Professional Documents

Culture Documents

Aci Rectangular Tanks2010

Aci Rectangular Tanks2010

Uploaded by

morphie_blackCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aci Rectangular Tanks2010

Aci Rectangular Tanks2010

Uploaded by

morphie_blackCopyright:

Available Formats

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

CVNG 3016 DESIGN OF ENVIRONMENTAL SYSTEMS

TOPIC:

Design of Reinforced Concrete Liquid Retaining Structures

LECTURER: Dr.WilliamWilson

DESIGNOFREINFORCEDCONCRETETANKS(ACI318/ACI350)

Recommended Reading:

A. Codes

1. ASCE7-05 - Minimum Design Loads for Buildings and other Structures

2. ACI 318-06 Building Code requirements for Reinforced Concrete

3. ACI 350R 06 Environmental Engineering Concrete Structures.

B. Technical Literature

1. Munshi, Javeed A. Rectangular Concrete Tanks (Rev. 5th Ed.), Portland Cement

Association, 1998.

2. Portland Cement Association, 1992. Underground Concrete Tanks

3. Portland Cement Association, 1993. Circular Concrete Tanks without prestressing

RECTANGULARTANKS

DesignConsiderations

Flexure

bendinginwallsandbase

Shear

- wall-to-base, wall-to-wall junctions

Tension

- horizontal tension in walls, base

Deflection

vertical/ horizontal deflections of wall

Cracking

Flotation

thermal, flexural, tension cracks

- when base is located below water table level

Base Fixity - (i) Fixed (ii) Pinned

LoadingConditions

Condition 1 Condition 2 Condition 3 -

in reality neither of these

conditions may actually exist

Both may need to be investigated

Internal Water Pressure only (before backfilling, i.e. leakage test)

External Earth Pressure only (before filling tank)

Tank full and Soil backfilled (resistance provided by soil is ignored)

1

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

Moments

pinned base

fixed base

+

Fv

(a) Liquid pressure in Tank

Fv

Ft

(b) Vertical Forces

Fv

M (-)

Fv

Ft

Ft

M (+)

Fv

(shear)

Ft

M

Fv

M (-)

Fv

Fv

(c) Horizontal Forces

FIGURE 1 FORCES IN RECTANGULAR TANK WALLS

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

STRENGTHDESIGNMETHOD

Basic Requirement:

Design Strength Required Strength

(Nominal Strength) U

Rn U

(ACI 318 Sect. 9.2)

U = 1.4 (D + F)

(2.1)

(ACI 350 cl. 2.6.5)

U = 1.7 (D + F)

(2.2)

D = dead load

F = liquid pressure

Sanitary Durability Factors - ACI 350 applies sanitary durability factors (based on crack width

calculations) to obtain the Required Strength

Required Strength = Sanitary Coefficient x U

Ur = Cs x U

(2.3)

Sanitary Coefficients are:

(bending)

Cs = 1.3

Cs = 1.65

(direct tension / hoop tension)

Cs = 1.3

(shear beyond shear capacity of concrete stirrup design)

Cs = 1.0

(concrete shear)

Strength Design Requirements

(a) Flexural Reinforcement

Design Strength 1.3U

Mn 1.3(1.4MD+ 1.7 ML+1.7 MF)

(2.4)

(b) Direct Tension Reinforcement

Design Strength 1.65U

Nn 1.65(1.4ND+ 1.7NL+1.7NF)

(2.6)

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

(c) Stirrup Shear Reinforcement

Design Strength 1.3 (Vc - Vc)

Vs 1.3 (Vu - Vc)

(2.7)

(d) Concrete Shear and Compression Reinforcement

Design Strength 1.0 U

Vn 1.0Vu

(2.8)

(e) Minimum reinforcement (ACI 318-05 cl. 10.5)

As, min =

f c

fy

b w d 200

(f) Minimum cover = 2 in.

bw d

fy

Concrete sections with t 24 use

minimum

temperature

and

(2.9)

shrinkage reinforcement at each

face based on 12 thickness.

Size of rebar #11

Max. spacing of rebar 12

Minimum cover in tank walls = 2

(g) Minimum thickness for walls over 10 ft. high = 12 ins.

