Professional Documents

Culture Documents

Development and Validation of RP-HPLC Method For Tapentadol HCL Bulk and Tablet PDF

Uploaded by

Nájla Kassab0 ratings0% found this document useful (0 votes)

95 views6 pagesRP-HPLC method developed for estimation of Tapentadol hydrochloride in bulk and tablet dosage forms. Developed a simple, novel, sensitive, precise and specific method. Precision study showed % recoveries less than 2% in all selected concentrations.

Original Description:

Original Title

Development and validation of RP-HPLC method for tapentadol HCl bulk and tablet.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRP-HPLC method developed for estimation of Tapentadol hydrochloride in bulk and tablet dosage forms. Developed a simple, novel, sensitive, precise and specific method. Precision study showed % recoveries less than 2% in all selected concentrations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

95 views6 pagesDevelopment and Validation of RP-HPLC Method For Tapentadol HCL Bulk and Tablet PDF

Uploaded by

Nájla KassabRP-HPLC method developed for estimation of Tapentadol hydrochloride in bulk and tablet dosage forms. Developed a simple, novel, sensitive, precise and specific method. Precision study showed % recoveries less than 2% in all selected concentrations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Original Article

Development and validation of RP-HPLC method for

estimation of Tapentadol hydrochloride in bulk

and tablet dosage forms

Y. Indira Muzib

a,

*, J. Ravi Kumar Reddy

b,c

, K.P.R. Chowdary

d

, E. Swathi

c

a

Department of Pharmaceutics, Sri Padmavati Mahila Visvavidyalayam, Tirupati 517501, Andhra Pradesh, India

b

Jawaharlal Nehru Technological University Kakinada, Kakinada 500 003, Andhra Pradesh, India

c

Department of Pharmaceutics, Annamacharya College of Pharmacy, Rajampet 516126, Andhra Pradesh, India

d

Department of Pharmaceutics, Andhra University, Vishakhapatnam 530003, Andhra Pradesh, India

a r t i c l e i n f o

Article history:

Received 6 March 2013

Accepted 27 May 2013

Available online 6 August 2013

Keywords:

Licrosphere column

Methanol

Isocratic mode

Quantitative analysis

Tapentadol hydrochloride

a b s t r a c t

Objective: To develop a simple, novel, sensitive, precise and specic RP-HPLC method for the

determination of Tapentadol hydrochloride in bulk and its tablet dosage forms.

Methods: The chromatographic separation was achieved on C18 Licrosphere column

(150 mm 4.6 mm inner diameter, 5 mm particle size) as a stationary phase using Meth-

anol: 0.1 mM Dipotassium Phosphate buffer (pH 4, adjusted with ortho phosphoric acid) as

mobile phase at detection wavelength 280 nm in isocratic mode at a ow rate of 1 ml/min.

Results: The calibration curve for Tapentadol hydrochloride was linear from 75 to 450 mg/ml.

The correlation coefcient (r

2

) value was found to be 0.9994. Precision study showed % CV

value less than 2% in all selected concentrations. The % recoveries of Tapentadol hydro-

chloride are in the range of 99.96e100.01%. The limit of detection and limit of quantica-

tion for Tapentadol hydrochloride were found to be 0.25 mg/ml and 0.75 mg/ml respectively.

Conclusion: The developed method has good sensitivity, reproducibility and specicity for

the determination of Tapentadol hydrochloride in bulk and its tablet dosage forms. This

method was simple, fast, accurate, and precise. Hence this method was validated and

found to be suitable for determining the purity of Tapentadol hydrochloride in bulk drugs

and pharmaceutical formulations. The proposed validated method was successfully used

for the quantitative analysis of commercially available dosage form.

Copyright 2013, JPR Solutions; Published by Reed Elsevier India Pvt. Ltd. All rights

reserved.

1. Introduction

Tapentadol, 3-[(1R,2R)-3-(dimethylamino)-1-ethyl-2-methyl]-

propylphenol hydrochloride (TAP), differs distinctly from

previously characterized centrally acting analgesics in that a

peculiar dual mechanism of action that has demonstrated

efcacy in clinical application.

1

Tapentadol is a centrally

acting synthetic analgesic, received initial U.S. approval in

* Corresponding author. Tel.: 91 9441593292, 91 7702229333.

