Professional Documents

Culture Documents

Heater Lowers Methanol Temp from 95C to 40C

Uploaded by

Hamdan ShdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heater Lowers Methanol Temp from 95C to 40C

Uploaded by

Hamdan ShdCopyright:

Available Formats

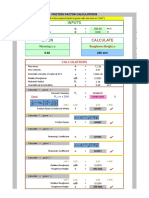

PERHITUNGAN HEATER

Fungsi : Menurunkan temperatur methanol dari 95C ke 40 C

Gambar :

Fluida dingin : coolant

T1 = 25 C =

T2 = 40 C =

k = 0.59 W/m.C

viscosity = 8.00E-01 mNs/m2

Cp rata2 = 4.2 Kj/kg.C =

density = 995 kg/m3

Fluida panas : metanol

Flowrate, W2 = 100000.0000 Kg/hr =

t1 = 95 C =

t2 = 40 C =

density = 7.50E+02 Kg/m3 =

viscosity metanol = 0.34 Ns/m2

konduktivitas termal = 0.19 W/m.C

Cp rata2 = 2.84 Kj/kg.C =

1. Beban Panas Heater

Q lepas = W.Cp.dT

Q = -15620000.0000 KJ/hr =

flow steam = Q/Cp.dt

= 68.8712522 kg/H

Flowrate, W1 = 68.8713 Kg/hr

2. LMTD

T1

= 25.00

T2

= 40.00

15.00

coolant

Suhu Tinggi

Suhu Rendah

selisih

Return bend Gland

Return Head

Gland

Gland

Tee

) / ( ln

1 2

1 2

t t

t t

D D

D - D

LMTD =

= 30.7862

C

Ft = 0.85

Dt = 26.1683

C

3. T

c

= T

avg coolant

= =

t

c

= t

avg methanol

= =

Trial, Luas Perpindahan Panas

- Asumsi UD = 610.5 W/m2.C

= 2187.1773 kj/H.m2.c

A =

A = 271.5925 m2

digunakan tipe split-ring floating head, karena efisiensinya dan kemudahan dalam

pembersihan. etanol mengalir melalui tube dan steam melalui shell

.

Tubes Sizes

id = 16 mm

od = 20 mm

L = 4.83 m

tubes pass = 2

dipilih triangular pitch, 1,25od 25 mm

pitch diameter = 1.25 in

Number of Tubes

area of one tubes, a" = L x od x 3,14

= 0.303324 m2

no. Of tubes, Nt = A/a"

= 895.3872786

=

tubes passes, n = 2

tubes per passes = Nt/n

= 447.6936393

tube cross sectional area, at = (3,14 x id^2)/4

= 0.00020096 m2

area per pass = Nt/n x at

= 0.089968514 m2

) / ( ln

1 2

1 2

t t

t t

D D

D - D

t U

Q

D

D .

vol. Flow, Vw = W/(area per pass)

= 7.66E+02 kg/s m2

tube velocity, ut = Vw/density

= 9.57E+02 m/s

"laju alir antara 1 - 2 m/s, velocity yang terlalu rendah dapat menyebabkan fouling menurun"

dan membuat pressure drop naik,sehingga nilai koefisien transfer panas

dari perhitungan, didapat jumlah tubes per pass .maka digunakan shell tipe E

Koefisien transfer panas tube, hi (Bell's method)

eq. 12.28

= 1.49E+04

= 5.69E+00

L/id = 301.875

dari fig. 12.23, jh = 3.90E-06

hi = 3.81E+03 W/m2.C

tube row correction factor, Fn

tube vertical pitch, Pt' = 0,87 x 1,25 OD

= 21.75 mm

Baffle Cut Hc = % Baffle Cut x Ds

= 221.2309702 mm

height between buffle tips = Ds-2 x Hc

= 442.4619404 mm

Ncv = Height Between Buffle Tips /pt'

