Professional Documents

Culture Documents

MIG Welding PWPS

Uploaded by

electronicmail2ughf65250 ratings0% found this document useful (0 votes)

319 views1 pagePreliminary WPS for MIG Welding

Original Title

MIG Welding pWPS

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPreliminary WPS for MIG Welding

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

319 views1 pageMIG Welding PWPS

Uploaded by

electronicmail2ughf6525Preliminary WPS for MIG Welding

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

CHADWICK

TECHNOLOGY

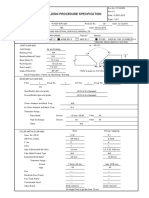

PRELIMINARY WELDING PROCEDURE SPECIFICATION (p-WPS) : CW / pWPS / GMAW - 001

Welding process(es) : MIG (131)

Weld Type(s): Groove, Plug, Slot & Fillet Weld

Joint Type(s): Butt, Corner, Lap, Tee & Edge Joints

Backing

Backing material: Weld Metal

Details of Back Gouging: Arc Gouging / Welding

Method of preparation & Cleaning : Cutting / Grinding & Wire brush cleaning

PARENT METAL

Specification: BS EN 10025 S355 JR+N to S355 JR+N

Material Group No: Qualified for Group 1 1

Material Thickness: 3mm to 20mm

Joint Design

Welding Sequences

GASES: Argon & Co2 Mixture

FLOW RATE: 23 to 29 CFH

WELDING CONSUMABLE

ELECTRICAL CHARACTERISTIC Current: up to 130 Amp

Polarity: N/A

Mode of Metal Transfer: N/A

Tungsten Electrode Type & size: N/A

Other: N/A

Filler Metal Designation: EN ISO 14341-A G42 4 M21 3Si

Manufacturer: ESAB

WELDING POSITION: All (Except PG & J-L045)

PREHEAT & INTERPASS

Preheat Temperature : 27 C (Ambient Temperature)

Interpass Temperature: 250 C (max.)

TECHNIQUE

String or weave beads: Stringer/Weaving

Orifice or gas cup size: N/A

Distance contact tube work piece: 5 to15mm

Multiple, single pass (for side): Multiple pass

Single or multiple electrodes: Single

Torch angle direction of welding: N/A

PWHT and/or AGEING

Temperature Range: N/A

Time Range (hour): N/A

Heating rate: N/A

Cooling rate: N/A

Filler metal

Run(s) or

Layer(s)

Welding

process

1 to n

MIG 131

EN designation or trade

name.

EN ISO 14341-A G42 4 M21 3Si

Current

Size

(mm)

Type &

polarity

1.2mm

DCEP

PREPARED BY

Voltage

V

Travel

Speed

Heat input

KJ/mm

Other

24

110

1.33

N/A

Amperage

A

130

Ahmed Fahad

PreliminaryWeldingProcedureSpecification

You might also like

- WPS Format For ISO 15614-1 PQRDocument3 pagesWPS Format For ISO 15614-1 PQRThe Welding Inspections Community100% (2)

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Basic Fabrication Process FlowchartDocument2 pagesBasic Fabrication Process FlowchartGodwin A.udo-akan100% (1)

- Weld Visual Inspection ReportDocument1 pageWeld Visual Inspection ReportfarjadulhaqNo ratings yet

- WPS, PQR 041Document21 pagesWPS, PQR 041swamykommula100% (1)

- Preliminary Welding Procedure Specification: Code: EN ISO 15609-1Document2 pagesPreliminary Welding Procedure Specification: Code: EN ISO 15609-1wentropremNo ratings yet

- Weld Map SampleDocument2 pagesWeld Map SampleKhushal TripathiNo ratings yet

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- Welding Procedure Specification - TemplateDocument2 pagesWelding Procedure Specification - TemplateDiosdado Mingi Jr.100% (3)

- Welding Procedure Specification (WPS)Document31 pagesWelding Procedure Specification (WPS)Cui Xiao89% (9)

- Filler Metal Selection ChartDocument1 pageFiller Metal Selection Chartavinash19870% (1)

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Document12 pagesPT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Wps Fillet AWSDocument4 pagesWps Fillet AWSMohd Ashraf100% (1)

- Weld Map (17007 Ab)Document22 pagesWeld Map (17007 Ab)9913489806100% (2)

