Professional Documents

Culture Documents

BOILER STEAM BLOWING PROCEDURE

Uploaded by

kannagi198Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BOILER STEAM BLOWING PROCEDURE

Uploaded by

kannagi198Copyright:

Available Formats

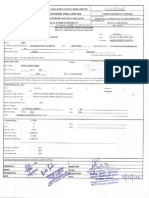

Station: NTPC- Simhadri BHEL Ref No.

PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 1 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SLNO

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

LIST OF CONTENTS

PLANT DETAILS

OBJECTIVE

PROPOSAL

SERVICES REQUIRED

SAFETY PERECAUTIONS

EER!ENCY PROCEDURE

STATE OF T"E PLANT

ET"OD

COPLETION CRITERIA

APPENDICES

#$ DRA%IN!

&$ LO! S"EET

'$ DISTURBANCE FACTOR (CALCULATED VALUE$

)$ S*ETC" FOR TAR!ET PLATE + ASSEBLY (TYPICAL$.

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet $ of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

1.0 PLANT DETAILS,

The steam Generator is a controlled circulation plus Radiant

Reheat (Type CC+RR) boiler. Firing equipment consists of five

elevation of remotely controllable high energy arc lgnitors five

elevations of air cooled non!retractable steam atomising oil Gun

and nine elevations of pulveri"ed coal no""ies. The nine

elevations of pulveri"ed coal no""ies are supplied #ith coal from

nine numbers of type $R% &''( )o#l mills #hich form the load

carrying fuel for the boiler.

Control equipment provided consists of furnace safeguard

supervisory system scanner air control system and a secondary

air control system.

*a+or au,iliary equipment provided consiss of pulveri"ers

feeders fans and miscellaneous valves. Three number of boiler

circulating pumps are provided to ensure proper circulation of

#ater in the furnace #all circuits.

The circuits #hich are sub+ected to steam blo#ing are super

-eater.ections of boiler *anisteam line up to -% Turbine Cold

Reheat line up to )oiler Reheater inlet Reheater .ections -ot

Reheat line up to /% turbine inlet t#o sections of -% and 0%

bypass .ections and all au,iliary steam lines. These circuits are

described stage #ise in section (.'

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

1ther ma+or au,iliaries provided consists of )oiler Feed %umps (&

2o. of motor driven and 3 2os. of turbine driven) condensate

e,traction %umps 4acuum %umps etc #ith %re!boiler system

consisting of 0%5-% heaters 6eaerator Feed storage tan7 and

other au,iliaries such as chemical conditioning system (0% 5 -%

dosing system).

The technical specification of steam generator and steam lines

are given belo#.

P-.)/'0.) P.-12-3#4'. D#0# (500 % 5/06 "P ".#0.-7 /4 +

D.7/84 C2#9)

&. .team Flo# (.- outlet) 8 &9:;.< T%-

3. .team Flo# (R- outlet) 8 &((<.3 T%-

(. Feed =ater Flo# 8 &9;'.& T%-

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 1 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

9. .- 1ut let Temperature 8 <9' deg C

<. R- 1utlet Temperature 8 <9' deg C

>. F= Temp (?co 1utlet) 8 (3; deg C

@. .- 1utlet %ressure 8 &@>.( A.C

;. R- 1utlet %ressure 8 9&.9 A.C

:. Coal 8 ((: T%-

L/4. S/:.7

&. .- 1utlet %ipes 8 9'> , 93

3. *.0 8 <>9 , <@

(. CR- 8 ;>9 , 39

9. CR- to Reheater inlet 8 >>' , 3'

<. R- to -R- 8 @3' $ 9<

>. -R- 8:>: $ >'

@. -% )% line 8(39 $ (<

;. 0% )% line 8@3' $ 9<

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 5 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

%lant /tem completion list for areas such as mechanical ?lectrical

and C 5 / are to be listed out at site.

The signed copy of safety rules clearance certificate is to be

enclosed.

The follo#ing schenialic dra#ing are enclosed in section &'.'

a) .cheme for steam blo#ing of )oiler and associated steam

line

b) .cheme for steam blo#ing of au,iliary steam lines

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 6 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

2.0 OBJECTIVE,

The ob+ective of steam blo#ing is to remove scales loose

material iron cuttings etc that might have been entrapped in

.uper -eaters .team piping reheaters during manufacture

storage erection at site. Failure to remove the debris may result

in damage to turbine blades. 4alves etc.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 2 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

3.0

(.&

(.3

(.(

(.9

PROPOSAL,

The ob+ectives are achieved by carrying out the follo#ing

proposals.

