Professional Documents

Culture Documents

Socketing of Bored Piles in Rock

Socketing of Bored Piles in Rock

Uploaded by

anhkhoacgOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Socketing of Bored Piles in Rock

Socketing of Bored Piles in Rock

Uploaded by

anhkhoacgCopyright:

Available Formats

Socketing of Bored Piles in Rock

678

SOCKETING OF BORED PILES IN ROCK

B.R. Srinivasamurthy

Professor (Retd), Indian Institute of Science, Bangalore560012, India.

E-mail: murthybrs@gmail.com.

K.L. Pujar

Director, United Foundations Pvt Ltd., Chennai600041, India.

E-mail: ufcfoundation@yahoo.com.

ABSTRACT: Socketing of bored piles in rock is always seen as matter of debate at construction site between consultants &

contractors. Normal assumption is that rock socketed piles are end bearing piles and friction component developed in the

length of socket is neglected. To achieve the proper socketing of pile on rock surface, the rock layer is subjected to heavy

chiseling may cause cracks in rock mass and heavy grinding may cause reduction in friction component due to smooth

surface of drill holes in rock. Both the above effects may become detrimental to safe load carrying capacity of piles. Hence it

is necessary to take proper care to decide the socketing of pile in rock and to determine the length of socketing so that effects

of friction (in rock strata surface) and bearing on rocks can be utilized judiciously to their optimum values. The socketing

depth normally depends on type of rock, depth at which the rock is available below the pile cap and load carrying capacity of

pile. In this paper the review of existing methods to determine the socketing length is made and an attempt has been made to

formulate a practical approach & determine length of socketing of bored piles in rock. Also a realistic method of estimating

the friction capacities of the socketed length of the pile has been proposed.

1. INTRODUCTION

In the present construction activities, large diameter bored

piles are being used to carry heavy loads from super

structures. Almost in all infrastructure projects, the diameters

of bored piles being used are 1000 mm, 1200 mm and 1500

mm. Since these piles are designed for heavy loads (from

450T to 650T per pile), they are essentially to be taken to bed

rock level and are to be socketed into rock.

In the piling specifications, socketing in solid/hard rock is

usually specified for termination criteria. For all practical

considerations the socketing in solid rock is very much

essential where the piles are resting on rock situated at

shallow depths (with lesser depth of over burden) and/or on

the sloping solid rock. Where the hard rock is situated at

greater depths i.e. having larger over burden to resist lateral

displacement, the socketing of piles as being currently

specified in most of piling specifications may not be

necessary and heavy chiseling for specified socket length

will be a wasteful exercise and sometimes the heavy

chiseling may spoil the quality of hard rock.

Boring up to rock surface will practically have no difficulty,

except for intermittent service lines and boulders. Socketing

in rock will pose many practical problems which generally

range from classification of rock to socketing length and

final termination criteria. In this paper, some of the practical

problems faced during socketing of piles into hard rock are

discussed and probable solutions are recommended.

2. BRIEF HISTORY

Piles carry load by friction and end-bearing. In case of major

structures like bridges, flyovers, high rise buildings, etc the

load carried by end-bearing component only will be

considered as safe load carrying capacity of pile. This is to

avoid any settlement in the friction-end bearing combination.

In doing so, the strength contribution by skin friction of the

pile length drilled through weathered/soft rock will be

neglected completely. If the thickness of weathered/soft rock

is less, then neglecting the strength contribution from this

layer may be justified. If the thickness of weathered/soft rock

is more, say to the extent of 5 m and above (for large

diameter of piles, say 1.2 m dia.), neglecting the strength

contribution from this layer may become uneconomical and

time consuming in boring through rock layers resulting into

over-run of project time.

3. SOCKETING OF PILES

Present practice of socketing the piles in rock is being done,

or rather being insisted upon, by cutting the sound rock for a

minimum of 1D (for large diameter piles). If the pile

diameter is 1.2 m, the socketing is to be done for a depth of

1.2 m by chiseling the sound hard rock. Chiseling the hard

rock whose crushing strength is of the order of 1000 kg/cm

requires heavy chisel energy and chiseling for more time.

Both of these aspects may cause damage to structure of rock.