Serviceability for Normal Sanitary Exposure (ACI 350, cl. 2.6.6)

Crack Control

Maximum Design crack width

Severe exposure

Aesthetics

= 0.010 in.

= 0.008 in.

Crack width calculation is based on the following equation:

z=f s 3 d c A

(2.10)

Where,

Z is a quantity limiting distribution of flexural reinforcement

(ACI 350 limits)

z 115 kips/in

(crack width = 0.010 in)

z 95 kips/in

(crack width = 0.008 in)

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

fs = calculated stress in reinforcement at service loads, ksi

dc = concrete cover to centroid of closest rebar

A = effective area of concrete surrounding flexural reinforcement with same

centroid divided by the number of bars, in2.

The maximum spacing it given by,

Z3

bw = 2 3

2d c f s

(2.11)

A= 2dcbw

t

dc

bw

Fig. 1.0 - Calculation of A

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

EXAMPLE 1

2010

RectangularTank

20'-0

10'-0

30'-0

2.5'

Cross Section

350

20'-0

Longitudinal Section

30'-0

Plan

Fig. E1 Plan and sections of Tank

Design Data

Weight of Liquid, w =

70 lbs/ft3

Weight of Soil, s =

100 lbs/ft3

=

0.3

ka

'

=

4000 psi

fc

fy

=

60,000 psi

Wall thickness, t

=

18 in.

Base slab projection beyond wall = 2.5 ft.

Water pressure at base,

p = wa = 70 x 10 = 700 lbs/ft2

6

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

DesignforVerticalBendingMoments

Wall considered fixed at base and free at top

Using PCA Charts to calculate moments (Table 3-29: case 3 Long side)

Ratio of length/height = b/a = 30/10 = 3.0 (long side)

Ratio of width/height = c/a = 20/10 = 2.0 (short side)

Mx = CMx x pa2/1000

= CMx x 700 x 102 / 1000

= CMx x 70 ft-lbs

= CMx x 0.84 in-kips

For sanitary structures

Mu = Sanitary coef x 1.7 x M

Mux = 1.3 x 1.7 x Mx

Mux = 1.3 x 1.7 x CMx x 0.84 in-kips

= 1.86 x CMx

Maximum positive moment at 0.7 a

(CMx = +10) Mux = +18.6 kips-in

Maximum negative moment at bottom (CMx = -129) Mux = -239.9 kips-in

a = 10'

M = + 18.6 kips-in

V = 3500 lbs

M = - 239.9 kips-in

Fig E2 Vertical Moments at mid-length

Assuming No. 5 bars at 12in. c/c

Cover = 2 in.

Wall thickness = 18 in.

d = 18 2 5/16 = 15.7 in.

(db = 5/8 in.)

7

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

f c bd

239.9

0.9x4x12x (15.7 )

(From Appendix A)

A s =bd

2010

=0.0225

= 0.023

f c'

4

= 0.023x12x15.7x

= 0.29in 2

fy

60

Checkminimumsteel (ACI 318-05 cl. 10.5)

fc'

4000

x12x15.7=0.595in 2 200 bwd/fy

fy

60000

200b w d 200x12x15.7

=

=

=0.628in 2 (governs)

fy

60,000

Asmin =

bw d=

(ACI 318 -05 cl. 10.5.3)

Use 4/3 of As required by analysis

As = 4/3 x 0.29 = 0.39in2

Provide No. 5 @ 9 in c/c on inside face (As =0.41 in2)

DesignforHorizontalBendingMoments

2590 lbs

2590

-65.6 in-kip

1890 lbs

-65.6

1890

1890

2590

2590

+35.93 in-kip

+35.93

1890

-65.6

1890

-65.6

1890 lbs

2590

2590

Fig. E3- Horizontal Forces (un-factored) at mid-height of tank)

NB: Shear Forces calculations on Page 9 below

8

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

(a)

2010

At Corner - Horizontal Moment Steel

Muy = 1.3 x 1.7 x 65.66

Muy = 145.1 in-kips

Mu

145.1

=

=0.0136

1

2

f c bd 0.9x4x12x15.7 2

(From Appendix A)

= 0.014

A s =bd

(b)

f c'

4

=0.014x12x15.7x

=0.18in 2

fy

60

Steel required for Direct Tension in Long Wall

Factored tension Nu = 1.65 x 3213 = 5301 lbs/ft width

As=

Nu

5301

=

=0.1in 2

0.9f y 0.9x60,000

Direct tension steel is equally distributed on inside and outside faces of wall.