E-mail address: yindira2002@rediffmail.com (Y.I. Muzib).

Available online at www.sciencedirect.com

j ournal homepage: www. el sevi er. com/ l ocat e/ i j cas

i nt e r na t i o na l j our na l of c he mi c a l a nd a na l yt i c a l s c i e nc e 4 ( 2 0 1 3 ) 6 7 e7 2

0976-1209/$ e see front matter Copyright 2013, JPR Solutions; Published by Reed Elsevier India Pvt. Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.ijcas.2013.07.001

2008

2

and was then placed into the schedule II category of

the Controlled Substances Act in May, 2009.

3

It is suggested

that the broad analgesic prole of Tapentadol and its rela-

tive resistance to tolerance development may be due to a

dual mode of action consisting of both MOR activation and

NE reuptake inhibition

4

(Fig. 1).

To date, only two LCeMS methods to detect Tapentadol in

biological matrices (urine and urine and oral uid)

5

have been

reported in the literature; however there have been no studies

on HPLC method for detection of Tapentadol in pharmaceu-

tical formulations. To address this shortfall, the aim of the

present paper was to develop and validate a new simpler

methodology to quantify Tapentadol in tablet formulation

using HPLC with diode array detection (HPLCeDAD).

2. Materials and methods

2.1. Chemicals and reagents

Tapentadol hydrochloride working standard powder was

gifted by MSN Laboratories, Hyderabad and was used

without further purication. Tapentadol hydrochloride

tablets containing 100 mg were purchased from local

pharmacy, Tirupathi. HPLC grade Methanol and Dipotas-

sium Phosphate buffer was purchased from S.D. Fine Chem.

(Mumbai, India). All solutions were ltered through 0.45

micron membrane lters purchased from Pall Pharmalab

Filtration Pvt. Ltd. (Mumbai, India). All chemicals were of

analytical grade unless stated otherwise and used as

received. Puried HPLC grade water was obtained by reverse

osmosis and ltration through a milli-Q system and was

used to prepare all solutions.

2.2. Instrumentation

The HPLC analysis was carried out by using system(Shimadzu

Co., Kyoto, Japan) consisted of a Shimadzu model LC-10 ADVP,

SPD 10 A VP variable wavelength detector (possessing deute-

rium lamp with a sensitivity of 0.005 AUFs and adjusted to an

absorbency of 280 nm), a Shimadzu model C-R5A chromato-

graph integrator module (chart speed at 10 mm/min), a Shi-

madzu model SIL-6A auto injector, and a Shimadzu module

SCL-6A system controller.

2.3. Chromatographic conditions

Chromatographic separation was achieved on Isocratic

elution of the mobile phase Methanol: 0.1 mM Dipotassium

Phosphate buffer (pH 4, adjusted with ortho phosphoric acid)

with the ow rate of 1 ml/min. Separation was performed on

C18 Licrosphere column (150 mm 4.6 mm inner diameter,

5 mm particle size). The ow rate was 1.0 ml/min and detector

wavelength was kept at 280 nmfor monitoring the separation.

The column back pressure was maintained at 110e115 kg/cm.

Integration of the detector output was performed using the

Shimadzu Empower software to determine the peak area. The

contents of the mobile phase were ltered through a 0.45-mm

membrane lter and degassed by sonication before use. In-

jection volume was 20 mL and total run time was 10 min, and

column temperature was maintained at ambient. The eluent

was detected at 280 nm.

2.4. Preparation of standard stock solution

The stock solution of Tapentadol hydrochloride was prepared

by dissolving accurately weighed 10 mg in 10 mL of methanol

to obtain a nal concentration of 1.0 mg/mL. The prepared

stock solution was stored at specied temperatures in amber

glass scintillation vial. The diluted solutions were ltered

through 0.45 mm membrane lter. From this stock solution

Tapentadol hydrochloride calibration standards were freshly

prepared prior to analysis prepared at concentrations of

75e600 mg/mL from a standard solution of 100 mg/mL by

appropriate dilution with mobile phase.

