Professional Documents

Culture Documents

GT Combustion

GT Combustion

Uploaded by

Hendra Frans0 ratings0% found this document useful (0 votes)

4 views51 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views51 pagesGT Combustion

GT Combustion

Uploaded by

Hendra FransCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 51

GAS TURBINE COMBUSTION

Scheme of gas turbine

Gas turbine (GT) is composed with turbine (4), compressor (1) and

combustion chamber (2) (combustor)

fuel

flue gas air

Principle of GT operation

Kinetic energy of flowing flue gas is converted into the turbine

rotor, which shaft has a compressor supplying the combustor with

air.

Gas turbines

Rotor of turbine and air compressor on a common shaft.

Types of GT combustors

There are two basic types of combustors:

annular

tubular.

ANNULAR COMBUSTION

CHAMBERS

Annular chambers

Gas turbines may have from 7

to 16 annular combustion

chambers mounted

concentrically. Each of

combustor has his fuel supply

and injection system.

There are three systems of

annular combustors:

individual, sectional,

annular.

Types of combustors: 1

individual, 2 sectional, 3

annular.

Example of GT with annular combustors

Scheme of GT with annular

combustors

Temperature at the inlet of GT 1500 C

No. of combustors 16

Annular combustion chambers of GT

Annular combustion chambers in GT

Combustor of annular system of

combustion of GT

Low-NOx hybrid burner

of V94.3 GT (Siemens)

Scheme of GT combustion chamber

Single combustion chamber

Fuel nozzle primary zone secondary zone dilution zone

Nozzle Swirler Air-slots

Furnace tubes (flame tubes)

Flame tube

Sequential combustion system of GT26

(ABB)

TUBULAR COMBUSTION

CHAMBERS

TG with tubular combustor

Parallel-flow

tubular

combustor

Tubular combustion chamber

Oposite-flow

tubular combustor

Details of tubular combustor

Burners

Furnace tube

Jacket

Air channel

Single EV

burner (ABB)

Scheme of EV burner (ABB)

EV burner (ABB)

ORGANIZATION OF

COMBUSTION PROCESS IN TG

Flame stabilization in GT

Combustion of lean fuels with

preliminary evaporation and mixing - LPP

(lean, premixed, prevaporised)

a) The principle is complete evaporation of fuel and

mixing with air, because of:

avoid of droplets,

Temperature of lean mixture flame is low.

Combustion systems LPP should co-operate with the systems of

variable geometry, tu avoid danger of extinction due to LEL for

small load.

Flame-holder operation

Principle of stabilization with flame-holder

Influence of flameholder size on the lower

limit of stability for different fuels

P = 100 kPa

T

0

= 300 K

SMD = 60 m

U = 30 m/s

Influence of particle size on the lower

limit of stability for different fuels

U=15 m/s, T

0

=300K, p = 100 kPa

Counter-flow stabilisation effect

Recirculation induced stopping of flow

Organisation of the 1-st zone of

combustion

Stabilisation by jets

collision (counter-flow)

Stabilisation by swirling

Stabilisation by

combination of swirling

and counter-flow

Fuel staging design example

COOLING OF FLAME TUBE

Methods of cooling of flame tube

A) Warstwowe

- polega na przenikaniu powietrza na stron wewntrzn

pomienicy przez rzd otworkw o maej rednicy. Strugi

powietrza tworz kurtyn oddzielajc wewntrzn stron

pomienicy od gorcych spalin.

B) Konwekcyjno-warstwowe

- polega na przedueniu kanalikw doprowadzajcych powietrze

do wntrza pomienicy. Dziki temu poprawia si efektywno

chodzenia pomienicy, ale zwiksza si jej ciar.

C) Transpiracyjne (z porowat cian)

- polega na przenikaniu powietrza przez porowat cian

pomienicy i tworzc kurtyn powietrzna od gorcych spalin.

Cooling of flame tube

CATALITYC GAS TURBINES

Conventional and catalytic GT

Catalytic combustion chamber

(combustor)

Catalytic combustion system applied to gas turbine

Parts of catalytic combustion chamber

Catalysts

HEAT RECOVERY STEAM

GENERATORS

Combined cycle power plant

Gas turbine combined cycle CTCC

Heat recovery

steam

generator

Heat recovery steam generator

Scheme of channel burner

Channel burner operation

Channel burners for HRSGs

GT 100 MW

GAS TURBINE FUELS

GT fuels general requirements

1. Low cost and easy excess.

2. Low risk of fire.

3. High HCV.

4. High thermal stability..

5. Low pressure of evaporation.

6. High specific heat.

Types of gas turbine fuels

1. Gasoline

2. Kerosines

3. Diesel oil

4. Heating fuel oil

5. Natural gas

6. Syngas

7. Others (H

2

, NH

3

, C

3

H

8

, C

4

H

10

, alcohols,..)