IGC 2009, Guntur, INDIA

Socketing of Bored Piles in Rock

679

Piles on rocks carry the load by point bearing. To ensure the

proper contact between base of pile and rock surface, it is

needed to socket the pile into hard rock by cutting through

weathered and soft rock and by cutting the hard rock for a

reasonable depth mainly to get the level surface of rock and

to remove the top weathered surface of rock. This reasonable

depth may vary from 150 mm to 300 mm. Further if soft and

medium rocks are preceding the hard rock the socketing

length may be counted from the level at which soft rock with

N more than 50 has been met.

Most of the times there are differences in recognizing the

type of rockweathered/soft/hard. First, the classification of

rock layer is to be done properly. For this purpose we can

refer to field test reports like RQD, CRR and SPT results and

crushing strength of rock core samples.

For major projects like bridges and flyovers, the soil

investigation is to be done under every pier location. Hence

the above-mentioned tests are essential to be carried out for

every pier location.

Rock Quality Designation (RQD) is expressed as,

RQD = L

a

/L

t

(1)

where

L

a

= total length of intact hard rock of core length 100 mm

or more arranged in its proper position

L

t

= total length of drilling

The behavior of rock mass is affected by factors like

presence of fractures in the rock, size and spacing of the

fractures, degree of weathering of fractures and presence of

soil within the fractures.

4. METHODS TO DETERMINE SOCKETED

LENGTH OF PILE IN ROCK

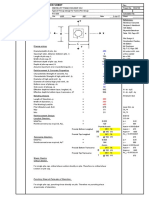

4.1 Based on Uniaxial Compression Strength of Rock

Rock socketing of piles is mainly done to utilize the full

structural capacity of piles. Since rock socketed piles can be

designed to carry compressive loads by skin friction and end

bearing, it is necessary to collect all details mentioned above.

In addition, chemical properties of rock at founding level

also should be obtained to find out chemical constituents

affecting the strength of pile (concrete and rock).

With all the above details, safe load carrying capacity of the

piles socketed in rock can be calculated by combining the

skin friction and end bearing components of the load.

Normally, sound rock free from fractures and fissures

(compressive strength greater than 500 kg/cm

2

, i.e. more than

the compressive strength of concrete) will have the required

strength to carry the designed load on piles. Based on

uniaxial compression strength of rock, the safe load carrying

capacity of pile, Q

s

, is given by

Q

s

= q

c

N

j

N

d

A

p

+ q

c

Dl

s

(2)

where q

c

= uniaxial compression strength of rock, T/m

2

N

d

= Depth factor = 0.8 + 0.2l

s

/D, limited to 2

A

p

= Area of pile toe, sq m

D = Dia of pile, m

l

s

= socket length into rock, m

= rock socket side resistance reduction factor

(Figure 1)

= rock socket correction factor (Figure 2)

N

j

= values as per Figure 2 of IS 12070

N

j

value also depends on spacing of discontinuities.

For sound rock having negligible discontinuities, q

c

can be

taken as equal to safe strength of concrete in T/m

2

N

j

= 0.3

= 0.05

= 1 and

N

d

= 1

For safe load of 500 mT for 1200 mm dia pile with M40

grade concrete, the socketed length of pile will be

500 = 1330 0.3 1.13 + 1330 3.14 1.2 l

s

0.05 1

= 450.87 + 79.8 l

s

l

s

= (500 450.87)/79.8

= 0.61 m

From the above, it can be seen that for a socketed length of

61 cm i.e. about 0.5D in sound hard rock, we can get the safe

load of 500T for 1.2 m dia pile.

Fig. 1: Side Resistance Reduction Factor Reflecting

Variation of Rock Strength

Fig. 2: Side Resistance Reduction Factor Reflecting

Variation of Mass Factor

Uniaxial Compressive strength q

in T/m

2

Mass reduction factor i =

i

E

Ed

S

i

d

e

R

e

s

i

s

t

a

n

c

e

R

e

d

u

c

t

i

o

n

F

a

c

t

o

r

S

i

d

e

R

e

s

i

s

t

a

n

c

e

R

e

d

u

c

t

i

o

n

F

a

c

t

o

r

Socketing of Bored Piles in Rock

680

4.2 Based on Shear Strength of Parameters of Rock

Shear stress of rock () is a fraction of its unconfined

compression strength (

c

).

may be taken either as a linear fraction of

c

with

coefficients ranging from 0.1 to 0.4 or as a fraction of square

root of

c

with coefficients ranging from 0.2 to 0.6. Shear

strength of rock can also be determined by testing the

samples in laboratory or by some in situ tests in the bore

hole.

