Professional Documents

Culture Documents

Thermopack Heat Generation Calculation

Uploaded by

Ayush AgrawalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermopack Heat Generation Calculation

Uploaded by

Ayush AgrawalCopyright:

Available Formats

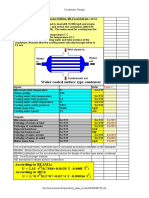

THERMOPACK HEAT GENERATION CALCULATION

Kcal (lakhs)

M/C RAD.TUBE NO M/C NO CHM RPM RATING W.HOUR TOTAL

PTG 48 5 1 1000 0.65 16.00 52

52 - 16.00 -

Total PTG 52

ROTARY 66 1 3 1050 0.68 15.00 31

Total Rot+Ptg 83

Stenter 44 2 8 1000 0.65 22.00 229

66 - 22.00 -

98 1 3 1000 0.65 22.00 43

Total Stenter 272

LOOP 240 0 2 1350 0.88 24.00 -

280 - 24.00 -

320 - 24.00 -

380 - 24.00 -

240X240 1 3 1350 0.88 24.00 63

Total Loop 63

Extra Oil line Usage

Padding 44 1 2 1400 0.91 - -

Ptg heater 2 1 0.10 24.00 5

Dry heater 26 2 1 0.20 14.00 6

SAMPLE 1 0.80 24.00 -

TABLE

Total extra usage 10

Direct injection before losses 428

SEASON VARIATION 8% 1.00 34

NET HEAT REQUIRMENT 462

DRY WET

FUEL CONSM-Impo 5800 11.39 18.98

FUEL CONSM-PETCOKE 6.87 6.87

COST NET COST/CV

CALVALUE DRY WET DRY WET DRY

BAGAS 2500 63% 40% 1,563 1,000 1600 1.02

LAKDA BABUL 3200 65% 0% 2,080 - 3000 1.44

PANCH 2500 62% 0% 1,550 - 2500 1.61

NAGPUR 4700 65% 65% 3,055 3,055 4400 1.44

TADKESHWAR 2800 68% 0% 1,904 - 2110 1.11

RAJPARDI 3300 70% 0% 2,310 - 3122 1.35

IMPO 5800 5800 70% 42% 4,060 2,436 4970 1.22

PETCOKE 8200 82% 82% 6,724 6,724 9300 1.38

BLOWER 65 KCAL/RPM

EFFICIENCY NET CV REAL.

NET COST/CV

WET

1.60

#DIV/0!

#DIV/0!

1.44

#DIV/0!

#DIV/0!