2.5. Preparation of sample solution

Twenty tablets of Tapentadol hydrochloride were weighed,

crushed and mixed in a mortar and pestle to ne powder. A

portion of powder equivalent to the weight of one tablet was

accurately weighed into each of six 25 ml volumetric asks

and 10 ml of mobile phase was added to each ask. The

volumetric asks were sonicated for 20 min to effect com-

plete dissolution of the Tapentadol hydrochloride and the

solutions were then made up to the volume with mobile

phase. Suitable aliquots of solution were ltered through a

0.45 mm nylon lter. One microlitre of the ltered solution

was transferred to a volumetric ask and made up to the

volume with mobile phase to yield concentration of Tapen-

tadol hydrochloride in the range of linearity previously

described.

2.6. Assay

A mass of not less than 20 tablets was prepared by grinding

them to a ne, uniform particle size powder using a mortar

and pestle. After calculating the average tablet weight, a

composite equivalent to the 10 mg was accurately weighed

and quantitatively transferred into a 100 ml volumetric ask.

Approximately, 10-ml milli-Q water was added, the solution

was sonicated for 10 min, 70 ml diluent was added to it, and

mechanically shaken for 10 more minutes. The ask was

equilibrated to room temperature, carefully lled to volume

with the diluent, and mixed well. Aportion of the solution was

ltered through a 0.45 mm membrane lter, discarding the

rst 2e3 ml of the ltrate. A portion of the ltered sample

(5.0 ml) was diluted into a 50 ml volumetric ask with the

mobile phase and mixed well. Fig. 1 e Structure of Tapentadol.

i nt e r na t i o na l j o ur na l o f c he mi c a l a nd a na l y t i c a l s c i e nc e 4 ( 2 0 1 3 ) 6 7 e7 2 68

3. Method validation

The developed method was validated for assay of Tapentadol

hydrochloride in accordance with ICH guidelines.

6

3.1. Detection and quantitation limits (sensitivity)

Limits of detection (LOD) and limit of quantitation (LOQ) were

estimated from the signal-to-noise ratio.

7,8

LOD is dened as

the lowest concentration resulting in a peak area of three

times the baseline noise. LOQ is dened as the lowest con-

centration that provides a signal-to-noise ratio higher than 10,

with precision (%CV) and accuracy (% bias) within their

acceptable range (10%).

3.2. Linearity (calibration curve)

Thecalibrationcurveswereconstructedwithsixconcentrations

of Tapentadol hydrochloride ranging from 75 to 450 mg/mL.

Calibration curves were constructed by plotting the ratio of the

mean peak area of either Tapentadol hydrochloride versus the

concentration. The linearity was assessed by linear regression

analysis, which was calculated by the least square method.

3.3. Accuracy and precision

Precision of the assay was determined by repeatability (intra-

day) and intermediate precision (inter-day) for 3 consecutive

days.

8e10

Three different concentrations of Tapentadol hy-

drochloride were analyzed in six independent series in the

same day (intra-day precision) and 3 consecutive days (inter-

day precision). Every sample was injected in triplicate. The

accuracy of the method, which is dened as the nearness of

the true value and found value, was evaluated as % bias for

Tapentadol hydrochloride according to the following equation:

%Accuracy observedconcentration=nominal concentration

100:

3.4. System suitability

The system suitability was evaluated by six replicate analyses

of a Tapentadol hydrochloride at a concentration of 60 mg/

mL.

9,10

The acceptance limit was 2% for the percent coef-

cient of variation (% CV) of the peak area and the retention

time of Tapentadol hydrochloride.

3.5. Recovery

The absolute recovery was calculated from the peak area of

Tapentadol hydrochloride methanolic standard solutions to

those containing Tapentadol hydrochloride at three different

concentrations.

3.6. Statistical analysis

Data collected in this study were analyzed using JMP statistical

software package by one-way analysis of variance (ANOVA).

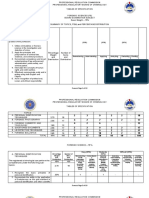

Table 1 e Optimized HPLC conditions for the estimation

of Tapentadol HCl.