Ultimate capacity of pile Q

u

in rock for socketed length l

s

is

given by

Q

u

= C

u

N

c

D

2

/4 + C

s

Dl

s

(3)

where C

u

= Shear strength of rock below pile tip, T/m

2

N

c

= BC Factor = 9

C

s

= Arc. shear strength of rock in socketed area,

T/m

2

= shaft adhesion factor, varies from 0.3 to 0.9 and

l

s

= socket length in m

Rock socket length can be calculated by knowing the shear

values of rock.

4.3 Based on Energy Criteria

Designing of rock socketing length of pile in weathered/soft

rock can also be calculated based on energy criteria. Rock

socketing criteria gains much importance in weathered/soft

rock. Core recovery ratio/Rock Quality Designation is the

ideal test for determining the type of rock.

It is difficult to get cores in weathered/soft rock. To

determine the length of socketing of piles in weathered rock

to get the pile capacity and its structural strength, the method

suggested by Cole and Stroud is being used widely. Cole and

Stroud method uses N values to identify the type of rock and

its shear strength. Table 1 gives the relationship between SPT

values and strength of rocks as suggested by Cole and

Stroud.

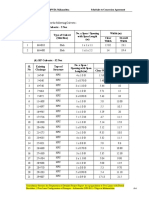

Table 1: Scale of Strength and SPT Values for Rocks

[Cole and Stroud]

Value

of N

Shear Strength (kg/cm

2

) Strength Grade Breakability Penetration Scratch

600

400

200

100

80

60

400

200

100

80

60

40

20

10

8

6

4

Strong

Moderate

ly Strong

Moderate

ly weak

Weak

Hard or

very

weak

A

B

C

D

E

F

Difficult to break against solid

object with hammer

Broken against solid object by

hammer

Broken in hand by hitting with

hammer

Broken by leaning on sample

with hammer

Broken by hand

Easily broken by hand

No

penetration

with knife

2 mm with

knife

5 mm with

knife

Cannot be scratched

with knife

Can just be scratched

with knife

Can be just scratched

by thumb nail

Can be scratched by

thumb nail

(N less than 60 are considered as soil)

Socketing of Bored Piles in Rock

681

Equation 3 can be used to arrive at socketing length of pile to

get the capacity of pile equal to its structural strength.

Another method by using chisel is also in practice to

determine the type of rock and socket length. In the chisel

energy method, the main points to be considered are: weight

of chisel, weight of fall, number of blows and penetration in

rock for pre-determined number of blows. Though this

approach seems to be more practical and rational, there are

so many limitations to use this approach, like sharpness of

chisel, chisel falling through water/bentonite solution, weight

of chisel for particular diameter of pile, type of chisel, etc.

Chisel energy can be calculated by the formula

Tm/sqm/cm

s A

N n W

p

=

(4)

where W = weight of chisel, Tones

n = weight of fall, meters

= reduction factor, usually varies between

0.6 to 0.8

N = Number of blows

A

p

= Base area of bore hole, sq m

s = penetration, cm

Value of varies with respect to the diameter of bore hole

and can be fixed based on local conditions and experience of

consultant under similar conditions or based on results of

load tests conducted in such areas. Based on energy value,

the socket length can be divided.

In general for piles resting on sound rock with sufficient over

burden and with level surface, rock socketing should not be

more than 0.5D, where D is the diameter of pile.

5. PRECAUTIONS TO BE TAKEN IN ROCK

SOCKETING

Apart from drilling\chiseling the rock up to required depth of

rock socketing, there are some more very important practical

aspects to be observed:

(i) During rock socketing process, heavy chiseling of high

torque drilling may produce vibrations. These vibrations

may cause destabilization of soft rock/soil strata over

laying the rock layer. Thus the pile will lose friction

component from these layers. Hence greater care should

be taken to reduce the vibrations.