2.04

1.38

STEAM GENERATION CALCULATION

STEAM W.HOUR CALCULATION

M/C SIZE NO M/C RATING W.HOUR TOTAL BATCHES

ADD

U-JET 50 60 6.20 - 4

100 120 6.50 - 4

150 180 6.50 - 4

200 220 6.70 - 4

250 280 6.70 - 4

300 330 6.70 - 4

350 380 6.90 - 4

400 440 7.00 - 4

SOFLEENA 400 220 6.00 - 4

Total U-Jet -

H-JET 200 370 7.00 - 4

300 550 7.00 - 4

Total H-Jet - 4

DRUM 500 750 7.00 - 4

200 300 7.00 - 4

250 350 7.00 - 4

300 450 7.00 - 4

400 600 7.00 - 4

Total Drum -

Extra Steam Usage

DHULAI 70 20.00 -

ZERO 120 20.00 -

LOOP 240 350 24.00 -

280 375 24.00 -

320 400 24.00 -

380 450 24.00 -

240X240 600 24.00 -

pin bar 30 3.00 -

HP AGER 150 - -

JIGGER SMALL 70 12.00 -

BIG 90 12.00 -

COLOUR 50 12.00 -

KITCHEN -

SAMPLE 30 24.00 -

TABLE -

DECA 54" 275 10.00 -

84" 350 10.00 -

Total extra usage -

Direct injection before losses -

Energy losses

DRUM INSULATION 17% 1 - IF INSULATION DONE TYPE 1

JET INSULATION 15% 1 - IN YELLOW MARK

-

BLOWEN LOSES

BOILER FEED WATER TDS

BLOWDOWN TDS

% OF BLOW DOWN 1% - -

OR -

Blowdown -

SMC+BORING 7% - PRESS 1 IN RUNNING SYSTEM

RO 2% 1 -

Boring Soft Water 12% 0 -

JET PRODN M F - Production more than 4 batch excess %

DRUM PRODN M F - Production more than 4 batch excess %

Radiation line losses 5% - FIXED LOSSES

H-JET PRODN M F - Production more than 4 batch excess %

Total losses -

Total Steam consumed -

SEASON VARIATION 8% 1 -

condensate 8% -

cooling recovery usesd 21% jet - IF RECOVERY USE PRESS 1

drum depressure 15% drum -

direct injection 20% jet -

RECOVERY OF HEAT -

NET STEAM REQUIRMENT -

BOILER FEED WATER TEMP 70

DRY WET

FUEL REQUIREMENT-Impo 5800 - -

FUEL REQUIREMENT-Petcoke - -

W.HOUR CALCULATION CALVALUE DRY WET DRY WET

WH/BATCH BAGAS 2500 63% 40% 1,563 1,000

LAKDA BABUL 3200 65% 0% 2,080 -

1.550 PANCH 2500 62% 0% 1,550 -

1.625 NAGPUR 4700 65% 65% 3,055 3,055

1.625 TADKESHWAR 2800 68% 0% 1,904 -

1.675 RAJPARDI 3300 70% 0% 2,310 -

1.675 IMPO 5800 5800 70% 42% 4,060 2,436

1.675 PETCOKE 8300 80% 80% 6,640 6,640

1.725

1.750

1.750

1.750

1.750

1.750

1.750

1.750

1.750

1.750

EFFICIENCY NET CV REAL.

PRESS 1 IN RUNNING SYSTEM

Production more than 4 batch excess %

Production more than 4 batch excess %

Production more than 4 batch excess %

COST NET COST/CV

DRY WET

1600 1.02 1.60

3000 1.44 #DIV/0!

2500 1.61 #DIV/0!

4400 1.44 1.44

2110 1.11 #DIV/0!

3122 1.35 #DIV/0!

4970 1.22 2.04

9300 1.40 1.40

You might also like

- Calculation of Heat and Mass BalanceDocument18 pagesCalculation of Heat and Mass BalanceJitendra Bhatia100% (3)

- Line Sizing GuidelinesDocument2 pagesLine Sizing GuidelinesHarryBouterNo ratings yet

- Boiler NG CalculationDocument9 pagesBoiler NG CalculationChirag DarjiNo ratings yet

- Boiler FormulasDocument3 pagesBoiler FormulasCaliman SabinaNo ratings yet

- Boiler CalculationDocument4 pagesBoiler Calculationmohsin husen BargirNo ratings yet

- MOPX 309 Separation System With Build-On PumpDocument38 pagesMOPX 309 Separation System With Build-On PumpBalaNo ratings yet

- Reaction mass balance and energy analysisDocument4 pagesReaction mass balance and energy analysisparthNo ratings yet

- Advanced Distillation Technologies: Design, Control and ApplicationsFrom EverandAdvanced Distillation Technologies: Design, Control and ApplicationsNo ratings yet

- DIIPA Lecture-4 Grain Based Distillery 07042020Document26 pagesDIIPA Lecture-4 Grain Based Distillery 07042020chandrasekhar chNo ratings yet

- JBC Common Boiler FormulasDocument12 pagesJBC Common Boiler Formulasnesrine10No ratings yet

- Pulse Jet Bag Filter Specification for Boiler D-dustingDocument2 pagesPulse Jet Bag Filter Specification for Boiler D-dustingAdarsh PandeyNo ratings yet