S. no Parameter Description/value

1 Stationary phase C18 Licrosphere column

(150 mm 4.6 mm inner

diameter, 5 mm particle size)

2 Mobile phase Methanol: 0.1 mM Dipotassium

Phosphate buffer (pH 4, adjusted

with ortho phosphoric acid)

3 Flow rate 1 ml/min

4 Detection wavelength 280 nm

5 Detector UV (diode array detector)

6 Elution Isocratic

7 Injection volume 20 ml

8 Column temperature 25

C

9 Run time 6 min

10 Diluent Mobile phase

Fig. 2 e Typical chromatogram of Tapentadol HCL.

i nt e r na t i o na l j our na l of c he mi c a l a nd a na l yt i c a l s c i e nc e 4 ( 2 0 1 3 ) 6 7 e7 2 69

Univariate linear regression analysis using least square

method was applied to test the tted model. Correlation co-

efcient was calculated and the results of the statistical anal-

ysis were considered signicant if their corresponding p-values

were less than 0.05.

4. Results and discussion

4.1. Method development and optimization

The chromatographic conditions were optimized for the

determination of Tapentadol hydrochloride within a short

analysis time (<6 min). To accomplish these objectives, the

chromatographic column was rst chosen based on peak

shapes and resolution. C18 Licrosphere column

(150 mm 4.6 mm inner diameter, 5 mm particle size), main-

tained at ambient temperature (25

C) was used for the sepa-

ration and the method validated for the determination of

Tapentadol hydrochloride in pharmaceutical dosage forms.

The stressed samples were initially analyzed using a mobile

phase consisting of Methanol: 0.1 mMDipotassiumPhosphate

buffer (pH 4, adjusted with ortho phosphoric acid) at a ow

rate of 1 ml per min and UV detection at 280 nm. The Rt of

Tapentadol was found to be 3.1 min. Optimized HPLC

conditions for the estimation of Tapentadol HCl given in

Table 1 and typical chromatogram of Tapentadol HCl shown

in Fig. 2.

4.2. Validation

The method was validated with respect to parameters

including linearity, limit of quantitation (LOQ), and limit of

detection (LOD), suitability, precision and accuracy.

4.3. Accuracy

The accuracy of the proposed analytical method was deter-

mined by recovery experiments. The recovery studies were

carried out at three different concentration levels in triplicate

(80, 100, and 120%). The analyzed samples yielded high re-

covery values from the developed method. The % recovery

results of the method are given in Table 2.

4.4. Linearity

The linearity of the calibration curve for Tapentadol hydro-

chloride was calculated and constructed by plotting the mean

peak area versus concentration. The correlation coefcient of

regression r

2

0.9999 over a concentration range (75e450 mg/

ml), the representative linear regression equation for Tapen-

tadol hydrochloride Y 21349x 32996 as shown in Fig. 3, and

the corresponding results given in Table 3.

4.5. Precession (reproducibility)

In order to demonstrate the reproducibility of the method for

the assay of a tablet pharmaceutical preparation, ve tablet

extracts were injected in to the capillary in duplicate. The

resultant RSDs for migration time and peak are were 0.25%

and 0.65%, respectively for Tapentadol hydrochloride. The

results are shown in Table 4. Fig. 3 e Linearity of Tapentadol.

Table 2 e Accuracy (recovery) of Tapentadol hydrochloride.

Sample

no.

Spiked

level

Sample

weight (mg)

Sample

area

mg/ml added mg/ml found % recovery % mean

recovery

% mean

recovery

1 50% 135.45 4288421 199.9926 195.7401 98 100 100

2 50% 135.45 4408154 199.9926 201.2051 101

3 50% 135.45 4309312 199.9926 196.6936 98

4 50% 135.45 4440198 199.9926 202.6677 101

5 50% 135.45 4362190 199.9926 199.1072 100

6 50% 135.45 4420919 199.9926 201.7878 101

1 100% 270.91 8857334 400.0000 404.2829 101 100

2 100% 270.91 8725612 400.0000 398.2706 100

3 100% 270.91 8660061 400.0000 395.2786 99

1 150% 406.36 12766075 599.9926 582.6929 97.12 99

2 150% 406.36 12889590 599.9926 588.3306 98.06

3 150% 406.36 13052655 599.9926 595.7735 99.30

4 150% 406.36 13112499 599.9926 598.5050 99.75

5 150% 406.36 13047794 599.9926 595.5516 99.26

6 150% 406.36 13143562 599.9926 599.9228 99.99

i nt e r na t i o na l j o ur na l o f c he mi c a l a nd a na l y t i c a l s c i e nc e 4 ( 2 0 1 3 ) 6 7 e7 2 70

4.6. Determination of the main drug in bulk and tablet

dosage form (assay)

Six solutions of Tapentadol hydrochloride prepared from the

bulk drug and tablet dosage form were prepared and analyzed

with the same experimental conditions and found to be drug

content within the specied limits. The results were shown in

Table 5.

