Professional Documents

Culture Documents

Module 2 - GEARS L Ecture 10 - Spur Gear Design: C Ontents

Module 2 - GEARS L Ecture 10 - Spur Gear Design: C Ontents

Uploaded by

RefkiDespratamaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module 2 - GEARS L Ecture 10 - Spur Gear Design: C Ontents

Module 2 - GEARS L Ecture 10 - Spur Gear Design: C Ontents

Uploaded by

RefkiDespratamaCopyright:

Available Formats

Machine Design II Prof. K.Gopinath & Prof. M.M.

Mayuram

Indian Institute of Technology Madras

Module 2 - GEARS

Lecture 10 - SPUR GEAR DESIGN

Contents

10.1 Problem 3 Spur gear design

10.1.1 Buckingham Approach

10.1.2 AGMA Approach

10.1 Problem 3 - Design of Spur gear

A pair of gears is to be designed to transmit 30kW power from a pinion running at

960rpm to a gear running at 320rpm. Design the gears so that they can last for 10

8

cycles. Assume 20

o

full depth involute spur gear for the system. Motor shaft diameter is

30mm.

Data given:

W = 30 kW; n

1

= 960 rpm; n

2

= 320 rpm; Life = 10

8

cycles; 20

o

full depth involute spur

gear.

Solution:

i = n

1

/ n

2

= 960 / 320 = 3

In order to keep the size small and meet the centre distance, Z

1

= 17 chosen

Z

2

= i Z

1

= 3 x 17 = 51

n x x

. rad/ s

t t

= = e=

1

2 2 960

100 48

60 60

Torque is given by,

1

w 30x1000

T 298

100.48

= = =

e

.57 Nm

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

From Lewis equation for pinion we have,

t 1

p p 2

1

F 2T

[ ]

bYm bYZ m

o = = s o

(10.1)

SAE 1050 hardened by OQT with permissible bending strength of 532 and hardness of

223Bhn is selected for pinion and SAE 1045 hardened by WQT with permissible

bending strength of 487 and hardness of 215 Bhn is selected for the gear from Table

10.1. Face width b = 10m is chosen for both wheels.

Table 10.1 Safe static stresses for use in the Lewis equation

Material [ ] MPa BHN

Gray cast iron

ASTM 25

ASTM 35

ASTM 50

Cast steel(low carbon)

0.2% C not heat treated

0.2% C WQT

Forged carbon steel

SAE 1020 case hardened and WQT

SAE 1030 not heat treated

SAE 1035 not heat treated

SAE 1040 not heat treated

SAE 1045 hardened by WQT

SAE 1045 hardened by WQT

SAE 1050 hardened by OQT

Alloy steel

SAE 2320 case hardened and WQT

SAE 2345 hardened by OQT

SAE 3115 case hardened and OQT

SAE 3145 hardened by OQT

SAE 3245 hardened by OQT

SAE 4340 hardened by OQT

SAE 4640 hardened by OQT

SAE 6145 hardened by OQT

122

183

228

304

380

274

304

350

380

456

487

532

761

761

563

806

989

989

837

1019

174

212

223

180

250

156

180

190

202

205

215

223

225

475

212

475

475

475

475

475

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

10.1.1 Buckingham approach:

The preliminary dimensions are found from Lewis equation and then they are checked

for dynamic loads by Buckingham equation.

From equation (10.1) substituting the value of b = 10m, we have,

(10.2)

1

p 3

1

p

T

[ ] (

5YZ m

o = s o

From Table 10.2, for the pinion Y = 0.25808 for Z

1

= 17

For the gear, Y = 0.39872, for Z

2

= 51

For gear, Y[]

g

= 0.39872x 487 = 194.17

For pinion, Y[]

p

= 0.25808 x 542 = 139.87

Table 10.2 Values of the Lewis form factor Y

Number of

teeth

=20

a=0.8m*

b=m

=20

a=m

b=1.25m

=25

a=m

b=1.25m

12

13

14

15

16

17

18

19

20

21

22

24

26

28

30

34

38

45

50

60

75

100

0.335 12

0.348 27

0.359 85

0.370 13

0.379 31

0.387 57

0.395 02

0.401 79

0.407 97

0.413 63

0.418 83

0.428 06

0.436 01

0.442 94

0.449 20

0.459 20

0.467 40

0.478 46

0.484 58

0.493 91

0.503 45

0.513 21

0.229 60

0.243 17

0.255 30

0.266 22

0.276 10

0.285 08

0.293 27

0.300 78

0.307 69

0.314 06

.0319 97

0.330 56

0.339 79

0.347 90

0.355 10

0.367 31

0.377 27

0.390 93

0.398 60

0.410 47

0.422 83

0.435 74

0.276 77

0.292 81

0.307 17

0.320 09

0.331 78

0.342 40

0.352 10

0.360 99

0.369 16

0.376 71

0.383 70

0.396 24

0.407 17

0.416 78

0.425 30

0.439 76

0.451 56

0.467 74

0.476 81

0.490 86

0.505 46

0.520 71

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Hence, for the same face width pinion will be weaker and consideration for the design

