Professional Documents

Culture Documents

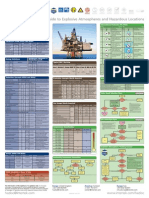

CSA Sira Wallchart 2013

CSA Sira Wallchart 2013

Uploaded by

ryanseg21Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CSA Sira Wallchart 2013

CSA Sira Wallchart 2013

Uploaded by

ryanseg21Copyright:

Available Formats

Guide to Equipment Certification

Requirements for Hazardous Locations

Call us on: + 44 (0) 1244 670 900

Visit our website: www.siracertification.com

or Email us: info@siracertification.com

CCSAUS

ATEX & IECEx

Typical North American Marking (CSA)

Sira ATEX & IECEx Certificate Number

SIRA

13

ATEX

1234

Name of notified body performing

EC-type examination

Year of

certification

Reference to

ATEX 95 Directive

Serial number

Class I, Division 1, Groups A&B T4

Hazard Class

Gas

Group

Area

Classification

Temperature

Class

Class I, Zone 0, AEx ia IIC T4

Hazard Class

Area

Classification

Approved to

US Standards

Protection

Concept

Code

Gas

Group

Typical ATEX & IECEx Marking [*ATEX only]

IECEx

CSA

Reference to

IECEx scheme

Name of body performing

IECEx certification

Temperature

Class

*Complies

with European

Directive

13.1234

Year of

certification

Serial number

Suffixes: U component certification X special conditions for safe use apply

Protection Concepts

Type of

Protection

Code

Classification of Divisions and Zones

Country

Class

Division / Zone

Standard

Basic Concept

of Protection

Electrical Equipment for Flammable Gas, Vapors and Mist - Class I

US

Class I

Division 1 & 2

FM 3600

General

AEx

CA

Class I

Division 1 & 2

Requirements

Ex

US

Class I

Zone 1 & 2

ISA 60079-0

CA

Class I

Zone 1 & 2

CSA 60079-0

Type of Area

NEC and CEC*

ATEX and IEC

Definitions

Continous

hazard

Division 1

Zone 0 / Zone 20

Cat 1

A place in which an explosive atmosphere is

continually present

Intermittent

hazard

Division 1

Zone 1 / Zone 21

Cat 2

A place in which an explosive atmosphere is

likely to occur in normal operation

Division 2

Zone 2 / Zone 22

Cat 3

A place in which an explosive atmosphere is

not likely to occur in normal operation, but

may occur for short periods

Hazard under

abnormal conditions

Increased

AEx e

US

Class I

Zone 1

ISA 60079-7

Safety

Ex e

CA

Class I

Zone 1

CSA E60079-7

(NI)

US

Class I

Division 2

ISA 12.12.01 / FM 3611

No arcs, sparks

(NI)

CA

Class I

Division 2

C22.2 No. 213

or hot surfaces

AEx nA

US

Class I

Zone 2

ISA 60079-15

EX nA

CA

Class I

Zone 2

CSA E60079-15

(XP)

US

Class I

Division 1

UL 1203 / FM 3615

(XP)

CA

Class I

Division 1

C22.2 No. 30

AEx d

US

Class I

Zone 1

ISA 60079-1

AEx d

US

Class I

Zone 1

UL 1203 / FM 3615

Ex d

CA

Class I

Zone 1

CSA 60079-1

AEx q

US

Class I

Zone 1

ISA 60079-5

Ex q

CA

Class I

Zone 1

CSA E60079-5

AEx nC

US

Class I

Zone 2

ISA 60079-15

Ex nC

CA

Class I

Zone 2

CSA E60079-15

(IS)

US

Class I

Division 1

UL 913 / FM 3610

(IS)

CA

Class I

Division 1

C22.2 No. 157

AEx ia

US

Class I

Zone 0

ISA 60079-11 / FM 3616

Limit energy

First Number (protect from solid bodies)

Second Number (protect from water)

AEx ib

US

Class I

Zone 1

ISA 60079-11 / FM 3616

of sparks

No protection

No protection

EX ia

CA

Class I

Zone 0

CSA E60079-11

and surface

Ex ib

CA

Class I

Zone 1

CSA E60079-11

temperature

Objects > 50mm

Vertical drip

AEx nC

US

Class I

Zone 2

ISA 60079-15

Objects > 12.5mm

Angled drip

Objects > 1.0mm

Splashing

Dust-protected

Jetting

Dust-tight

Non-Incendive

Non-Sparking

Explosion Proof

Flame Proof

Power Filled

Enclosed Break

Intrinsic Safety

Limited Energy

Pressurised

* On occasion the ATEX and IEC Zones may be used in the corresponding NEC and CEC system