- WPQR - Form As Per EN PDFDocument3 pagesWPQR - Form As Per EN PDFAnilNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Welding Procedure Qualification Certificate (EN ISO 15614-1)Document8 pagesWelding Procedure Qualification Certificate (EN ISO 15614-1)Jagjeet SinghNo ratings yet

- Welder WQTDocument85 pagesWelder WQTKy100% (1)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- WPQR6Document3 pagesWPQR6Dimitris NikouNo ratings yet

- WPS & PQR - 2021Document82 pagesWPS & PQR - 2021Subramanian RNo ratings yet

- How To Write A Welding Procedure Specification (WPS For ISO 15614-1)Document9 pagesHow To Write A Welding Procedure Specification (WPS For ISO 15614-1)weldnote100% (2)

- Approved Welding Procedures List RegioDocument2 pagesApproved Welding Procedures List Regiogabriel__regio100% (1)

- WPQT CertificateDocument104 pagesWPQT CertificateMaged Lotfy Abdel-aal100% (2)

- WPS Format For ISO 15614-1 WPSDocument1 pageWPS Format For ISO 15614-1 WPSThe Welding Inspections CommunityNo ratings yet

- Welding ReportDocument52 pagesWelding ReportalidadNo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- WPS Format For ISO 9606-1 WelderDocument2 pagesWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- Quality Control ManualDocument50 pagesQuality Control ManualKhairul Azri100% (1)

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Document2 pagesWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- Welding Consumable ChartDocument2 pagesWelding Consumable ChartAfetNo ratings yet

- Weld GaugesDocument15 pagesWeld Gaugesraobabar21100% (1)

- Pulse Mig WeldingDocument7 pagesPulse Mig WeldingajayNo ratings yet

- Welder IdentificationDocument9 pagesWelder Identificationdandiar1No ratings yet

- ATF - WelderTestPackage - v2 Welder and Welding Operator Perfomance Qualification RecordDocument5 pagesATF - WelderTestPackage - v2 Welder and Welding Operator Perfomance Qualification Recordfallalovaldes61No ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline Sungahid100% (2)

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Alumana Welder IDDocument7 pagesAlumana Welder IDZuberYousufNo ratings yet

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocument1 pagePQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraNo ratings yet

- PQRDocument2 pagesPQRalokbdasNo ratings yet

- WPS & PQRDocument46 pagesWPS & PQRJohn Candidate CIns88% (8)

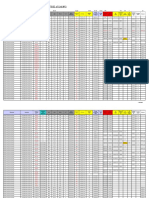

- Welding Log PipingDocument322 pagesWelding Log PipingSalman Khan100% (1)

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Document2 pagesWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialNo ratings yet

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- WPS - D1.1Document1 pageWPS - D1.1Nam_HitechNo ratings yet

- Email Over QuotaDocument1 pageEmail Over Quotaelectronicmail2ughf6525No ratings yet

- Email Over QuotaDocument1 pageEmail Over Quotaelectronicmail2ughf6525No ratings yet

- TATA Product Range 10 - UpdateDocument67 pagesTATA Product Range 10 - UpdateKrishnadas GouravNo ratings yet

- Aluminum Comparison (BS & ASTM STD)Document1 pageAluminum Comparison (BS & ASTM STD)electronicmail2ughf6525No ratings yet

- Seals & Gasket ManufacturerDocument8 pagesSeals & Gasket Manufacturerelectronicmail2ughf6525No ratings yet

- Operation PoloDocument33 pagesOperation Poloelectronicmail2ughf6525100% (1)

- Aluzinc Corrosion Resistance en 2012Document17 pagesAluzinc Corrosion Resistance en 2012electronicmail2ughf6525No ratings yet

- Aluminium Alloy Comparison TableDocument1 pageAluminium Alloy Comparison Tableelectronicmail2ughf6525No ratings yet

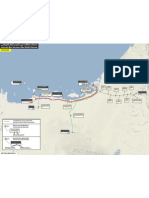

- Intercity Bus ServicesDocument1 pageIntercity Bus Serviceselectronicmail2ughf6525No ratings yet

- Employment & Salary Trends GCC 2012Document40 pagesEmployment & Salary Trends GCC 2012electronicmail2ughf6525No ratings yet

- 5S Project FormatDocument7 pages5S Project Formatelectronicmail2ughf6525No ratings yet