is,

(10.3)

p 3 3

1

T 298.57x1000 13610

5YZ m 5x0.25808x17m m

532MPa

o = = =

s

3

m = 2.93 mm. Since motor shaft diameter is 30 mm, to get sufficiently large pinion m = 4

mm is taken.

Table 10.3 Data for pinion and gear

Wheel Z m b=10m d V =wrv Material Hardness

Pinion 17 4mm 40 mm 68mm 3.42 m/s SAE1050 223

Gear 51 4mm 40 mm 204mm 3.42 m/s SAE1045 215

We will now use Buckingham dynamic load approach for the design.

F

t

= T

1

/r

1

= 298.57/0.034 = 8781 N

Buckingham dynamic load is given by,

(10.4)

t

i

t

9.84V(Cb+F )

F

9.84V+0.4696 Cb+F

(

=

(

(

For V=3.42 m/s permissible error is e= 0.088 mm from Fig.10.1. From Table 10.4, if we

choose I class commercial cut gears, expected error is 0.050 for m=4mm. In order to

keep the dynamic load low precision cut gears are chosen. So, e = 0.0125

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Fig. 10.1 Permissible error

Table 10.4 Expected error in tooth profile

Gear quality and expected error e

Module

First class commercial

gears

Carefully cut gears Precision gears

Up to 4

5

6

7

8

9

10

0.050

0.056

0.064

0.072

0.080

0.085

0.090

0.025

0.025

0.030

0.035

0.038

0.041

0.044

0.0125

0.0125

0.0150

0.0170

0.0190

0.0205

0.0220

Table 10.5 Value of C

Tooth form Material of pinion and

gear

C

14.5

o

Cast iron and cast iron

steel and cast iron

steel and steel

5720 e

7850 e

11440 e

20

o

Full depth

Cast iron and cast iron

steel and cast iron

steel and steel

5930 e

8150 e

11860 e

20

o

Stub

tooth

Cast iron and cast iron

steel and cast iron

steel and steel

6150 e

8450 e

12300 e

From Table 10.5, if material for both gear and pinion are steel, then,

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

C = 11860e = 11860 x 0.0125 = 148.25

Substituting the values F

t

= 8781 N, C = 148 .25, V=3.42 m/s, b= 40mm in eqn. (10.4),

Buckingham dynamic load is given by,

(10.5)

(10.6)

6 for steel vs steel, pinion and gear C

p

= 191 MPa

0.5

and substituting i

3, =20

0

we

Elastic coefficient C

p

for spur gears in MPa

0.5

M

i

9.84x3.42(148.25x40+8781)

F 5464N

9.84x3.42+0.4696 148.25x40+8781

(

= =

(

F

d

= F

t

+ F

i

= 8781 + 5464 = 14245 N

Beam strength of the pinion is given by,

F

tp

= bYm []

p

= 40x0.25808 x4x542 = 22381 N

Since F

tp

(22381)> F

d

(14245) the design is safe from tooth bending failure

consideration.

Wear strength of the pinion is given by,

2

[ ] o

| |

From Table 10.

H

t s 1

F bd I

C

=

|

|

p

\ .

=

o o

sin cos i sin20 cos20 3

I 0.1205

2 i 1 2 3 1

| |

= = =

+ +

Table 10.6

Gear aterial Pinion Material

(=0.3 in all cases)

Steel Cast iron Al Bronze Tin Bronze

Steel, E=207 GPa 191 166 162 158

Cast iron, E=131 GPa 166 149 149 145

Al Bronze, E=121 GPa 162 149 145 141

Tin Bronze,

GPa

158 145 141 137 E=110

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Surface fatigue strength of the pinion material is

sf

=

sf

K

L

K

R

K

T

raph1

o

Pa) for metallic spur gears (10

7

cycle

life 99% reliability and temperature <120

o

C)