= 20.34307772

Dari Fig. 12.32 di dapat

Fn = 1.03

Windows Correction Factor, Fw

Hb = 187.2309702 mm Eq. 12.38

Bundle Cut = Hb/Db

= 0.229190228

= 22.91902276 %

Dari Fig. 12.41 pada Bundle Cut di atas

R'a = 0.18

Tube in one window area, Nw = Nt x R'a

= 161.1697102 Eq. 12.41

Tube In Cross Flow Area, Nc = Nt - 2Nw Eq. 12.42

= 573.0478583

Rw = 2 Nw/Nt Eq. 12.43

= 0.36

Dari Fig. 12.33 maka Fw = 1.02

Bypass Correction, Fb

Ab = 0.012034965 m2 Eq. 12.47

Ab/As = 0.384213837

Fb = 0.215056316 eq. 12.30

alpha = 4 karena aliran turbulen

sangat rendah, coba dengan 1 strip utk tiap 5 vertical rows baffle

Ns/Ncv = 1/5

Fb = 0.667547497 eq. 12.30

Leakage correction, Fl

gunakan clearances standar,

tube to baffle 1/32 in = 0.8 mm

baffle to shell 3/16 in = 4.8 mm

Atb = 18443.54532 mm2 eq. 12.45

0.018443545 m2

dari fig. 12.41 , 25%cut ob = 2.1 rads

Asb = 8877.556372 mm2

0.008877556 m2

Al = Atb + Asb

0.027321102

Al/As = 0.872220693

dari fig. 12.35, Bl = 0.52

Fl = 0.311034291 eq. 12.31

Shell Side Coeff.

hs = 6.13E-01 W/m2.C eq. 12.27

Pressure Drop pada Cross - Flow Zone, dPc

density steam = 750 kg/m3

Ideal tube bank pressure drop, dPi

dari fig. 12.36, Re = 3.70E+04

jf = 4.30E-03

koreksi viskositas diabaikan

dPt = 7.34E+02 N/m2 eq. 12.33

= 7.34E-01 kPa

= 7.34E-03 bar

"acceptable, karena dP pada stream etanol harus <0,7 bar"

karena Re > 100, alpha = 4

0.215056316

dari fig. 12.37, Fb' = 0.45

dari fig. 12.38, Bl' = 0.43

Fl' = 0.755212412

dPc = 2.49E+02 N/m2

window Zone

dari fig. 12.41, untuk baffle cut 25%

Ra = 0.19

Aw = 66190.6255 mm2 eq. 12.44

0.066190626 m2

Uw = 0.559551096 m/s

uz = 0.813396094 m/s eq. 12.36

Nwv = 8.608320469 eq. 12.40

dPw = 1342.518497 N/m2 eq. 12.34

end zone

dPe = 530.7237351 N/m2 eq. 12.36

no. Of baffles, Nb = L/pt - 1

= 12.64524143

dPs = 2.09E+04 N/m2 eq. 12.37

= 2.09E+01 kPa

= 2.09E-01 bar

= 3.04E+00 psi

dengan data tabel 12.7, dPs dalam fouled condition

dPs = 2.89E+01 kPa

2.89E-01 bar

4.19E+00 psi

acceptable, karena allowable dari dPs adalah 10 bar

Karena A < 200 ft , maka direncanakan menggunakan Double Pipe Heat Exchanger

dengan klasifikasi sebagai berikut (dari tabel 11, Kern):

IPS = 3 IPS

Sch. No = 40 inch Sch. No.

OD = 3.5 inch OD

ID = 2.953 inch ID

a'' = 0.917 ft

2

a''

ANNULUS : FLUIDA DINGIN AIR

4. Flow area, aa

D2 = 2.9530 inch =

D1 = 2.3800 inch =

aa =

= 0.0167 ft

2

Equivalent diameter, De

De =

= 0.1070 ft

5. Laju Alir Massa, Ga

Outer Pipe Inner Pipe

4 ) (

2

1

2

2

D D - p

1

2

1

2

2

) ( D D D -

Ga = W / aa

= ############## 0.0167

= 13234281.64 lb/hr ft

2

6. Reynold number, Re

pada T

avg

= 67.50

o

F

= 0.7500 cp =

Rea =

Rea = 780174.49

7. JH = 110

8. Pada Tavg = 67.50

o

F

k = 0.3620 Btu/hr ft

o

F

Cp = 1.0302 Btu/lb

o

F

=

= 1.7286

=

9.

