Professional Documents

Culture Documents

Caliper Logs: Figure 9.1 The Reeves 2 Arm Caliper Tool

Uploaded by

ThiagoCabralOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caliper Logs: Figure 9.1 The Reeves 2 Arm Caliper Tool

Uploaded by

ThiagoCabralCopyright:

Available Formats

Petrophysics MSc Course Notes

9.

CALIPER LOGS

9.1

Introduction

Caliper Logs

The Caliper Log is a tool for measuring the diameter

and shape of a borehole. It uses a tool which has 2, 4,

or more extendable arms. The arms can move in and

out as the tool is withdrawn from the borehole, and the

movement is converted into an electrical signal by a

potentiometer.

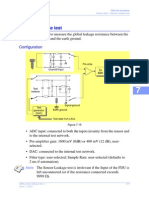

In the two arm tool (Fig. 9.1), the borehole diameter is

measured. This is shown in track 1 of the master log

together with the bit size for reference. Borehole

diameters larger and smaller than the bit size are

possible. Many boreholes can attain an oval shape

after drilling. This is due to the effect of the pressures

in the crust being different in different directions as a

result of tectonic forces. In oval holes, the two arm

caliper will lock into the long axis of the oval crosssection, giving larger values of borehole diameter than

expected. In this case tools with more arms are

required.

In the 4 arm (dual caliper) tool, the two opposite pairs

work together to give the borehole diameter in two

perpendicular directions. An example of a 4 arm tool is

the Borehole Geometry Tool (BGT). This has 4 arms

that can be opened to 30 inches (40 inches as a special

modification), and give two independent perpendicular

caliper readings. The tool also calculates and integrates

the volume of the borehole and includes sensors that

measure the direction (azimuth) and dip of the

borehole, which is useful in plotting the trajectory of

the borehole.

In the multi-arm tools, up to 30 arms are arranged

around the tool allowing the detailed shape of the

borehole to be measured.

Some of the other tools in this course have sensors

attached to pads that are pressed against the borehole

wall. The pressing device is also a form of caliper, and

so caliper information can sometimes also be obtained

from these tools.

Figure 9.1 The Reeves 2 arm caliper tool.

Dr. Paul Glover

Page 88

Petrophysics MSc Course Notes

9.2

Caliper Logs

Log Presentation

The caliper logs are plotted in track 1 with the drilling bit size for comparison, or as a differential

caliper reading, where the reading represents the caliper value minus the drill bit diameter (Fig. 9.2).

The scale is generally given in inches, which is standard for measuring bit sizes.

BIT SIZE (in)

6

BIT SIZE (in)

16 -2

CAL (in)

6

16

Figure 98.2 Presentation of 2 arm caliper log data.

The 4 arm (or dual caliper) tools are presented in a range of formats, an example of which is given in

Fig. 9.3. Note that data from the caliper pairs are shown together, and that they are different indicating

an oval hole. Also the tool rotates in the hole (the pad 1 azimuth P1AZI changes). The hole azimuth is

reasonably constant at HAZI180o, and the dip is almost vertical (DEVI is about 0o).

The ticks represent borehole volume. This information is useful to estimate the amount of drilling mud

in the borehole, and to estimate the amount of cement required to case the hole. There are engineering

approximation formulas to calculate both of these from caliper data.

Dr. Paul Glover

Page 89

Petrophysics MSc Course Notes

Caliper Logs

Figure 9.3 Presentation of 4 arm caliper log data (After Rider, 1996).

9.3

Simple Caliper Interpretation

Figure 9.4 shows a schematic hole with caliper information, and Table 9.1 describes the main

influences on caliper values. Note that when a hole is the same diameter as the bit-size it is called on

gauge.

Dr. Paul Glover

Page 90

Petrophysics MSc Course Notes

Caliper Logs

Table 9.1 Factors influencing caliper responses.

Hole Diameter

Cause

Possible Lithologies

On Gauge

Well consolidated formations

Non-permeable formations.

Larger than Bit

Size

1. Formation soluble in drilling

mud.

2. Formations weak and cave in.

Smaller than Bit

Size

1. Formations swell and flow into

borehole.

2. Development of mudcake for

porous and permeable

formations.