Material

sf

= 2.8(Bhn) 69MPa

= 2.8 x 223-69 = 555.4MPa

K

L

= 0.9 for 10

8

cycles life from g

K

R

= 1.0 taken for 99 reliability

K

T

= 1.0 for operating temperature <120 C (assumed)

Table 10.7 Surface fatigue strength

sf

(M

sf

(MPa)

Steel 2.8 (Bhn)-69MPa

Nodular iron 0.95(2.8(Bhn)-69MPa)

Cast iron, grade 20 379

Cast iron, grade 30 482

Cast iron, grade 40 551

Tin Bronze, AGMA 2C (11% Sn) 207

Aluminium Bronze (ASTM 148 52) (Alloy 9C H.T.) 448

Fig.10.2 Life factor K

L

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Table 10.8 Reliability factor K

R

Reliability (%) K

R

50 1.25

99 1.00

99.9 0.80

Surface fatigue strength of the pinion material is

sf

=

sf

K

L

K

R

K

T

= 555.4x0.9x1x1 = 500MPa

a

ear strength of the pinion is:

ince F

ts

(1860) << F

d

(14245), the design is not safe. Revision is necessary.

ing,

and increase the b to 13m = 13 x 4 = 52 mm.

w that,

ig.10.1

= 1261x0.9x1x1 = 1135MPa

Assuming, factor of safety, s = 1.1

[

H

] =

sf

/s = 500/1.1 = 455MP

W

2

2

H

t s 1

p

[ ] 455

F =bd I =40x68x0.1205 =1860 N

C 191

| |

| |

|

|

|

\ .

\ .

S

As the SAE1050 can attain a hardness of 800 VPN(~750 Bhn) after oil quench

increase the hardness to 475 Bhn

From Table 10.7, we kno

sf

= 2.8(Bhn) 69MPa

= 2.8 x 475-69 = 1261MPa

K

L

= 0.9 for 10

8

cycles life from F

K

R

= 1.0 taken for 99 reliability

K

T

= 1.0 for operating temperature <120

o

C Assumed.

Surface fatigue strength of the pinion material is

sf

=

sf

K

L

K

R

K

T

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

ntent on the hardness of fully hardened steel

H

] =

sf

/s = 1135 /1.1 = 1032MPa

Since F

ts

(12439)< F

d

(14245), still it is not safe. Hence increase the module to 5mm.

Table 10.9 Properties of p d

Material Hardness

Fig.10.3 Effect of carbon co

Assuming factor of safety, s = 1.1

[

2

2

H

t s 1

p

C 191

|

\ .

\ .

[ ] 1032

F =bd I =52x68x0.1205 =12439N

| |

| |

|

|

inion an gear

Wheel Z m b=13m d V =wrv

Pinion 17 5mm 65 mm 85mm 4.27 m/s C 50 475

Gear 51 5mm 65 mm 255mm 4.27 m/s C 45 450

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

With new dimensions F

d

= 16098 N

F

ts

= 19436 N. Since F

ts

> F

d

, the revised design is safe from surface fatigue (pitting)

ts

= 14951 N , Face width of 50 mm is adequate

Approach

0 kW; n

1

= 960 rpm; n

2

= 320 rpm; Life = 10

8

cycles; 20

o

full depth involute spur

ear.

e of gears small and avoid interference, Z

1

= 17 is chosen.

2

= i Z

1

= 3 x 17 = 51

h bending stress is,

considerations.

If b = 50 mm, F

d

= 13186 N

F

10.1.2 AGMA

Data given:

W = 3

g

Solution:

i = n

1

/ n

2

= 960 / 320 = 3

In order to keep the siz

Z

1

1

2 n 2 x960

= = 100.48rad/ s

60 60

t t

e =

1

1

100.48 e

1000W 1000x30

T 298.57Nm = = =

AGMA equation for toot

d

1

= m Z

1

Face width, b= 10 to 13 m.

t

v o m

K K K o =

F

b m J

1

v o m 2

1

bZ m J

K K

2T

K [ ] o = s o

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

b = 10 m is assumed for the first trial.