4.7. Ruggedness and robustness

Preliminary experiments revealed that amongst the many

operating parameters involved. The buffer pH is the most

inuential parameter on the repeatability of the method,

when suitable precautions have been taken with regard to

instrumental aspects of injection and capillary condition-

ing. The method was employed for two different in-

struments and with two different operators. In these

experiments, ve standard solutions of Tapentadol hydro-

chloride (at 0.05 mg ml

1

) were assessed on each of two

occasions and the results showed no signicant statistical

differences between operators or between instruments. The

RSD values for migration time and peak area for the initial

start time were 0.30% and 0.83% (n 5) respectively, and for

measurements at two months the RSDs were 0.26% and

1.05%, respectively.

4.8. Limits of detection and quantication

The LOD for Tapentadol hydrochloride, on the basis of a

signal-to-noise ratio of 3, was determined to be 0.001 mg/ml

(the sample injection time was 4 s). In addition, the LOQ, based

on a signal-to-noise ratio of ten was found to be 0.003 mg/ml.

The results were shown in Table 6.

5. Conclusion

A rapid, precise, user friendly and reproducible HPLC method

for estimation of Tapentadol hydrochloride in bulk and its

tablet pharmaceutical dosage forms was developed and vali-

dated as per ICH Guidelines. The LOD and LOQ measurements

were also established for the further scope of utilizing this

method. Because of its wide range of linearity, use of readily

available mobile phase and RSD values for all parameters

were found to be less than 2, which indicates the validity of

method and results obtained by this method fairly reliable.

This method can be used by the industries and academic in-

stitutions for the estimation of hydrochloride.

Conict of interest

All authors have none to declare.

Acknowledgements

The authors are expressing sincere thanks and appreciation to

JPR solutions for funding of this research work to publish in the

journal. The authors extend thanks to the Management of Anna

macharya college of Pharmacy and School of Pharmaceutical

Sciences, JNTU-K, Kakinada for their cooperation in the present

research work. The corresponding author expresses deep appre

ciation to B. Mohammed Ishaq for his help during this work.

r e f e r e n c e s

1. Giorgi M, Meizler A, Mills PC. Quantication of tapentadol in

canine plasma by HPLC with spectrouorimetric detection:

Table 3 e Linearity data.

Linearity level Concentration (mg/ml) Peak area

25% 75 555890

50% 150 1116635

75% 225 1673640

100% 300 2228914

125% 375 2782306

150% 450 3335847

Table 4 e Precision of Tapentadol hydrochloride.

S. no Sample

name

Inj.

(20 ml)

Name RT Area

1 Precision1 1 Tapentadol 3.155 2156575

2 Precision2 1 Tapentadol 3.143 2150804

3 Precision3 1 Tapentadol 3.136 2159065

4 Precision4 1 Tapentadol 3.127 2154633

5 Precision5 1 Tapentadol 3.120 2150334

6 Precision6 1 Tapentadol 3.114 2150547

Mean 2153660

Std. dev. 3676

% RSD 0.2

Table 5 e Assay of formulation.

Sample no. Sample

weight (mg)

Sample

area e 1

% Assay e 1

1 271.0 8735989 99.10

2 271.0 8809425 99.93

3 271.0 8675493 98.41

4 271.0 8898726 100.94

5 271.0 8852017 100.41

6 271.0 8903936 101.00

Average Assay: 100

STD 1.04

% RSD 1.04

Table 6 e System suitability parameters.

Parameters Value

Calibration range 75e450 mg/ml

Theoretical plates 5021

Rt 3.126

Tailing Factor 0.58

LOD 0.001 mg/ml

LOQ 0.003 mg/ml

i nt e r na t i o na l j our na l of c he mi c a l a nd a na l yt i c a l s c i e nc e 4 ( 2 0 1 3 ) 6 7 e7 2 71

development and validation of a new methodology. J Pharm

Biomed Anal. 2012;67e68:148e153. PBA-8601 http://dx.doi.org/

10.1016/j.jpba.2012.04.020.

