Professional Documents

Culture Documents

Ansi Asme A13.1

Uploaded by

romi_hamdaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ansi Asme A13.1

Uploaded by

romi_hamdaniCopyright:

Available Formats

ANSI / ASME A13.

1

Has Changed!

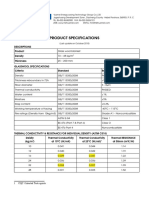

Pipes with Diameter (O.D.)

3/4 to 1-1/4

(19 to 32mm)

Marker Length: 8 (200mm)

Legend Height: 1/2 (13mm)

Pipes with Diameter (O.D.)

1-1/2 to 2

(38 to 51mm)

Marker Length: 8 (200mm)

Legend Height: 3/4 (19mm)

Pipes with Diameter (O.D.)

2-1/2 to 6

(64 to 150mm)

Marker Length: 12 (300mm)

Legend Height: 1-1/4 (32mm)

Pipes with Diameter (O.D.)

8 to 10

(200 to 250mm)

Marker Length: 24 (600mm)

Legend Height: 2-1/2 (64mm)

Pipes with Diameter (O.D.)

Over 10

(Over 250mm)

Marker Length: 32 (800mm)

Legend Height: 3-1/2 (89mm)

Latest Revision ANSI / ASME A13.1-2007

ANSI / ASME A13.1 is the most common pipe identification standard used in the United

States, and until the latest revision dated 2007 the standard has been unchanged for

nearly a half a century. The standard specifies the primary and secondary means of

identifying pipe content, as well as, the size, color and placement of the identification

device.

Primary Identification:

The legend (name of pipe content) and directional flow arrow remain the primary means

of identifying pipe content. The size and placement of the marker and arrow has not

changed. See ANSI / ASME size chart and installation guide for details.

Secondary Identification:

The secondary means of identification is the color code of the marker. That portion of the

standard has changed dramatically. In addition, the terminology of inherently hazardous

or non hazardous has been removed from the standard. The most obvious change, which

will affect most of Brimars customers is the color code assignment of two of the most

widely used color combination of Yellow / Black and Green / White. The combination of

Yellow / Black is now assigned with flammable fluids, and Green / White shall now

identify potable, cooling, boiler feed and other waters. These two changes mean that

legends such as hot water, cold water and steam will now all use the color code of Green /

White.

The other significant color changes include the addition of Brown / White for combustible

fluids and Orange / Black for toxic and corrosive fluids. The fact that the standard has

identified specific colors for flammable fluids, combustible fluids and toxic or corrosive

fluids means that Brimar and our customers must consult Material Safety Data Sheets

before selecting a color. Further, if the pipe content contains multiple hazards

(flammable and toxic) it must be determined which poses the greatest risk. For example,

if chilled or heating water systems contain a toxic treatment the color combination should

be Orange / Black. The new 2007 standard also identifies for the first time four additional

user defined color combinations and specifically identifies all of the exact background

colors to be used. The exact colors are safety colors contained in the ANSI Z535.1-2007

standard.

ANSI / ASME Color Code & Comparison

Fluid Service Colors

Material Inherently Hazardous

- Flammable or Explosive

- Chemical Active or Toxic

- Extreme Temp. of Pressures

- Radioactive

Mat. of Inherently Low Hazard

- Liquid or Liquid Admixtures

Mat. of Inherently Low Hazard

- Gas or Gaseous Admixtures

Fire Quenching Fluids

- Water, Foam, CO2, Halon, etc.

Yellow / Black

Green / White

Green / White

Blue / White

Red / White

ANSI / ASME A13.1-1996 Colors ANSI / ASME A13.1-2007 Colors

ANSI / ASME Size Chart

w w w . p i p e m a r k e r . c o m

04

T o O r d e r : C a l l Y o u r L o c a l R e p r e s e n t a t i v e

Fluid Service Colors

Flammable Fluids Yellow / Black

Potable, Cooling,

Boiler Feed & Other Waters

Compressed Air Blue / White

Fire Quenching Fluids Red / White

Toxic & Corrosive Fluids Orange / Black

Combustible Fluids Brown / White

Defined by User Purple / White

Defined by User White / Black

Defined by User Gray / White

Defined by User Black / White

w w w . p i p e m a r k e r . c o m

T o O r d e r : C a l l 8 0 0 - 2 7 4 - 6 2 7 1

05

ANSI / ASME A13.1

Has Changed!

