Professional Documents

Culture Documents

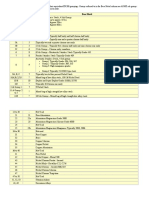

Summary ISO TR 15608 Metallic Materials Grouping System

Uploaded by

hamoody_007Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Summary ISO TR 15608 Metallic Materials Grouping System

Uploaded by

hamoody_007Copyright:

Available Formats

Metallic Materials Grouping System

Page 1 of 4

S SS S S SS Su uu u u uu um mm m m mm mm mm m m mm ma aa a a aa ar rr r r rr ry yy y y yy y o oo o o oo of ff f f ff f I II I I II IS SS S S SS SO OO O O OO O / // / / // / T TT T T TT TR RR R R RR R 1 11 1 1 11 15 55 5 5 55 56 66 6 6 66 60 00 0 0 00 08 88 8 8 88 8

Steel (Group 1 11)

Group 1:

Steels with C 0.25, Si 0.60, Mn 1.8, etc. with yield strength specified as below:

Gr 1.1: y.s 275 N / mm

2

Gr 1.2: 275 N / mm

2

y.s 360 N / mm

2

Gr 1.3: Normalised Steels with y.s > 360 N / mm

2

Gr 1.4: Steels with improved atmospheric corrosion resistance, with analysis

which may exceed the above specification.

Group 2:

Thermo mechanically treated fine grain steels and cast steels with as below:

2.1: 360 N / mm

2

< y.s. 460 N / mm

2

2.2: y.s. > 460 N / mm

2

Group 3:

Quenched and Precipitation hardened fine grain steels (except stainless steels)

with y.s. > 360 N / mm

2

Group 4:

Low Vanadium Alloyed Cr-Mo-(Ni) steels with MO 0.7 % and V 0.1 %

Group 5:

Cr-Mo steels free of Vanadium and C 0.35 %

Group 6:

High Vanadium alloyed Cr-Mo-(Ni) steels.

Group 7:

Ferritic, Martensitic or Precipitation hardened stainless steels with

C 0.35 % and 10.5 % Cr 30 %

Group 8:

Austenic Stainless Steels, Ni 31 %

Group 9:

Nickel Alloy steels.

Group 10:

Austenitic Ferritic (duplex) stainless steels.

Group 11:

Steels covered by Group I with 0.25 % C 0.85 %

Metallic Materials Grouping System

Page 2 of 4

Aluminium and Aluminium Alloys (Group 22 - 26)

Group 21:

Pure Aluminium with 1 % impurities or alloy content.

Group 22:

Non Heat Treatable Al alloys

Al Mn & Al - Mg alloys.

Group 23:

Heat Treatable Al alloys.

Al Mg -Si , Al Zn - Mg alloys.

Group 24:

Al Si alloys.

Group 25:

Al-Si-Cu alloys.

Group 26:

Al Cu alloys.

Copper and Copper Alloys (Group 31 38)

Group 31:

Copper with 6 % Ag and 3 % Fe

Group 32:

Copper Zinc alloys.

Group 33:

Copper tin alloys.

Group 34:

Copper Nickel alloys.

Group 35:

Copper Aluminium alloys.

Group 36:

Copper Nickel Zinc alloys.

Group 37:

Copper alloys, low alloyed.

Group 38:

Other Copper alloys.

Metallic Materials Grouping System

Page 3 of 4

Nickel and Nickel Alloys (Group 41 48)

.

Group 41:

Pure Nickel

Group 42:

Nickel Copper alloys.

Group 43:

Nickel Chromium alloys.

Group 44:

Nickel Molybdenum alloys.

Group 45:

Nickel Iron Chromium alloys.

Group 46:

Nickel Chromium Cobalt alloys.

Group 47:

Nickel Iron Chromium Copper alloys.

Group 48:

Nickel Iron Cobalt alloys.

Titanium and Titanium Alloys (Group 51 54)

Group 51:

Pure Titanium

Group 52:

Alpha alloys.

Group 53:

Alpha Beta alloys.

Group 54:

Near Beta and Beta alloys.