- J = 0.34404 for pinion Z

1

= 17 mating with gear Z

2

=51

AGMA geometry factor J for teeth having = 20

o

, a=1m, b=1.25m and

r

- For gear J = 0.40808

- These values are obtained from the table

Table 10.10

f

=0.300m

Number of teeth in mating gear Number

of teeth

1 17 25 35 50 85 300 1000

18

19

20

21

22

24

26

28

30

34

38

45

50

60

75

100

150

300

Rack 0.305 75 0.465 54 0.484 15 0.499 88 0.534 67 0.534 67 0.552 72 0.571 73

0.244 86

0.247 94

0.250 72

0.253 23

0.255 52

0.259 51

0.262 89

0.265 80

0.268 31

0.272 47

0.275 75

0.280 13

0.282 52

0.286 13

0.289 79

0.293 13

0.297 38

0.301 41

0.324 04

0.330 29

0.336 00

0.341 24

0.346 07

0.354 68

0.362 11

0.368 60

0.374 62

0.383 94

0.391 70

0.402 23

0.408 08

0.417 02

0.426 20

0.435 61

0.445 30

0.455 26

0.332 12

0.338 78

0.344 85

0.350 44

0.355 59

0.364 77

0.372 72

0.379 67

0.385 80

0.396 71

0.404 46

0.415 79

0.422 08

0.431 73

0.441 63

0.451 80

0.462 26

0.473 04

0.338 40

0.345 37

0.351 76

0.357 64

0.363 06

0.372 75

0.381 15

0.388 51

0.395 00

0.405 94

0.414 80

0.426 85

0.435 55

0.443 83

0.454 40

0.465 27

0.476 45

0.487 98

0.344 04

0.351 34

0.358 04

0.364 22

0.369 92

0.380 12

0.388 97

0.396 73

0.403 59

0.415 17

0.424 56

0.437 35

0.444 48

0.455 40

0.466 68

0.478 27

0.490 23

0.502 78

0.350 50

0.358 22

0.365 32

0.371 86

0.377 92

0.388 77

0.398 21

0.406 50

0.413 83

0.426 24

0.436 33

0.450 10

0.457 78

0.469 60

0.481 79

0.494 37

0.507 36

0.520 78

0.355 94

0.364 05

0.371 51

0.378 41

0.384 79

0.396 26

0.406 25

0.415 04

0.422 83

0.436 04

0.446 80

0.461 52

0.469 75

0.482 43

0.495 54

0.509 09

0.523 12

0.537 65

0.361 12

0.369 63

0.377 49

0.384 75

0.391 48

0.403 60

0.414 18

0.423 51

0.431 79

0.445 86

0.457 35

0.473 10

0.481 93

0.495 57

0.509 70

0.524 35

0.539 54

0.555 33

The t iven by, ooth bending stress is g

0.5

0.5

is assumed.

v

78 (200V)

K 1.15

78

( +

= =

(

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

K

o

= 1.25 is taken assuming uniform power source and moderate shock load from the

table 7

K

m

= 1.3 assuming accurat for face width of about

50mm.

v

Driv chinery

e mounting and precision cut gears

Table 10.11 -O erload factor K

o

en Ma

Source of power U Moderate Shock Heavy Shock niform

Uniform 1.00 1.25 1.75

Light shock 1.25 1.50 2.00

Medium 2.25 shock 1.50 1.75

10.12 Load distribu cto

Face width ( mm)

Table tion fa r K

m

Characteristics of Support 0 - 50 150 225 400 up

Accurate mountings, small bearing 1.3 1.4 1.5 1.8

clearances, minimum deflection, precision

gears

Less rigid mountings, less accurate gears,

contact across the full face

1.6

1.7

1.8

2.2

Accuracy and mounting such that less than Over

2.2

Over

2.2

Over

2.2

Over

2.2 full-face contact exists

Substituting these values in the equation,

1

1 v o m 2 2

1

298570x1.15x1.25x1.3

K K

10mx17xm x0.34404

2T

K

bZ m J

o = =

3

m

o=

9539

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

e

=

e

k

L

k

v

k

s

k

r

k

T

k

f

k

m

The pinion is of steel C50 OQT with 223Bhn hardness and tensile strength of 660MPa

Bhn and tensile strength of 465MPa.

be <5mm; k

S

= 0.73 from the

ig.10.4 for

Fig. 10. 4 Surface factor k

s

able Re ty r K

factor R

and the gear is of C45 OQT with hardness 210

For pinion

e

= 0.5

ut

= 0.5 x 660 = 330MPa

k

L

= 1 for bending, k

V

= 1 assumed expecting m to

F

ut

= 660MPa, k

r

= 0.897 for 90% reliability

T 10.13 liabili facto

r

Reliability 0.50 0.90 0.95 0.99 0.999 0.9999

Factor K

r

1.000 0.897 0.868 0.814 0.753 0.702

k

T

=1 assumed based on operating temperature <120

o

C

k

f

= 1.- and k

m

= 1.33 for

ut

= 660MPa ( Ultimate tensile strength = 660 MPa for

SAE 1050 con

e

3 = 287.4MPa

umed

OQT dition)