(ii) Rock socketing takes more time and also imparts

disturbance to the layers over laying the rock strata. This

disturbance will cause spalling of fine particles which

will settle at the bottom. To remove these fine particles

and other cuttings, the bore hole should be thoroughly

washed with fresh bentonite slurry just before pouring

concrete.

6. CONCLUSION

Length of socketing of piles into rock should be such that the

pile can carry its structural strength as safe load.

To determine optimum length of socket in rock, various

methods are described. It is a waste of time, energy and

money to go for more length of socketing than required. For

rock socketing in weathered/soft rock, both end bearing and

frictional component from side friction in socketed length

should be taken into account.

For rock socketing to be most effective, the precautions

mentioned in paragraph V are to be considered carefully.

Heavy chiseling of rock should be avoided to maintain the in

situ quality of rock.

REFERENCES

A. Serrano

and C. Olalla (2004). Shaft Resistance of a Pile

Embedded in rock, International Journal of Rock

Mechanics & Mining Sciences 41: 2135.

IS: 2911 ( Part I/Sec 2) (1979). Code of Practice For Design

and Construction of Pile Foundation, Bureau of Indian

Standards.

IS: 456 (1978). Design Aids for Reinforced Concrete,

Bureau of Indian Standards.

Murthy, V.N.S. Soil Mechanics and Foundation Engineer,

CBC Publishers & Distributors.

Varghese, P.C. Foundation Engineering, Prentice Hall of

India Private Limited, 2007.

You might also like

- Wallap ManualDocument142 pagesWallap ManualAlden Cayaga75% (8)

- Waler Beam Design TemplateDocument1 pageWaler Beam Design TemplateArjun RajaNo ratings yet

- Sheet Pile DesignDocument5 pagesSheet Pile DesignnileshbhusariNo ratings yet

- Design of Pipe CulvertDocument10 pagesDesign of Pipe Culvertvijayunity100% (8)

- Retaining Wall On Pile FoundationDocument43 pagesRetaining Wall On Pile FoundationPrashant Jha100% (1)

- Pile Capacity Calculation As Per IS 2911/section-3Document24 pagesPile Capacity Calculation As Per IS 2911/section-3Srikalpa Rajguru100% (3)

- Pile Capacity On RockDocument2 pagesPile Capacity On RockSathyanarayanan Dhandapani100% (1)

- Design of Well FoundationDocument18 pagesDesign of Well Foundationvijayunity57% (7)

- Micropile Design ExampleDocument2 pagesMicropile Design ExampleLuis Orlando Ibanez Mora100% (3)

- Paper Presented at CRRI On Bottom Plug in Well FoundationsDocument11 pagesPaper Presented at CRRI On Bottom Plug in Well FoundationskishoredataNo ratings yet

- Bored Pile With Permanent CasingDocument20 pagesBored Pile With Permanent CasingJM SubionNo ratings yet

- Pile Cap Design OriDocument14 pagesPile Cap Design OriHoihogo Hoi100% (1)

- Methodlogy of Bridge Cum BarrageDocument18 pagesMethodlogy of Bridge Cum BarragePraveen Prakash100% (1)

- Project: Proposed Development of 242 Units of 27 Storeys Condominium (Phase 1A-Rc3)Document8 pagesProject: Proposed Development of 242 Units of 27 Storeys Condominium (Phase 1A-Rc3)pakbilal1100% (1)

- Sheet Pile Wall DesignDocument7 pagesSheet Pile Wall DesignSavy VannNo ratings yet

- Design of Stone Columns HooghlyDocument4 pagesDesign of Stone Columns Hooghlyhemantkle2u100% (2)

- IRC - SP Well Foundation by Balwant Rao PDFDocument133 pagesIRC - SP Well Foundation by Balwant Rao PDFAnoopNo ratings yet

- Piles Design Calc PDFDocument15 pagesPiles Design Calc PDFMukhlish Akhatar100% (2)

- Steel Transverse Seismic ArrestorDocument3 pagesSteel Transverse Seismic ArrestorNAUTILUS87100% (1)

- Jalmahal ProjectDocument5 pagesJalmahal ProjectAdnanKhan100% (1)

- Aurora Chain White Paper enDocument36 pagesAurora Chain White Paper enwahyuNo ratings yet

- Case AuditinggggDocument13 pagesCase AuditinggggCrystal100% (1)