Total steel required on inside face =

As,min =

0.18+

0.1

=0.23in 2

2

200b w d

=0.625in 2 (governs)

fy

4/3 of As required by analysis = 4/3 x 0.23 = 0.31 in2

Provide No.5 @ 12 in (As = 0.31 in2) horizontal steel on inside face of long walls.

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

(c)

2010

Horizontal steel near centre of outside face of wall

Design for M = 40.91 in-kips

(d)

CrackControl - Check Maximum Spacing of bars

Maximum un-factored moment

M=

239.9

=108.6in-kips

(1.7x1.3)

Stress in steel reinforcement

M

A s jd

As = 0.41 in2/ft

fs =

n=

29,000

57

4000

d = 15.7 in

=8

0.41

= 0.00218

(12 x 15.7 )

k = 2 n + ( n ) n = 0.17

2

j = 1 k/3 = 0.94

fs =

108.6

=17.95ksi

0.41x0.94x15.7

z3

s m ax =

( 2 x d c2 x f s3 )

dc = cover +

2

z = 115 kips/in

= 2 + 0.313=2.313in

fs = 17.95 ksi

115 3

s max =

=24.6in>9in

2x2.313 2 x17.95 3

OK

10

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

DesignforShearForces

Using PCA Charts to calculate moments (Table 2-17: CASE 3 Long side)

Ratio of length/height = b/a = 30/10 = 3.0 (long side)

Ratio of width/height = c/a = 20/10 = 2.0 (short side)

Shear, V = Cs x p x a

(a)

Check Shear at bottom of Wall

Maximum shear at bottom of long wall,

V = 0.50 x 700 x 10 = 3500 lbs

Vu =1.7x3500=5950 lbs

Since tensile force from adjacent wall is small

Vc =2 fc' bd

=2 4000x12x15.7 = 23,831 lbs

Vc = 0.85 x 23,831= 20,256lbs > 5950 lbs

(b)

OK

Check Shear at side edge of long wall

V = 0.37 x 700 x 10 = 2590 lbs

Vu = 1.7 V = 1.7 x 2590 = 4403 lbs

Wall subjected to simultaneous tensile force due to shear in short side wall;

(ACI 318 cl.11.3.2.3) gives allowable shear as:

Nu

V c = 2 1+

500A g

f c' b d

Nu = tension in long wall due to shear in short wall.

Shear in short side wall V = 0.27 x 700 x 10 = 1890 lbs.

11

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

Nu = -1.7 x 1890 = -3213 lbs

Ag = 18 x 12 = 216 in2

-3213 1

Vc =2 1+

f c bd

500x216

=1.94 4000x12x15.7 = 23,116 lbs

Vc = 0.85 x 23,116 = 19,649 lbs > 4403 lbs

OK

(e)

ShrinkageandTemperatureReinforcement

Assuming the walls will be in one pour of 30 ft long.

Minimum Temperature and Shrinkage reinforcement

(Fig 1-2)

A st

=0.0033

bh

1

A st = x12x18=0.356in 2 (No. 5 @ 10)

2

< 0.41 in2

(No. 5 @ 9)

OK

SummaryofReinforcement

Inside face vertical

Outside face vertical

Inside face horizontal

Outside face horizontal

No. 5 @ 9 in

No. 5 @ 10 in (Use No. 5 @ 9 in for consistency)

No. 5 @ 12 in

No. 5 @ 12 in

12

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

BASESLABDESIGN

Design as a 2-way spanning slab, simply supported at edges.

Assume that the pressure beneath the slab is uniform and is generated by the weight

of the walls spread over entire area.