=

= 643.3241 Btu/hr ft

2 o

F

INNER PIPE : FLUIDA PANAS PRODUK

Flow area ap

Dp = 1.969 in

ap =

= 0.1640 ft

m

a e

G x D

3 / 1

) ( k x C m

14 , 0

3

1

=

w

H o

k

Cp

D

k

j h

m

m m

4

2

D p

m

= 0.0211 ft

Laju Alir Massa, Gp

Gp = W / ap

= 0.0000 / 0.0211

= 0.0000 lb/hr ft

2

Reynold Number, Rep

Pada tavg = 32.5

o

F

= 0.3666 cp =

Rep = D.Gp /

= 0.0000

JH = 600

Pada tavg = 32.5

o

F

k = 0.67440 Btu/hr ft

o

F

cp = 0.5939 Btu/lb

o

F

= 0.9211

=

= 2272.1028 Btu/jam ft

2 o

F

hio = hi x (ID/OD)

=

= 1879.2581 Btu/jam ft

2 o

F

Clean Overall coefficient, Uc

Uc =

= 479.2597 Btu/jam ft

2 o

F

4

2

D p

3 / 1

) ( k x C m

14 , 0

3

1

=

w

H i

k

Cp

D

k

j h

m

m m

) (

) (

o io

o o i

h h

h x h

+

m

m

Design Overall, UD

1 / UD = 1 / Uc + Rd , Rd =

= 0.0041

UD = 244.7051 Btu/jam ft

2 o

F

Required Surface Area

A =

= #REF! ft

2

External surface / lin ft, a''

a'' = 0.6220 ft

Required length, L = A / a''

L = #REF!

Ambil panjang 1 harpin sepanjang = 12 ft

Banyaknya harpin yang diperlukan,

= #REF! #########

= #REF! buah

2 buah

Actual length = 48 ft

A sebenarnya = L x a''

= 29.8560 ft

2

Actual Design Overall Coeffesient, UD act

UD =

t U

Q

D

D .

t A

Q

D .

= #REF! Btu/hr ft

2 o

F

Dirt Factor, Rd

Rd =

= #REF! hr ft

2 o

F/ Btu

ANNULUS : FLUIDA DINGIN

1. De' = (D2 - D1)

= 0.0478 ft

Rea' = 348174.6272

f =

= 0.0047

= 59.43 lb/ft

3

2. Fa =

PRESSURE DROP

D c

D c

U x U

U U -

42 , 0

) (Re

264 , 0

0035 , 0

a

+

e

D g

L Ga f

. . 2

. . . 4

2

2

r

r

= 1130.9761 ft

3. Va = Ga / (3600 . )

= 61.8575 ft/det

F1 =

= 178.2459 ft

4. Pa =

= 540.3269 psi

INNER PIPE : FLUIDA PANAS

1. Rep = 0

f =

= #DIV/0!

= 42.3000 lb/ft

3

2. Fp =

= #DIV/0!

3. Pp =

( 1)

144

Fa F x r D+D

42 , 0

) (Re

264 , 0

0035 , 0

p

+

D g

L Gp f

. . 2

. . . 4

2

2

r

.

144

Fp r D

r

r

2

3

2

V

x

g

= #DIV/0!

643.3241

Uc =

UD =

RD calculated =

RD required =

540.3269

10.0000

SUMMARY

h outside

P Calculated (psi)

P Allowable (psi)

77.00 F

104.00 F

0.0127637 btu/lb.F

220462.0000 lb/hr

203.00 F

104.00 F

0.008630692 btu/lb.F

4338.888889 kW

Selisih

t

2

= 40.0 15.0

t

1

= 95.0 55.00

-55 40.00

R =

= 3.667

metanol

Return bend Gland

Return Head

Gland

Gland

Tee

1 2

2 1

t t

T T

-

-

S =

= 0.21428571

32.50

oC

67.50

oC

tabel 12.1 Coulson

digunakan tipe split-ring floating head, karena efisiensinya dan kemudahan dalam

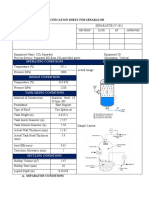

Bundle & Shell Diameter

dari tabel 12.4 Coulson untuk tube 2 passes

K1 = 0.249

n1 = 2.207

bundle diameter, Db = 816.9238808 mm eq. 12.3b

= 0.816923881 m

dari fig. 12.10 untuk split-ring floating head

shell bundle C' = 68 mm

Ds = 884.9238808 mm

= 0.884923881 m

baffle space (trial) = Ds/5

= 176.9847762 mm

baffle pitch = 353.9695523 mm

As = 0.031323611 m2 eq. 12.21

Gs, mass flowrate = 886.7999856 kg/s.m2

de = 14.201

us = 1.182399981 m/s

= 3.70E+04

dari fig. 12.31, jh = 3.30E-03

1 1

1 2

t T

t t

-

-

= 5.08E+00

koef. Transfer panas utk cross flow area ideal tube bank

hoc = 2.81E+00 W/m.C

"laju alir antara 1 - 2 m/s, velocity yang terlalu rendah dapat menyebabkan fouling menurun"

koefisien transfer panas shell (Bell's method)