System #1 Pipe Markers

System #4 Pipe Markers

System #2 Pipe Markers

Markers on a Roll / 2 Roll Sizes

8 x 1 & 14 x 2-1/4

EZ Pipe Markers

System #3 Pipe Markers

Markers on a Roll / 2 Roll Sizes

8 x 30 & 12 x 30

Compliance

The new standard does not require the replacement of previously installed markers. The

standard only applies to new installations. Brimar products comply with ANSI / ASME

A13.1 standards and we are committed to a uniform standard of pipe identification. We

recognize that it is not possible or realistic for everyone to adopt the new 2007 standard

immediately and therefore Brimar will continue to offer markers that comply with the old

and new standards. The Product Compliance Guide on the right shows the products that

comply with the new standard. In addition, within the stock lists of each of these

products, Brimar has identified which color combinations comply with the old and new

standards.

Installation Guide

BRIMAR Compliance Guide

Stick-On Labels comply with A13.1 2007

when used in conjuction with arrows

Brimars products comply with the

recommendations stated in the

ANSI / ASME A13.1 2007 Standard,

including: marker length, legend size

and marker colors. Below we have

highlighted the most popular pipe

markers we offer that are in compliance

with the new standard.

High Temperature Resistant Markers

Available in 6 different sizes

2nd Most Popular Pipe Markers

Available in 8 different sizes

The above information is an accurate interpretation of the standard and related changes.

To obtain a copy of the latest ANSI / ASME A13.1-2007 visit www. asme.org

Legends shall be installed close to valves

Legends shall be installed near branches and whenever a pipe changes direction.

Legends shall be installed before and after all wall, floor and ceiling penetrations.

Legends shall be at frequent intervals on straight pipe runs. Brimar recommends 20 ft.

Legends shall be installed on pipes to achieve the best visibility.

You might also like

- MSS SP 58 PDFDocument2 pagesMSS SP 58 PDFbuddhikasat67% (3)

- CIC BIM EIR With Sample Project EIR 2021Document75 pagesCIC BIM EIR With Sample Project EIR 2021Cheung SUM YI100% (2)

- Asme B31.9Document86 pagesAsme B31.9mrivera100% (5)

- Latest Revision ANSI / ASME A13.1-2015Document2 pagesLatest Revision ANSI / ASME A13.1-2015Mohamad Azizi AzizNo ratings yet

- AWWA C151-02 Ductile-Iron Pipe, Centrifugally Cast, For WaterDocument50 pagesAWWA C151-02 Ductile-Iron Pipe, Centrifugally Cast, For Waterneno2405No ratings yet

- Color Coding of Pipeline and Piping IdentificationDocument3 pagesColor Coding of Pipeline and Piping IdentificationLisa Malone50% (2)

- Ansi A13.1 Piping Systems, Scheme For The IdentificationDocument13 pagesAnsi A13.1 Piping Systems, Scheme For The Identification_rolex_No ratings yet

- UL Scopes For Standards PDFDocument22 pagesUL Scopes For Standards PDFoctavinavarro8236100% (1)

- Awwa C504-1997Document24 pagesAwwa C504-1997evangalionNo ratings yet

- Ul555s - Test ProceedersDocument2 pagesUl555s - Test Proceedersahmedomar_953724702No ratings yet

- MSS SP-89 (1998) PDFDocument20 pagesMSS SP-89 (1998) PDFadprimNo ratings yet

- Spray-Applied Rigid Cellular Polyurethane Thermal InsulationDocument4 pagesSpray-Applied Rigid Cellular Polyurethane Thermal InsulationsabinNo ratings yet