2. Physicians Desk Reference, LLC. 64th ed. vol. 8. Montvale, NJ:

PDR Network; 2009:2643e2648.

3. Schedules of controlled substances: placement of tapentadol

into schedule II. FR Doc E9-11933. Fed Regist.

2009;74:23790e23793.

4. Tzschentke MThomas, ChristophThomas, Ko gel Babette, et al.

(e)-(1R,2R)-3-(3-Dimethylamino-1-ethyl-2-methyl-propyl)-

phenol hydrochloride (tapentadol HCl): a novel m-opioid

receptor agonist/norepinephrine reuptake inhibitor with

broad-spectrum analgesic properties. J Pharmacol Exp Ther.

2007;323:265e276. http://dx.doi.org/10.1124/jpet.107.126052.

5. Coulter C, Taruc M, Tuyay J, Moore C. Determination of

tapentadol and its metabolite N-desmethyltapentadol in

urine and oral uid using liquid chromatography with

tandem mass spectral detection. J Anal Toxicol.

2010;34:458e463.

6. Validation of analytical procedures: text and methodology;

International Conference on Harmonization, draft revised

guidance on Q2(R1). Fed Regist. March 1, 1995;60.

7. Ermer J. Validation in pharmaceutical analysis. Part I: an

integrated approach. J Pharm Biomed Anal. 2001;24:755e767.

8. Shabir GA. Validation of high-performance liquid

chromatography methods for pharmaceutical analysis.

Understanding the differences and similarities between

validation requirements of the US Food and Drug

Administration, the US Pharmacopeia and the International

Conference on Harmonization. J Chromatogr A.

2003;987:57e66.

9. ICH draft guidelines on validation of analytical procedures:

denitions and terminology. Fed Regist. 1995;60. IFPMA,

Switzerland.

10. Anonymous Guidelines for Validation of Analytical

Procedures: Methodology e International Conference of

Harmonization of Technical Requirements for Registration of

Pharmaceutical for Human Use, 1996.

i nt e r na t i o na l j o ur na l o f c he mi c a l a nd a na l y t i c a l s c i e nc e 4 ( 2 0 1 3 ) 6 7 e7 2 72

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Esmolol - Hydrochloride m30580 sm2 PDFDocument2 pagesEsmolol - Hydrochloride m30580 sm2 PDFNájla KassabNo ratings yet

- Simultaneous Determination of Methylparaben + Propylparaben + Hidrocortisone Topical Cream PDFDocument7 pagesSimultaneous Determination of Methylparaben + Propylparaben + Hidrocortisone Topical Cream PDFNájla KassabNo ratings yet

- Simultaneous HPLC Analysis of Betamethasone and Clotrimazole in Cream Formulation PDFDocument4 pagesSimultaneous HPLC Analysis of Betamethasone and Clotrimazole in Cream Formulation PDFNájla KassabNo ratings yet

- Simultaneous HCTZ + Amlodipine + Losartan HPLC PDFDocument6 pagesSimultaneous HCTZ + Amlodipine + Losartan HPLC PDFNájla KassabNo ratings yet

- Pharmaceutical Salts - A Formulation Trick or A Clinical Conundrum - The British Journal of Cardiology PDFDocument9 pagesPharmaceutical Salts - A Formulation Trick or A Clinical Conundrum - The British Journal of Cardiology PDFNájla KassabNo ratings yet

- Nadifloxacin - HPTLC Stability Indicating PDFDocument8 pagesNadifloxacin - HPTLC Stability Indicating PDFNájla KassabNo ratings yet

- Pharmaceutical Salts - A Formulation Trick or A Clinical Conundrum - The British Journal of Cardiology PDFDocument9 pagesPharmaceutical Salts - A Formulation Trick or A Clinical Conundrum - The British Journal of Cardiology PDFNájla KassabNo ratings yet

- Comparative - First derivative-HPLC-v52n10 PDFDocument5 pagesComparative - First derivative-HPLC-v52n10 PDFNájla KassabNo ratings yet