=

e

k

L

k

v

k

s

k

r

k

T

k

f

k

m

= 330x1x1x0.73x0.897x1x1x1.3

Factor of safety on bending of 1.5 ass

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

[] =

e

ous effects factor k

m

rom tooth bending fatigue considerations,

andard value. From this module, the dimensions

alculated are given in Table 10.14.

Tab 10 ens s o a

Material Hardness

/ s = 287.4 / 1.5 =191.6MPa

Fig.10.5 - Miscellane

F

1 3

m

9539

[ ] 191.6 o = s o =

Solving the equation we get m = 3.68mm

Now take m=4 mm as the next st

c

le .14 Dim ion f pinion nd gear

Wheel Z m b=10m d V =wrv

Pinion 17 4mm 40 mm 68mm 3.42 m/s C 50 223

Gear 51 4mm 40 mm 204mm 3.42 m/s C 45 205

F

t

= T

1

/ r

1

= 29857/34 = 8781N

The tooth has to be checked from surface durability considerations now.

he contact stress equation of AGMA is given below:

steel

T

t

H p V o m

1

bd I

F

C K K K o =

C

p

= 191 MPa

0.5

from the table for steel vs

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Substituting i =3, =20 we get I= 0.1205

0

o

= 1.25 and K

m

= 1.3 assumed as in the case of bending stress calculation

H

= 1209MPa

strength of the pinion material is given by,

ph1

o

C assumed.

lues in the equation,

get,

0/1.1 = 455MPa

o o

sin cos i sin20 cos 20 3

I 0

2 i 1 2 3 1

| |

= = =

+ +

.1205

0.5 0.5

0.5 0.5

v

78 (200V) 78 (200x3.42)

K 1

78 78

( ( + +

= =

( (

.15 =

From Table 10.11 and 10.12,

K

t

o m

F 8781x1.15x1.25x1.3

K K 191

H p V

1

C K

bd I 40x68x0.1205

o = =

The surface fatigue

sf

=

sf

K

L

K

R

K

T

Where

sf

= 2.8(Bhn) 69MPa

= 2.8 x 223-69 = 555.4MPa

K

L

= 0.9 for 10

8

cycles life from gra

K

R

= 1.0 taken for 99% reliability

K

T

= 1.0 for operating temperature <120

Substituting the va

sf

=

sf

K

L

K

R

K

T

= 555.4x0.9x1x1 = 500MPa

Assuming a factor of safety, s = 1.1

From Fig. 10.2 and Table 10.8, we

[

H

] =

sf

/s = 50

H

= 1209MPa

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

Since

H

(1209) >> [

H

] (455), the design is not safe and surface fatigue failure will

hardness of the material to 475Bhn and also increase the b to 13m

,

sf

=

sf

K

L

K

R

K

T

475-69 = 1261MPa

R

= 1.0 taken for 99% reliability

<120

o

C Assumed.

ssuming a factor of safety s = 1.1

H

] =

sf

/s = 1135 /1.1 = 1032MPa

s

H

(1185) > [

H

] (1032) the design is not safe from surface durability considerations.

ence increase the module to 5mm and take b=10m

occur.

Solution:

Increase the surface

= 13 x 4 = 52 mm

From Fig. 3 we get

Surface fatigue strength of the pinion material as

where

sf

= 2.8(Bhn) 69MPa = 2.8 x

K

L

= 0.9 for 10

8

cycles life from graph1

K

K

T

= 1.0 for operating temperature

Substituting these values we get,

sf

=

sf

K

L

K

R

K

T

= 1261x0.9x1x1 = 1135MPa

A

[

t

H p V o m

1

K 191

F 8781x1.15x1.25x1.3

C K K

bd I 52x68x0.1205

o = =

A

H

t

H p V o m

1

F 7025x1.17x1.25x1.3

C K K K 191

bd I 50x85x0.1205

o = =

Machine Design II Prof. K.Gopinath & Prof. M.M.Mayuram

Indian Institute of Technology Madras

H

=975MPa < [

H

] (1032MPa). Hence the design is safe from surface durability

consideration. Final specification of the pinion and gear are given in the Table 10.20

and 10.21.