The steam blo#ing is done in five stages. 4i" .tage & .tage 3

(3a 5 3b) .tage ( ((a 5 (b) stage 9a 5 9b and .tage <. The

?lectrically 1perated Temporary 4alve (?1T4) is to be located in

the place as sho#n in the scheme. 0oop pipes from ?.4 and /4

to turbine are to be ta7en care for cleanliness before erection and

not to be steam blo#n.

Bll critical pipe lines covered in stage & 3a (a 5 (b #ill be steam

blo#n using ?1T4. 1nly in .tage &b *. stop valve at boiler end

#ill be used.

.team blo#ing is carried out by adopting puffing method for

stages & 3a 3b (a 5 (b in #hich boiler pressure is raised to <'

A.C and released through a quic7 opening valve and steam

blo#ing done till the 6rum pressure drops from <' A.C to 3<

A.C.

.team blo#ing for stages 9a 5 9b and < are carried out by

continous method. .team blo#ing by continous method shall be

done at 9'!<'C of normal operating pressure of the respective

system for period of 3' to (' minutes. )lo#ing repeated after a

time gap of 3 -rs.

)oth the above techniques give a thermal shoc7 to the contours

being purged and results in loosening of the adhered scale #hich

is subsequently removed by e,panding steam.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 8 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

(.< The effects of steam blo#ing are evaluated and steam blo#ing

concluded as per the completion criteria given in section :.'

.ystem covered in each stage are as follo#s8

#$ S0#8.1, .- *.0 ?.4 temporary line from ?.4 to ?1T4

and ?1T4 to e,haust #ith temporary piping #ill be concluded

by observing the indents on the target plate and required

disturbance factor achieved.

&$ S0#8. ; 2# .- *.0 ?.4 temporary lines from ?.4 to

?1T4 ?1T4 to CR- line CR- lines upto boiler end #ith

temporary e,haust pipe.

Tap off lines from CR- for deaerator T6)F%s au,iliary

%R6. -% heater >a 5 >b gland sealing etc. shall be remain

closedDisolated.

stage 3a end point #ill be concluded by observing the indents

on the target plate and required disturbance factor achieved.

'$ S0#8. ; 2& , 3a plus -% bypass inter connection hand

operated valve mounted in place of -% bypass valve and

CR- lines upto )oiler end #ith temporary e,haust piping.

/n this stage > to ; blo#s #ill be given through -% bypass

to ensure cleanliness of the limb. )oiler *. stop valve #ill

be used for stage 3b. ?1T4 #ill be 7ept closed. *anually

1perated /solation 4alves in -% bypass lines #ill be 7ept

opened fully.

)$ S0#8. ; 3# , 2# plus reheater -R-0 /4 and temporary pipe.

CR- line along #ith attemperator shall be #elded #ith reheater

before start of stage (a. 0% bypass lines shall be blan7ed during

stage (a. .tage (a end point #ill be concluded by observing the

indents on target plates and required 6isturbance Factor

achieved.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 3 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

.. S0#8. ; 3& , + (a upto /4 + 0% bypass lines #ith temporary

e,haust pipe.

.tage (b blo#ing #ill be parallel blo# in the path (a 5 (b. 0%

)ypass blan7s shall be removed for stage (b. 9 blo#s #ill be

given through 0.%. )ypass line to ensure cleanliness of the

limbs.

1. S0#8. ; 4# From CR- to steam inlet line to )F% Turbine /

?.4 5 .team valve of B%R6. line #ill be 7ept closed.

?lectro!hydraulic control valve #ill not be erected and steam

blo#ing arrangement ()lan7ing device) #ill be used.

8. S0#8. ; 4& From CR- to .team inlet line to )F% Turbine //

?.4 5 .team valve of B%R6. line #ill be 7ept closed.

?lectro!hydraulic control valve #ill not be erected and steam

blo#ing arrangement )lan7ing derice #ill be used.

6. S0#8. ; 5 Bu,iliary .team 0ines

<a) From to B%R6. through B.!& and B.!3

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 10 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

<b) B%R6. through B.!9 and B.!( and B.!9

<c) CR- to turbine e,traction line through

?$ &@ ?$ &; ?$ ; ?$ @ and ?$ &< in that order.

<d) CR- to ?,traction E 9 to 6eaerator

<e) CR- to 6eaerator D F.t through CR- ! ;

<f) CR- to -% -eaters.

<g) CR- steam line to Turbine gland seating line

<h) CR- to B%R6.

<i) *.0 to B%R6..