- Scour in Bouldery Bed Proposed Formula (IRC PAPER NO 508)Document28 pagesScour in Bouldery Bed Proposed Formula (IRC PAPER NO 508)Ram Kumar Dhiman67% (3)

- Morth 2400 Surface and Sub Surface Geotechnical ExplorationDocument17 pagesMorth 2400 Surface and Sub Surface Geotechnical ExplorationRamesh100% (1)

- Pile Capacity As Per IRC-78Document17 pagesPile Capacity As Per IRC-78Mahadev SastryNo ratings yet

- RE Wall - RDSO PDFDocument65 pagesRE Wall - RDSO PDFgaurave50% (4)

- Calculation of Rock Socketing Length: Calculation of Pile Capacity As Per Irc:78-2014 CL 9.2Document1 pageCalculation of Rock Socketing Length: Calculation of Pile Capacity As Per Irc:78-2014 CL 9.2vivekNo ratings yet

- Design of Pile FoundationDocument16 pagesDesign of Pile FoundationJagal Udaya100% (3)

- Rock Anchor DesignDocument2 pagesRock Anchor Designraj.karanNo ratings yet

- Gabion Design: 1) Calculation For Earth PressureDocument2 pagesGabion Design: 1) Calculation For Earth PressureAvinash Sahu67% (6)

- Micropile Structural Capacity CalculationDocument7 pagesMicropile Structural Capacity CalculationEncik Badrul100% (1)

- IRC 78 Part-2-2020Document369 pagesIRC 78 Part-2-2020Ashisa Ranjan Jena0% (1)

- Determination of AffluxDocument2 pagesDetermination of AffluxHegdeVenugopal100% (1)

- For Calculation of SBC From RMR VALUEDocument5 pagesFor Calculation of SBC From RMR VALUESrikalpa RajguruNo ratings yet

- Is SP 16 1980 PDFDocument255 pagesIs SP 16 1980 PDFShaik Abdul RaheemNo ratings yet

- Diaphragm Wall ConstructionDocument14 pagesDiaphragm Wall ConstructionAkshay Kumar Sahoo100% (6)

- BA 80-99 Use of Rock Bolts (DMRB Vol 2, Section 1, Part 7, 1999)Document69 pagesBA 80-99 Use of Rock Bolts (DMRB Vol 2, Section 1, Part 7, 1999)sandycastleNo ratings yet

- Structural Design of Pile 400 MM DIADocument3 pagesStructural Design of Pile 400 MM DIAkarthik_iit100% (2)

- Soil Nail Wall Design ReportDocument37 pagesSoil Nail Wall Design Reportkanishka100% (1)

- Pile Design EN1997Document4 pagesPile Design EN1997ikanyu79No ratings yet

- Bearing Capacity of RockDocument19 pagesBearing Capacity of Rockfruitplus.epalNo ratings yet

- Sheet Pile Calc Sheet - 2 (Propped Cantiliver) - REV1Document5 pagesSheet Pile Calc Sheet - 2 (Propped Cantiliver) - REV1channajayamangalaNo ratings yet

- GeoGuide1 RetainingWallDocument259 pagesGeoGuide1 RetainingWallClaireNgok100% (1)

- Laterally Loaded PileDocument151 pagesLaterally Loaded Pilevpamatya100% (1)

- Geotechnical PDFDocument150 pagesGeotechnical PDFDalia Sultana MouriNo ratings yet

- 1893 PART 3 2014 Bridges, Retaining WallsDocument33 pages1893 PART 3 2014 Bridges, Retaining WallsMadhusudhanReddy Sappidi50% (2)

- Is 14458Document9 pagesIs 14458thirumalaichettiar0% (1)

- Design Example of A Sheet Pile Retaining WallDocument4 pagesDesign Example of A Sheet Pile Retaining WallKhurram Nazir100% (1)

- Piles and Piling FormulaDocument10 pagesPiles and Piling FormulaSamia H. BhuiyanNo ratings yet

- Pile Design As Per Is CodeDocument28 pagesPile Design As Per Is CodeStructural Spreadsheets100% (1)

- Pile EccentricityDocument8 pagesPile EccentricitySiongyung KongNo ratings yet

- Pile Capacity Calculation As Per IS 2911 Part 2 Section 1 PDFDocument7 pagesPile Capacity Calculation As Per IS 2911 Part 2 Section 1 PDFBishow KC100% (1)