Equipment Groups [ATEX and IECEx]

Equipment Group

Equipment

Category

Equipmet

Protection

Level

Atmosphere

Protection

Level

Required Protection

Performance & Operation

I (Mines with firedamp)

M1

Ma

Methane & Dust

Very High

Two Faults, Remain

energised and functioning

Contain the

explosion and

I (Mines with firedamp)

M2

Mb

Methane & Dust

High

Severe normal operation,

De-energise in explosive

atmosphere

II (all other areas)

Ga / Da

Gas, Vapour, Mist, Dust

Very High

Two Faults

II (all other areas)

Gb / Db

Gas, Vapour, Mist, Dust

High

One Fault

II (all other areas)

Gc / Dc

Gas, Vapour, Mist, Dust

Low

Normal operation

extinguish the

flame

Class I

Zone 2

CSA E60079-15

Type X

US

Class I

Division 1

NFPA 496 (FM 3620)

Type X

CA

Class I

Division 1

NFPA 496

Powerful jetting

Type Y

US

Class I

Division 1

NFPA 496 (FM 3620)

Temporary immersion

Type Y

CA

Class I

Division 1

NFPA 496

Continuous immersion

Type Z

US

Class I

Division 2

NFPA 496 (FM 3620)

Type Z

CA

Class I

Division 2

NFPA 496

AEx px

US

Class I

Zone 1

ISA 60079-2

Enclosure Type Ratings (NEMA / CSA / UL)

Ex px

CA

Class I

Zone 1

CSA E60079-2

Type

Area

Brief Definition

AEx py

US

Class I

Zone 1

ISA 60079-2

Ex py

CA

Class I

Zone 1

CSA E60079-2

Keep

Indoor

General Purpose

AEx pz

US

Class I

Zone 2

ISA 60079-2

flamable

Indoor

Protection against angled dripping water

CSA E60079-2

gas out

3, 3R, 3S

Indoor / Outdoor

Protection against rain, snow

4, 4X

Indoor / Outdoor

Protection against rain, snow, hose directed water

Class I

Zone 2

AEx nR

US

Class I

Zone 2

ISA 60079-15

Breathing

Ex nR

CA

Class I

Zone 2

CSA E60079-15

Indoor

Protection against angled dripping water, dust, fibers, flyings

Indoor / Outdoor

Protection against temporary submersion

Oil Emmersion

AEx ma

US

Class I

Zone 0

ISA 60079-18

AEx m

US

Class I

Zone 1

ISA 60079-18

6P

Indoor / Outdoor

Protection against prolonged submersion

Ex m

CA

Class I

Zone 1

CSA E60079-18

12, 12K

Indoor

Protection against circulating dust, fibers, flyings

AEx mb

US

Class I

Zone 1

ISA 60079-18

13

Indoor

Protection against circulating dust, fibers, flyings, seepage

AEx o

US

Class I

Zone 1

ISA 60079-6

EX o

CA

Class I

Zone 1

CSA E60079-6

Atmosphere Groups [ATEX and IECEx]

Electrical Equipment for Combustible Dust and Fibres - Class II / Class III

General

Requirements

Dust Ignition

Proof

Dust Protected

Ex

(DIP)

(NI)

US

Class II

Division 1 & 2

FM 3600

Group

CA

Class II

Division 1 & 2

CSA C22.2 No.0

US

Class III

Division 1 & 2

FM 3600

CA

Class III

Division 1 & 2

CSA C22.2 No.0

US

Zone 20, 21, 22

ISA 60079-0

US

Class II

Division 1

UL 1203 / FM 3616

CA

Class II

Division 1

CSA C22.2 No. 25

US

Class II

Division 2

ISA 12.12.01 / FM 3611

CA

Class II

Division 2

CSA C22.2 No. 25

Typical Substance

Coal Mining

Methane (Fire damp)

Surface

and other

locations

Gases, Vapours

Di-ethyl ether, Ethylene, Methyl ethyl ketone

(MEK), Propan-1-ol (n-propyl alcohol)