12

10'

30'

Vs = 4150 lbs

3500 lbs

Vls

Mls = 8497 ft-lb

2500 lbs

Mss = 15,413 ft-lb

2500 lbs

3500 lbs

k

Fig E4 Forces on Base Slab

Unit weight of concrete = 150 lbs/ft3

13

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

Wall Dead load = 150 ( 2 x 1.5 x 10 x ( 30 + 0.75) + ( 20+0.75) ) = 231,750 lbs

Factored DL = 1.4(231,750) = 324,450 lbs

324,450

p=

= 509 lbs/ft 2

( 30.75 x 20.75)

Using PCA Tables

Mss (short span)

Mls (long span)

Vss

Vls

Ft (long span)

=

=

=

=

=

78 x 509 x 202 /1000

43 x 509 x 202 / 1000

0.24 x 509 x 20

0.42 x 509 x 20

0.4 x 700 x 10

= 15,881 ft-lb = 191 in-k

= 8755 ft-lb = 105in-k

= 2443 lbs = 2.4 k

= 4276 lbs = 4.3 k

= 2800 lbs

Design of Short Span

2.4k

12

191 in-k

3.5 k

Assume slab thickness, h = 12 ins.

For #6 bars and 2 cover

d = 12 2 0.75/2 = 9.625 ins.

Short Span

(a)

Mid-span Moment Steel

(NB: ACI 350 is silent on use of sanitary coefficient for slabs, but we will apply

same here)

Muy = 1.3 x 191

Muy = 248.3 in-kips

Mu

248.3

=

= 0.062

'

2

fcbd 0.9 x 4 x 12 (9.625)2

(From Appendix A)

14

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

= 0.064

f c'

4

A s =bd =0.064 x 12 x 9.7x

= 0.49in 2

fy

60

(b)

Steel required for Direct Tension in short span

Factored tension Nu = 1.65 x 3500 = 5775 lbs/ft width

As=

Nu

5775

=

=0.11in 2

0.9f y 0.9x60,000

Direct tension steel is equally distributed on inside and outside faces of slab.

Total steel required on top face =

As,min =

0.49+

0.11

=0.55 in 2

2

200b w d 200 (12 x 9.7 )

=

= 0.39 in 2

fy

60000

4/3 of As required by analysis = 4/3 x 0.55 = 0.73 in2

Provide No.6 @ 7 in crs.

direction.

(As = 0.75 in2) steel on top face of slab in short

(c) Long Span

Muy = 1.3 x 105 in-kips

Muy = 136.5 in-kips

d = 12 -2 -0.625- 0.625/2 = 9.0625

Mu

136.5

=

= 0.0385

1

2

fc bd 0.9 x 4 x 12 x 9.06252

(From Appendix A)

= 0.039

15

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

f c'

4

A s =bd =0.039 x 12 x 9.0625x

= 0.283 in 2

fy

60

Steel required for Direct Tension in long span

Factored tension Nu = 1.65 x 2800 = 4620 lbs/ft width

As=

Nu

4620

=

=0.085in 2

0.9f y 0.9x60,000

Direct tension steel is equally distributed on inside and outside faces of slab.

Total steel required on top face =

As,min =

0.283+

0.085

=0.326 in 2

2

200b w d 200 (12 x 9.7 )

=

= 0.39 in 2 (governs)

fy

60000

4/3 of As required by analysis = 4/3 x 0.31 = 0.41 in2

Provide No.5 @ 8 in crs

(b)

Check Shear at side edge of long span

V = 4276 lbs

Vu = 1.0 V = 4276 lbs

Wall subjected to simultaneous tensile force (ACI 318 cl.11.3.2.3) gives allowable

shear as:

Nu

V c = 2 1+

500A

g

f c' b d

Nu = 3500 lbs

Ag = 12 x 12 = 144 in2

16

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

-3500 '

Vc =2 1+

fc bd

500 x 144

=1.90 4000x12 x 9.7= 14,008 lbs

Vc = 0.85 x 14,008 = 11,907 lbs > 4276 lbs

OK

(e)

ShrinkageandTemperatureReinforcement

Assuming the walls will be in one pour of 30 ft long.