Ideal bank coefficeint, hoc

baffle pitch

Karena A < 200 ft , maka direncanakan menggunakan Double Pipe Heat Exchanger

= 2

= 80 inch

= 2.38 inch

= 1.9685 inch

= 0.622 ft

2

0.2461 ft

0.1983 ft

Inner Pipe

0.345223255 (Fig.4 Kern)

1.8150 lb/hr ft

(Fig.24 Kern)

(Tabel.5 Kern)

0.8872 lb/hr ft

(fig.24 Kern)

0.002

(Tabel.11 Kern)

(Fg. 6.4 Kern.)

100.4

PRESSURE DROP

1879.2581

479.2597

#REF!

#REF!

0.0020

#DIV/0!

10.0000

SUMMARY

h outside

P Calculated (psi)

P Allowable (psi)

Shell Side Coeff.

tanpa koreksi viskositas

koefisien transfer panas shell (Bell's method)

Ideal bank coefficeint, hoc

= 0,8Ds

= 707.9391 mm

You might also like

- 7D162B Pressure Drop For Double Pipe Heat Exchanger SiDocument4 pages7D162B Pressure Drop For Double Pipe Heat Exchanger SiparagmhamunkarNo ratings yet

- Distillation Column: Major Equipment DesignDocument45 pagesDistillation Column: Major Equipment Designrubesh_rajaNo ratings yet

- Acetic 2520acid 2520 - Design 2520of 2520equipments PDFDocument41 pagesAcetic 2520acid 2520 - Design 2520of 2520equipments PDFTanuj HandaNo ratings yet

- Pipe Flow Friction Factor CalculationsDocument11 pagesPipe Flow Friction Factor CalculationsVictor ValenciaNo ratings yet

- Friction Factor CalculationsDocument1 pageFriction Factor Calculationseco protectionNo ratings yet

- Design of Air Pre Heater and EconomizerDocument4 pagesDesign of Air Pre Heater and EconomizerRyan PerezNo ratings yet

- Centrif Pumps1 SpreadsheetDocument2 pagesCentrif Pumps1 SpreadsheetCast Ed Iv0% (1)

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićNo ratings yet

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- ParalDocument9 pagesParalTahirJabbarNo ratings yet

- 11.3 KernDocument78 pages11.3 KernChou ChouNo ratings yet

- AF84C8 Excel Template Prelim Double Pipe Heat Exchanger Design Us UnitsDocument8 pagesAF84C8 Excel Template Prelim Double Pipe Heat Exchanger Design Us Unitss111_sunilNo ratings yet

- SI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RDocument3 pagesSI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RAhmad ZaenudinNo ratings yet

- Design of Heat ExchangersDocument23 pagesDesign of Heat ExchangersKhalid Turki100% (2)

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocument6 pagesShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharNo ratings yet

- Project No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasDocument11 pagesProject No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasrajachemNo ratings yet

- Heat Transfer. Heat Loss From A Pipe in An Oudoor Location (This File Is in Working)Document65 pagesHeat Transfer. Heat Loss From A Pipe in An Oudoor Location (This File Is in Working)vyrgoNo ratings yet

- RELIEF VALVE PARAMETERSDocument6 pagesRELIEF VALVE PARAMETERSMa AlNo ratings yet

- Friction Loss in Pipe LineDocument3 pagesFriction Loss in Pipe LineAvinash VasudeoNo ratings yet

- Heat CapacityDocument2 pagesHeat CapacityAbhijit MokashiNo ratings yet

- MP Separator1Document2 pagesMP Separator1ToyinNo ratings yet

- JR Heat Exchanger DesignDocument14 pagesJR Heat Exchanger Designjanelle ramdahinNo ratings yet

- Observations Water in DF Out DF Oil DF Flow Ml/s Flow ft3/hrDocument2 pagesObservations Water in DF Out DF Oil DF Flow Ml/s Flow ft3/hrUmair FareedNo ratings yet