Table 10.20 Values for gear and pinion

Wheel Z m b=10m d

Pinion 17 5mm 50 mm 85mm

Gear 51 5mm 50 mm 255mm

Table 10.21 Specification of gear and pinion

Wheel Material Steel Hardness Manufacturing quality

Pinion SAE1050 OQT 475Bhn Precision cut

Gear SAE 1045 OQT 450Bhn Precision cut

-------------------

You might also like

- Conoco Phillips Specification - Surface Christmas Trees, Christmas Tree Valves and WellheadsDocument15 pagesConoco Phillips Specification - Surface Christmas Trees, Christmas Tree Valves and WellheadsJaveed A. KhanNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Drill Jig BushingsDocument74 pagesDrill Jig BushingsMEHABOOBBEPARINo ratings yet

- Technical Specifications For Gantry Crane With Double GirdersDocument12 pagesTechnical Specifications For Gantry Crane With Double GirdersSujay SantraNo ratings yet

- Cedarapids Js Series Spec Sheet r1!4!2023Document8 pagesCedarapids Js Series Spec Sheet r1!4!2023Juan Marcos Rodriguez100% (1)

- C Rollway PDFDocument16 pagesC Rollway PDFoxonoerNo ratings yet

- Crusher PlantDocument29 pagesCrusher PlantPrafull Agrawal0% (1)

- Chinese To DinDocument7 pagesChinese To DinDamla KaymakçıNo ratings yet

- TS 5 Transfer SystemDocument246 pagesTS 5 Transfer SystemSantosh DengleNo ratings yet

- Series: The Reliable Brand!Document6 pagesSeries: The Reliable Brand!Cristian J. MejíaNo ratings yet

- Dozer: Engine WeightsDocument28 pagesDozer: Engine WeightssafvafNo ratings yet

- 2013 Wright Specifications CatalogDocument189 pages2013 Wright Specifications CatalogcenicercNo ratings yet

- Manual E11 Bucket Elevator Jema AgroDocument40 pagesManual E11 Bucket Elevator Jema AgroMuhammad Wasay KhalidNo ratings yet

- Masta SDG SeriesDocument26 pagesMasta SDG SeriesSandip GhoshNo ratings yet

- NUST Hostel Admission Form New PDFDocument2 pagesNUST Hostel Admission Form New PDFMuhammad Waqas0% (1)

- Junttan PMx27 DatasheetDocument4 pagesJunttan PMx27 DatasheetIkhsan SetiawanNo ratings yet

- Imt International Drilling Rigs Spec F3f1a4Document16 pagesImt International Drilling Rigs Spec F3f1a4Phinto YuliandraNo ratings yet

- Presentation On WeldingDocument103 pagesPresentation On WeldingBharath KumarNo ratings yet

- WR432GB00C CATdisc1 PDFDocument16 pagesWR432GB00C CATdisc1 PDFgovindsrNo ratings yet

- 15ME3112 Design of Machine ElementsDocument29 pages15ME3112 Design of Machine Elementslikhith saiNo ratings yet

- Shimpo Circulute 3000 CatalogDocument36 pagesShimpo Circulute 3000 CatalogElectromateNo ratings yet

- Track Drill: General DataDocument20 pagesTrack Drill: General Datadeath666darkNo ratings yet

- Pmi ProcedureDocument8 pagesPmi Proceduresaurabh joshiNo ratings yet

- Time Temperature Transformation (TTT) Diagrams PDFDocument108 pagesTime Temperature Transformation (TTT) Diagrams PDFSerkan Apay100% (1)

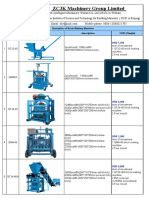

- ZCJK Brick Machine Price List - LilyDocument4 pagesZCJK Brick Machine Price List - LilyTimothy Ndeleva100% (1)

- Internal GearsDocument4 pagesInternal GearsBranislav DjordjevicNo ratings yet

- PowerPack+brochure+ (V1 0)Document2 pagesPowerPack+brochure+ (V1 0)Khánh VũNo ratings yet

- Cbs CatalogueDocument195 pagesCbs Cataloguemadaboutalfa8168No ratings yet

- Gears: Looking For GATE Preparation Material? Join & Get Here Now!Document8 pagesGears: Looking For GATE Preparation Material? Join & Get Here Now!Akash SoniNo ratings yet