Minimum Temperature and Shrinkage reinforcement

(Fig 1-2)

A st

=0.0033

bh

1

A st = x 0.0033x12x12=0.238 in 2

2

< 0.73 in2

OK

Summary of Reinforcement

Top face short direction (mid-span)

Top face short direction (edges)

Top face - long direction (mid-span)

Bottom face - both direction (edges)

Bottom face both direction (mid-span)

No. 6 @ 7 in crs

No. 5 @ 7 in crs (for consistency)

No. 5 @ 7 in (for consistency)

No. 5 @ 7 in

No. 5 @ 12 in

17

UWU/Civil&EnvironmentalEngineeringCVNG3016DesignofEnvironmentalEngineeringSystems

2010

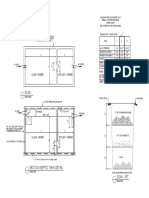

RectangularTank

No. 5 @ 10 in c/c

No. 5 @ 12 in. c/c

No. 5 @ 12 in. c/c

No. 5 @ 10 in c/c

No. 5 @ 9 in. c/c

Water

stop

No. 6 @ 7 in. c/c

No. 5 @ 7 in. c/c

Water stop

No. 5 @ 7 in. c/c both ways

Section showing Reinforcement Details for Rectangular Tank

Dr. William Wilson

17 March 2010

18

You might also like

- Design of A Modern High Rise Building in Abu-Dhabi (United Arab Emirates University) Graduation Project II Fall 2010Document50 pagesDesign of A Modern High Rise Building in Abu-Dhabi (United Arab Emirates University) Graduation Project II Fall 2010April Ingram100% (1)

- RectangularTanks PCADocument61 pagesRectangularTanks PCAvictorcivNo ratings yet

- Slab On Grade Excel SheetDocument10 pagesSlab On Grade Excel SheetEngrDebashisMallick100% (3)

- Structural Design of Raft Foundation Based On Geotechnical AnalysisDocument6 pagesStructural Design of Raft Foundation Based On Geotechnical AnalysisNaresh KumarNo ratings yet

- Reinforced Concrete Beam Design ACI 318 08Document11 pagesReinforced Concrete Beam Design ACI 318 08AhmadGhanem88% (8)

- SlabsOnGrade - Ppthandout ACI 360Document7 pagesSlabsOnGrade - Ppthandout ACI 360Ivan Pacompia Calcina50% (2)

- Tower Crane Foundation Design 24.07.2016Document11 pagesTower Crane Foundation Design 24.07.2016Gihan Chathuranga92% (13)

- Slab On GradeDocument56 pagesSlab On GradeTere Mota DondéNo ratings yet

- Water Tank Design (Aci 318-05 & 350-01)Document5 pagesWater Tank Design (Aci 318-05 & 350-01)Arman20190% (10)

- Slab On Grade Design NotesDocument54 pagesSlab On Grade Design NotesrealchicNo ratings yet

- Rectangular Concrete Beam Analysis - Design Per ACI 318-99Document20 pagesRectangular Concrete Beam Analysis - Design Per ACI 318-99Anonymous w5SJiLs100% (1)

- PCA Rectangular - Tank Design ExampleDocument15 pagesPCA Rectangular - Tank Design ExampleConrad Otieno100% (4)

- Design of Slab On GradeDocument6 pagesDesign of Slab On GradeLa BeamNo ratings yet

- Staad - Foundation Isolated Footing DesignDocument44 pagesStaad - Foundation Isolated Footing DesignboyzesNo ratings yet

- 4 Rectangular Concrete TanksDocument15 pages4 Rectangular Concrete Tanksajitgijare85% (13)

- ACI - Rectangular Tanks 2010Document18 pagesACI - Rectangular Tanks 2010Yulian Jesús100% (1)

- 3.0crack Width Check (Aci)Document48 pages3.0crack Width Check (Aci)klynchelle100% (1)

- Reinforced Concrete Slab DesignDocument70 pagesReinforced Concrete Slab DesignLeandro Madeira100% (1)

- Fire Wall DesignDocument4 pagesFire Wall DesignIrshad KhanNo ratings yet

- Analysis and Design of Strap (Cantilever) Footing According To ACI 318Document12 pagesAnalysis and Design of Strap (Cantilever) Footing According To ACI 318rukesh104100% (1)

- Design Shear WallDocument26 pagesDesign Shear WallCaoTrungThành100% (2)

- Analysis and Design of Network of Interacting Primary and Secondary Beams in Large Span ConstructionDocument9 pagesAnalysis and Design of Network of Interacting Primary and Secondary Beams in Large Span ConstructionselinaNo ratings yet