Massive sandstones

Calcareous shales

Igneous rocks

Metamorphic rocks

1. Salt formations drilled with fresh

water.

2. Unconsolidated sands, gravels,

brittle shales.

1. Swelling shales.

9.4

2. Porous, permeable sandstones.

Uses of the Caliper Log

The commoner uses of the caliper log are as follows:

Contributory information for lithological assessment (see Table 9.1 and Fig. 9.4).

Indicator of good permeability and porosity zones (reservoir rock) due to development of mudcake

in association with gamma ray log.

Calculation of mudcake thickness, hmc = (dbit dh)/2, where h stands for the hole, in inches.

Measurement of borehole volume, Vh = (dh2/2)+1.2%, in litres per metre.

Measurement of required cement volume, Vcement = 0.5 (dh2 d2casing) + 1%, in litres per metre.

Indication of hole quality for the assessment of the likely quality of other logs whose data quality

is degraded by holes that are out of gauge. Other log data can often be corrected for bad hole

conditions using the caliper readings, but the larger the correction, the less reliable the final data

will be. Centralized tools are designed to be about 4 inches in diameter for a standard 8.5 inch

hole, and they are designed to work with 2.25 inches of drilling mud between them and the

formation. If the hole caves to 14 inches, which is not uncommon, the distance to the formation

becomes 5 inches and the tool responses are degraded. This can be corrected for to some extent if

the caliper value is known. Tools that work by being pressed up against the side of the borehole

wall have even greater problems because the irregularity of the borehole wall makes it impossible

to obtain reliable readings. In both cases the recognition that a borehole has bad caving or thick

mudcake can help us judge the reliability of other tools readings.

Selection of consolidated formations for wireline pressure tests, recovery of fluid samples, for

packer seating for well testing purposes, and for determining casing setting depths.

Dr. Paul Glover

Page 91

Petrophysics MSc Course Notes

Caliper Logs

BIT SIZE (in)

6

16

CAL (in)

Bit

Size

Brittle Shale

16

6

Bit

Size

Caving

Caving

Impermeable

Sandstone

On

Gauge

Sloughing

Sloughing

Shale

On

Gauge

Tight Spot

Impermeable

Limestone

Permeable

Sandstone

Mud

Cake

Mud Cake

Anhydrite

Marl

Caliper

Curve

Shale

Figure 9.3 Typical caliper responses to various lithologies.

Dr. Paul Glover

Page 92

You might also like

- Ec Trak ManualDocument426 pagesEc Trak ManualAnonymous VVPsrs4Hxy100% (1)

- Magnetic and Fravity ToolfaceDocument17 pagesMagnetic and Fravity Toolfacemadonnite3781100% (1)

- General RTK Survey SpecificationsDocument6 pagesGeneral RTK Survey SpecificationsSajjad MunirNo ratings yet

- Stress and Strain - Axial LoadingDocument18 pagesStress and Strain - Axial LoadingClackfuik12No ratings yet

- Basic Load On The StringDocument7 pagesBasic Load On The Stringabodolkuhaa100% (1)

- PDC Bits - All Comes From The Cutter Rock Interaction PDFDocument9 pagesPDC Bits - All Comes From The Cutter Rock Interaction PDFMejbahul SarkerNo ratings yet

- Pressure Operated Tester Valve POTVDocument1 pagePressure Operated Tester Valve POTVJeff GanglNo ratings yet

- MWD Mechanics: How Is This Data Communicated To The Surface While Drilling Ahead?Document26 pagesMWD Mechanics: How Is This Data Communicated To The Surface While Drilling Ahead?Ali ChouayaNo ratings yet

- 2 - Magnetic Declination & Grid ConvergenceDocument35 pages2 - Magnetic Declination & Grid ConvergenceASIEA WORLDNo ratings yet

- Pinnacle - BD Overview EJD PDFDocument94 pagesPinnacle - BD Overview EJD PDFaliNo ratings yet

- Electrolytic Tiltmeter Basics: Jewell Electrolytic Sensor Technical NoteDocument2 pagesElectrolytic Tiltmeter Basics: Jewell Electrolytic Sensor Technical NoteSamudera Dandi ANo ratings yet