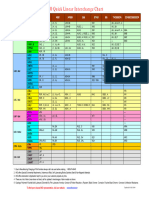

Selected parameters of GT fuels

0.82-0.88

2-4

339-367

253-273

42-43

0.1-0.8

0.793

1.4

311-344

228

42.8

0.01-0.1

Relative density at 311 K

Viscosity 311 K, cSt

Temperature of ignition (Flash point), K

Temperature of freezing (Pour point), K

LHV, MJ/kg

Sulfur, % mas.

Kerosine Gazoline Parameter

Non-conventional GT fuels

You might also like

- Boiler Fuel Savings by Heat Recovery and Reduced Standby Losses B. GrabsDocument7 pagesBoiler Fuel Savings by Heat Recovery and Reduced Standby Losses B. GrabsPhilip ShihNo ratings yet

- The Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995From EverandThe Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995Rating: 5 out of 5 stars5/5 (1)

- OISD StandardsDocument12 pagesOISD StandardsPratiek RaulNo ratings yet

- Combustion Chamber: Aircraft Engines LLDocument6 pagesCombustion Chamber: Aircraft Engines LLSouhaib K Al-AzzawiNo ratings yet

- Combustion Chamber: Aircraft Engines LLDocument6 pagesCombustion Chamber: Aircraft Engines LLSouhaib K Al-AzzawiNo ratings yet

- Co HenDocument40 pagesCo HenHiltonNo ratings yet

- Flame StabilityDocument11 pagesFlame StabilityMir Reza Negahban100% (1)

- SEV CombustorDocument9 pagesSEV CombustorSaransiri Wongsiri100% (1)

- Performance Evaluation of Gas-Steam Combined Cycle Having Transpiration Cooled Gas TurbineDocument18 pagesPerformance Evaluation of Gas-Steam Combined Cycle Having Transpiration Cooled Gas TurbineRi KoNo ratings yet

- Shiv Pratap PatelDocument19 pagesShiv Pratap PatelShubham JeengarNo ratings yet

- Boiler Fuel Firing SystemDocument44 pagesBoiler Fuel Firing Systemrashm006ranjanNo ratings yet

- ASME90 GT 335 BollandDocument9 pagesASME90 GT 335 Bollandank_mehraNo ratings yet

- Combined Cycle PowerDocument3 pagesCombined Cycle PowerEmergrace TamayoNo ratings yet

- Presentation On Gas Power PlantDocument82 pagesPresentation On Gas Power Plantakshay gupta100% (3)

- Gas Turbine Combustion ChamberDocument22 pagesGas Turbine Combustion ChamberChoiruel MunaNo ratings yet

- Gas Turbine Combustion Chamber: Akash James Asst. Professor, Dept. of Mechanical EngineeringDocument22 pagesGas Turbine Combustion Chamber: Akash James Asst. Professor, Dept. of Mechanical Engineeringسجى رزاق مزعل بطيNo ratings yet

- Boiler CombustionDocument20 pagesBoiler CombustionAnand SwamiNo ratings yet

- Cement Kiln Flame FormationDocument7 pagesCement Kiln Flame Formationengr kazamNo ratings yet

- Updated Boiler and Auxiliaries2Document105 pagesUpdated Boiler and Auxiliaries2Gaurav kumar100% (1)

- Performance Improvement of Combined Cycle Power Plant Based On The Optimization of The Bottom Cycle and Heat RecuperationDocument6 pagesPerformance Improvement of Combined Cycle Power Plant Based On The Optimization of The Bottom Cycle and Heat Recuperationwgxiang100% (4)

- 3 Gas and Oil FuelsDocument20 pages3 Gas and Oil FuelsCristhian Garcia VillarroelNo ratings yet

- 04 BoilersDocument59 pages04 BoilersMHD Abdi MuttaqinNo ratings yet

- Combined - Cycle Power PlantDocument9 pagesCombined - Cycle Power PlantRavi Kumar GuptaNo ratings yet

- Regenerative Burners PDFDocument30 pagesRegenerative Burners PDFsimu84No ratings yet

- Boilers: D N SonawaneDocument59 pagesBoilers: D N Sonawanedn_sonawane1975100% (1)

- GT PPT 2022Document173 pagesGT PPT 2022chinmayspiNo ratings yet

- CCGTDocument74 pagesCCGTAbhishek Prakash SrivastavaNo ratings yet

- 2 BoilersDocument58 pages2 BoilersParameswararao BillaNo ratings yet

- Advanced Gas Turbine Cycles For Power GenerationDocument10 pagesAdvanced Gas Turbine Cycles For Power GenerationRenzo Alexander RestrepoNo ratings yet