- Simultaneous Determination Ofloxacin + Ornidazole - SpectrophotometricDocument6 pagesSimultaneous Determination Ofloxacin + Ornidazole - SpectrophotometricNájla KassabNo ratings yet

- Identification Chiral Capillary ElectrophoresisDocument45 pagesIdentification Chiral Capillary ElectrophoresisNájla KassabNo ratings yet

- 05 Theochem 722 161-EF-EE PDFDocument8 pages05 Theochem 722 161-EF-EE PDFNájla KassabNo ratings yet

- Derivative Spectrophotometry PDFDocument22 pagesDerivative Spectrophotometry PDFNájla KassabNo ratings yet

- Losartan Espectro FormulacaoDocument5 pagesLosartan Espectro FormulacaoNájla KassabNo ratings yet

- Analyses-Losartan Hctz-Nevin Erk PDFDocument9 pagesAnalyses-Losartan Hctz-Nevin Erk PDFNájla KassabNo ratings yet

- Losartan HCTZ Anti Beer PDFDocument15 pagesLosartan HCTZ Anti Beer PDFNájla KassabNo ratings yet

- Development and Validation of An Uv Spectrophotometric Method For The Determination of Aliskiren in Tablets PDFDocument5 pagesDevelopment and Validation of An Uv Spectrophotometric Method For The Determination of Aliskiren in Tablets PDFNájla KassabNo ratings yet

- Derivative Spectrophotometry PDFDocument22 pagesDerivative Spectrophotometry PDFNájla KassabNo ratings yet

- Analysis Sulfonamidas + Quinolonas Koreia MilkDocument5 pagesAnalysis Sulfonamidas + Quinolonas Koreia MilkNájla KassabNo ratings yet

- Antimicrobial Effect and PH of Chlorhexidine Gel Cylinder-PlateDocument6 pagesAntimicrobial Effect and PH of Chlorhexidine Gel Cylinder-PlateNájla KassabNo ratings yet

- Quantitative Determination of Gemifloxacin Bulk Pharmaceutical and SerumDocument6 pagesQuantitative Determination of Gemifloxacin Bulk Pharmaceutical and SerumNájla KassabNo ratings yet

- Determination of Cefixime and Ofloxacin by Ratio Spectra and Zero CrossingDocument6 pagesDetermination of Cefixime and Ofloxacin by Ratio Spectra and Zero CrossingNájla KassabNo ratings yet

- (Veterinary Systemic) FluoroquinolonesDocument26 pages(Veterinary Systemic) FluoroquinolonesAvelox FloxNo ratings yet

- Simultaneous HPLC Analysis of Betamethasone and ClotrimazoleDocument3 pagesSimultaneous HPLC Analysis of Betamethasone and ClotrimazoleNájla KassabNo ratings yet

- First Derivative Spectrophotometric CetoconazolDocument8 pagesFirst Derivative Spectrophotometric CetoconazolNájla KassabNo ratings yet

- Acyclovir HPLCDocument23 pagesAcyclovir HPLCNájla KassabNo ratings yet

- Artigo-Quimica Nova - Levofloxacin - PublicadoDocument4 pagesArtigo-Quimica Nova - Levofloxacin - PublicadoNájla KassabNo ratings yet

- Artigo Jpharm Bioq Analysis PublicadoDocument6 pagesArtigo Jpharm Bioq Analysis PublicadoNájla KassabNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Final Research PaperDocument37 pagesFinal Research PaperBea LagayaNo ratings yet

- Npioh, JURNAL ERIKA 203-207 PDFDocument5 pagesNpioh, JURNAL ERIKA 203-207 PDFReski AmaliyaNo ratings yet

- Cox Elen Steegen 2017 Systems Thinking in Geography - Can High School Students Do It?Document17 pagesCox Elen Steegen 2017 Systems Thinking in Geography - Can High School Students Do It?Javier PNo ratings yet

- The Efficacy of Oxalic Acid As An Alternative Anticoagulant From Fruit Extract of Averrhoa Carambola (Starfruit)Document2 pagesThe Efficacy of Oxalic Acid As An Alternative Anticoagulant From Fruit Extract of Averrhoa Carambola (Starfruit)doraemonNo ratings yet

- Grammatical Errors in Writing Skills Committed by Grade 10 Students Malapit NaDocument62 pagesGrammatical Errors in Writing Skills Committed by Grade 10 Students Malapit NaFrans Anacis GarciaNo ratings yet