Acetylene, Hydrogen

AEx ta

US

Class II

Zone 20

ISA 60079-31

IIC

US

Class II

Zone 21

ISA 60079-31

IIIA

AEx tc

US

Class II

Zone 22

ISA 60079-31

IIIB

Enclosure

Ex ta

CA

Class II

Zone 20

CSA C22.2 No. 60079-31

Ex tb

CA

Class II

Zone 21

CSA C22.2 No. 60079-31

Surface

and other

locations

Combustible Dusts

IIIC

Ex tc

CA

Class II

Zone 22

CSA C22.2 No. 60079-31

Keep

Fiber & Flying

US

Class III

Division 1 & 2

UL 1203 / ISA 12.12.01

combustible

Protection

CA

Class III

Division 1 & 2

CSA C22.2 No. 25

dust out

AEx maD

US

Zone 20

ISA 60079-18

AEx mbD

US

Zone 21

ISA 60079-18

(PX)

US

Class II

Division 1

NFPA 496 (FM 3620)

(PX)

CA

Class II

Division 1

NFPA 496

(PY)

US

Class II

Division 1

NFPA 496 (FM 3620)

(PY)

CA

Class II

Division 1

(PZ)

US

Class II

Division 2

(PZ)

CA

Class II

Division 2

NFPA 496

AEx pD

US

Zone 21

ISA 61241-2

Acetic acid, Acetone, Ammonia, Butane,

Cyclohexane, Ethanol (ethyl alcohol),

Gasoline (petrol), Kerosene, Methane

(natural gas) (non-mining), Methanol (methyl

alcohol), Propane, Propan-2-ol (iso-propyl

alcohol), Toluene, Xylene

IIB

AEx tb

Pressurisation

Location

IIA

Protection by

Encapsulation

Environment

Combustible flyings

Conductive

Hazard Class

Acetylene

Hydrogen

Ethylene

IIC

T4

Gb

Explosion

Protection

Type of

Protection

Gas group

Temperature

Class (T1-T6)

Equipment

Protection Level

Ex

tb

IIIC

T135C

Db

Explosion

Protection

Type of

Protection

Dust type

Temperature

Class (C)

Equipment

Protection Level

Protection Concepts [ATEX and IECEx]

Type of

Protection

Symbol

0,1,2

IEC 60079-0

Optical Radiation

Op pr

Op sh

Op is

Gb

Ga

Ga

1,2

0,1,2

0,1,2

IEC 60079-28

IEC 60079-28

IEC 60079-28

Inherently safe

protected by shutdown

Increased safety

Type n (non-sparking)

e

nA

Gb

Gc

1,2

2

IEC 60079-7

IEC 60079-15

No arcs, sparks or hot surfaces.

Enclosure IP54 or better

Flameproof

Gb

1,2

IEC 60079-1

Type n (enclosed break)

nC

Gc

IEC 60079-15

Contain the explosion,

quench the flame

Quartz / sand filled

Gb

1,2

IEC 60079-5

Quench the flame

Intrinsic safety

ia

ib

ic

Ga

Gb

Gc

0,1,2

1,2

2

IEC 60079-11

IEC 60079-11

IEC 60079-11

Limit the energy of sparks

and surface temperatures

Pressurised

px

py

pz

Gb

Gb

Gc

1,2

1,2

2

IEC 60079-2

IEC 60079-2

IEC 60079-2

Type n (sealing & hermetic sealing)

Type n (restricted breathing)

nC

nR

Gc

Gc

2

2

IEC 60079-15

IEC 60079-15

Encapsulation

ma

mb

mc

Ga

Gb

Gc

0,1,2

1,2

2

IEC 60079-18

IEC 60079-18

IEC 60079-18

Oil immersion

Gb

1,2

IEC 60079-6

Class I

Flammable Gases

Limit energy

of sparks

AEx ibD

US

Zone 21

ISA 60079-11

and surface

(IS)

US

Class III

Division 1

UL 913 / FM 3610

temperature

(IS)

