Professional Documents

Culture Documents

Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16

Uploaded by

gyanwapiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16

Uploaded by

gyanwapiCopyright:

Available Formats

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

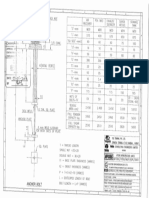

Moment Connection Design for Beam to Weak Axis Column Based on AISC 360-10/16

DESIGN CRITERIA

1. The moment load, M, is supported by top and bottom flanges, and the

vertical load, P, by beam web. But the axial load, T, may be supported

by flanges/web, or by both, so the design conservatively double

accounts that the axial load fully by both flanges and web.

2. The additional thickness of connection plates and/or shims may

be used to accommodate tolerances for fabrication.

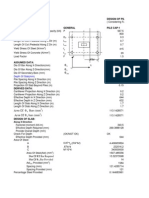

INPUT DATA & DESIGN SUMMARY

WF BEAM SECTION => W24X94

MOMENT LOAD, ASD M = 75 ft-kips

VERTICAL SERVICE LOAD, ASD P = 43 kips

HORIZONTAL TENSION LOAD, ASD T = 60 kips

PLATE THICKNESS t = 0.625 in

PLATE STEEL YIELD STRESS Fy = 50 ksi

WELD SIZE w = 0.5 in ( 1/2 in)

BOLT DIAMETER f = 1 in ( 1 in)

BOLT MATERIAL (A307, A325, A490) ASTM = A325

HOLE TYPE (STD, NSL, OVS, SSL, LSL) => STD

STD = Standard round holes ( d + 1/16 " )

NSL = Long or short-slotted hole normal to load direction

OVS = Oversize round holes

SSL = Short-slotted holes

LSL = Long-slotted holes

CONNECTION TYPE (SC, N, X) => SC

SC = Slip critical connection THE DESIGN IS ADEQUATE.

N = Bearing-type connection with threads included in the shear plane

X = Bearing-type connection with threads excluded from the shear plane

WEB BOLT NO. 2 rows & 7 bolts per row, (total 14 bolts.)

WEB PLATE EXTENDED DIMENSION a = 7.11 in

EACH FLANGE BOLT NO. 2 rows & 3 bolts per row, (total 6 bolts.)

ANALYSIS

BEAM SECTION PROPERTIES (AISC Manual Table 1) d tw tf k bf

24.3 0.515 0.875 1.38 9.07

CHECK CAPACITY OF WEB BOLTS (AISC 360 J3)

Allow shear per bolt = 11.5 kips / bolt, (Rn / Wv, AISC Manual Table 7)

(P2 + T2 )0.5 = 74 kips

No. of bolts required = 6.4 Number of bolts used = 14 bolts [Satisfactory]

Bolt spacing required = 3.00 in Bolt spacing used = 3.00 in [Satisfactory]

Edge spacing required = 1.25 in, (Tab J3.4) Edge spacing used = 1.25 in [Satisfactory]

Number of rows required = 2 rows Number of rows used = 2 rows [Satisfactory]

Bolt group capacity = 161 kips > (P2 + T2 )0.5 = 74 kips

> P = 43 kips [Satisfactory]

CHECK CAPACITY OF WEB PLATE WELDING (AISC 360 J2)

e, (including a) = 10.36 in, (AISC 360 Table J3.4)

Plate thickness = 0.63 in

Weld size,w = 0.50 in

Min allowable weld = 0.25 in [Satisfactory]

Max allowable weld = 0.56 in [Satisfactory]

te = 0.35 in

I = 2 ( te d3 / 12 ) = 845.4 in4 q= 54.3721 deg, (AISC 360 J2-5)

Vertical shear = P / A w = P / 2 d te = 2.5 ksi Du = 0.03781 in

Bending stress = 0.5 P e d / I = 6.4 ksi Dm = 0.02876 in

Tension stress = T / A w = T / 2 d te = 3.5 ksi f(p) = 1.18978 , (AISC 360 J2-9)

Resultant Stress = [ (P/Aw)2 + (0.5 P e d / I + T/Aw)2 ]0.5 = 10.2 ksi Fw = 68.2804 ksi, (AISC 360 J2-8)

Allow shear Fw / W = Fw / 2.0 = 34.1 ksi

> 10.2 ksi [Satisfactory]

CHECK WEB PLATE FLEXURE CAPACITY WITH VON-MISES REDUCTION (AISC Manual page 10-103)