- Manuskrip Ana JihadDocument16 pagesManuskrip Ana Jihadjihan islamiyahNo ratings yet

- KTEA Technical and Interpretive ManualDocument690 pagesKTEA Technical and Interpretive ManualVanity TrimbleNo ratings yet

- EBS 341-Lab Briefing-19 Feb 2019Document71 pagesEBS 341-Lab Briefing-19 Feb 2019NNadiah Isa100% (1)

- Hypothesis Statistical Test and Research ProposalDocument16 pagesHypothesis Statistical Test and Research ProposalRex IanNo ratings yet

- A Students Dictionary of Psychology and Neuroscience, 7th Edition (Hayes, Nicky, Stratton, Peter)Document435 pagesA Students Dictionary of Psychology and Neuroscience, 7th Edition (Hayes, Nicky, Stratton, Peter)Aiatul IslamNo ratings yet

- Evaluation and The User Experience: Designing The User Interface: Strategies For Effective Human-Computer InteractionDocument26 pagesEvaluation and The User Experience: Designing The User Interface: Strategies For Effective Human-Computer InteractionMoody KatNo ratings yet

- Lab Sheet PDFDocument9 pagesLab Sheet PDFtehpohkeeNo ratings yet

- General PsychologyDocument171 pagesGeneral PsychologyYoomif Tube100% (1)

- DLP COT DrugsDocument2 pagesDLP COT DrugsJelly Mae Getalla100% (1)

- .Adverse Childhood Experiences (ACEs), Stress and Mental Health in College StudentsDocument10 pages.Adverse Childhood Experiences (ACEs), Stress and Mental Health in College StudentsAndreea PalNo ratings yet

- Thesis Chapter 1Document27 pagesThesis Chapter 1Jefferson Ayubo BroncanoNo ratings yet

- Mercy Corps Jobs Monitoring, Evaluation and Learning (MEL) SpecialistDocument7 pagesMercy Corps Jobs Monitoring, Evaluation and Learning (MEL) Specialistعدنان باحكيمNo ratings yet

- Chapter 14 Anxiety and Anxiety DisordersDocument4 pagesChapter 14 Anxiety and Anxiety DisordersCatia Fernandes100% (2)

- Unit Assessment BDocument3 pagesUnit Assessment BRitchie MiguelNo ratings yet

- Jimed, Vol. 4, No. 2 P-Issn 2356-301X E-Issn 2621-7457: Ildsa Maulidya, Gatotmurtiwibowo, Emi MurniatiDocument8 pagesJimed, Vol. 4, No. 2 P-Issn 2356-301X E-Issn 2621-7457: Ildsa Maulidya, Gatotmurtiwibowo, Emi MurniatiMuh FadilNo ratings yet

- Bmri2017 2760716Document13 pagesBmri2017 2760716PradhitaRizkaNo ratings yet

- Hero Motors ProjectDocument18 pagesHero Motors ProjectSrikanth SrikanthNo ratings yet

- Project Three: Simple Linear Regression and Multiple RegressionDocument10 pagesProject Three: Simple Linear Regression and Multiple RegressionnellyNo ratings yet

- The Effect of Using Multimedia in Teaching and Learning Mathematics and Academic Achievement of Secondary School Students in MathrlematicsDocument99 pagesThe Effect of Using Multimedia in Teaching and Learning Mathematics and Academic Achievement of Secondary School Students in MathrlematicsOmotoye DanielNo ratings yet

- Rubric Research PaperDocument3 pagesRubric Research PaperhimaNo ratings yet

- 2015ConferenceProceedings PDFDocument378 pages2015ConferenceProceedings PDFDmitry StepanovNo ratings yet

- Software Project ManagementDocument57 pagesSoftware Project ManagementSameer MemonNo ratings yet

- TOS ForensicDocument10 pagesTOS ForensicHarley IluminNo ratings yet

- How To Negotiate With Someone More Powerful Than YouDocument7 pagesHow To Negotiate With Someone More Powerful Than YougshirkovNo ratings yet

- TensiNews14 PDFDocument24 pagesTensiNews14 PDFpedrogasparmendoncaNo ratings yet