- Ashrea Duct WorkDocument55 pagesAshrea Duct WorkHaja MydeenNo ratings yet

- ASME B36.19M Stainless Steel PipesDocument14 pagesASME B36.19M Stainless Steel Pipesdssscarface50% (2)

- Metricon Studio-M House Product CatalogueDocument68 pagesMetricon Studio-M House Product CatalogueAlvinNo ratings yet

- Asme Ansi A 13.1Document4 pagesAsme Ansi A 13.1Deniss GálvezNo ratings yet

- Pipe Color Code Standard and Piping Color Codes ChartDocument25 pagesPipe Color Code Standard and Piping Color Codes Chartkapal 80m100% (1)

- Scheme For The Identification of Piping Systems: ASME A13.1-2007Document10 pagesScheme For The Identification of Piping Systems: ASME A13.1-2007roberto cNo ratings yet

- Part Ul.142 PDFDocument44 pagesPart Ul.142 PDFisaudkNo ratings yet

- Fire Piping Astm A795Document3 pagesFire Piping Astm A795sinahimsNo ratings yet

- Pages From ASME A13.1-2015Document4 pagesPages From ASME A13.1-2015dinukaeeNo ratings yet

- Nfpa 54 (Ansi Z223.1), 2021Document177 pagesNfpa 54 (Ansi Z223.1), 2021Dr kadhum shramaNo ratings yet

- Ultra FrecuenciasDocument293 pagesUltra FrecuenciasEnriqueMartinezRomeroNo ratings yet

- Asme B31 1 PDFDocument331 pagesAsme B31 1 PDFjulian100% (2)

- Spec For Hvac Fire Rated Duct InsulationDocument8 pagesSpec For Hvac Fire Rated Duct InsulationPradeep SukumaranNo ratings yet

- Hepworth ProfileDocument19 pagesHepworth Profilediljamchris100% (1)

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- Asme A 13.1Document13 pagesAsme A 13.1Eswin Paico de la Cruz100% (1)

- Astm f442f442m 13 6943Document3 pagesAstm f442f442m 13 6943Binodh DanielNo ratings yet

- ANSI/ASME Standard: For Pipe IdentificationDocument3 pagesANSI/ASME Standard: For Pipe IdentificationFredy Samuel Emah EmahNo ratings yet

- Combination Standpipe - Sprinkler Risers - Nfpa PDFDocument10 pagesCombination Standpipe - Sprinkler Risers - Nfpa PDFodemircioglu2No ratings yet

- Corrugated Single Wall PCPP BrochureDocument1 pageCorrugated Single Wall PCPP BrochurebcsmurthyNo ratings yet

- استاندارد SMACNADocument310 pagesاستاندارد SMACNASeyed100% (1)

- Chilled Water Pipe DESIGNDocument22 pagesChilled Water Pipe DESIGNTanjim FakirNo ratings yet

- Round Industrial Duct Construction Standards: Sheet Metal and Air Conditioning Contractors' National Association, IncDocument19 pagesRound Industrial Duct Construction Standards: Sheet Metal and Air Conditioning Contractors' National Association, IncNathanNo ratings yet

- Astm C533 PDFDocument4 pagesAstm C533 PDFoscargon19No ratings yet

- Asme 31.9Document86 pagesAsme 31.9Onur AltuntaşNo ratings yet

- A338 Steel StandardDocument2 pagesA338 Steel StandardguilhermehsssNo ratings yet

- Butterfly ValveDocument1 pageButterfly ValveDnyaneshwar0% (1)

- Geberit HDPE Installation GuideDocument71 pagesGeberit HDPE Installation GuideinstalbuzauNo ratings yet

- TR 33 Generic Butt Fusion Joining Gas PipeDocument40 pagesTR 33 Generic Butt Fusion Joining Gas PipeRamonezeNo ratings yet