- Development of The Sequential Combustion System For The GT24/GT26 Gas Turbine FamilyDocument13 pagesDevelopment of The Sequential Combustion System For The GT24/GT26 Gas Turbine FamilySanthosh LingappaNo ratings yet

- 62 EngDocument2 pages62 EngStefanos DiamantisNo ratings yet

- Performance of Simple Gas Turbine Cycle Performance of Simple Gas Turbine CycleDocument25 pagesPerformance of Simple Gas Turbine Cycle Performance of Simple Gas Turbine CycleVenkatesh Vakalapudi100% (1)

- Managing The Operation of Propulsion Plant Machinery CDocument109 pagesManaging The Operation of Propulsion Plant Machinery CPanagiwtis M.No ratings yet

- Topping & Bottoming CycleDocument28 pagesTopping & Bottoming CycleNadeem TanwariNo ratings yet

- Retrofitting Duct Burners For CO ControlDocument7 pagesRetrofitting Duct Burners For CO ControlarjmandquestNo ratings yet

- System DescriptionDocument28 pagesSystem DescriptionGloria HamiltonNo ratings yet

- E0512029038 PDFDocument10 pagesE0512029038 PDFHeber Farid Fabrica QuispeNo ratings yet

- MSR - Externally Fired Gas Combustion TurbineDocument10 pagesMSR - Externally Fired Gas Combustion TurbineAnonymous K3FaYFlNo ratings yet

- Combined Cycle Power PlantDocument17 pagesCombined Cycle Power PlantJennifer L. Madronio100% (2)

- Power Generation From Combustion NEWDocument49 pagesPower Generation From Combustion NEWhridita purbaNo ratings yet

- Design Optimization of Can Type Combustor: T J Prasanna Kumar, S Koteswara Rao, S Durga Prasad, MD Faisal, P AnilDocument8 pagesDesign Optimization of Can Type Combustor: T J Prasanna Kumar, S Koteswara Rao, S Durga Prasad, MD Faisal, P AnilSakuNo ratings yet

- The Boiler DesignDocument154 pagesThe Boiler DesignAyman Esa100% (2)

- A Training Seminar ON 135 MW Gas Based Power Plant Utran, SuratDocument20 pagesA Training Seminar ON 135 MW Gas Based Power Plant Utran, SuratGangwal AkashNo ratings yet

- Design and Commisioning 700 MW CFB PDFDocument5 pagesDesign and Commisioning 700 MW CFB PDFUntung SetiawanNo ratings yet

- Chapter 5 - CombustionDocument5 pagesChapter 5 - CombustionAparna RNo ratings yet

- Unit 4-Combustion ChamberDocument13 pagesUnit 4-Combustion ChamberADVAITH P SHETTYNo ratings yet

- Gas Engines Prechamber Vs OpenDocument13 pagesGas Engines Prechamber Vs Openvictor.ciprianiNo ratings yet

- Oil & Gas BurnersDocument8 pagesOil & Gas BurnersgoelamitaNo ratings yet

- Integrated CHP Using Ultra-Low-Nox Supplemental FiringDocument11 pagesIntegrated CHP Using Ultra-Low-Nox Supplemental FiringOmar SelamiNo ratings yet

- Boiler Efficiency and CombustionDocument12 pagesBoiler Efficiency and Combustionhafidhrahadiyan2No ratings yet

- Features of Commissioning A Gas Turbine Unit WithDocument10 pagesFeatures of Commissioning A Gas Turbine Unit WithdkjdblkdslksjbNo ratings yet

- Mee 181 - L6Document13 pagesMee 181 - L6Tawsiful AlamNo ratings yet

- Optimize Fired Heater Operations To Save MoneyDocument8 pagesOptimize Fired Heater Operations To Save Moneyyogitadoda100% (2)

- Fired Heater Optimization ISA ADDocument12 pagesFired Heater Optimization ISA ADNagaphani Kumar RavuriNo ratings yet

- Book - 2 - Energy Efficiency in Thermal UtilitiesDocument274 pagesBook - 2 - Energy Efficiency in Thermal Utilitiesarkadjyothiprakash67% (9)

- 08 Steam Raising: Boiler Operation/designDocument1 page08 Steam Raising: Boiler Operation/designNorman IskandarNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- 17-Superheated Water ExtractionDocument43 pages17-Superheated Water ExtractionJayanath Nuwan SameeraNo ratings yet

- Asia Naphtha Monthly Outlook: November 9, 2020Document18 pagesAsia Naphtha Monthly Outlook: November 9, 2020asad razaNo ratings yet

- Flare Vent GuidelinesDocument71 pagesFlare Vent Guidelinesshank100100% (2)