- Triple Effect EvaporatorDocument8 pagesTriple Effect Evaporatormfruge7No ratings yet

- EvapDocument7 pagesEvapwestewrNo ratings yet

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel SizingzamijakaNo ratings yet

- Reactors Dimensions - 1Document10 pagesReactors Dimensions - 1Abhijit MoreNo ratings yet

- Jacket Area CalculationDocument12 pagesJacket Area CalculationPraveen Prajapati100% (2)

- Press MUd To Bio GasDocument5 pagesPress MUd To Bio GasAyush AgrawalNo ratings yet

- 5 Pillars of the Visual WorkplaceDocument30 pages5 Pillars of the Visual WorkplaceMayur12345dtNo ratings yet

- Distillation Column Design (Trial and Error)Document29 pagesDistillation Column Design (Trial and Error)AlexandraBarbeConawayNo ratings yet

- Mollie ChartDocument15 pagesMollie ChartKriz EarnestNo ratings yet

- Blowdown Economizer CalculationDocument2 pagesBlowdown Economizer CalculationSajjad AhmedNo ratings yet

- Plant Capacity 200 / 300: Operation & Maintenance Manual For Sanghi-Org Oxygen / Nitrogen Gas PlantDocument51 pagesPlant Capacity 200 / 300: Operation & Maintenance Manual For Sanghi-Org Oxygen / Nitrogen Gas PlantEdduin Rodriguez100% (5)

- KW Calculation For Pumps MotorDocument14 pagesKW Calculation For Pumps MotorAnonymous JWI6rqtNo ratings yet

- Final Ventury Working For Wet Alkaline ScrubberDocument11 pagesFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapNo ratings yet

- Heat ExchangerDocument53 pagesHeat ExchangerNurulHidayahNo ratings yet

- BhajansDocument68 pagesBhajansPaola Vazquez100% (1)

- BEML Delivery Extension 36 Lot DozerDocument5 pagesBEML Delivery Extension 36 Lot DozerPRADEEPNo ratings yet

- Guid To Design of EvaporatorDocument40 pagesGuid To Design of Evaporatorscranderi100% (2)

- Steam CalculationDocument27 pagesSteam CalculationRAVI KUMAR CarpenterNo ratings yet

- Energy BalanceDocument11 pagesEnergy BalanceBharat VaajNo ratings yet

- Tripple Effect Evaporator Design CalculationDocument6 pagesTripple Effect Evaporator Design CalculationCathal McKeownNo ratings yet

- Evaporator (D-1) Design ExcelDocument7 pagesEvaporator (D-1) Design ExceldiRkdARyLNo ratings yet

- Evaporator Design CalculationDocument20 pagesEvaporator Design CalculationDaniyal HashmiNo ratings yet

- Calculation of Boiler EfficiencyDocument43 pagesCalculation of Boiler EfficiencyTamer Abd ElrasoulNo ratings yet

- Nitincalculation Spray Dryer & HagDocument5 pagesNitincalculation Spray Dryer & HagNITIN P SHAH100% (2)

- Wet Air Properties Calculation Sheet: at Low PressureDocument2 pagesWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- Boiling Up Rate For Batch DistillationDocument4 pagesBoiling Up Rate For Batch DistillationKanhaiyalal PatilNo ratings yet

- UtilityDocument8 pagesUtilityAmit JainNo ratings yet

- Boiler FormulasDocument5 pagesBoiler FormulasAnonymous 6Mb7PZjNo ratings yet

- CONDENSATE AND STEAM TRAP IN STEAM LINEDocument16 pagesCONDENSATE AND STEAM TRAP IN STEAM LINEreach_arindomNo ratings yet

- Header & Piping SizingDocument9 pagesHeader & Piping Sizingmedicbest0% (1)

- Vapor Line Sizing-Mpp6Document10 pagesVapor Line Sizing-Mpp6Nitin KurupNo ratings yet