- Design of Machine Members II R5320305 Set 3Document2 pagesDesign of Machine Members II R5320305 Set 3Ravi Kumar KamarthiNo ratings yet

- Spur GearDocument11 pagesSpur GearvenkatkavinNo ratings yet

- Note On Gear BoxDocument32 pagesNote On Gear BoxanupbagNo ratings yet

- Triangular LoadsDocument4 pagesTriangular LoadsMark SyNo ratings yet

- Spec Plummer Block BearingDocument2 pagesSpec Plummer Block BearingSithipol PoprayoonNo ratings yet

- Analysis of Shaft AssemblyDocument8 pagesAnalysis of Shaft Assemblyvarshasdm1987No ratings yet

- EMCO Electro - Hydraulic Drum BrakeDocument7 pagesEMCO Electro - Hydraulic Drum Brakehardik033No ratings yet

- Fenner Dual Duty Pulley With Taper Lock Bush: A / Spa C / SPC 8V Timing PulleyDocument3 pagesFenner Dual Duty Pulley With Taper Lock Bush: A / Spa C / SPC 8V Timing PulleyPankaj Pandey100% (1)

- Designn of Tranmission SystemDocument4 pagesDesignn of Tranmission Systemsathiskumar411No ratings yet

- SIS User's Guide: Service Information SystemDocument31 pagesSIS User's Guide: Service Information SystemKeith McCannNo ratings yet

- Hammer MillsDocument3 pagesHammer Millswebmaster9441No ratings yet

- Hydraulic Cone Crusher PDFDocument16 pagesHydraulic Cone Crusher PDFJanethDeNunuraNo ratings yet

- ABB CatalogueDocument6 pagesABB CatalogueNavneet SinghNo ratings yet

- BearingDocument4 pagesBearingFidatul Ain HalidNo ratings yet

- Design of Steel and RCC Structures Unit 2 Deign of Bolted ConnectionDocument52 pagesDesign of Steel and RCC Structures Unit 2 Deign of Bolted Connectionlammii waaqNo ratings yet

- Stress Analysis of Tractor Trolley Chassis With Effect of Various Thickness and Design Optimization For Weight Reduction Ijariie1894Document7 pagesStress Analysis of Tractor Trolley Chassis With Effect of Various Thickness and Design Optimization For Weight Reduction Ijariie1894anil sajjanarNo ratings yet

- Design and Fabrication of Eccentric Punching MachineDocument12 pagesDesign and Fabrication of Eccentric Punching MachineSankarasubbu NirmalaNo ratings yet

- WEG Crusher Duty Three Phase Motor Usacd10.2016 Brochure EnglishDocument8 pagesWEG Crusher Duty Three Phase Motor Usacd10.2016 Brochure EnglishbahramhooNo ratings yet

- Roller Conveyor Chain AttachmentsDocument19 pagesRoller Conveyor Chain AttachmentsRichard VachonNo ratings yet

- E1102m PDFDocument283 pagesE1102m PDFBhawani Singh RajawatNo ratings yet

- Dmu 60 / 80 / 100 Monoblock Classic Series: CNC Universal Milling MachinesDocument24 pagesDmu 60 / 80 / 100 Monoblock Classic Series: CNC Universal Milling MachinesButch BorjaNo ratings yet

- Prefab 2marksDocument16 pagesPrefab 2marksSulthan SuperTrampNo ratings yet

- KG125Document36 pagesKG125Bülent KabadayiNo ratings yet

- The Perfect Blend of Technology, Performance and Product SupportDocument1 pageThe Perfect Blend of Technology, Performance and Product SupportFelipe HernandezNo ratings yet

- NSK Electrically Insulated Bearings 1306Document2 pagesNSK Electrically Insulated Bearings 1306Leroy AraoNo ratings yet

- Renold Chain CatalogueDocument24 pagesRenold Chain CatalogueThang NguyenNo ratings yet

- Expandable MandrelsDocument3 pagesExpandable Mandrelsali-masoodNo ratings yet

- Unirol CatalogDocument22 pagesUnirol CatalogDerlan MarzelaNo ratings yet

- General Design RequirementsDocument8 pagesGeneral Design RequirementsRohit ShresthaNo ratings yet

- ME308 Second Project PDFDocument13 pagesME308 Second Project PDFOzan OzgenNo ratings yet

- Analysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisDocument7 pagesAnalysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisEditor IJTSRDNo ratings yet