- ACI 350 06 ACI224R 01 Rec Sec Flexural Crack Width Control Rev00 07 Sep 2013Document5 pagesACI 350 06 ACI224R 01 Rec Sec Flexural Crack Width Control Rev00 07 Sep 2013Aie Bantugan100% (5)

- Slab-on-Ground DesignDocument28 pagesSlab-on-Ground DesignvNo ratings yet

- Circular WTanks 2012 16 9 2012Document85 pagesCircular WTanks 2012 16 9 2012Andres CI100% (1)

- Design of Circular Concrete TanksDocument85 pagesDesign of Circular Concrete TanksRoda Cadiz88% (8)

- Anchor Bolt Design (ACI318)Document5 pagesAnchor Bolt Design (ACI318)Ashraful AlamNo ratings yet

- Masonry Design ExamplesDocument13 pagesMasonry Design ExamplesRoger FonsecaNo ratings yet

- Concrete Tanks Design NotesDocument14 pagesConcrete Tanks Design NotesJulían Darío Medina100% (5)

- Step by Step Design of PSC Girder by Working Stress MethodDocument50 pagesStep by Step Design of PSC Girder by Working Stress Methodpravin100% (3)

- Anchor Bolt and Shear Key DesignDocument3 pagesAnchor Bolt and Shear Key DesignsvgkraoNo ratings yet

- Bridge Construction Terminology PDFDocument23 pagesBridge Construction Terminology PDFElisabetta Bolzoni100% (1)

- All Cells in Red Colour Are Meant For Data Input: MM 22.5 MMDocument30 pagesAll Cells in Red Colour Are Meant For Data Input: MM 22.5 MMRenuga DeviNo ratings yet

- (Engineersdaily - Com) RCC62 Retaining WallDocument12 pages(Engineersdaily - Com) RCC62 Retaining WallMuhammad WaqasNo ratings yet

- Design of Underground Water TankDocument6 pagesDesign of Underground Water Tanksijuwolaoluranti100% (1)

- ACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev01 - 04-Nov-2014Document13 pagesACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev01 - 04-Nov-2014jeanfatNo ratings yet

- Design of Continuous Beam and Slab Footing Using BS 8110-1:1997Document8 pagesDesign of Continuous Beam and Slab Footing Using BS 8110-1:1997Ubani Obinna Ranks80% (5)

- Single Box Culvert Structural Design 1.5m X 1.5mDocument28 pagesSingle Box Culvert Structural Design 1.5m X 1.5mAYEDNo ratings yet

- Circular Tank DesignDocument10 pagesCircular Tank DesignKatyayini Nelli50% (2)

- DECKSLABDocument13 pagesDECKSLABASQ100% (1)

- Crackwidth (Gergely & Lutz)Document61 pagesCrackwidth (Gergely & Lutz)Medianna Novita100% (1)

- CSE 28363 - Structural Concrete Design: Lecture 10: Shear and ServiceabilityDocument44 pagesCSE 28363 - Structural Concrete Design: Lecture 10: Shear and ServiceabilityBitch CarrieNo ratings yet

- Emmedue m2 Styrofoam Building System - 26 - Pac-EmmedueDocument39 pagesEmmedue m2 Styrofoam Building System - 26 - Pac-EmmedueRohn J JacksonNo ratings yet

- 6 Design For Deep Excavation Civil EngineeringDocument121 pages6 Design For Deep Excavation Civil EngineeringSathya Putra Wijaya100% (1)

- ACI Rectangular Tanks2010Document18 pagesACI Rectangular Tanks2010Rohn J Jackson86% (7)

- PCA Teoria-Rectangular Concrete TanksDocument27 pagesPCA Teoria-Rectangular Concrete TanksAlberto Muñoz Vizcarra100% (3)

- Septic Tank DetailsDocument1 pageSeptic Tank DetailsRohn J JacksonNo ratings yet

- Design of Strip Footing 2014Document8 pagesDesign of Strip Footing 2014api-190618655100% (3)

- Paper Reinforced Concrete SlabsDocument32 pagesPaper Reinforced Concrete SlabsTHRESNANo ratings yet

