- Rev G Connection-Double AngleDocument12 pagesRev G Connection-Double AnglePankaj_Taneja_9684No ratings yet

- Solid MOdel - Beam DesignDocument31 pagesSolid MOdel - Beam Designblisscutest beagleNo ratings yet

- WALLPRES ExcavationDocument11 pagesWALLPRES ExcavationShekh Muhsen Uddin AhmedNo ratings yet

- RC Beam - CantileverDocument2 pagesRC Beam - CantilevermayphyoNo ratings yet

- Main Truss Design DetailsDocument19 pagesMain Truss Design Detailsformwork companyNo ratings yet

- Calculation of Crack Width in Accordance With EN 1992-1-1:2004 (E)Document2 pagesCalculation of Crack Width in Accordance With EN 1992-1-1:2004 (E)Yaser ShabasyNo ratings yet

- Design of ColumnDocument8 pagesDesign of ColumnAfsar MansuriNo ratings yet

- Dowel Bars at Joints / Jacketing Requirement R4Document1 pageDowel Bars at Joints / Jacketing Requirement R4Kumy engineeringNo ratings yet

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Document2 pagesEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingNo ratings yet

- Design of Pier Cap Corbel ReinforcementDocument3 pagesDesign of Pier Cap Corbel ReinforcementpsconsultantsNo ratings yet

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument8 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design Summarychristian abogadoNo ratings yet

- Bolts ConnectionDocument3 pagesBolts Connectionrizwanjawaid.meenaNo ratings yet

- Bolt capacity and plate designDocument2 pagesBolt capacity and plate designvtalexNo ratings yet

- Pile Length (Frank)Document22 pagesPile Length (Frank)RayodcNo ratings yet

- DNV CN30 7 - 2014Document151 pagesDNV CN30 7 - 2014hendry_hdwNo ratings yet

- 液压冲击式桩锤结构设计说明书Document51 pages液压冲击式桩锤结构设计说明书RayodcNo ratings yet

- 236 Floating StructuresDocument2 pages236 Floating StructuresRayodcNo ratings yet

- Engine Vibration Analysis Guidelines InProgressDocument4 pagesEngine Vibration Analysis Guidelines InProgressRayodcNo ratings yet

- In Place+Structural+Strength+and+Fatigue+Analysis+for+Floating+Platform+TopsidesDocument11 pagesIn Place+Structural+Strength+and+Fatigue+Analysis+for+Floating+Platform+TopsidesAdaya Muminah AljabarNo ratings yet

- Engineering Design Guideline Separator Vessel Rev01Document28 pagesEngineering Design Guideline Separator Vessel Rev01Yan Laksana50% (4)

- Efficient Finite Element Techniques For Limit Analysis of Suction Caissons Under Lateral Loads PDFDocument34 pagesEfficient Finite Element Techniques For Limit Analysis of Suction Caissons Under Lateral Loads PDFRayodcNo ratings yet

- Rational Upscaling of A Semi-Submersible Floating Platform Supporting A Wind Turbine PDFDocument9 pagesRational Upscaling of A Semi-Submersible Floating Platform Supporting A Wind Turbine PDFRayodcNo ratings yet

- Rational Upscaling of A Semi-Submersible Floating Platform Supporting A Wind Turbine PDFDocument9 pagesRational Upscaling of A Semi-Submersible Floating Platform Supporting A Wind Turbine PDFRayodcNo ratings yet

- A New Foundation Model For Integrated Analyses of Monopile-Based Offshore Wind TurbinesDocument8 pagesA New Foundation Model For Integrated Analyses of Monopile-Based Offshore Wind TurbinesRayodcNo ratings yet

- Rational Upscaling of A Semi-Submersible Floating Platform Supporting A Wind Turbine PDFDocument9 pagesRational Upscaling of A Semi-Submersible Floating Platform Supporting A Wind Turbine PDFRayodcNo ratings yet

- 字体目录Document60 pages字体目录RayodcNo ratings yet

- KHH951 S81HKJ Bu9p9t Ub05cf 6M9JH8 HD7TFJDocument1 pageKHH951 S81HKJ Bu9p9t Ub05cf 6M9JH8 HD7TFJRayodcNo ratings yet

- Finite Element Analysis of Suction Penetration Seepage Field of Bucket Foundation Platform With Application To Offshore Oilfield DevelopmentDocument9 pagesFinite Element Analysis of Suction Penetration Seepage Field of Bucket Foundation Platform With Application To Offshore Oilfield DevelopmentRayodcNo ratings yet

- Test On The Dynamic Response of The Offshore Wind Turbine Structure With The Large-Scale Bucket FoundationDocument8 pagesTest On The Dynamic Response of The Offshore Wind Turbine Structure With The Large-Scale Bucket FoundationRayodcNo ratings yet

- Rational Upscaling of A Semi-Submersible Floating Platform Supporting A Wind Turbine PDFDocument9 pagesRational Upscaling of A Semi-Submersible Floating Platform Supporting A Wind Turbine PDFRayodcNo ratings yet

- Determination of Plasticity Index and Compression Index of Soil at PerlisDocument5 pagesDetermination of Plasticity Index and Compression Index of Soil at PerlisRayodcNo ratings yet

- A Fully Coupled Method For Numerical Modeling and Dynamic Analysis of Floating Vertical Axis Wind TurbinesDocument43 pagesA Fully Coupled Method For Numerical Modeling and Dynamic Analysis of Floating Vertical Axis Wind TurbinesRayodcNo ratings yet

- Wang Et Al. 2014Document10 pagesWang Et Al. 2014vananhlt18No ratings yet

- Numerical Analysis of A Hybrid Substructure For 3MW Offshore Wind Turbines Due To Soil ConditionsDocument1 pageNumerical Analysis of A Hybrid Substructure For 3MW Offshore Wind Turbines Due To Soil ConditionsRayodcNo ratings yet

- Plaxis 3D Foundation TutorialDocument88 pagesPlaxis 3D Foundation Tutorialcelalunal58No ratings yet

- PLAXIS - Finite Element Code For Soil and PDFDocument2 pagesPLAXIS - Finite Element Code For Soil and PDFRayodcNo ratings yet

- Bluewhale II H1278 UDW D90 5 Outline Specification R1Document5 pagesBluewhale II H1278 UDW D90 5 Outline Specification R1RayodcNo ratings yet

- Bluewhale I H1277 UDW D90 5 Outline Specification R1Document5 pagesBluewhale I H1277 UDW D90 5 Outline Specification R1RayodcNo ratings yet

- Beacon Atlantic Short Spec R1 141118 NBDocument4 pagesBeacon Atlantic Short Spec R1 141118 NBRayodcNo ratings yet

- A Fixed Platform Topside Piping System Strength Analysis Under Dynamic PiggingSlugging LoadsDocument9 pagesA Fixed Platform Topside Piping System Strength Analysis Under Dynamic PiggingSlugging LoadsRayodcNo ratings yet

- Antenna em Modeling MatlabDocument284 pagesAntenna em Modeling MatlabMarcelo Perotoni100% (3)

- A Study of Shock Analysis Using The Finite Element Method VerifieDocument105 pagesA Study of Shock Analysis Using The Finite Element Method VerifieYasinozNo ratings yet

- A Study of Shock Analysis Using The Finite Element Method VerifieDocument105 pagesA Study of Shock Analysis Using The Finite Element Method VerifieYasinozNo ratings yet