- CONDENSATE DE-SUPERHEATING CALCULATIONSDocument8 pagesCONDENSATE DE-SUPERHEATING CALCULATIONSMechanicalVee18No ratings yet

- Thermo PacDocument4 pagesThermo Pacsushant_jhawerNo ratings yet

- Calculate Heat-Cool Time - Batch ReactorDocument2 pagesCalculate Heat-Cool Time - Batch ReactorGargiulo Anita100% (1)

- Characteristics Hytherm 500 Hytherm 600Document3 pagesCharacteristics Hytherm 500 Hytherm 600Cal India -GeneralNo ratings yet

- Drum Flaker Introduction Guide by FUJI KOKI CO.,LTDDocument20 pagesDrum Flaker Introduction Guide by FUJI KOKI CO.,LTDAna Quintana100% (2)

- Condenser DesignDocument2 pagesCondenser DesignRahul ChandrawarNo ratings yet

- Designing a Chlorine Sparger for Gas DispersionDocument18 pagesDesigning a Chlorine Sparger for Gas DispersionsrshahNo ratings yet

- Ammonium 2520sulphate Material 2520balance.Document9 pagesAmmonium 2520sulphate Material 2520balance.AgadmatorNo ratings yet

- Series & Parallel ArrangementDocument12 pagesSeries & Parallel ArrangementNoman AslamNo ratings yet

- Design of Boiler Forced Draft FanDocument5 pagesDesign of Boiler Forced Draft FanAu TagolimotNo ratings yet

- Stacks: Ammonia Injection: A Route To CleanDocument8 pagesStacks: Ammonia Injection: A Route To CleanZEN MA100% (1)

- Chillere Cu Adsorbtie: Recuperare de Caldura Racire SolaraDocument18 pagesChillere Cu Adsorbtie: Recuperare de Caldura Racire Solaraxenia_1970No ratings yet

- K321-05041 A2 - Electrical Load AnalysisDocument4 pagesK321-05041 A2 - Electrical Load AnalysisJerome EugeneNo ratings yet

- Maintenance Plan - SoalDocument15 pagesMaintenance Plan - SoalMuhamad KarisNo ratings yet

- OACOACHMANUAL05282008Document29 pagesOACOACHMANUAL05282008G MartinNo ratings yet

- Technical Data Sheet Mx21Fga 200-220/220-230V 50/60Hz 1 R404ADocument4 pagesTechnical Data Sheet Mx21Fga 200-220/220-230V 50/60Hz 1 R404AFreddyNo ratings yet

- Tabela MaxtempDocument1 pageTabela MaxtempMarcio JuniorNo ratings yet

- Danfoss HPY14RAb R600a 220 50Document4 pagesDanfoss HPY14RAb R600a 220 50zach yvesNo ratings yet

- Full Line Brochure 7-2021Document32 pagesFull Line Brochure 7-2021PrudzNo ratings yet

- 121 Master CatalogDocument60 pages121 Master CatalogericlearnNo ratings yet

- DGI900 QUICK INSTALLATIONDocument5 pagesDGI900 QUICK INSTALLATIONGökhan KaracaNo ratings yet

- Insulation of MachinesDocument1 pageInsulation of MachinesAyush AgrawalNo ratings yet

- Ayush Agarwal 3N Bal 4N Sin 3N CruDocument4 pagesAyush Agarwal 3N Bal 4N Sin 3N CruAyush AgrawalNo ratings yet

- DG Set CompariosnDocument3 pagesDG Set CompariosnAyush AgrawalNo ratings yet

- Ladies SangeetDocument6 pagesLadies SangeetAyush AgrawalNo ratings yet

- Chapter Electric MotorsDocument24 pagesChapter Electric MotorsDenstar Ricardo SilalahiNo ratings yet

- Is 44 Practical KM Guide For SME OwnerManagerDocument93 pagesIs 44 Practical KM Guide For SME OwnerManagerChong Sien TanNo ratings yet