- Composite Beam ExampleDocument7 pagesComposite Beam ExampleFong Pei TyngNo ratings yet

- Composite Construction Design (ULS Only)Document93 pagesComposite Construction Design (ULS Only)CawanNeroMiranio100% (1)

- Elevated Storage Reservoir DesignDocument47 pagesElevated Storage Reservoir Designpsconsultants100% (7)

- Chapter 24 WexDocument7 pagesChapter 24 WexCiprian VarlanNo ratings yet

- ACI 350 3 06 Appendix BRev00 29 Sep 2013Document11 pagesACI 350 3 06 Appendix BRev00 29 Sep 2013Ghencea Adrian100% (2)

- CRL Srs Standoff Railing System: CRL Glass Rail Standoff Fittings Rs0B20 W/ Rectangular Back PlateDocument8 pagesCRL Srs Standoff Railing System: CRL Glass Rail Standoff Fittings Rs0B20 W/ Rectangular Back PlateHanmant OulkarNo ratings yet

- Reinforced Concrete Lecture Notes University of HongKongDocument32 pagesReinforced Concrete Lecture Notes University of HongKongApril Ingram100% (4)

- Bridge-Ch-5-Example On Slab Bridge EDITEDFINALDocument15 pagesBridge-Ch-5-Example On Slab Bridge EDITEDFINALkassahun kebede100% (1)

- Modeling of Diaphragms in STAAD ProDocument13 pagesModeling of Diaphragms in STAAD Proclarkorbe50% (2)

- Architects DictumDocument3 pagesArchitects DictumChristian James TuazonNo ratings yet

- Division of Lanao Del Norte Maliwanag Elementary SchoolDocument7 pagesDivision of Lanao Del Norte Maliwanag Elementary SchoolNoeme VillarealNo ratings yet

- TEAM X. Between Modernity and The EverydayDocument226 pagesTEAM X. Between Modernity and The EverydayAntonio Gil diaz marotlNo ratings yet

- DeflectionDocument31 pagesDeflectionAnonymous nQ9RqmNo ratings yet

- Architecture of 19th Century PDFDocument12 pagesArchitecture of 19th Century PDFrajat charayaNo ratings yet

- Nol DRCDocument158 pagesNol DRCMuthu Praveen SarwanNo ratings yet

- Tutorial 5Document11 pagesTutorial 5Bitch CarrieNo ratings yet

- Special Topics H.W 1:: Design An Interior Panel of A Span Continuous Slab For H20-44 LoadingDocument7 pagesSpecial Topics H.W 1:: Design An Interior Panel of A Span Continuous Slab For H20-44 LoadingHAKAM AL ABBASNo ratings yet

- Lecture 12Document37 pagesLecture 12pddiosNo ratings yet

- Answer For Question 4 Structural DesignDocument16 pagesAnswer For Question 4 Structural DesignFaizalhizam NoordinNo ratings yet

- Design Analysis Beam ACI PDFDocument48 pagesDesign Analysis Beam ACI PDFAlbert DimayugaNo ratings yet

- Preliminary PDFDocument12 pagesPreliminary PDFMunzuara AktherNo ratings yet

- Bearing Capacity Values of Different Types of SoilDocument3 pagesBearing Capacity Values of Different Types of SoilRohn J JacksonNo ratings yet

- Hurricane HardwareDocument20 pagesHurricane HardwareRohn J JacksonNo ratings yet

- CodeMaster - Strength Design For Masonry 2006 IBCDocument6 pagesCodeMaster - Strength Design For Masonry 2006 IBCRohn J JacksonNo ratings yet

- CodeMaster - Wind Ddesign Overview 2000 IBCDocument4 pagesCodeMaster - Wind Ddesign Overview 2000 IBCRohn J JacksonNo ratings yet

- Notice ChangestoFees Oct15 2017Document1 pageNotice ChangestoFees Oct15 2017Rohn J JacksonNo ratings yet

- Valuaton Principles and PracticesDocument50 pagesValuaton Principles and PracticesRohn J JacksonNo ratings yet

- Mesh Product Guide South Island Jul16Document16 pagesMesh Product Guide South Island Jul16Rohn J JacksonNo ratings yet