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocument9 pagesL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariNo ratings yet

- Tube Side Velocity CalculationDocument20 pagesTube Side Velocity CalculationNitin KurupNo ratings yet

- SFW - FV Flash Steam and Flash Vessel CalculationDocument2 pagesSFW - FV Flash Steam and Flash Vessel CalculationjnmanivannanNo ratings yet

- Nonboiling Liq Outflow F Vertical Cyl VesselDocument26 pagesNonboiling Liq Outflow F Vertical Cyl VesselSrihari KodimelaNo ratings yet

- REBOILER (RB-101) : Operating ConditionsDocument27 pagesREBOILER (RB-101) : Operating ConditionsBenedick Jayson MartiNo ratings yet

- Shell & Tube Condenser Design MethodDocument4 pagesShell & Tube Condenser Design MethodwestewrNo ratings yet

- CCC1Document5 pagesCCC1Uok RitchieNo ratings yet

- Liquid Orifice SizingDocument4 pagesLiquid Orifice SizingrmaganNo ratings yet

- h-101 TwiceDocument20 pagesh-101 TwiceAdela ShofiaNo ratings yet

- Section 7 - Separation EquipmentDocument9 pagesSection 7 - Separation Equipmentlulis171No ratings yet

- Perancangan CycloneDocument20 pagesPerancangan CycloneDavid LambertNo ratings yet

- Pipes. Maxi 1Document1 pagePipes. Maxi 1Nasrul AdliNo ratings yet

- Waymouth CalculationDocument8 pagesWaymouth CalculationSURJYA TAMULINo ratings yet

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDocument6 pagesSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareNo ratings yet

- Mixer (So3 Jadi H2so4)Document6 pagesMixer (So3 Jadi H2so4)Evi SiswantoNo ratings yet

- Centrifugal Pump Temperature Rise CalculationDocument1 pageCentrifugal Pump Temperature Rise CalculationJohn PacelloNo ratings yet

- Density of WaterDocument5 pagesDensity of WaterJean Pajuelo0% (1)

- 2002 Foster Wheeler Energy Limited. All Rights ReservedDocument4 pages2002 Foster Wheeler Energy Limited. All Rights Reservedhwang2No ratings yet

- Quick estimation compressor settle out conditionsDocument1 pageQuick estimation compressor settle out conditionsAhmed GattoufiNo ratings yet

- Design of a Double Pipe Heat Exchanger CalculationsDocument2 pagesDesign of a Double Pipe Heat Exchanger CalculationsSaqib RaoufNo ratings yet

- Calc-Plum Fire IrtankDocument6 pagesCalc-Plum Fire IrtankAmro Metwally El HendawyNo ratings yet

- API 2000 guidance for inert gas blanketing of tanksDocument2 pagesAPI 2000 guidance for inert gas blanketing of tankssandeshNo ratings yet

- Water PropertiesDocument4 pagesWater Propertiesaw_aeNo ratings yet

- Reciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsDocument9 pagesReciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsSlim Toumi0% (1)

- Restriction OrificeDocument8 pagesRestriction OrificekarthickNo ratings yet

- PACKED COLUMN DESIGN FOR HCL SCRUBBERDocument11 pagesPACKED COLUMN DESIGN FOR HCL SCRUBBERsoreksatuNo ratings yet

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water Requirementmehul10941No ratings yet

- Nozzle Calculation NewDocument4 pagesNozzle Calculation NewAffian WidjanarkoNo ratings yet

- Steam Properties Paper2Document9 pagesSteam Properties Paper2Gary JonesNo ratings yet

- Salt Water CalculationsDocument13 pagesSalt Water CalculationsHsein WangNo ratings yet

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- Design of A Vapor-Liquid SeparatorDocument2 pagesDesign of A Vapor-Liquid SeparatorpowerveeNo ratings yet

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignAbhijeet JhaNo ratings yet

- Design of EquipmentDocument14 pagesDesign of EquipmentNaeem KhanNo ratings yet

- Solution Exercise9Document4 pagesSolution Exercise9leo letrainNo ratings yet

- Condenser Without SubcoolingDocument19 pagesCondenser Without SubcoolingtatvaNo ratings yet

- Heat Exchanger DesignDocument26 pagesHeat Exchanger DesignHerman Susanto100% (1)