Refer .ection &'.' for schemalic detail of all stages referred

above

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 11 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

4.0

9.&

9.3

9.(

9.9

9.<

9.>

9.@

9.;

9.:

9.&'

SERVICES REQUIRED,

Bvailability of required quantity of 6* #ater and Fuel 1il for the

operation.

Bvailability of -.TD0.TD33' 46CD &&' 4BC %o#er .upply.

Bvailability of /nstrument D .ervice Bir

Bvailability of 0ab facility for boiler #ater regime maintanance.

Bvailability of Bu,iliary steam.

Bvailability of *anual feeding arrangement of Bmmonia 5

-ydra"ine to F.T.

Bvailability of portable fire e,tinguishers at selected locations.

Bvailability of required lighting D communication facility D

manpo#er.

Bvailability of %ublic address .ystem or .iren to communicate the

commencement of steam blo#ing.

Bvailability of Bmbulance D Fire tender in the %o#er station

premises.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 1$ of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

5.0

<.&

<.3

<.(

<.9

<.<

<.>

SAFETY PRECAUTIONS,

Required quantities of safety gears such as helmets Bsbestos

hand gloves ?ar *ufflers etc are available.

First aid 7it bo, available in control room

.ervice #ater shall be made available near the activity area.

Required stair cases or platform or approaches etc #ith hand

rails to electrical operated quic7 opening temporary valves are

made available.

Required barricades to be made to prevent personal from coming

into contact #ith temporary piping.

Required number of sign boards to be put into position at

selected locations to indicate the ongoing process of steam

blo#ing.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 1 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

6.0

>.&

>.3

>.(

EER!ENCY PROCEDURES,

The group consisting of 2T%C and )-?0 #hich is carrying out

steam )lo#ing should be a#are of procedures to be follo#ed in

case of accidents involving in+ury to personnel.

The group should be a#are of operating procedures of portable

fire e,tinguishers to be used for quenching minor fires.

The group should be a#are that if any abnormality is observed in

the permanent and temporary system during the steam blo#ing

operation the operation should be immediately terminated and

appropriate action ta7en to address the emergency.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 11 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

7.0

@.&

@.3

@.(

@.9

@.<

@.>

@.@

@.;

@.:

STATE OF T"E PLANT,

)oiler made ready in all aspects after chemical cleaning.

*a7e up for deaerator made ready.

*otor 6riven )F% #ith all controls made ready.

-ydraulic test of the follo#ing lines completed8

- Feed 0ines

- *. -R- CR- 0ines

- *. to Bu,. %R6. 0ine

- Bll other au,iliary lines identified for steam blo#ing (Refer

section (.')

Bll permanent piping 5 temporary piping insulated and

supportsDhangers are released #ith cold setting.

Feed #ater and drum sampling system made ready.

*anual feeding of Bmmonia and -ydra"ine to F.T made ready.

Bll safety valve disc installed after removing hydro!static plug.

Bdequate communication bet#een control room boiler and TG

area ensured.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 15 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

@.&'

@.&&

@.&3

@.&(

@.&9

@.&<

@.&>

Temporary piping are routed to safe direction so as to avoid

damage to men and material. The piping is #ell supported to #ith

stand the reaction forces during blo#ing. The temporary pipe

e,haust area is suitably cordoned off and notices displayed

prominantly.

.pecial steam blo#ing devices are placed for ?.4 5 /4. These

#or7s are to be ensured before commencing steam blo#ing.

Target plate fi,ing arrangement are made in temporary pipe

connected to

i) Temporary pipe at ?.4 outlet.

ii) CR- line at boiler end

iii) Bt the /4 outlet temporary pipes.

iv) Bt the )F% / 5 // outlet temporary pipes.

-% bypass valves and brea7do#n orifices are not erected before

steam blo#ing. -and operated temp. valves (-1T4 & 5 3) along

#ith spool piece are erected in its place.

0% bypass valve erected #ith steam blo#ing insert.

CR- Bttemperator section not be erected before completion of

.tage 3 steam blo#ing and spool piece erected.

*. stop valves at boiler outlet and ?lectrically 1perated

Temporary 4alves (?1T4) are made operational from FC) on

inching mode.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 16 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

@.&@

@.&;

@.&:

@.3'

@.3&

@.33

@.3(

@.39

Brrangement for measurement of pressure and temperature are

made for calculation of disturbance factor at specified locations

as sho#n in the .chematic dra#ings

.trainer elements are removed before the steam blo#ing

operation.

Flo# no""le control valves and 2R4 flaps #herever applicable

are not erected before steam blo#ing and suitable spool pieces

are erected.

6o#n stream lines of /4 and 0% )ypass valves cross around

pipes are to be manually cleaned.