D = 20.5 in

fv = [(P/A)2 + (T/A + 6Pe / tD2 )2 ]0.5 = 15.2 ksi

Fcr = (Fy2 - 3 fv2 )0.5 = 42.5 ksi

M = Pe = 37.1 ft-k < Fcr Z / W = 139.2 ft-k [Satisfactory]

CHECK WEB PLATE FOR SHEAR CAPACITY (AISC 360 G2)

P/A = 3.4 ksi < 0.6 Fy Cv / Wv = 0.6 Fy 1.0 / 1.5 = 20 ksi [Satisfactory]

(cont'd)

CHECK WEB PLATE FOR TENSION CAPACITY (AISC 360 D)

T/A= 4.7 ksi < Fy / Wt = Fy / 1.67 = 29.94 ksi [Satisfactory]

CHECK WEB NET SHEAR FRACTURE (AISC 360 J4.2)

Fu = 70 ksi ( AISC Manual Pg. 2-39)

Pallow = 0.6 Fu / W [ D - n (ds + 1/8 ) ] t = 166 kips > 43 kips [Satisfactory]

CHECK WEB NET TENSION FRACTURE (AISC 360 J4.1)

Fu = 70 ksi

Tallow = Fu / W [ D - n (ds + 1/8 ) ] t = 276 kips > 60 kips [Satisfactory]

CHECK CAPACITY OF EACH FLANGE BOLTS (AISC 360 J3)

One flange bolt group capacity = 69 kips > (M / d + 0.5 T) = 67 kips

[Satisfactory]

CHECK EACH FLANGE PLATE FOR TENSION CAPACITY (AISC 360 D)

(M / d + 0.5 T) / A = 11.83 ksi < Fy / Wt = Fy / 1.67 = 29.94 ksi [Satisfactory]

CHECK FLANGE NET SHEAR FRACTURE (AISC 360 J4.2)

Vallow = 0.6 Fu / W [ 1.5 + 3 (n - 1) - n (ds + 1/8 ) ] 2 tmin = 89 kips

> 67 kips [Satisfactory]

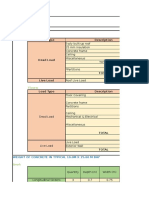

TABLE 7-1 SHEAR (AISC 13th)

NOMINAL BOLT DIAMETER, d ( in )

#REF! #REF! #REF! #REF! #REF! #REF! #REF! #REF!

ASTM 0.625 0.75 0.875 1.00 1.125 1.25 1.375 1.50

Designation Conn. Hole Fv Loading AREA BASED ON NOMINAL DIAMETER ( in^2 )

Type Type ( ksi ) 0.307 0.442 0.601 0.785 0.994 1.227 1.485 1.767

A307 - STD 12 S 3.68 5.30 7.22 9.42 11.90 14.70 17.80 21.20

- NSL D 7.36 10.60 14.40 18.80 23.90 29.50 35.60 42.40

STD S 4.29 6.33 8.81 11.50 12.70 16.00 19.20 23.30

SC D 8.59 12.70 17.60 23.10 25.30 32.10 38.40 48.60

CLASS OVS, S 3.65 5.38 7.49 9.80 10.80 13.60 16.30 19.80

A SSL D 7.30 10.80 15.00 19.60 21.50 27.30 32.70 39.60

A325 LSL S 3.01 4.43 6.17 8.07 8.86 11.20 13.40 16.30

D 6.01 8.86 12.30 16.10 17.70 22.50 26.90 32.60

N STD, 24 S 7.36 10.60 14.43 18.85 23.86 29.45 35.64 42.41

NSL D 14.73 21.21 28.86 37.70 47.71 58.90 71.28 84.82

X STD, 30 S 9.2 13.3 18.0 23.6 29.8 36.8 44.5 53.0

NSL D 18.4 26.5 36.1 47.1 59.6 73.6 89.1 106.0

STD S 5.42 7.91 11.10 14.50 18.10 23.10 27.30 33.40

SC D 10.80 15.80 22.10 28.90 36.20 46.10 54.70 66.90

CLASS OVS, S 4.61 6.72 9.41 12.30 15.40 19.60 23.20 28.40

A SSL D 9.22 13.40 18.80 24.60 30.70 39.20 46.50 56.90

A490 LSL S 3.80 5.54 7.75 10.00 12.70 16.10 19.10 23.40

D 7.59 11.10 15.50 20.20 25.30 32.30 38.30 46.80

N STD, 30 S 9.20 13.25 18.04 23.56 29.82 36.81 44.55 53.01

NSL D 18.41 26.51 36.08 47.12 59.64 73.62 89.10 106.02

X STD, 37.5 S 11.5 16.6 22.5 29.5 37.3 46.0 55.7 66.3

NSL D 23.0 33.1 45.1 58.9 74.6 92.0 111.4 132.5

TABLE 1-E. BEARING (AISC 9th)