- Retaining WallDocument20 pagesRetaining WallJaya Ram100% (1)

- Box Culvert - 2x2-4.0m CushionDocument69 pagesBox Culvert - 2x2-4.0m CushionsmitaNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- T11 08Document4 pagesT11 08akshay kothiyalNo ratings yet

- Literature: 2.1 GeneralDocument11 pagesLiterature: 2.1 GeneralchetanNo ratings yet

- Mechanism of Rock Burst Occurrence in Specially Thick Coal Seam With Rock PartingDocument14 pagesMechanism of Rock Burst Occurrence in Specially Thick Coal Seam With Rock PartingRicardo Huisa BustiosNo ratings yet

- Barton 2018Document18 pagesBarton 2018ERLAND FERNANDEZ CANONo ratings yet

- Chapter 2 - Shear Zone Treatment in Tunnels - 2011 - Engineering Rock Mass ClasDocument5 pagesChapter 2 - Shear Zone Treatment in Tunnels - 2011 - Engineering Rock Mass ClasAna Maria100% (1)

- Chapter 6 - Foundation in RockDocument52 pagesChapter 6 - Foundation in RockKoh Jia Jie100% (1)

- Principles of Rockbolting Design PDFDocument18 pagesPrinciples of Rockbolting Design PDFJaime BojorqueNo ratings yet

- CourseICCE1992 BurcharthADocument35 pagesCourseICCE1992 BurcharthAAlexandru PavelNo ratings yet

- Behaviour of Soft Soil Reinforced With Encased Stone ColumnsDocument4 pagesBehaviour of Soft Soil Reinforced With Encased Stone ColumnsSushovan DuttaNo ratings yet

- 012-General Arrangement For Pipe Culvert at CH-7+590 & 10+720Document1 page012-General Arrangement For Pipe Culvert at CH-7+590 & 10+720NAUTILUS87No ratings yet

- 012-General Arrangement For Pipe Culvert at CH-7+590 & 10+720Document1 page012-General Arrangement For Pipe Culvert at CH-7+590 & 10+720NAUTILUS87No ratings yet

- Pckg-1 Schedule - A-1Document2 pagesPckg-1 Schedule - A-1NAUTILUS87No ratings yet

- Sr. No. Bridge at KM Utility Service To Be Carried Remark: 7.2 CulvertsDocument3 pagesSr. No. Bridge at KM Utility Service To Be Carried Remark: 7.2 CulvertsNAUTILUS87No ratings yet

- Strut and Tie LectureDocument9 pagesStrut and Tie LectureNAUTILUS87No ratings yet

- Sr. No. Bridge at KM Utility Service To Be Carried Remark: 7.2 CulvertsDocument3 pagesSr. No. Bridge at KM Utility Service To Be Carried Remark: 7.2 CulvertsNAUTILUS87No ratings yet

- Stodola MethodDocument42 pagesStodola MethodRahul Chandel0% (3)

- Geometric Properties of The Cross-Section Parameter Value: V, y V, ZDocument2 pagesGeometric Properties of The Cross-Section Parameter Value: V, y V, ZNAUTILUS87No ratings yet

- CAD For High Embankments-IITDocument29 pagesCAD For High Embankments-IITNAUTILUS87No ratings yet

- Irc Gov in SP 082 2008Document162 pagesIrc Gov in SP 082 2008NAUTILUS87No ratings yet

- IRC SP 73 2015 Manual 2 LaningDocument191 pagesIRC SP 73 2015 Manual 2 LaningJithesh GowdaNo ratings yet

- Plate Center Stress Summary: Shear Membrane Bending Plate L/C QX Qy SX Sy Sxy MX My MxyDocument1 pagePlate Center Stress Summary: Shear Membrane Bending Plate L/C QX Qy SX Sy Sxy MX My MxyNAUTILUS87No ratings yet

- Acad Aag 2007Document362 pagesAcad Aag 2007NAUTILUS87No ratings yet

- 6M-Live Load Away CorrectedDocument1 page6M-Live Load Away CorrectedNAUTILUS87No ratings yet