2o loose debris D e,traneous materials are left inside the

permanent D temporary piping

Bll drains should be left open to atmosphere suitably outside TG

-all. Required allo#ances are given for the thermal e,pansion of

the pipe lines.

Thermo#ells required for 6isturbance factor calculation alone are

erected and the rest are erected after the completion of steam

blo#ing.

Required number of Target %lates and holder are made available.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 12 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

8.0

;.&

;.3

;.(

;.9

ET"OD,

The boiler is to be started in a normal manner follo#ing start up

procedure.

First steam blo# in stage & 3a 3b (a 5(b should be given at a

lo#er pressure say 3< 7gDsq.cm. at )oiler drum and the pipe

lines including temporary piping are surveyed for proper

e,pansion and supports. .ubsequent blo#s are given at higher

pressure as given in ;.(.

Raise the boiler pressure to <' 7gDsq.cm. .hut off firing and at the

same time open the steam blo#ing valves. (Temporary valve

?1T4s or *.!& *.!3 as the case may be). The steam lines

#hich are being steam blo#n should be #armed up prior to

blo#ing. The opening of steam blo#ing valve allo#s steam to

escape to atmosphere at high velocity carrying #ith it loose and

dislodged debris. To prevent thermal stresses in the thic7 #alled

shell li7e drum and headers the saturation temperature change in

drum is limited to 9' deg. C. ma,imum. -ence for the purpose of

steam blo#ing of all critical piping the steam blo#ing valve #ill

be opened at <' 7gDsq.cm. and closed at 3< 7gDsq.cm. drum

pressure.

The #ater level in the drum s#ings beyond visible limits at the

start during and the end of steam blo#ing. There are chances of

#ater droplets to carry over to the saturated steam pipes and lo#

temperature superheater. Bt the same time too lo# #ater level

#ill affect the C.C. pumps running. -ence optimum level is to be

maintained in the drum. /t is preferable to 7eep +ust & port (<'

mm) belo# the normal level at the time of starting the steam blo#.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 18 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

;.<

;.>

;.@

;.;

;.:

;.&'

;.&&

;.&3

Bt the end of steam blo#ing #ater level in drum #ill be lo# and

hence ma7e up the drum level by establishing suitable feed #ater

flo# rate through feed pump.

Bll the steam lines are purged as per various stages and it is a

standard practice to limit number of blo#s per day to ; #ith an

interval of &!& G hours for cooling in addition to overnight cooling.

The furnace e,it gas temperature should be limited to <9' deg. C

to safeguard superheaters and reheaters.

/nternal boiler #ater treatment to be carried out #ith liquid

ammonia and hydra"ine hydrate only to maintain p- value of

&'.' in )oiler #ater and < to 3< ppm of 23-9 in feed #ater.

(*anual 6osing)

-ot tightening of flanges studsDbolts is to be done #herever such

connections have been made.

6uring steam blo#ing. *. CR- 5 -R- line drains are 7ept open

to atmosphere #ithout any valve for achieving free and

uninterrupted flo#.

Target %lates #ill be used for stages & 3a 5 (a. .tainless .teel

target plates having mirror finish #ill be used in final stages. /n

the preceding stages target plates of *.. #ill be used. 6uring

steam blo#ing pressure and temperature readings at selected

locations #ill be noted do#n for the purpose of determining

disturbance factor (Refer .ection &'.' for scheme and method of

calculation).

Completion criteria for all the stages of steam blo#ing is given in

.ection :.'.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet 13 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

;.&(

;.&9

;.&<

;.&>

;.&@

;.&;

;.&:

;.3'

=hile blo#ing stage (a suitable dummies #ill be put at 0%)%

outlet temporary line. Required flange provisions are made in

these temporary lines for installation of dummies. 6rains of

suitable si"e to be provided at the upstream of flange locations

for #arm up purposes.

Follo#ing steps are follo#ed for steam blo#ing stage 9a and 9b.

Bfter completing the stage (b blo#ing dummy to be provided at

the 0%)% outlet temporary piping and at the /4 outlet temporary

piping.

)oiler lighted up and drum pressure raised to 3' 7gDcm

3

and

steam lines charged from )oiler outlet up to dummies provided in

the temporary piping of stages (a and (b.

Temporary steam valve or 6ummy provided in the Temporary

e,haust line connected to permanent steam line to )F% Turbine

is 7ept open.

.team inlet valves CR- E & CR- ! ( are gradually opened and

steam blo#ing carried out for 3'!(' minutes at about 9'!<'C of

system operating pressure.