Slip-critical and Bearing-type Connections

Fu = 58 ksi Fu = 65 ksi Fu = 70 ksi Fu = 100 ksi

Bolt Dia Bolt Dia Bolt Dia Bolt Dia

Material

Thickness 0.75 0.875 1 0.75 0.875 1 0.75 0.875 1 0.75 0.875 1

1/8 6.5 7.6 8.7 7.3 8.5 9.8 7.9 9.2 10.5 11.3 13.1 15.0

3/16 9.8 11.4 13.1 11.0 12.8 14.6 11.8 13.8 15.8 16.9 19.7 22.5

1/4 13.1 15.2 17.4 14.6 17.1 19.5 15.8 18.4 21.0 22.5 26.3 30.0

5/16 16.3 19.0 21.8 18.3 21.3 24.4 19.7 23.0 26.3 28.1 32.8 37.5

3/8 19.6 22.8 26.1 21.9 25.6 29.3 23.6 27.6 31.5 33.8 39.4 45.0

7/16 22.8 26.6 30.5 25.6 29.9 34.1 27.6 32.2 36.8 45.9 52.5

1/2 26.1 30.5 34.8 29.3 34.1 39.0 31.5 36.8 42.0 60.0

9/16 29.4 34.3 39.2 32.9 38.4 43.9 41.3 47.3

5/8 32.6 38.1 43.5 42.7 48.8 45.6 52.5

11/16 41.9 47.9 46.9 53.6 57.8

3/4 45.7 52.2 58.5

13/16 56.6

7/8 60.9

15/16

1 52.2 60.9 69.6 58.5 68.3 78.0 63.0 73.5 84.0 90.0 105.0 120.0

S = Single shear

D = Double shear

SC = Slip critical connection

N = Bearing-type connection with threads included in the shear plane

X = Bearing-type connection with threads excluded from the shear plane

STD = Standard round holes ( d + 1/16 " )

LSL = Long-slotted holes

NSL = Long or short-slotted hole normal to load direction

OVS = Oversize round holes

SSL = Short-slotted holes holes

You might also like

- Uk Drawing Jan09 PDFDocument17 pagesUk Drawing Jan09 PDFMirko Flores Jimenez100% (1)

- Wall FootingDocument1 pageWall FootingImranSohailNo ratings yet

- Design of corbel reinforcementDocument9 pagesDesign of corbel reinforcementalurabhilash1No ratings yet

- Pile Cap Design (4-Piles)Document4 pagesPile Cap Design (4-Piles)Uttam Kumar GhoshNo ratings yet

- Ghana Building Code - Part 05 PDFDocument132 pagesGhana Building Code - Part 05 PDFvasvuk100% (16)

- Boundary-Layer Theory by H. Schlichting, Seventh EditionDocument1 pageBoundary-Layer Theory by H. Schlichting, Seventh EditionColtonThomasNo ratings yet

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument2 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryRayodcNo ratings yet

- Sleeve Joint Connection Design, For Steel Cell Tower / Sign, Based On AISC 360-10 Input Data & Design SummaryDocument2 pagesSleeve Joint Connection Design, For Steel Cell Tower / Sign, Based On AISC 360-10 Input Data & Design SummaryAmey GudigarNo ratings yet

- AnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTDocument3 pagesAnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTRobert Díaz CornejoNo ratings yet

- Beam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)Document64 pagesBeam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)christian abogadoNo ratings yet

- Concrete Shear: Tank SupportDocument12 pagesConcrete Shear: Tank SupportfostbarrNo ratings yet

- Structural analysis and design of shedDocument24 pagesStructural analysis and design of shedvtalexNo ratings yet

- ASCE7 Wind For Cladding CN8 Block BDocument4 pagesASCE7 Wind For Cladding CN8 Block BCheng KoNo ratings yet