CA

Class III

Division 1

CSA C22.2 No. 157

Da

Db

Dc

20

21

22

IEC 60079-11

Limit the energy of sparks

and surface temperatures

Encapsulation

ma

mb

mc

Da

Db

Dc

20

21

22

IEC 60079-18

Protection by encapsulation

of incendive parts

Pressurised

pD

Db

21,22

Dc

22

IEC 61241-4

Protection by pressurisation

of enclosure

General Requirements

0,1,2,

20,21,22

EN 13463-1

Low potential energy

Flow restricted enclosure

flameproof enclosure

fr

d

2,22

1,2,21,22

EN 13463-2

EN 13463-3

Relies on tight seals, closely

matched joints and tough

enclosures to restrict the

breathing of the enclosure

Constructional safety

0,1,2,

20,21,22

EN 13463-5

Ignition hazards eliminated

by good engineering methods

Control of ignition sources

0,1,2,

20,21,22

EN 13463-6

Control equipment fitted

to detect malfunctions

Pressurisation

1,2,

21,22

EN 60079-2

EN 61241-4

Enclosure is purged and

pressurised to prevent ignition

sources from arising

Liquid immersion

0,1,2,

20,21,22

EN 13463-8

Enclosure uses liquid to prevent

contact with explosive atmosphere

Temperature Classification

Classification of maximum surface temperatures

for Group II Electronic Equipment (T Class).

700

IIA

T1

Ammonia

630

IIC

T1

Hydrogen

560

IIA

T1

Methane

537

IIA

T1

Propane

470

IIB

T2

Ethylene

425

IIA

T2

Butane

372

IIC

T2

Acetylene

305

Di-ethyl Ether

160

ISA 60079-11

ia

ib

ic

T4

Group G

CSA C22.2 No. 157

Intrinsic safety

IIB

Zone 20

Standard protection for dusts,

rugged tight enclosure

210

Group F

Division 1

IEC 60079-31

Kerosene

Enclosure

T3

Class II

IIA

Group E

US

IEC 60079-0

20

21

22

IIC

Group D

CA

20,21,22

Da

Db

Dc

Group B

Combustible Metal Dusts

AEx iaD

ta

tb

tc

259

Methane (mining)

(IS)

Cyclohexane

NFPA 496 (FM 3620)

Class II

Combustible Dusts

Combustible Dusts not in Group E or F

(Flour, Grain, Wood, Plastics, Chemicals)

Keep the flammable

gas out

General Requirements

T3

NFPA 496

UL 913 / FM 3610

Basic Concept

of Protection

IIA

IIA

Division 1

IEC Standard

General Requirements

IIC

IIB

Class II

Typical

Zone(s)

Electrical equipment for gases, vapours and mists (G)

Group A

Group D

US

Typical

IEC EPL

NEC 505

Group C

(IS)

*Environment

NEC 500

Propane

Combustible Carbonaceous Dusts

*Equipment

Category

600

IIC

T6

Carbon Disulphide

500

Non-conductive

Atmosphere Groups (US / CAN)

Substance

*Equipment

Group

Non-Electrical equipment

Restricted

Encapsulated

Electrical equipment for combustible dusts (D)

CA

CA

*Specific

Marking for

Explosion

Protection

Ex

Ingress Protection Codes

Ex nL

Ex pz

*Notified

Body

Number

II

T1 450

400

300

T2 300

200

T3 200

T4 135

100

95

T6 85

T5 100

Dusts Typical Ignition Temperatures (C)

Dusts

Cloud

Layer

Aluminium

590 C

>450 C

Coal dust (lignite)

380 C

225 C

Flour

490 C

340 C

Grain dust

510 C

300 C

Methyl cellulose

420 C

320 C

Note: For associated intrinsically safe apparatus suitable for installation in a hazardous location, the symbol for the type

Phenolic resin

530 C

>450 C

of protection ia or ib are enclosed within square brackets on the marking, e.g. AEx d [ia] IIC T4.

Polythene

420 C

(melts) C

PVC

700 C

>450 C

Note: For intrinsically safe apparatus not suitable for installation in a hazardous location, both the symbol Ex or AEx

Soot

810 C

570 C

and the symbol for the type of protection ia or ib are enclosed within the same square brackets on the marking,

Starch

460 C

435 C

e.g. [AEx ia] IIC; in this case, a temperature class is not included.

Sugar

490 C

460 C

Intrinsic Safety

Combustible Fibers and Flyings

Class III

Fibers and Flyings

Quality Assurance

ATEX & IEC Training & Competence

Functional Safety

Quality Assurance is concerned with the continued monitoring of systems and processes in

relation to manufacturers of Ex products, and is concerned mainly with post-compliance activities.