This blo#ing is continued #ith a gap of 3 -rs bet#een the blo#s.

Bfter fe# blo#s Target %lates are put and further blo#ing

continued. Termination of stage 9a and 9b are as per Target plate

results only as given in .ection :.'.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet $0 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

;.3&

;.33

;.3(

;.39

;.3<

;.3>

Follo#ing steps are follo#ed for steam blo#ing of stage <. Bll the

sub!stages are mentioned in .ection (.'.

)efore commensing the sub stages <a to <i blo#ing any one of

the follo#ing to be completed D made available.

a. .team line to )F%T / and // to be normali"ed.

or

b. Temporary valve (-and 1perated) in )F%T / 5 // e,haust

line is available and closed.

or

c. 6ummies in )F%T / 5 // e,haust line retained.

.ystem charged as per ;.&> and steam inlet valves in each sub

system are opened gradually 5 steam blo#n for &' minutes

duration.

)lo#ing shall be repeated once more after a gap of 3 hours.

.ub!stages <a to <i are blo#n on lines as e,plained above in

steps ;.3( 5 ;.39

Completion criteria for all stages in < is given in section :.'.

ST)T'S

Si.nat/re0

NTPC BHEL

Station: NTPC- Simhadri BHEL Ref No.PS-DC-186-500-000

NTPC Ref no S!"#1#TS#1#006

Sheet $1 of $5

P%ant area: B&!LER

PR&CED'RE (&R STE)" BL&*!N+ &( B&!LER )ND )SS&C!)TED STE)" L!NE

!NCL'D!N+ )',!L!)R- STE)" L!NES

SL.NO

9.0

:.&

:.3

:.(

COPLETION CRITERIA,

/ndications for the result of each blo#ing is the number of pittings

found on the target plate mounted in the temporary e,haust pipes

nearer to the permanent line. The highest velocity of steam is in

the center of the pipe. -ence +udgement should be made for the

end point of steam blo#ing in this area. The area for the above is

(D9the the discharge pipe diameter at the center. /t is

recommended to install the target plate after completing fe#

blo#s in each stage.

For evaluating the cleanliness and termination point of the steam

blo#ing target plate of stainless steel of mirror finish are to be

used.

For stages & 3a (a 9a 5 9b the result of the blo#ing operations

can be +udged by the absolute number of pittings on the target

plate in the central "one. The piping is considered clean if there

are not more than < (five) pittings and shall not have any

deformed edges. )esides there shall be no pitting in the rim

"one ie area other than central "one. This should be achieved in

three consecutive forget plates. Bt least one over night cooling is

to be ensured for steam blo#ing of pipe lines leading to Turbine.

/n addition to this for stages & 3a 5 (a 6isturbance factor value

at selected locations should be &.9 and above.

For all .ub!stages in .tage < the blo#ing is completed based

visual observation. The steam blo#n should be clean and

normally this is achieved in 3 blo#s.

ST)T'S

Si.nat/re0

NTPC BHEL

SHEET $$ &( $5

ET"OD FOR CALCULATIN! DISTURBANCE FACTOR

DURIN! STEA BLO%IN!

6isturbance Factor H Ib

3

, 4b

I

3

*CR , 4*CR

Ib ! .team flo# during blo#ing

I*CR ! .team flo# at *CR

4b ! .p. 4olume of steam during blo#ing

4*CR ! .p. 4olume of steam at *CR

Ib H .onic 4elocity , Brea , &

6uring blo#ing

4b

=here

Ib H .t. flo# in 7gDsec

.onic 4elocity H A% 4b g H *Dsec

Brea H .q.*

4b H Cu.mDAg

A H Constant H &.(

% H %ressure at the e,it pipe H AgD.q.m

4b H .p. 4olume HCu.*DAg

g H Bcceleration due to gravity H *D.ec

3

PROCEDURE FOR STEA BLO%IN! OF BOILER AND

ASSOCIATED STEA LINE INCLUDIN! AU<ILIARY STEA LINES

S"EET 23 OF 25

10.0 &$ LO! S"EET

DATE ,

PROJECT ,

UNIT ,

ACTIVITY , P=T=DF , PRESSURE=TEPERATURE=DISTURBANCE FACTOR.

S.NO STA!E

BLO%

NO

LOCATION

REAR*S I II III IV

P T DF P T DF P T DF P T DF

Si.nat/re0

NTPC BHEL

SHEET $1 &( $5

10.0 C$

DISTURBANCE FACTOR (CALCULATED VALUE$ DURIN!