- Anchor Design for 219mm Pole SupportDocument1 pageAnchor Design for 219mm Pole SupportS A K ClostreNo ratings yet

- BasePlate 1 Check 46.8TDocument63 pagesBasePlate 1 Check 46.8TrustamriyadiNo ratings yet

- Members With Combined Bending and Axial ForceDocument32 pagesMembers With Combined Bending and Axial ForceJohn RomanusNo ratings yet

- Shear Lug Verification Example 2Document1 pageShear Lug Verification Example 2Nasrul AdliNo ratings yet

- Lateral Force For One-Story Wall Based On ASCE 7-16 & 2018 IBCDocument2 pagesLateral Force For One-Story Wall Based On ASCE 7-16 & 2018 IBCxaviernpNo ratings yet

- NDS 11.3.1 Yield Limit EquationsDocument6 pagesNDS 11.3.1 Yield Limit Equationspazz0No ratings yet

- Drilled Cast-In-Place Pile Design Based On ACI 318-19: Project: Client: Design By: Job No.: Date: Review byDocument2 pagesDrilled Cast-In-Place Pile Design Based On ACI 318-19: Project: Client: Design By: Job No.: Date: Review byafvilavilanoriegaNo ratings yet

- Design of Composite Beam With Formed Steel DeckDocument2 pagesDesign of Composite Beam With Formed Steel DeckKhắc ĐăngNo ratings yet

- FND BoltDocument1 pageFND BoltArunkumar RackanNo ratings yet

- Strength Requirement: (1) - Pile Shear CapacityDocument4 pagesStrength Requirement: (1) - Pile Shear CapacityAlma M. LaraNo ratings yet

- Foundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21Document22 pagesFoundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21BAWA ALEXNo ratings yet

- Lateral Pile Capacity Caculation Using Broms's Method (Free Head Type)Document8 pagesLateral Pile Capacity Caculation Using Broms's Method (Free Head Type)Mohammad Tawfiq WaraNo ratings yet

- Daniel Tian Li: Circular Column Design Based On ACI 318-05Document1 pageDaniel Tian Li: Circular Column Design Based On ACI 318-05OswardMorenoNo ratings yet

- Reference Output Calculations & FormulasDocument4 pagesReference Output Calculations & FormulasAddrien DanielNo ratings yet

- Aashto I-Beams Section PropertiesDocument45 pagesAashto I-Beams Section PropertiesAnonymous pD2ymRUguNo ratings yet

- POLEFDNDocument10 pagesPOLEFDNcoolkaisyNo ratings yet

- Cell K11 1 Cell K11 0.5 For F 0, For F 0Document9 pagesCell K11 1 Cell K11 0.5 For F 0, For F 0HaymanAHMEDNo ratings yet

- Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionDocument3 pagesCapacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionShanoor ASNo ratings yet

- Tunnel LiningDocument5 pagesTunnel Liningp_ignatiusNo ratings yet

- Design and reinforcement of flat slab with column strips and middle stripsDocument6 pagesDesign and reinforcement of flat slab with column strips and middle stripsJohnclaude ChamandiNo ratings yet

- Column Base Plate (Fixed Type)Document13 pagesColumn Base Plate (Fixed Type)KM YapNo ratings yet

- Shear Wall DesignDocument9 pagesShear Wall DesignrpdicNo ratings yet

- Base Plate Design SummaryDocument3 pagesBase Plate Design SummarySơn Nguyễn-LêNo ratings yet

- DESIGN FLOOR JOISTS SPECIFICATIONSDocument7 pagesDESIGN FLOOR JOISTS SPECIFICATIONSTalen Marzan-LelisNo ratings yet

- Design circular column uni-axial bi-axial load capacityDocument7 pagesDesign circular column uni-axial bi-axial load capacityDhananjay ShindeNo ratings yet

- Foundation Design As Per ACI & BowlesDocument17 pagesFoundation Design As Per ACI & BowlessivakumarNo ratings yet

- FOOTINGSDocument14 pagesFOOTINGSabb13No ratings yet

- Calculation Report - C01Document29 pagesCalculation Report - C01francis0511No ratings yet

- "Bracket13" - Bracket Plate Stress Analysis ProgramDocument7 pages"Bracket13" - Bracket Plate Stress Analysis ProgramFarid TataNo ratings yet