- Plate FeederDocument4 pagesPlate FeederAnonymous 8t0V9SNo ratings yet

- Tongil Gu SeriesDocument3 pagesTongil Gu Seriesmatthew_k_kohNo ratings yet

- Tehnicki Vodic PDFDocument273 pagesTehnicki Vodic PDFSlaven Dadan-NanoNo ratings yet

- Sepction - 3Document3 pagesSepction - 3k koradiaNo ratings yet

- WND Petrojet NDT RT and PWHT Unit RatesDocument4 pagesWND Petrojet NDT RT and PWHT Unit RatesAhmed al-sheaikhNo ratings yet

- Rocker Bogie CalculationsDocument13 pagesRocker Bogie Calculationsravi100% (2)

- WeldingDocument1 pageWeldingNNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- HW 8Document1 pageHW 8Muhammad WaqasNo ratings yet

- Fire Damper PDFDocument20 pagesFire Damper PDFMuhammad WaqasNo ratings yet

- Ishq Ka SheenDocument271 pagesIshq Ka Sheenroadsign100% (3)

- Module 2 - GEARS Lecture - 4: Worked Out Problems On Involute Spur GearsDocument8 pagesModule 2 - GEARS Lecture - 4: Worked Out Problems On Involute Spur GearsMuhammad WaqasNo ratings yet

- Shiglay SM ch17Document33 pagesShiglay SM ch17Muhammad WaqasNo ratings yet

- Spur GearDocument12 pagesSpur GearIsrael CeballosNo ratings yet

- Datasheet For Steel Grades Special Alloy GH3128Document2 pagesDatasheet For Steel Grades Special Alloy GH3128Ishaq Khan IKNo ratings yet

- Manufacturing Process of A BearingDocument4 pagesManufacturing Process of A Bearingalif hasyimNo ratings yet

- Astm A 729Document6 pagesAstm A 729Jamil SalmanNo ratings yet

- Failure Analysis of A Helical GearDocument7 pagesFailure Analysis of A Helical Geartheerapat patkaewNo ratings yet

- ZG42Cr1MoZG42CrMo Datasheet PDFDocument2 pagesZG42Cr1MoZG42CrMo Datasheet PDFImmalatulhusnaNo ratings yet

- LCN Door Parts Pricing PDFDocument60 pagesLCN Door Parts Pricing PDFJoshua SanchezNo ratings yet

- 08chapters7 8Document26 pages08chapters7 8Bucket IdliNo ratings yet

- ThyssenKrupp - XAR PLUSDocument3 pagesThyssenKrupp - XAR PLUSParametric EngineeringNo ratings yet

- A Review of Metastable Beta Titanium AlloysDocument41 pagesA Review of Metastable Beta Titanium AlloysANIGANI SUDARSHAN REDDYNo ratings yet

- Internship Report HMCDocument29 pagesInternship Report HMCAsad Raza100% (3)

- Microstructure and Fatigue Resistance of Carburized Steels PDFDocument10 pagesMicrostructure and Fatigue Resistance of Carburized Steels PDFyh1.yuNo ratings yet

- SUNFLAGDocument56 pagesSUNFLAGsandy maliNo ratings yet

- Ferritic Malleable Iron Castings: Standard Specification ForDocument6 pagesFerritic Malleable Iron Castings: Standard Specification ForAAYNo ratings yet

- Tubing ComparisonsDocument2 pagesTubing ComparisonsBrummerNo ratings yet

- Paper 2Document204 pagesPaper 2Fahad ShaikhNo ratings yet

- Journal PublicationsDocument38 pagesJournal Publicationschetan mNo ratings yet

- Metals: A Study On Two-Stage Cold Forging For A Drive Shaft With Internal Spline and Spur Gear GeometriesDocument18 pagesMetals: A Study On Two-Stage Cold Forging For A Drive Shaft With Internal Spline and Spur Gear GeometriesEngineerNo ratings yet

- Casting Alloys - PPT - 2nd BDS 1Document92 pagesCasting Alloys - PPT - 2nd BDS 1Syeda Umaima FathimaNo ratings yet

- Katanka SAE1006 SAE1008 ENDocument1 pageKatanka SAE1006 SAE1008 ENPhong ThanhNo ratings yet

- Asme Specifications SA36 ToSA423Document4 pagesAsme Specifications SA36 ToSA423Venkat Dora100% (1)

- S 1166501305921Document8 pagesS 1166501305921Raj RajeshNo ratings yet

- Asl Enterprses LimitedDocument26 pagesAsl Enterprses LimitedMohamed ShabanNo ratings yet