STEA BLO%IN! (PUFFIN! ET"OD$

A$ CR P#-#3.0.-7

#$ S0.#3 F925 (S" 2>09.0$ , 1498.5 TP"

&$ S0.#3 P-.77>-. (S" 2>09.0$ , 176.3 *SC

'$ S0.#3 T.3?.-#0>-. , 540

0

C

B$ P-.)/'0.) P#-#3.0.- )>-/48 S0.#3 B925/48 + D/70>-'. F#'02-

(C#9'>9#0.)$

STA!E S.NO L2'#0/247

P-.)/'0.)

P#-#3.0.- D>-/48

S0.#3 B925/48

D/70>-'.

F#'02-

R.3#-@

P-.77>-.

*SC

T.3?.

0

C

&

& .- 1D0 (B&!B3) &;.' 93' 3.(:

3 ?.4 /nlet ()&!)3) <.' 9&' @.&<

3a

& .- 1D0 (B&!B3) 3'.' 93' &.<@

3 ?.4 /nlet ()&!)3) @.' 9&' (.:;

( CR- 1D0 (C&! C3) 3.' 9'' (.<>

SHEET $5 &( $5

STA!E S.NO L2'#0/247

P-.)/'0.)

P#-#3.0.- D>-/48

S0.#3 B925/48

D/70>-'.

F#'02-

R.3#-@

P-.77>-.

*SC

T.3?.

0

C

(a

& .- 1D0 (B&!B3) 3>.' 93' &.&3

3 ?.4 ()&!)3) &3.' 9&' 3.3<

( CR- 1D0 (C&!C3) <.' 9'' &.@;

9 -R- 1D0 (6&!63) (.' 9'' &.@:

< /4 /D0 (?&!?3) 3.' 9'' 3.(

You might also like

- API 510 Certification Data Sheets Title GeneratorDocument11 pagesAPI 510 Certification Data Sheets Title Generatornikafiq100% (1)

- Red 670Document28 pagesRed 670Mahmoud Shafie100% (1)

- Heat Transfer Excel Calculations 1Document48 pagesHeat Transfer Excel Calculations 1Felix100% (1)

- Equivalent Circuit of A Three Phase Induction Motor: Experiment No: 2Document6 pagesEquivalent Circuit of A Three Phase Induction Motor: Experiment No: 2Bodhayan PrasadNo ratings yet

- Piping Stress SpecificationDocument23 pagesPiping Stress Specificationpourang1361No ratings yet

- DG SET DATA SHEET AND PANEL DETAILSDocument22 pagesDG SET DATA SHEET AND PANEL DETAILStceterexNo ratings yet

- High Density Polyethylene (HDPE) Pipe and FittingsDocument8 pagesHigh Density Polyethylene (HDPE) Pipe and FittingsJhe InibamNo ratings yet

- O&M Manual For FCUDocument30 pagesO&M Manual For FCUBeatrice Li50% (2)

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- Site Inspection and Test Record: Feeder/Bay: Ohl - 9013 1 General Data and InformationDocument15 pagesSite Inspection and Test Record: Feeder/Bay: Ohl - 9013 1 General Data and InformationMahmoud ShafieNo ratings yet

- STM32F103ZET6 Development BoardDocument10 pagesSTM32F103ZET6 Development BoardpiramidonNo ratings yet

- Energy Conversion Lab Manual NewDocument50 pagesEnergy Conversion Lab Manual NewRavi TejNo ratings yet

- AEC Lab MannualDocument45 pagesAEC Lab MannualBrian TylerNo ratings yet

- MANUFACTURER'S DATADocument4 pagesMANUFACTURER'S DATAfaharaNo ratings yet

- 1800 KVAR PF Test Report For CRTS-27Document5 pages1800 KVAR PF Test Report For CRTS-27saikatNo ratings yet

- WPS PQR-02Document8 pagesWPS PQR-02Ranjan Kumar100% (1)

- (Ref. Code: ME/LM/HTHP/R00) : Centurion Institute of TechnologyDocument79 pages(Ref. Code: ME/LM/HTHP/R00) : Centurion Institute of TechnologyNabin Chandra SahuNo ratings yet

- Control Systems Lab ManualDocument37 pagesControl Systems Lab ManualAmy MaggiNo ratings yet

- Generai ($eiectric: (All Values K Min Max Are in L Nun Inches) L Max Min Min Min NomDocument1 pageGenerai ($eiectric: (All Values K Min Max Are in L Nun Inches) L Max Min Min Min NomMohamed HamedNo ratings yet

- WPS PQR-01Document9 pagesWPS PQR-01Ranjan Kumar0% (1)