- Base Plate Hss2Document37 pagesBase Plate Hss2Sana UllahNo ratings yet

- 2 - 4 Gutter and Downspout Sizing and LocationDocument5 pages2 - 4 Gutter and Downspout Sizing and LocationansepachecoNo ratings yet

- Anchor Bolt Design For Portal and Connecting BridgeDocument2 pagesAnchor Bolt Design For Portal and Connecting BridgeAbhinav YadavNo ratings yet

- Anchor Bolt As Per BS CodeDocument16 pagesAnchor Bolt As Per BS Codesuvodip khanNo ratings yet

- Seismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameDocument34 pagesSeismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameEmmanuel LazoNo ratings yet

- Shear Check for 530UB82.0 Beam ProjectDocument1 pageShear Check for 530UB82.0 Beam ProjectArjun RajaNo ratings yet

- Beam TabDocument19 pagesBeam Tab45k4No ratings yet

- Design of Base Plate by EurocodeDocument13 pagesDesign of Base Plate by EurocodeBharati MajlekarNo ratings yet

- Design of Steel ColumnDocument7 pagesDesign of Steel ColumnKim Javier EstaNo ratings yet

- Axial Circular Column DesignDocument5 pagesAxial Circular Column Designkalpanaadhi100% (1)

- Pile Length Calculation in Rock Is-14593 & IRC-78-1Document2 pagesPile Length Calculation in Rock Is-14593 & IRC-78-1Gouranga MunainNo ratings yet

- CivilBay Engineering XXX Design Project Shear Connection Shear-1 PDFDocument9 pagesCivilBay Engineering XXX Design Project Shear Connection Shear-1 PDFhemantcabhaleNo ratings yet

- Concrete Beam Design, For New or Existing, Based On ACI 318-14Document2 pagesConcrete Beam Design, For New or Existing, Based On ACI 318-14JuanAlfaroRodríguezNo ratings yet

- Double Angle CapacityDocument2 pagesDouble Angle CapacityAlphaNo ratings yet

- Corbel S&TDocument4 pagesCorbel S&TrajivkannanNo ratings yet

- Bridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-14Document10 pagesBridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-14jklo12No ratings yet

- Cantilever SlabDocument3 pagesCantilever SlabMatiur Rahman BasumNo ratings yet

- Beam connection design summaryDocument1 pageBeam connection design summaryKaren Esther Acuña VelasquezNo ratings yet

- Beam ConnectionDocument3 pagesBeam ConnectionLeonardo PimentelNo ratings yet

- Beam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)Document2 pagesBeam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)Yisrael AshkenazimNo ratings yet

- Beam ConnectionDocument3 pagesBeam ConnectionMalik awanNo ratings yet

- Koc Design BasisDocument92 pagesKoc Design BasisgyanwapiNo ratings yet

- Bolt DesignDocument2 pagesBolt DesigngyanwapiNo ratings yet

- Foundation Bolts For PSA Nitrogen PlantDocument1 pageFoundation Bolts For PSA Nitrogen PlantgyanwapiNo ratings yet

- Design BasisDocument46 pagesDesign BasisgyanwapiNo ratings yet

- FounadtionDocument3 pagesFounadtiongyanwapiNo ratings yet

- Scale Model Drawing Guide with 1⁄2Document1 pageScale Model Drawing Guide with 1⁄2jh50000No ratings yet

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionfuffinoNo ratings yet

- FLRPLATEDocument3 pagesFLRPLATEcravikumar1971No ratings yet

- Email Signature Gallery TemplateDocument5 pagesEmail Signature Gallery TemplateArmagedon92No ratings yet

- Idea StaticaDocument17 pagesIdea StaticagyanwapiNo ratings yet

- Bolt Connection Design Based On AISC 360-10/16: Input Data & Design SummaryDocument1 pageBolt Connection Design Based On AISC 360-10/16: Input Data & Design SummaryKaren Esther Acuña VelasquezNo ratings yet

- Dj1 Dj2 Unb Unt Unl Ver 1.5Document2 pagesDj1 Dj2 Unb Unt Unl Ver 1.5ajayssarode100% (1)

- Dj1 Dj2 Unb Unt Unl Ver 1.5Document2 pagesDj1 Dj2 Unb Unt Unl Ver 1.5ajayssarode100% (1)