- F2620 PDFDocument19 pagesF2620 PDFAhmad Zubair RasulyNo ratings yet

- NFPA Codes & Standards - 3Document1 pageNFPA Codes & Standards - 3karpanai100% (1)

- Astm A234Document8 pagesAstm A234Asad Bin Ala Qatari100% (4)

- Latest Revision ANSI / ASME A13.1Document2 pagesLatest Revision ANSI / ASME A13.1Tusar KoleNo ratings yet

- ANSI Pipe Labeling and Marking StandardsDocument8 pagesANSI Pipe Labeling and Marking Standardsmyo zawNo ratings yet

- General Pipe Label SpecificationDocument2 pagesGeneral Pipe Label SpecificationJacques J PienaarNo ratings yet

- Pipe Marking GuideDocument2 pagesPipe Marking Guideop910auNo ratings yet

- Wolkite University: College of Engineering and Technology Department of Food Process Engineering Food Engineering DrawingDocument154 pagesWolkite University: College of Engineering and Technology Department of Food Process Engineering Food Engineering DrawingTemesgen MuletaNo ratings yet

- Durapipe Abs Chilled PipeDocument32 pagesDurapipe Abs Chilled Pipeike BlaccNo ratings yet

- Chapter 11 Piping SystemDocument13 pagesChapter 11 Piping SystemJinky Mae PobrezaNo ratings yet

- Section 23 0553 Identification FOR Hvac Piping, Ducting AND Equi P MentDocument91 pagesSection 23 0553 Identification FOR Hvac Piping, Ducting AND Equi P MentkareemNo ratings yet

- ANSI Pipe Marking StandardsDocument4 pagesANSI Pipe Marking StandardsRobert Emile Santiago JimenezNo ratings yet

- Guide Pipe MarkingDocument20 pagesGuide Pipe MarkingMELVIN MAGBANUANo ratings yet

- Dhamma TYCO & MEP PresentationDocument12 pagesDhamma TYCO & MEP PresentationNeoteric IndustrialNo ratings yet

- Pipe and Valve IdentificationDocument27 pagesPipe and Valve Identificationanwerquadri100% (1)

- Instrument Tubing Selection Guide: Contact InformationDocument4 pagesInstrument Tubing Selection Guide: Contact InformationdagauthamNo ratings yet

- Msi Ansi Asme StandardsDocument2 pagesMsi Ansi Asme StandardstuyencntnNo ratings yet

- Marcado de Tuberias ANSIDocument4 pagesMarcado de Tuberias ANSIJulio Pablo Garcia DiazNo ratings yet

- Piping Design (Revised)Document22 pagesPiping Design (Revised)Yash PatelNo ratings yet

- Class 1 Thermoplastic Hose For ACDocument14 pagesClass 1 Thermoplastic Hose For ACurp30234No ratings yet

- Basics of Piping Scribd PDFDocument60 pagesBasics of Piping Scribd PDFmohamed sheerazNo ratings yet

- L W H Area Ft2 M2 Utilization Weight LBDocument4 pagesL W H Area Ft2 M2 Utilization Weight LBreji1usNo ratings yet

- 1 480 0 1370 55 675 425 587.41 9.36 Anodic / Cathodic 2 3 4 5 Make Serial No. Calibration DateDocument4 pages1 480 0 1370 55 675 425 587.41 9.36 Anodic / Cathodic 2 3 4 5 Make Serial No. Calibration Datereji1usNo ratings yet

- CP Design Calculaton SheetDocument19 pagesCP Design Calculaton Sheetreji1usNo ratings yet

- Gas Evolution Calculation: Description Value Uom Description Value UomDocument1 pageGas Evolution Calculation: Description Value Uom Description Value Uomreji1usNo ratings yet

- SMPS Fly Back Design Using Tl431Document11 pagesSMPS Fly Back Design Using Tl431reji1usNo ratings yet

- E LNR 876308Document5 pagesE LNR 876308reji1usNo ratings yet

- Science NutritionDocument2 pagesScience Nutritionreji1usNo ratings yet

- Graphic SymbolsRP30 11Document38 pagesGraphic SymbolsRP30 11reji1usNo ratings yet