- SS6800 - Line Management System Manual Second RevDocument62 pagesSS6800 - Line Management System Manual Second RevGonza Pf0% (1)

- 9307-32525-1-Pb Paper Factor de FlotacionDocument18 pages9307-32525-1-Pb Paper Factor de FlotacionAlex Jimenez100% (1)

- The Spectral Gamma Ray Log Chapter 12Document10 pagesThe Spectral Gamma Ray Log Chapter 12PedroNietoNo ratings yet

- Geoelectric Strike and Its Application in MagnetotelluricsDocument40 pagesGeoelectric Strike and Its Application in MagnetotelluricsamiruddinNo ratings yet

- Logging While Drilling PDFDocument37 pagesLogging While Drilling PDFArpan BiswasNo ratings yet

- Spe 135704 MS PDFDocument9 pagesSpe 135704 MS PDFKd FaNo ratings yet

- Specific Gravity@ 60 ° FDocument9 pagesSpecific Gravity@ 60 ° FindahNo ratings yet

- SPE6760 - Determining Stressintubing Usingtriaxial EvaluationDocument8 pagesSPE6760 - Determining Stressintubing Usingtriaxial EvaluationYoucef Benferdi100% (1)

- Identifying Critically-Stressed FaultsDocument4 pagesIdentifying Critically-Stressed FaultsSajjad Munir100% (1)

- Well Logging+ CaliperDocument11 pagesWell Logging+ Caliperginozky100% (1)

- Induction LoggingDocument11 pagesInduction LoggingWankah Ac100% (1)

- Depositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12From EverandDepositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12No ratings yet

- Caliper Logs: Instructor: Hamad Ur Rahim Class: DDE Semester: IIIDocument19 pagesCaliper Logs: Instructor: Hamad Ur Rahim Class: DDE Semester: IIINaser KhanNo ratings yet

- Engineering Vol 72 1901-10-18Document31 pagesEngineering Vol 72 1901-10-18ian_newNo ratings yet

- Chapter 5 Formation EvaluationDocument28 pagesChapter 5 Formation EvaluationDeniz AkoumNo ratings yet

- Spe 25872 PaDocument7 pagesSpe 25872 PaPeng TerNo ratings yet

- Racture Pressure: Fracture GradientsDocument13 pagesRacture Pressure: Fracture GradientsPrasanti Plaban DashNo ratings yet

- 1D PetroMod Software Modeling of The Basrah Oil Fields Art-3A10.1007-2Fs12517-012-0640-4Document26 pages1D PetroMod Software Modeling of The Basrah Oil Fields Art-3A10.1007-2Fs12517-012-0640-4Charles PaikiNo ratings yet

- Cement OsDocument28 pagesCement OsLuis Romer Soliz AndiaNo ratings yet

- Arc VISIONDocument4 pagesArc VISIONBASNo ratings yet

- Chap 03-Rotary Percussive Drilling Accessories PDFDocument12 pagesChap 03-Rotary Percussive Drilling Accessories PDFpnakurNo ratings yet

- 53 222 PDFDocument29 pages53 222 PDFAhmed GalalNo ratings yet

- Weight-Material: Dynamic Sag Test VSST MethodDocument3 pagesWeight-Material: Dynamic Sag Test VSST MethodLMP2 Mud EngineerNo ratings yet

- Surface BOP Stack Operations BL 0.0981 - Deviated Well Kill SheetDocument3 pagesSurface BOP Stack Operations BL 0.0981 - Deviated Well Kill SheetbodiemcdNo ratings yet

- Hole Opener PDC Series BorchureDocument2 pagesHole Opener PDC Series BorchureHassan GaferNo ratings yet

- Slim Hole Drilling TechnologyDocument11 pagesSlim Hole Drilling TechnologyMuhammad MohtashimNo ratings yet

- Logiq Compensated Spectral Natural Gamma Ray (CSNG™) ToolDocument2 pagesLogiq Compensated Spectral Natural Gamma Ray (CSNG™) ToolChesy MeifaniNo ratings yet