Zirconium and Zirconium Alloys (Group 61 62)

Group 61:

Pure Zirconium

Group 62:

Zirconium with 2.5 % Nb.

Metallic Materials Grouping System

Page 4 of 4

Cast Iron (Group 71 76)

Group 71:

Grey Cast Iron.

Group 72:

Spheroidal Graphitic Cast Iron.

Group 73:

Malleable Cast Iron.

Group 74:

Austempered ductile Cast Iron.

Group 75:

Austenetic Cast Iron.

Group 76:

Cast Irons excepting groups 71 75.

You might also like

- This Is A General Guide ASME P Numbers and Their Equivalent EN288 Groupings. Groups Referred To in The Base Metal Column Are ASME Sub Groups. EN288 Material Groups Are Included For Comparison OnlyDocument2 pagesThis Is A General Guide ASME P Numbers and Their Equivalent EN288 Groupings. Groups Referred To in The Base Metal Column Are ASME Sub Groups. EN288 Material Groups Are Included For Comparison OnlyAmit shahNo ratings yet

- This Is A General Guide ASME P Numbers and Their Equivalent EN288 Groupings. Groups Referred To in The Base Metal Column Are ASME Sub Groups. EN288 Material Groups Are Included For Comparison OnlyDocument2 pagesThis Is A General Guide ASME P Numbers and Their Equivalent EN288 Groupings. Groups Referred To in The Base Metal Column Are ASME Sub Groups. EN288 Material Groups Are Included For Comparison OnlyAmit shahNo ratings yet

- P # NumberDocument4 pagesP # NumberManzar KhanNo ratings yet

- P No. EN288 Base MetalDocument2 pagesP No. EN288 Base Metalகோகுல் இராNo ratings yet

- P NumbersDocument2 pagesP Numbersகோகுல் இராNo ratings yet

- ASME Material Numbers PDocument2 pagesASME Material Numbers PVivek S SurendranNo ratings yet

- ASME P No. and GR PDFDocument2 pagesASME P No. and GR PDFnoell gunawanNo ratings yet

- ASME P NumberDocument1 pageASME P NumberIsmail Mohd FadhlanNo ratings yet

- ASME P Material NumbersDocument1 pageASME P Material Numbers전상문No ratings yet

- ASME P-NumbersDocument2 pagesASME P-NumbersAnonymous XwaOunGK100% (1)

- ASME P Material NumbersDocument3 pagesASME P Material NumbersTeodor EzaruNo ratings yet

- ASME P NumbersDocument2 pagesASME P NumbersArjun RawatNo ratings yet

- ASME P NumbersDocument2 pagesASME P Numbersprad_21adNo ratings yet

- ASME Definitions, Consumables, Welding PositionsDocument3 pagesASME Definitions, Consumables, Welding PositionsPhani Sridhar ChNo ratings yet

- APPENDIX C Typical Properties of MaterialsDocument18 pagesAPPENDIX C Typical Properties of MaterialsMAT-LIONNo ratings yet

- Metal Alloys, Emailed Aug. 24, 2017Document12 pagesMetal Alloys, Emailed Aug. 24, 2017Romel LeoNo ratings yet

- Earn A College Degree Online. Financial Aid Available. Call 24/7Document4 pagesEarn A College Degree Online. Financial Aid Available. Call 24/79885869251No ratings yet

- Chapter 1 Ferrous CharacteristicsDocument69 pagesChapter 1 Ferrous CharacteristicsTuan VuNo ratings yet

- 61fc14bb88a7a1f60f3b6a69 - SAE Steel GradesDocument6 pages61fc14bb88a7a1f60f3b6a69 - SAE Steel Gradesابو اسامةNo ratings yet

- Base Material Codes and DefinationDocument4 pagesBase Material Codes and Definationahmed nasserNo ratings yet

- Asme P NumberDocument4 pagesAsme P NumberTanveer Rajput EngrNo ratings yet

- Sae Grade SteelsDocument10 pagesSae Grade SteelsMekhmanNo ratings yet

- Steel ClassificationDocument8 pagesSteel ClassificationMidhun K ChandraboseNo ratings yet