- DD 121 PDFDocument7 pagesDD 121 PDFalexander nnaemekaNo ratings yet

- Factory Alarm Tvss - IvdDocument39 pagesFactory Alarm Tvss - IvdRohn J JacksonNo ratings yet

- Inflation Data mr110128Document4 pagesInflation Data mr110128Rohn J JacksonNo ratings yet

- SeismicDocument1 pageSeismicRohn J JacksonNo ratings yet

- The The: Evolution of Warren, or Triangular, TrussDocument1 pageThe The: Evolution of Warren, or Triangular, TrussMr. DreamNo ratings yet

- Smoke-Control Application Guide: Manual P/N: 06-470 Rev. No: 0, 10/08Document40 pagesSmoke-Control Application Guide: Manual P/N: 06-470 Rev. No: 0, 10/08Ernesto OtazuNo ratings yet

- PDF Catalogue - CNCQ - VRF HITACHIDocument44 pagesPDF Catalogue - CNCQ - VRF HITACHIArif Jubaidilah NingrumNo ratings yet

- 02-F-F Mezzanine Pentry KitchenDocument1 page02-F-F Mezzanine Pentry KitchenEngr.Moaz ArshadNo ratings yet

- Athangudi TilesDocument84 pagesAthangudi TilesSMITH DESIGN STUDIONo ratings yet

- The Hong Kong Steel Code "Structural Use of Steel Using Limiting State Approach"Document13 pagesThe Hong Kong Steel Code "Structural Use of Steel Using Limiting State Approach"uhu_plus6482100% (1)

- Tanja Poppelreuter - Raumplan After LoosDocument21 pagesTanja Poppelreuter - Raumplan After LoosleoriveraNo ratings yet

- 076328C-SI-89-E-DS-0015 - A-C - E&I Bulk Material Data Sheet (Cable Ladders & Trays, Support and Accessories)Document2 pages076328C-SI-89-E-DS-0015 - A-C - E&I Bulk Material Data Sheet (Cable Ladders & Trays, Support and Accessories)Bumi AzarakhNo ratings yet

- 1:00 PM SED: 1:00 PM / 23-04-2022 ATC Circle 1 . 300 IDJ21032205095607 21-03-2022Document3 pages1:00 PM SED: 1:00 PM / 23-04-2022 ATC Circle 1 . 300 IDJ21032205095607 21-03-2022praveen mNo ratings yet

- 16 PapastergiouDocument21 pages16 PapastergiouIoana PopescuNo ratings yet

- Magic's Danganronpa Kirigiri Volume 5 English TranslationDocument245 pagesMagic's Danganronpa Kirigiri Volume 5 English TranslationZakDJNo ratings yet

- 02 Spec Guniting Works Rev20200610Document8 pages02 Spec Guniting Works Rev20200610Tony JamesNo ratings yet

- Brochure - c7dc 288b 053e Ee11 7354 E0cf 47f9 1996 - 20230428032238Document1 pageBrochure - c7dc 288b 053e Ee11 7354 E0cf 47f9 1996 - 20230428032238DewaldNo ratings yet

- Schite BisericaDocument133 pagesSchite BisericaAndrei ZamfirNo ratings yet

- Design of 16 Bit RiscDocument15 pagesDesign of 16 Bit RiscKeerti RajNo ratings yet

- Rectagrid & Gripweld - GratingDocument20 pagesRectagrid & Gripweld - GratingJohan ConradieNo ratings yet

- Fisher HouseDocument5 pagesFisher HouseSuryadi Chandra0% (1)

- Bug Memlock CluvfyDocument2 pagesBug Memlock Cluvfyelcaso34No ratings yet

- One Way and Two Way SlabDocument46 pagesOne Way and Two Way SlabMohit DhimanNo ratings yet

- Roof Plan Floor Plan Section Thru K: Sulit PastelDocument1 pageRoof Plan Floor Plan Section Thru K: Sulit PastelAbegail PanangNo ratings yet

- A. Required Equipment/Apartus For Bitumen/DBM/BCDocument32,767 pagesA. Required Equipment/Apartus For Bitumen/DBM/BCmritunjaychaubeyNo ratings yet