CSA-Sira has been at the forefront of hazardous area training for over 25 years, utilising the

skills and experience of our highly specialised engineers and lecturers to transfer knowledge.

CSA-Sira offers the full range of QA services including ATEX & IECEx Product & Production Quality

Assurance, Certification of Service Facilities involved in Repair and overhaul of Ex Equipment

and technical auditing services.

This detailed knowledge and vast experience allows us to offer a comprehensive range of

training courses and competence schemes that can be delivered as part of our open training

programme or tailored to your needs and delivered on-site at your premises.

The routes to market for ATEX and IECEx:

Hazardous Area Training (ATEX, DSEAR & IEC)

CSA-Sira are leading providers of functional safety certification. IEC 61508 is the international

standard for electrical, electronic and programmable electronic safety (E/E/PE) related systems.

It sets out the requirements for ensuring that systems are designed, implemented, operated and

maintained to provide the required safety integrity level (SIL). Four SILs are defined according to

the risks involved in the system application, with SIL4 being used to protect against the highest risks.

The standard specifies a process that can be followed by all links in the supply chain so that

information about the system can be communicated using common terminology and system

parameters.

ATEX Quality Assurance Notification: Quality system certification for the manufacture of

category 1 and category 2 electrical equipment. (refer IEC/ISO 80079-34 and ATEX Directive

Annexes IV / VII)

Functional Safety Training

IECEx QAR (Quality Assessment Report): Required together with the ExTR (test report) to enable

issue of an IECEx Certificate of Conformity. (refer IEC/ISO 80079-34 and IECEx Scheme Rules)

Competence Certification (CoPC)

ATEX Conformity-to-Type Notification is certification for the manufacture of category 2

electrical equipment. (refer ATEX Directive Annexes VI)

ATEX Product Verification is certification for the manufacture of category 1 equipment

- 100% verification by the Notified Body. (refer ATEX Directive Annexes V)

ATEX or IECEx Unit Verification is certification covering design and manufacture of equipment

- 100% verification by the Notified Body. (refer ATEX Directive Annexes IX and IECEx Scheme Rules)

Environmental & MCERTS Training

- IECEx Certification of Personnel Competence Scheme

- Competence Professional Scheme

- MCERTS Personnel Competence Scheme

For further details please contact CSA-Sira on: 01244 670900 or Email: training@siraconsulting.com

The standard consists of the following parts:

IEC 61508-1 General requirements. IEC 61508-2 Requirements for E/E/PE safety-related systems.

IEC 61508-3 Software requirements. IEC 61508-4 Definitions and abbreviations.

IEC 61508-5 Examples and methods for the determination of safety integrity levels.

IEC 61508-6 Guidelines on the application of IEC 61508-2 and IEC 61508-3. IEC 61508-7 Overview of

techniques and measures.

Sector specific standards related to IEC 61508 include:

IEC 61511 Process industries. IEC 61513 Nuclear power plants. IEC 62061 Machinery sector

and ISO 13849. IEC 61800-5-2 Power drive systems. EN 50272 and EN 50402 Functional safety

requirements for portable and fixed gas detection systems. EN 50495 safety devices requirements

for safe operation of equipments with respect to explosion risks.

Issued January 2013

You might also like

- Tgs Example Crowd Control PlanDocument6 pagesTgs Example Crowd Control Planbootsevans100% (1)

- Hazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFDocument1 pageHazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFAgustinus Made Theo Dwijaya100% (4)

- Cold Work Permit: The Following Areas / Items Have Been Inspected by Issuer and ReceiverDocument2 pagesCold Work Permit: The Following Areas / Items Have Been Inspected by Issuer and Receiversindarth raveendrakrishnan100% (6)

- Implan SAKLOLO 2014 (Policing During Disaster) PDFDocument10 pagesImplan SAKLOLO 2014 (Policing During Disaster) PDFNing D. TalboNo ratings yet

- Bartec Hazardous Class PosterDocument1 pageBartec Hazardous Class PosterDen Andri Nchu100% (2)

- iUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBDocument1 pageiUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBAdemola Olajide TejumolaNo ratings yet

- Hazardous Area ClassificationsDocument1 pageHazardous Area ClassificationsAndrew Bull100% (2)

- What Is ATEXDocument21 pagesWhat Is ATEXBymohamedfb DrillerNo ratings yet

- Hazardous Area Classification Philosophy For Combustible DustsDocument5 pagesHazardous Area Classification Philosophy For Combustible DustsasNo ratings yet

