Professional Documents

Culture Documents

WPS 0250

Uploaded by

igorspirkoskiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS 0250

Uploaded by

igorspirkoskiCopyright:

Available Formats

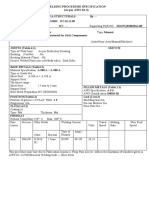

: /02-00-01

: 01

WELDING PROCEDURE SPECIFICATION

WPS : 0250

WPQR No:01 202 BG/V -140089

Manufacturer: D.M.B.Production:

Mode of metal transfer:

Joint Type and Weld Type:BW

Weld preparation Detail (Sketch)*:

Method of preparation and Cleaning:

Parent Material Designation:P235GH-TC1 (group 1.1)

Material Thickness (mm): 8,8

Outside diametar (mm): 406.4

Welding positions: PF

Joint Design

Welding Sequences

60

4

8.8

1-1.5

8.8

3

2

1

2-3

Welding Details

Size of

Current Voltage

filler

(V)

(A)

material

Type of

current /

Polarity

Wire Speed

Feed

Run out

length/travel

speed *

(mm/sec)

Heat Input

KJ/mm

Run

Welding

process

141

2.4

85

11

DC -

0.83

141

2.4

105

13

DC -

1.24

111

3.2

110-120

22

DC +

2.21

4-5

111

140-160

24

DC +

3.32

Filer material designation and make: : Boehler:W2Mo DMO IG (EN ISO 21952-A) / Elektrode Jesenice EVB50 E 42 4

B 32 H5 (EN ISO 2560-A)

Any special Backing or drying:2h 200-3000C

Designation Gas/Flux: - Shielding:Ar 100% (8-10 l/min)

Other information*

- Backing:

Weaving (maximum Width of run)

Fas Flow Rate

- Shielding:

Oscilation: amplitude, frequency:

- Backing:

Pulse Welding Details:

Tungsten electrode Type/Size: 2.4 mm

Distance contact tube/work piece:

Details of Back Gouging/ Backing:

Plasma welding details:

Preheat Temperature:

Torch Angle:

Interpass temperature: <3500C

Post heating

Pre-Heat maintenance Temperature:

Post-Weld Heat treatment and/or Ageing:

(Time, Temperature, Method):

Heating and cooling*- rates):

__________________________

(Name,Signature,Date)

__________________________

(Name,Signature,Date)

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification Sampleezdi2083% (23)

- WPS - D1.1Document1 pageWPS - D1.1Nam_HitechNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- WPSDocument1 pageWPSNidhinkorothNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Welding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauDocument5 pagesWelding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauTharakeshNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- P91 WPSDocument6 pagesP91 WPSPepe SagitarioNo ratings yet

- PQR-WPS-WPQR XXX Rev 0Document6 pagesPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Preliminary Welding Procedure Specification: Code: EN ISO 15609-1Document2 pagesPreliminary Welding Procedure Specification: Code: EN ISO 15609-1wentropremNo ratings yet

- Welder WQTDocument85 pagesWelder WQTKy100% (1)

- Welding Procedure Specification (As Per AWS D1.3) : With Preheat & PWHT (Auto/Semi-Auto/Manual/Machine) SketchDocument1 pageWelding Procedure Specification (As Per AWS D1.3) : With Preheat & PWHT (Auto/Semi-Auto/Manual/Machine) Sketchoomoom0% (1)

- Ami-003 WPSDocument2 pagesAmi-003 WPSBenjamin BrownNo ratings yet

- WPS P91Document6 pagesWPS P91JoseAlbertoNeyraNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- WPQR3Document3 pagesWPQR3Dimitris NikouNo ratings yet

- Clad PQRDocument5 pagesClad PQRRinshadNo ratings yet

- P91 Profile WpsDocument6 pagesP91 Profile WpsManzar KhanNo ratings yet

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- PQR SAW ProcessDocument1 pagePQR SAW Processdevendrasingh202133% (3)

- WPQR6Document3 pagesWPQR6Dimitris NikouNo ratings yet

- MIG Welding PWPSDocument1 pageMIG Welding PWPSelectronicmail2ughf6525No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- En Iso 15609Document2 pagesEn Iso 15609Parminder SinghNo ratings yet

- TopCorbelco - WPS FCAW Sa 516 GR 70Document6 pagesTopCorbelco - WPS FCAW Sa 516 GR 70miltonangulomorrisNo ratings yet

- Ami-001 WPSDocument2 pagesAmi-001 WPSPramod Athiyarathu100% (1)

- WpsDocument1 pageWpssathi_mechNo ratings yet

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Document2 pagesWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialNo ratings yet

- FCAW Overlay WPSDocument2 pagesFCAW Overlay WPSAsad Bin Ala Qatari100% (1)

- WPS - Welding Instruction - FUCHSDocument23 pagesWPS - Welding Instruction - FUCHSShanoor AS100% (1)

- P WPSDocument3 pagesP WPSAnilkumar G NairNo ratings yet

- WPS SiloDocument1 pageWPS SiloNidhinkorothNo ratings yet

- WPS FormatDocument1 pageWPS FormatbalamuruganNo ratings yet

- Scan 0002Document1 pageScan 0002Marjolein VerhoevenNo ratings yet

- Fab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSDocument2 pagesFab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSabidaliabid1100% (1)

- p22MNVMB MN Gtaw+Smaw (Pipe)Document2 pagesp22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1No ratings yet

- 0160e - Welding Procedures Data SheetDocument1 page0160e - Welding Procedures Data SheetAmanpreet SinghNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Welding Procedure Qualification Record: String or Weave Bead, Multipass, Single Electrode, Electrical Stick-Out:15-25mmDocument1 pageWelding Procedure Qualification Record: String or Weave Bead, Multipass, Single Electrode, Electrical Stick-Out:15-25mmBhanu Pratap ChoudhuryNo ratings yet

- WPS MCC 001 PDFDocument1 pageWPS MCC 001 PDFNuwan RanaweeraNo ratings yet

- Specification (WPS) Welding ProcedureDocument1 pageSpecification (WPS) Welding ProcedureBranko FerenčakNo ratings yet

- Arosta 304 LDocument2 pagesArosta 304 LMuhammad Zeeshan WasiNo ratings yet

- Welding ManualDocument9 pagesWelding Manualkawsar98No ratings yet

- WPQRDocument3 pagesWPQRDimitris NikouNo ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)