- ASME P Material NumbersDocument1 pageASME P Material Numbersmahi1437100% (1)

- Chap 5 Selection-Of-Ferrous-MaterialDocument28 pagesChap 5 Selection-Of-Ferrous-MaterialBernadetteNo ratings yet

- MaterialsDocument26 pagesMaterialsbadesharamkNo ratings yet

- SAE Steel GradesDocument21 pagesSAE Steel Gradescal2_uniNo ratings yet

- SAE Steel Grades - WikipediaDocument12 pagesSAE Steel Grades - WikipediaprabuNo ratings yet

- General Information About SteelsDocument20 pagesGeneral Information About SteelsilkinNo ratings yet

- SAE Steel Grades - ReferenceDocument12 pagesSAE Steel Grades - ReferenceJuan RodriguezNo ratings yet

- P NumberDocument2 pagesP NumberAndiappan PillaiNo ratings yet

- Material Manual First Semester 2023 - DR Morad EtierDocument61 pagesMaterial Manual First Semester 2023 - DR Morad EtierعبداللهNo ratings yet

- ASME P Material NumbersDocument2 pagesASME P Material NumbersAbdullah100% (1)

- SAE Steel GradesDocument8 pagesSAE Steel GradesbugmenotNo ratings yet

- SAE Steel Grades: Iron Alloy PhasesDocument5 pagesSAE Steel Grades: Iron Alloy Phaseshirenkumar patelNo ratings yet

- Alloy SteelsDocument9 pagesAlloy SteelsAileen Joy CananiaNo ratings yet

- SAE Steel Grades - WikipediaDocument30 pagesSAE Steel Grades - Wikipediamanoj ranathiive100% (1)

- SAE Steel GradesDocument19 pagesSAE Steel GradesCarlos BustamanteNo ratings yet

- Unit Iii: V 6Cwodc-3VrkDocument237 pagesUnit Iii: V 6Cwodc-3VrkDinesh KumarNo ratings yet

- Grading of AISI MaterialsDocument38 pagesGrading of AISI Materialsyair Enrique Romero OspinoNo ratings yet

- MEE 511 Course WorkDocument10 pagesMEE 511 Course WorktornakingstonNo ratings yet

- Non Ferrous: Aluminum and It'S AlloysDocument31 pagesNon Ferrous: Aluminum and It'S AlloysMunir DirgantaraNo ratings yet

- Assignment PDFDocument4 pagesAssignment PDFzayanNo ratings yet

- Section 3.3 Ferrous and Nonferrous MetalsDocument39 pagesSection 3.3 Ferrous and Nonferrous MetalsNguyễn Xuân NamNo ratings yet

- Heat Treatment of NiHardDocument6 pagesHeat Treatment of NiHardbadelog5297No ratings yet

- Theory of Non-Ferrous Metals and Alloys ProcessingDocument83 pagesTheory of Non-Ferrous Metals and Alloys ProcessingHimanshuDeepNo ratings yet

- Group IV Trends - Carbon To LeadDocument76 pagesGroup IV Trends - Carbon To LeadRhondene WintNo ratings yet

- Newnes Engineering Materials Pocket BookFrom EverandNewnes Engineering Materials Pocket BookRating: 3.5 out of 5 stars3.5/5 (2)

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- Advanced Materials in Japan: Source Book 1992From EverandAdvanced Materials in Japan: Source Book 1992No ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Extractive Metallurgy 2: Metallurgical Reaction ProcessesFrom EverandExtractive Metallurgy 2: Metallurgical Reaction ProcessesRating: 5 out of 5 stars5/5 (1)

- Technical Data Sheet For The HST3 Metal Expansion Anchor Technical Information ASSET DOC 5412122Document11 pagesTechnical Data Sheet For The HST3 Metal Expansion Anchor Technical Information ASSET DOC 5412122viveNo ratings yet

- Toray Btcy-1: Description FeaturesDocument6 pagesToray Btcy-1: Description FeaturesAkhil HebbarNo ratings yet