- 2.2.1 - SIS - Design, Analysis and Justification (EC50) - ISADocument2 pages2.2.1 - SIS - Design, Analysis and Justification (EC50) - ISARoberto CarrascoNo ratings yet

- Iecex TCD 02 Scheme Ed 7.0Document103 pagesIecex TCD 02 Scheme Ed 7.0Bhavik PrajapatiNo ratings yet

- ATEXDocument15 pagesATEXsagar_ovhalNo ratings yet

- Hazardous Area Equipment MarkingDocument1 pageHazardous Area Equipment MarkingAgus RianNo ratings yet

- UKOOA GuidelinesDocument70 pagesUKOOA Guidelinesscribd@omoa.co.uk100% (2)

- BS en 16348-2013Document32 pagesBS en 16348-2013Behrooz50% (2)

- Intertek Poster A1 (HazLoc - Guide) - 0Document1 pageIntertek Poster A1 (HazLoc - Guide) - 0Antonio FilipeNo ratings yet

- FM EXGas HazardPosterDocument1 pageFM EXGas HazardPosterrocket-vtNo ratings yet

- Guide To HAzardous Locations - Explosive Gas Atmosphere-FM ApprovalsDocument1 pageGuide To HAzardous Locations - Explosive Gas Atmosphere-FM Approvalsghoest_10No ratings yet

- IECDocument1 pageIECJay Jay100% (1)

- Hazardous Area Chart - E&H PDFDocument2 pagesHazardous Area Chart - E&H PDFBuddy EkoNo ratings yet

- Po Ex en 170413 WebDocument1 pagePo Ex en 170413 Webswordleee swordNo ratings yet

- iPRODUCT100: Ii 2 GD Ex D Iic T6 GB Ex TD Iiic T100°C DB I M2 Ex D I MBDocument1 pageiPRODUCT100: Ii 2 GD Ex D Iic T6 GB Ex TD Iiic T100°C DB I M2 Ex D I MBmlutfimaNo ratings yet

- Poster ATExDocument1 pagePoster ATExmarius_brkt6284No ratings yet

- Area Classification: (IEC/EN 60529)Document1 pageArea Classification: (IEC/EN 60529)nestkwt1No ratings yet

- Iec60079 18 2009Document35 pagesIec60079 18 2009Victor Castellanos AlegriaNo ratings yet

- Area Hazard ClassificatinsDocument3 pagesArea Hazard ClassificatinsshujjatNo ratings yet

- A Guide To European (Eec) Certification For Hzardus AreasDocument5 pagesA Guide To European (Eec) Certification For Hzardus AreasDeepak DinkarNo ratings yet

- 2 AschenbrennerDocument45 pages2 Aschenbrennercarine_moreira_7No ratings yet

- Section8C Intrinsically Safe BarriersDocument29 pagesSection8C Intrinsically Safe BarrierstasingenieriaNo ratings yet

- ATEX Requirements Adn EU Certification System PDFDocument37 pagesATEX Requirements Adn EU Certification System PDFtintucinbNo ratings yet

- IEC 60079-26 - Group II Zone 0 Electrical Apparatus - 2014Document20 pagesIEC 60079-26 - Group II Zone 0 Electrical Apparatus - 2014Institute of Marketing & Training ALGERIANo ratings yet

- Basic Concepts For Explosion ProtectionDocument52 pagesBasic Concepts For Explosion ProtectionReinaldo SouzaNo ratings yet

- Fire & Gas Capability BrochureDocument7 pagesFire & Gas Capability BrochureNazeeruddin MohammedNo ratings yet

- IECEX ATEX ComparisonDocument6 pagesIECEX ATEX ComparisonPilsner80No ratings yet

- Dust Explosion Protection Using Flameless Venting - FIKE EXEMPLOSDocument18 pagesDust Explosion Protection Using Flameless Venting - FIKE EXEMPLOSPedro Ceriolli100% (1)

- New Atex Directive: Lars EkströmDocument23 pagesNew Atex Directive: Lars EkströmvalimironescuNo ratings yet

- Iec Hazardous Locations Certification DocumentsDocument2 pagesIec Hazardous Locations Certification DocumentsbubuluqNo ratings yet