- COMPARISON OF PARTIAL DISCHARGE SENSORSDocument8 pagesCOMPARISON OF PARTIAL DISCHARGE SENSORSKUNALJAYNo ratings yet

- C443MDocument6 pagesC443MxuanquangprNo ratings yet

- WPS PQR 12Document9 pagesWPS PQR 12Ranjan KumarNo ratings yet

- Welding (General) : Plant Location Page 1 of 17 RevDocument17 pagesWelding (General) : Plant Location Page 1 of 17 RevRavindra S. JivaniNo ratings yet

- Fermilab d0 en 124Document12 pagesFermilab d0 en 124charleselitb92No ratings yet

- Pioneer SX 45 Service ManualDocument12 pagesPioneer SX 45 Service Manualel_lujoNo ratings yet

- PIC18 Microcontroller QuestionsDocument2 pagesPIC18 Microcontroller QuestionsRyan MillerNo ratings yet

- 3 Comments On Line Pipe Specifications 2013 08 27 RespuestasDocument3 pages3 Comments On Line Pipe Specifications 2013 08 27 Respuestasluisbazan7055No ratings yet

- Choose Cast-Iron, Bronze, or Stainless Steel Construction.: Self-Priming PumpsDocument12 pagesChoose Cast-Iron, Bronze, or Stainless Steel Construction.: Self-Priming PumpscarlofilippinNo ratings yet

- SmartTank Master SpecDocument13 pagesSmartTank Master Speccarlos030476No ratings yet

- BFP Oil FlushingDocument19 pagesBFP Oil FlushingParthiban KarunaNo ratings yet

- Office of Chief Engineer Panki Thermal Power Station Panki-KanpurDocument39 pagesOffice of Chief Engineer Panki Thermal Power Station Panki-Kanpuraharish_iitkNo ratings yet

- Hfe Teac v-480 Service enDocument26 pagesHfe Teac v-480 Service enGuglielmoNo ratings yet

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarNo ratings yet

- Understand IBM Mainframe COBOL Programming with OCCURS and SEARCHDocument15 pagesUnderstand IBM Mainframe COBOL Programming with OCCURS and SEARCHravikiran_8pNo ratings yet

- Electronics Today International April 1990Document68 pagesElectronics Today International April 1990Mitchell CifuentesNo ratings yet

- Procedure For WQTDocument13 pagesProcedure For WQTwalitedisonNo ratings yet

- Document No PCPL-0532-4-407-04-06-1 Control & Relay Panel Data Sheet Section - 4 PAGE: 1 of 12Document12 pagesDocument No PCPL-0532-4-407-04-06-1 Control & Relay Panel Data Sheet Section - 4 PAGE: 1 of 12tceterexNo ratings yet

- Ecspart IIDocument88 pagesEcspart IIKodali Naveen KumarNo ratings yet

- Process Control Lab ManualDocument51 pagesProcess Control Lab Manualkaushikei22100% (2)

- 8 Performance Requirement: 8.1 GeneralDocument142 pages8 Performance Requirement: 8.1 GeneralpzernikNo ratings yet

- RC Coupled Amplifier With ResponseDocument7 pagesRC Coupled Amplifier With ResponselekhapankajNo ratings yet

- Tender Document For Construction ProjectDocument389 pagesTender Document For Construction ProjectAndrew Keher100% (2)

- EP 600 Calibration ProcedureDocument12 pagesEP 600 Calibration ProceduregueridiNo ratings yet

- Report on blade failure of LP last stages in a 210 MW steam turbineDocument5 pagesReport on blade failure of LP last stages in a 210 MW steam turbinemanojpuru100% (1)

- Areva P443 DistanceDocument10 pagesAreva P443 DistancesrinivasaphanikiranNo ratings yet

- Abstract of Minor Bridge at KM 3+960Document5 pagesAbstract of Minor Bridge at KM 3+960Gobinder Singh VirdeeNo ratings yet

- Latest PDR SL-TWT Volume-1Document104 pagesLatest PDR SL-TWT Volume-1raktimguhaNo ratings yet

- Chasis Tmpa8873cscng6v11Document4 pagesChasis Tmpa8873cscng6v11domador1624No ratings yet

- Speed Stv2115anf Chasis Cy8873c Tmpa8873cscng6v11Document4 pagesSpeed Stv2115anf Chasis Cy8873c Tmpa8873cscng6v11domador162450% (2)

- Applied Gas DynamicsDocument11 pagesApplied Gas DynamicsAishwarya RaviNo ratings yet

- LM3 5 Precisio N Centigrad e Temperatur e Sensor S: FeaturesDocument31 pagesLM3 5 Precisio N Centigrad e Temperatur e Sensor S: FeatureslitodexNo ratings yet