- Generate STAAD Design ParametersDocument48 pagesGenerate STAAD Design ParameterswxwmnstrNo ratings yet

- GENERAL SPECIFICATION Water SupplyDocument14 pagesGENERAL SPECIFICATION Water SupplySagar AcharyaNo ratings yet

- Manual On Sewerage and Sewage Treatment 1Document774 pagesManual On Sewerage and Sewage Treatment 1sridharnatsNo ratings yet

- QM 05. Line PipesDocument2 pagesQM 05. Line Pipesmohamed elmasryNo ratings yet

- Concept To Completion For WebsiteDocument14 pagesConcept To Completion For WebsiteAntonNo ratings yet

- Fire Performance of Timber Construction: Andrew H Buchanan University of Canterbury, Christchurch, New ZealandDocument12 pagesFire Performance of Timber Construction: Andrew H Buchanan University of Canterbury, Christchurch, New ZealandnevinkoshyNo ratings yet

- Mozambique cement plant products and materials reportDocument6 pagesMozambique cement plant products and materials reportMgn SanNo ratings yet

- Seismic Design of Industrial StructuresDocument73 pagesSeismic Design of Industrial StructuresBang Success100% (1)

- KPC Biofilter Wastewater Treatment System For Single Dwellings PDFDocument14 pagesKPC Biofilter Wastewater Treatment System For Single Dwellings PDFqbich37No ratings yet

- OCW Rigid PavementDocument25 pagesOCW Rigid PavementFung XinRuNo ratings yet

- 44 Aux. Boiler, Exh. Gas EconomizerDocument132 pages44 Aux. Boiler, Exh. Gas EconomizerKrunal TandelNo ratings yet

- Improving Concrete Containment Structures Associated With Fixed-Cone ValvesDocument49 pagesImproving Concrete Containment Structures Associated With Fixed-Cone Valvesnb_norooziNo ratings yet

- 12.turbulent Flow Jan 2015 PDFDocument12 pages12.turbulent Flow Jan 2015 PDFburhanuddinNo ratings yet

- Air conditioning systems explainedDocument33 pagesAir conditioning systems explainedJagadish SahuNo ratings yet

- Method Statement For Cast-In-Site DrianDocument8 pagesMethod Statement For Cast-In-Site Drian张文亮No ratings yet

- Chemical Analysis and Mechancial Test Certificate: Yield Strength Tensile Strength ElongationDocument1 pageChemical Analysis and Mechancial Test Certificate: Yield Strength Tensile Strength ElongationDigna Bettin CuelloNo ratings yet

- Ce591intro F10Document31 pagesCe591intro F10cart_thickNo ratings yet

- Architectural DrawingsDocument33 pagesArchitectural DrawingserniE抖音 AI Mobile Phone Based MovieNo ratings yet

- Srividya College of Engineering and Technology Lecture NotesDocument32 pagesSrividya College of Engineering and Technology Lecture NotesvanshajNo ratings yet

- Cost Estimate for Road Upgradation ProjectDocument7 pagesCost Estimate for Road Upgradation Projecthakim imtiyazNo ratings yet

- Grey Modern Professional Business Project PresentationDocument15 pagesGrey Modern Professional Business Project Presentationelectrooulhaj206No ratings yet

- Ansys/Civilfem Overview: Peterrbarrettmscepe Peter R. Barrett, M.S.C.E., P.EDocument76 pagesAnsys/Civilfem Overview: Peterrbarrettmscepe Peter R. Barrett, M.S.C.E., P.EAnkur upadhyayNo ratings yet

- IRC 78 Part-2-2020Document369 pagesIRC 78 Part-2-2020Ashisa Ranjan Jena0% (1)

- Factors Affecting Inservice Cracking of Weld Zone in Corrosive ServiceDocument6 pagesFactors Affecting Inservice Cracking of Weld Zone in Corrosive ServicesuparnaNo ratings yet

- Pedda Cheruvu Monsoorabad Park Cost EstimatesDocument97 pagesPedda Cheruvu Monsoorabad Park Cost Estimateskiran raghukiranNo ratings yet

- CMK 13 PDFDocument228 pagesCMK 13 PDFSonja DragovicNo ratings yet

- Final Draft1Document47 pagesFinal Draft1Palash KukwasNo ratings yet

- Topic:Control of Ground Water in ExcavationDocument16 pagesTopic:Control of Ground Water in Excavationashok sutharNo ratings yet