- FMEDA E3 ModulevelDocument21 pagesFMEDA E3 ModulevelRonny AjaNo ratings yet

- ISA-61241 Electrical Aparatus To Use in Zone21y22Document26 pagesISA-61241 Electrical Aparatus To Use in Zone21y22nicolascsNo ratings yet

- Info Iec60079-14 (Ed3.0) en DDocument11 pagesInfo Iec60079-14 (Ed3.0) en DTam TranNo ratings yet

- ATEX Non ElectricalDocument10 pagesATEX Non ElectricalmigelNo ratings yet

- Guide To HAzardous Locations Explosive Gas Atmosphere FM Approvals PDFDocument1 pageGuide To HAzardous Locations Explosive Gas Atmosphere FM Approvals PDFBarbalat AlexandruNo ratings yet

- Iec60079-11 (Ed5.0) en D PDFDocument11 pagesIec60079-11 (Ed5.0) en D PDFSallar Qazi0% (1)

- Hazardous Area Classification QuestionsDocument9 pagesHazardous Area Classification QuestionsVraja KisoriNo ratings yet

- Zone ClassificationDocument9 pagesZone ClassificationibrahimkhansahilNo ratings yet

- ATEX - A Pragmatic ApproachDocument11 pagesATEX - A Pragmatic ApproachPaul JamesonNo ratings yet

- AN9003 - A Users Guide To Intrinsic Safety: Reasons For Selecting The Intrinsically Safe ConceptDocument20 pagesAN9003 - A Users Guide To Intrinsic Safety: Reasons For Selecting The Intrinsically Safe ConceptIC013 Rakshit JethwaNo ratings yet

- ATEXDocument12 pagesATEXJacqueline AdamsNo ratings yet

- D1P7 IECEx CN Conference CoPC Scheme PDFDocument35 pagesD1P7 IECEx CN Conference CoPC Scheme PDFmadjadNo ratings yet

- IEC 60079-29-1 - Gas Det, Perf Req Comb Det - 2009Document56 pagesIEC 60079-29-1 - Gas Det, Perf Req Comb Det - 2009Institute of Marketing & Training ALGERIA100% (1)

- Design of SIFs and SIL Calculation - v2 - Online PDFDocument8 pagesDesign of SIFs and SIL Calculation - v2 - Online PDFRabah AmidiNo ratings yet

- Intrinsic Safety MaintenanceDocument2 pagesIntrinsic Safety MaintenanceRoadieNo ratings yet

- ISA-84.00.02 Part 4 (2002)Document58 pagesISA-84.00.02 Part 4 (2002)Sergio LungrinNo ratings yet

- IEC 61508 OverviewDocument13 pagesIEC 61508 OverviewDámaso DortaNo ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- Major Accidents to the Environment: A Practical Guide to the Seveso II-Directive and COMAH RegulationsFrom EverandMajor Accidents to the Environment: A Practical Guide to the Seveso II-Directive and COMAH RegulationsNo ratings yet

- North America: Hazardous Areas, Explosive Atmospheres and Equipment GroupDocument1 pageNorth America: Hazardous Areas, Explosive Atmospheres and Equipment GroupkazdanoNo ratings yet

- CSA Group WallchartDocument1 pageCSA Group WallchartMohd Lutfi MahaliNo ratings yet

- FM EXGas HazardPosterDocument0 pagesFM EXGas HazardPosterFabio Emanuele BrandaNo ratings yet

- Hazardous Locations Poster - 2014 PDFDocument1 pageHazardous Locations Poster - 2014 PDFIo HitachiNo ratings yet

- P 0296 Hazardous Locations 2Document1 pageP 0296 Hazardous Locations 2Louis ChenNo ratings yet

- Equipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonDocument1 pageEquipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonBalan PalaniappanNo ratings yet

- At ExDocument2 pagesAt ExMoustafa Ibrahim YehyaNo ratings yet

- Arabic (Middle East and Gulf Countries)Document4 pagesArabic (Middle East and Gulf Countries)maniking1No ratings yet

- 33KV GTP WbsebDocument13 pages33KV GTP Wbsebmaniking1No ratings yet

- UIIC ClaimFormDocument6 pagesUIIC ClaimFormTeja NagetiNo ratings yet

- 14 - Section C - Electrical PDFDocument311 pages14 - Section C - Electrical PDFmaniking1100% (2)