- Sugesited ProjectsDocument23 pagesSugesited Projectsyut159753No ratings yet

- WPS PQR 15Document11 pagesWPS PQR 15Ranjan KumarNo ratings yet

- Medidor de Fly Backs k7205Document6 pagesMedidor de Fly Backs k7205Alejandro ChiappesoniNo ratings yet

- API 510 Data Sheet - AnswersDocument6 pagesAPI 510 Data Sheet - Answersjithinjose86No ratings yet

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198No ratings yet

- WEH61882-61886 High Temperature Resistance Finish Coat (200-600 ) (All K...Document5 pagesWEH61882-61886 High Temperature Resistance Finish Coat (200-600 ) (All K...kannagi198No ratings yet

- Port Matl Inspn ReportDocument2 pagesPort Matl Inspn Reportkannagi198No ratings yet

- 5 Key Things Power Plant Engineers Need to Know About PumpsDocument8 pages5 Key Things Power Plant Engineers Need to Know About Pumpskannagi198No ratings yet

- 5 Key Things Power Plant Engineers Need to Know About PumpsDocument8 pages5 Key Things Power Plant Engineers Need to Know About Pumpskannagi198No ratings yet

- CW PIPINGDocument2 pagesCW PIPINGkannagi198No ratings yet

- Gayatri Projects Limited Power Project Works, NelloreDocument4 pagesGayatri Projects Limited Power Project Works, Nellorekannagi198No ratings yet

- U#2 DBC DTCDocument96 pagesU#2 DBC DTCkannagi198No ratings yet

- Project Paint Details As On 05.01.2016Document3 pagesProject Paint Details As On 05.01.2016kannagi198No ratings yet

- Project Paint Details As On 05.01.2016Document3 pagesProject Paint Details As On 05.01.2016kannagi198No ratings yet

- Fees SharingDocument4 pagesFees Sharingkannagi198No ratings yet

- Thermal Powertech Corporation India Limited: Liquid Penetrant Examination ReportDocument4 pagesThermal Powertech Corporation India Limited: Liquid Penetrant Examination Reportkannagi198No ratings yet

- Thermal Powertech Corporation India Limited: Liquid Penetrant Examination ReportDocument4 pagesThermal Powertech Corporation India Limited: Liquid Penetrant Examination Reportkannagi198No ratings yet

- Preliminary Shipment Plan For 2013 (Excluding OCG Shipment, Updated On 16.05.2013)Document4 pagesPreliminary Shipment Plan For 2013 (Excluding OCG Shipment, Updated On 16.05.2013)kannagi198No ratings yet

- Thermal Powertech Corporation India Limited: Liquid Penetrant Examination ReportDocument4 pagesThermal Powertech Corporation India Limited: Liquid Penetrant Examination Reportkannagi198No ratings yet

- Preliminary Shipment Plan For 2013 (Excluding OCG Shipment, For Reference Only)Document1 pagePreliminary Shipment Plan For 2013 (Excluding OCG Shipment, For Reference Only)kannagi198No ratings yet

- Cleat CompDocument7 pagesCleat Compkannagi198No ratings yet

- EISENBISE-High Energy Piping PresentationDocument61 pagesEISENBISE-High Energy Piping Presentationkannagi198No ratings yet

- DPT Report - U1Document88 pagesDPT Report - U1kannagi198No ratings yet

- List of NDT inspections and tests with conclusionsDocument2 pagesList of NDT inspections and tests with conclusionskannagi198No ratings yet

- Guide Plate Nut Worn Out After 3000 HrsDocument3 pagesGuide Plate Nut Worn Out After 3000 Hrskannagi198No ratings yet

- In Situ ProcedureDocument19 pagesIn Situ Procedurekannagi198No ratings yet

- House 87X20Document1 pageHouse 87X20kannagi198No ratings yet

- Pmi On TG Dated 05-09-2014Document2 pagesPmi On TG Dated 05-09-2014kannagi198No ratings yet

- House 20X87Document1 pageHouse 20X87kannagi198No ratings yet

- Weld Deposite CalculationsDocument2 pagesWeld Deposite CalculationsGanesh YadavNo ratings yet

- SALEM SCH FeesDocument31 pagesSALEM SCH Feeskannagi198No ratings yet

- Release Note From BV For Unit - 1Document2 pagesRelease Note From BV For Unit - 1kannagi198No ratings yet

- Steel Test Report 8Document1 pageSteel Test Report 8kannagi198No ratings yet

- FormsDocument25 pagesFormskannagi198No ratings yet