- CHAPTER 2 Press WorkingDocument29 pagesCHAPTER 2 Press WorkingDen Yogi HardiyantoNo ratings yet

- Angus FireDocument2 pagesAngus Fireing.cayalaNo ratings yet

- Building Type 2: Wood Frames, Commercial and IndustrialDocument34 pagesBuilding Type 2: Wood Frames, Commercial and IndustrialShyn Marie MijaresNo ratings yet

- General Purpose Steel Grade ChartDocument2 pagesGeneral Purpose Steel Grade ChartDavid D'Agostino50% (2)

- EMsor2014 PDFDocument114 pagesEMsor2014 PDFRohan MahajanNo ratings yet

- Welding Consumables For Cast Iron MaterialsDocument4 pagesWelding Consumables For Cast Iron MaterialsskidanjeNo ratings yet

- Jig DW75 CNC2S 02Document1 pageJig DW75 CNC2S 02Luong LeNo ratings yet

- BMCT-5: Topic-Post TensioningDocument16 pagesBMCT-5: Topic-Post TensioningKush ParikhNo ratings yet

- CiatingBook SAES H 002 2018 1Document27 pagesCiatingBook SAES H 002 2018 1محمد العيسوىNo ratings yet

- 0 B4 GU13 C 4 Z Cu 1 VUx Ed 2 X 1 Un ZP TK UDocument16 pages0 B4 GU13 C 4 Z Cu 1 VUx Ed 2 X 1 Un ZP TK ULarizza Delos SantosNo ratings yet

- Structural AnalysisDocument120 pagesStructural Analysisdash1991100% (1)

- Repair Application ProceduresDocument6 pagesRepair Application ProceduresSatheesh Rama SamyNo ratings yet

- GS Peb QapDocument4 pagesGS Peb Qapshailendr12No ratings yet

- Guide To Toilet PlumbingDocument8 pagesGuide To Toilet PlumbingvigyanashramNo ratings yet

- Tle 6Document3 pagesTle 6Yu NaNo ratings yet

- A Chemistry Project On: Study of Constituents of AlloyDocument17 pagesA Chemistry Project On: Study of Constituents of AlloyParth ChakrabortyNo ratings yet

- ASTM D2992-06 Standard Practice For Obtaining Hydrostatic Pressure Design Basis For Fiberglass Pipe & Fittings PDFDocument11 pagesASTM D2992-06 Standard Practice For Obtaining Hydrostatic Pressure Design Basis For Fiberglass Pipe & Fittings PDFChengkc2014100% (1)

- Compact Enclosures AE: System Accessories Page 537 AE Stainless SteelDocument3 pagesCompact Enclosures AE: System Accessories Page 537 AE Stainless SteelUsman ZouqueNo ratings yet

- Answer RQ CHAPTER 2Document8 pagesAnswer RQ CHAPTER 2MirunNo ratings yet

- RingwallDocument8 pagesRingwallocayliNo ratings yet

- Astm A249Document5 pagesAstm A249TeoTyJayNo ratings yet

- Processing of Polymer Matrix Composites by P.K. MallickDocument356 pagesProcessing of Polymer Matrix Composites by P.K. MallickLinh Tú100% (2)

- BG UTIliies 3Document8 pagesBG UTIliies 3Ken ChiaNo ratings yet

- Satip F 001 04Document13 pagesSatip F 001 04Rijwan MohammadNo ratings yet

- ProRack 18U 600.600 Floor Standing Data SheetDocument5 pagesProRack 18U 600.600 Floor Standing Data SheetMina BarsoomNo ratings yet

- 49 - HD - 2000 New Logo LowDocument12 pages49 - HD - 2000 New Logo LowAgata OwczarekNo ratings yet

- Conduit Base: Dimensions Dimensions Dimensions DimensionsDocument2 pagesConduit Base: Dimensions Dimensions Dimensions DimensionsDamjan CvetkovicNo ratings yet

- Background Study: SCBA) Shown in Figure 2Document11 pagesBackground Study: SCBA) Shown in Figure 2Miza AneesaNo ratings yet