- E1 M1 C1 Presentation - enDocument1 pageE1 M1 C1 Presentation - enmaniking1No ratings yet

- What Is The Difference Between Power and Distribution TransformerDocument8 pagesWhat Is The Difference Between Power and Distribution Transformermaniking1No ratings yet

- BrochurePEARL Water HeaterDocument4 pagesBrochurePEARL Water Heatermaniking1No ratings yet

- Mini FP For Underbrdige LightingDocument1 pageMini FP For Underbrdige Lightingmaniking1No ratings yet

- Definitions - The Basics To The Advanced: EXW "Ex Works"Document8 pagesDefinitions - The Basics To The Advanced: EXW "Ex Works"maniking1No ratings yet

- RFP Inverter (Acme TelepowerDocument15 pagesRFP Inverter (Acme Telepowermaniking1No ratings yet

- Golden Rules (English)Document1 pageGolden Rules (English)mohammed tofiqNo ratings yet

- MSDS Diala S4 ZX-1Document20 pagesMSDS Diala S4 ZX-1M.nurNo ratings yet

- Clivet ManualDocument50 pagesClivet ManualPrestoneK75% (4)

- Channel Partner Agreement - Version - (CDMA) - 1.1Document105 pagesChannel Partner Agreement - Version - (CDMA) - 1.1Apte SatishNo ratings yet

- Quickguide WW90MDocument1,020 pagesQuickguide WW90Miosif_viorelm0% (1)

- Osha3903 PDFDocument3 pagesOsha3903 PDFgetz_meNo ratings yet

- Model Hirac PDFDocument12 pagesModel Hirac PDFHafiz Abu BakarNo ratings yet

- Mos WaterproofingDocument12 pagesMos Waterproofingeng mohamad husamNo ratings yet

- Endress Hauser LC301 ManualDocument24 pagesEndress Hauser LC301 Manualtopaz45No ratings yet

- Fes TBT Mobile CraneDocument1 pageFes TBT Mobile CraneMohammed AtefNo ratings yet

- 740 - Contemporary Design of Low Cost Se in Developing Countries PDFDocument300 pages740 - Contemporary Design of Low Cost Se in Developing Countries PDFHector Graffe100% (2)

- 701.0 Plunge Pool - MSSDocument9 pages701.0 Plunge Pool - MSSSanto ENo ratings yet

- DWDGM1011 ManualDocument24 pagesDWDGM1011 ManualAlezNgNo ratings yet

- Sterilizer Safety 安全手册Document8 pagesSterilizer Safety 安全手册Hangzhou Zhu Tai Trading Co.,LtdNo ratings yet

- WW ALL X X S 05 049 I REV.2 - Upstream SCE Management Procedure November 2019Document142 pagesWW ALL X X S 05 049 I REV.2 - Upstream SCE Management Procedure November 2019joeNo ratings yet

- Slipring ManualDocument66 pagesSlipring ManualRobin GhekiereNo ratings yet

- Gov. Role 184218Document65 pagesGov. Role 184218YIN SOKHENGNo ratings yet

- Annual Disaster Rick Reduction Mnge. PlantDocument10 pagesAnnual Disaster Rick Reduction Mnge. PlantMisyel CamposanoNo ratings yet

- Basic Training For Oil and Chemical Tanker Cargo OperationsDocument240 pagesBasic Training For Oil and Chemical Tanker Cargo Operationsbharatheeeyudu67% (6)

- MB0120120108 HS-450i Operator's ManualDocument152 pagesMB0120120108 HS-450i Operator's Manualjunior_radaicNo ratings yet

- ASD Pipe SystemDocument54 pagesASD Pipe SystemHeloá Andrade (Arquitetura e Urbanismo)No ratings yet

- Eng Isam Updated CVDocument4 pagesEng Isam Updated CVIsam GhawadrehNo ratings yet

- A System of Safety Management Practices PDFDocument14 pagesA System of Safety Management Practices PDFAnonymous FmXEu2cHxK100% (1)

- GSS Presentation 1 NashriDocument17 pagesGSS Presentation 1 NashrimuawizzatNo ratings yet

- HPSO NSO Risk - Management - Plan - Template Final Legal Approved 12 - 7 - 21 67 RevDocument8 pagesHPSO NSO Risk - Management - Plan - Template Final Legal Approved 12 - 7 - 21 67 RevcvacaNo ratings yet