- Plate Center Stress Summary: Shear Membrane Bending Plate L/C QX Qy SX Sy Sxy MX My MxyDocument1 pagePlate Center Stress Summary: Shear Membrane Bending Plate L/C QX Qy SX Sy Sxy MX My MxyNAUTILUS87No ratings yet

- Assignment MF0001: (2 Credits) Set 1Document9 pagesAssignment MF0001: (2 Credits) Set 1470*No ratings yet

- 2isp MikrotikDocument3 pages2isp MikrotikamirulmNo ratings yet

- Coull Hodson Design PDFDocument12 pagesCoull Hodson Design PDFSimone CastagnoNo ratings yet

- Inbound 4445609552032316026Document9 pagesInbound 4445609552032316026CyrishNo ratings yet

- Arab Open University Tutor Marked Assignment (TMA)Document4 pagesArab Open University Tutor Marked Assignment (TMA)Elena AbdoNo ratings yet

- Safety Instrumented System - BasicsDocument12 pagesSafety Instrumented System - BasicsJuan Carlos Zerling ManriquezNo ratings yet

- Principle of BankingDocument2 pagesPrinciple of BankingShan PalanivalNo ratings yet

- Manual Stacker: SDJ500 SDJ1000 SDJ1500 Sdja-IDocument1 pageManual Stacker: SDJ500 SDJ1000 SDJ1500 Sdja-IJuantonio GómezNo ratings yet

- Internet Pricing - Sigit HaryadiDocument12 pagesInternet Pricing - Sigit HaryadiJulioNo ratings yet

- The Greatest Trading Book Ever PDFDocument12 pagesThe Greatest Trading Book Ever PDFTrần Quốc HùngNo ratings yet

- GPS - TEC Readme PDFDocument9 pagesGPS - TEC Readme PDFIlham MalikNo ratings yet

- Thesis in Operations ManagementDocument6 pagesThesis in Operations ManagementTracy Morgan100% (2)

- (Ebook PDF Epub - Download - Life in The Victorian Age by Andrew Kerr-JarrettDocument3 pages(Ebook PDF Epub - Download - Life in The Victorian Age by Andrew Kerr-JarrettTeeba RoseNo ratings yet

- Monitor Fetal fc700 PDFDocument43 pagesMonitor Fetal fc700 PDFMiguelNo ratings yet

- Beharry v. Galley, 4th Cir. (2004)Document2 pagesBeharry v. Galley, 4th Cir. (2004)Scribd Government DocsNo ratings yet

- Arduino Nano and Visuino Control Servo With RotaryDocument10 pagesArduino Nano and Visuino Control Servo With Rotarypower system100% (1)

- The Blue Lotus 11Document180 pagesThe Blue Lotus 11Yusuf MartinNo ratings yet

- How To Hexcrawl: A Practical Guide To Wilderness Adventures For Labyrinth Lord (™)Document27 pagesHow To Hexcrawl: A Practical Guide To Wilderness Adventures For Labyrinth Lord (™)Ana Clara Rodrigues100% (1)

- (20666934 - Mathematical Modelling in Civil Engineering) Seismic Base Isolators For A Silo Supporting StructureDocument9 pages(20666934 - Mathematical Modelling in Civil Engineering) Seismic Base Isolators For A Silo Supporting StructureBayari ArNo ratings yet

- ChiccoDocument8 pagesChiccolisbethwaspenterprisesNo ratings yet

- Choke ManifoldDocument1 pageChoke ManifoldiswantmachooNo ratings yet

- Tutorial 2 - Introduction To JavaScript (Part 2)Document15 pagesTutorial 2 - Introduction To JavaScript (Part 2)Tủ LạnhNo ratings yet

- LibropublicadoNova2020 PDFDocument287 pagesLibropublicadoNova2020 PDFDanielNo ratings yet

- 4-3 Electrical Komponen SpecDocument9 pages4-3 Electrical Komponen Specibnu malkanNo ratings yet

- 4826 1979 Reff2021Document13 pages4826 1979 Reff2021GOOLY CONSULTANCY SERVICESNo ratings yet

- Tia PortalDocument15 pagesTia PortalEdison MalacaraNo ratings yet

- Technology For Teaching and Learning-2-UNIT-1Document30 pagesTechnology For Teaching and Learning-2-UNIT-1Jude Vincent MacalosNo ratings yet