- DCV G ProcedureDocument1 pageDCV G Procedurereji1usNo ratings yet

- 427Document56 pages427Taca BerenjiNo ratings yet

- Bolt and Stud DimentionDocument1 pageBolt and Stud DimentionwhngomjNo ratings yet

- Standard Penetration TestDocument59 pagesStandard Penetration TestcuervohijoguachoNo ratings yet

- Properties of SolidsDocument91 pagesProperties of Solidsshreyamammachen22No ratings yet

- TWF Temporary Works Toolkit Part 19Document5 pagesTWF Temporary Works Toolkit Part 19dhanya1995No ratings yet

- New ChangeDocument68 pagesNew ChangeAnoop Kamla PandeyNo ratings yet

- Time ScheduleDocument2 pagesTime ScheduleSanggalangi LatinroNo ratings yet

- Brazing Procedure 1Document5 pagesBrazing Procedure 1Tina MillerNo ratings yet

- Ft50get'08 Ft60det'08: 1G6C2-300F1 2G6C2-300F1Document57 pagesFt50get'08 Ft60det'08: 1G6C2-300F1 2G6C2-300F1Muhammad Safri Adi ZamilNo ratings yet

- Issb - CollectedDocument19 pagesIssb - CollectedBrhane Gadiyon100% (1)

- ElevatorDocument2 pagesElevatorneoNo ratings yet

- Distribution Board Specification: PT Fuji SMBE IndonesiaDocument2 pagesDistribution Board Specification: PT Fuji SMBE IndonesiajendrikoNo ratings yet

- Module 3 Shear Strength of SoilDocument7 pagesModule 3 Shear Strength of SoilJeth LawNo ratings yet

- Dynamic Study of Step Back and Set Back Building: ResearchDocument7 pagesDynamic Study of Step Back and Set Back Building: ResearchSristi GuptaNo ratings yet

- TYSONS - Food CourtDocument20 pagesTYSONS - Food CourtManivannan J100% (1)

- Cecw-Eg Engineer Manual 1110-2-2102 U.S. Army Corps of Engineers EM 1110-2-2102 30 September 1995Document23 pagesCecw-Eg Engineer Manual 1110-2-2102 U.S. Army Corps of Engineers EM 1110-2-2102 30 September 1995cp yangNo ratings yet

- Huamei Spec Sheets - 2018Document1 pageHuamei Spec Sheets - 2018Phan LongNo ratings yet

- Progress Report White CityDocument5 pagesProgress Report White CityMhlanga Bridget TanyaradzwaNo ratings yet

- Ansi-Rvia Egs-1-2022Document36 pagesAnsi-Rvia Egs-1-2022damaso taracena100% (1)

- Bomba Calpeda NM 25-160aeDocument12 pagesBomba Calpeda NM 25-160aeMarvin TorresNo ratings yet

- Analysis of Roller BearingDocument15 pagesAnalysis of Roller Bearingusama666No ratings yet

- BCM Roof Case StudyDocument10 pagesBCM Roof Case Studyojasvi kandhiaNo ratings yet

- Steel QB With SolutionDocument64 pagesSteel QB With SolutionShazNo ratings yet

- TROX Chilled Beam Design GuideDocument60 pagesTROX Chilled Beam Design GuideBRYMOENNo ratings yet

- Vantage Engine Service ManualDocument40 pagesVantage Engine Service ManualWaseem Khan100% (1)

- Is 3836Document10 pagesIs 3836maheshdabliNo ratings yet

- SOP ExcavationDocument5 pagesSOP ExcavationCharantej TejaNo ratings yet

- ME4105 NUS Offshore Oil and Gas Technology Lecture 3Document15 pagesME4105 NUS Offshore Oil and Gas Technology Lecture 3fardin77No ratings yet

- TF-450 Power EndDocument2 pagesTF-450 Power EndppglNo ratings yet