- HP Production Separator: 400 MM Inlet 300 MM Gas OutletDocument13 pagesHP Production Separator: 400 MM Inlet 300 MM Gas OutletDeri NgasalNo ratings yet

- Chemistry: Worksheet - 53 (Lecture-01) Topic: Haloalkanes & HaloarenesDocument5 pagesChemistry: Worksheet - 53 (Lecture-01) Topic: Haloalkanes & Haloarenesakhil sNo ratings yet

- Thermal Efficiency Fired HeaterDocument5 pagesThermal Efficiency Fired Heatermuhammad_asim_10No ratings yet

- AMP BrochureDocument8 pagesAMP BrochureDavid GNo ratings yet

- Beng (Hons) Petroleum Engineering: Course: Introduction To Petroleum Engineering Instructor Dr. Tarek DarwichDocument16 pagesBeng (Hons) Petroleum Engineering: Course: Introduction To Petroleum Engineering Instructor Dr. Tarek DarwichshanecarlNo ratings yet

- A Rotary EvaporatorDocument3 pagesA Rotary EvaporatorJuvy Anne LozanoNo ratings yet

- Naphtha UpgradingDocument9 pagesNaphtha UpgradingMohamed AlhayaniNo ratings yet

- Project Report On Continuous Contact EquipmentDocument16 pagesProject Report On Continuous Contact EquipmentSavan LadaniNo ratings yet

- Le Chatelier's PrincipleDocument15 pagesLe Chatelier's Principleshakeel shahulNo ratings yet

- Ollamini3 0.2mm PLA MK3SMMU2S 1h8mDocument2,369 pagesOllamini3 0.2mm PLA MK3SMMU2S 1h8mantonioysilvia23No ratings yet

- Filter Driers DCL DML Danfoss PDFDocument12 pagesFilter Driers DCL DML Danfoss PDFSujanto WidjajaNo ratings yet

- 1741094Document285 pages1741094biswanathsaha77No ratings yet

- Mexico New Players Market Report 2019-03-20Document76 pagesMexico New Players Market Report 2019-03-20jostein.aleksandersen5460100% (1)

- Chapter 2 Feasibility Study and Literature SurveyDocument9 pagesChapter 2 Feasibility Study and Literature SurveyAq AidilNo ratings yet

- Using Atmospheric Pressure Rotating Cage: Standard Test Method ForDocument6 pagesUsing Atmospheric Pressure Rotating Cage: Standard Test Method ForHadi HowaidaNo ratings yet

- Chapter No: 7 Physical and Chemical Changes and Processes: Multiple Choice QuestionsDocument3 pagesChapter No: 7 Physical and Chemical Changes and Processes: Multiple Choice QuestionsJamila FatimaNo ratings yet

- KORIŠĆENjE ZEOLITA KAO EKOLOŠKOG LEKA PROTIV ZAGAĐENjA ZEMLjIŠTADocument10 pagesKORIŠĆENjE ZEOLITA KAO EKOLOŠKOG LEKA PROTIV ZAGAĐENjA ZEMLjIŠTAAnonymous 0ghZ8cNo ratings yet

- IKO Linear Interchange ChartDocument1 pageIKO Linear Interchange ChartleviettienCTMNo ratings yet

- Lenntech Product List 17Document11 pagesLenntech Product List 17Megamax19850% (1)

- Fuels, Furnaces & Refractories 4Document6 pagesFuels, Furnaces & Refractories 4PRAKHAR SINGHNo ratings yet

- UOP GB 562S Adsorbent Data SheetDocument2 pagesUOP GB 562S Adsorbent Data SheetrbajuadiNo ratings yet

- BGA244 - Purging Hydrogen Atmospheres On Power GeneratorsDocument2 pagesBGA244 - Purging Hydrogen Atmospheres On Power Generatorslibint15No ratings yet

- Ex: # 01: A Sample of Dry Anthracite Has The Following: 44kg CODocument12 pagesEx: # 01: A Sample of Dry Anthracite Has The Following: 44kg COnicoolNo ratings yet

- Specification: Product Name: Base Oil Grade: 150 (Gr-I)Document1 pageSpecification: Product Name: Base Oil Grade: 150 (Gr-I)genebabaNo ratings yet

- Section 24 Neutralizing Filming AminesDocument3 pagesSection 24 Neutralizing Filming AminesSheikh SahabNo ratings yet

- "Complex Stuff": Year 13 Unit 5 Test 4 4.4 Transition Metals Answer All Questions Bonne Chance!Document8 pages"Complex Stuff": Year 13 Unit 5 Test 4 4.4 Transition Metals Answer All Questions Bonne Chance!Asma AkterNo ratings yet