- Presentation 1Document28 pagesPresentation 1Muhammad RaiesNo ratings yet

- 11 - Compass For DD - Data Structure Exercise - 061005Document7 pages11 - Compass For DD - Data Structure Exercise - 061005ebrahimNo ratings yet

- Pore Pressure Indicators - ADocument7 pagesPore Pressure Indicators - ADamaso Miguel Garcia CarvajalNo ratings yet

- Lecture 09 Prelimenary Itroduction To Well Logging (Compatibility Mode)Document26 pagesLecture 09 Prelimenary Itroduction To Well Logging (Compatibility Mode)Nadeem UsmaniNo ratings yet

- 00087167Document11 pages00087167JohnSmith100% (1)

- Lithology Identification of AquifersDocument13 pagesLithology Identification of AquifersSukawan Zaky100% (1)

- Central Myanmar Basin, Potential of Conventional and Unconventional Resources (Oil & Gas) Asia Oil & Gas Award, Bangkok (2013)Document51 pagesCentral Myanmar Basin, Potential of Conventional and Unconventional Resources (Oil & Gas) Asia Oil & Gas Award, Bangkok (2013)Sai Naing Lin aung100% (1)

- Catalogue 2018: Magnetic Thickness Detector (MTD)Document2 pagesCatalogue 2018: Magnetic Thickness Detector (MTD)wesam tetouhaNo ratings yet

- Openhole Crossplot Concepts - A Powerful Technique in Well Log AnalysisDocument15 pagesOpenhole Crossplot Concepts - A Powerful Technique in Well Log Analysisc_b_umashankarNo ratings yet

- WT AssignmentDocument27 pagesWT Assignmentabdilrhman sulimanNo ratings yet

- Case Study of Core and Pluge PreparationDocument9 pagesCase Study of Core and Pluge PreparationSpeculeNo ratings yet

- Part 7 - Wellbore Storage EffectsDocument5 pagesPart 7 - Wellbore Storage EffectsChai CwsNo ratings yet

- Datalog Introduction MudloggingDocument2 pagesDatalog Introduction MudloggingWaqas Arif100% (1)

- Well Completion and Its TypesDocument14 pagesWell Completion and Its TypesJagdish annayaNo ratings yet

- Sigma Log ProjectDocument23 pagesSigma Log ProjectUsama Bin Sabir100% (1)

- Blowout: PreventionDocument25 pagesBlowout: PreventionlcremaschiNo ratings yet

- Lab Experiment 1 Repaired)Document15 pagesLab Experiment 1 Repaired)Amirul Hakim100% (3)

- Drilling OptimizationDocument14 pagesDrilling Optimizationcontactsameer541No ratings yet

- Lab 3 Porosity Determination Using Helium Porosimeter MethodDocument6 pagesLab 3 Porosity Determination Using Helium Porosimeter MethodRichard OwusuNo ratings yet

- Strategies for Optimizing Petroleum Exploration:: Evaluate Initial Potential and Forecast ReservesFrom EverandStrategies for Optimizing Petroleum Exploration:: Evaluate Initial Potential and Forecast ReservesNo ratings yet

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Petrophysics MSC Course Notes Caliper LogsDocument5 pagesPetrophysics MSC Course Notes Caliper LogsAhmadLukmanNurKarimNo ratings yet

- Caliper Log: Department of Petroleum EngineeringDocument7 pagesCaliper Log: Department of Petroleum EngineeringnoormarkNo ratings yet

- 3..caliper LogggingDocument23 pages3..caliper LogggingSagar DadhichNo ratings yet

- Wetlands of Hindu Kush Himalayas - Ecosystem Functions, ServicesDocument9 pagesWetlands of Hindu Kush Himalayas - Ecosystem Functions, ServicesSajjad MunirNo ratings yet

- About FDU LeakageDocument3 pagesAbout FDU LeakageSajjad MunirNo ratings yet

- Field Report AbbotabadDocument6 pagesField Report AbbotabadSajjad MunirNo ratings yet

- The Swan Hills Formation at Kaybob South Field, Alberta : An Example of Remaining Reserves Potential Within Mature FieldsDocument5 pagesThe Swan Hills Formation at Kaybob South Field, Alberta : An Example of Remaining Reserves Potential Within Mature FieldsSajjad MunirNo ratings yet