Professional Documents

Culture Documents

Dry Process Kiln

Dry Process Kiln

Uploaded by

breakthrough1988Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dry Process Kiln

Dry Process Kiln

Uploaded by

breakthrough1988Copyright:

Available Formats

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 1

Dry process kiln systems

Highly reliable

Low emission levels

Efficient energy utilization

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 2

KILN SYSTEMS

Main features

Highly reliable

systems for any

production level

A wide range of

calciner systems to

suit specific requirements

Highly efficient low

pressure cyclones

Effective emission

control technology

Optimized fuel and

power consumption

Suitable for waste

fuels

Compact, space-saving

preheater designs

Matching state-ofthe-art technologies

for clinkerization,

cooling and firing:

ROTAX-2 two-support

kiln, SF Cross-Bar

clinker cooler and

Duoflex kiln burner

Dry process kiln systems

F.L.Smidth offers a range of six standard

dry-process kiln systems, each with its

unique advantages depending upon the

particular application. In this way we are

able to provide the industry with the most

suitable kiln system configuration for any

given set of conditions and requirements.

F.L.Smidth has supplied over 2500 rotary

kiln systems and more than 3500 clinker

coolers. This experience, coupled with the

latest advances in pyroprocessing system

design, makes our technology the logical

choice for both new installations and modernisation of existing cement making facilities.

In modern cement plants, raw meal is preheated to calcination temperature in a multi-stage cyclone preheater and most of the

calcination process takes place in a separately fired calciner. The remaining calcination

and clinkerization process takes place in a

short length-to-diameter rotary kiln without

internals.

Preference is commonly given to the cooling

of clinker in the SF Cross-Bar cooler in

which the two main functions, conveying

and cooling of clinker, are completely separated. The introduction of stationary air distribution plates with self-regulating

mechanical flow regulators (MFR) has revolutionized cooler operation.

This brochure describes each of the six preheater/calciner system configurations in

detail and presents general guidelines for

their selection depending upon capacity

requirements and whether the system is

new or an upgrade of an existing installation. System components other than

cyclones and calciners are dealt with in separate brochures that describe their mechanical

and operational features.

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 3

Six standard Dry-process kiln system

configurations

SP: Suspension Preheater kiln

ILC-E: In-Line Calciner using Excess air

ILC: In-Line Calciner

SLC-D: Separate Line Calciner Downdraft

SLC: Separate Line Calciner

SLC-I: Separate Line Calciner with In-line Calciner

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 4

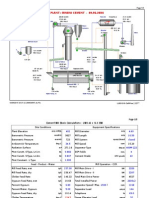

SP: Suspension Preheater kiln

Special advantages

Features

For small capacities

the economical solution.

Very low specific power consumption

with planetary cooler.

Simple operation

well suited for manual control.

Accepts higher input of chlorides than

precalcining systems with tertiary air duct

(without bypass).

Normal capacity range: 700-4500 tpd.

Ratio of firing in riser duct: 0-15%.

Bypass of kiln gas: 0-30%.

Planetary cooler can be employed.

material

-350mm WG

gas

282 C

fuel

1. Raw meal feed

2. Exhaust gas

454 C

3. Kiln gas by-pass, if any

4. Clinker

5. Kiln burner

608 C

6. Riser duct firing, if any

7. Cooler excess air

734 C

820 C

5-stage SP kiln system

and SF Cross-Bar

cooler

Typical temperatures in

the system are indicated

together with the negative pressure in the

exhaust gas exit based

on a system designed

for minimum overall

pressure drop. This type

of kiln system can be

converted to the SLC

precalcining system by

adding an extra calcining string. If no future

capacity increase is to

be considered, a planetary cooler may be

considered.

280 C

100 C

4

Dry process kiln systems

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 5

ILC-E: In-Line Calciner using Excess air

Special advantages

Features

Most economical solution for small and

medium capacities.

Low specific power consumption with

planetary cooler.

Easy operation due to high excess air

percentage in kiln.

Low coating tendency in kiln inlet

and riser duct.

Long kiln lining life due to stable kiln

coating.

Less sensitive to chlorides and sulphur

than precalcining systems with tertiary air

duct (without bypass).

Smaller kiln dimensions than SP system.

-395mm WG

material

269 C

gas

Normal capacity range: 800-5500 tpd.

Ratio of firing in calciner: 10-25%.

Bypass of kiln gas: 0-25%.

Calcination at kiln inlet: 50-70% (compared to 30-40% for SP operation).

Planetary cooler can be employed.

fuel

1. Raw meal feed

437 C

2. Exhaust gas

3. Kiln gas by-pass, if any

4. Clinker

5. Kiln burner

594 C

6. Calciner burners

7. Cooler excess air

727 C

ILC-E kiln system with

five-stage preheater

and SF Cross-Bar

cooler

Typical temperatures in

the system are indicated, together with the

negative pressure in the

exhaust gas exit, based

on a system designed

for minimum overall

pressure drop. If no

future capacity increase

is to be considered, a

planetary cooler may

be considered.

840 C

280 C

100 C

Dry process kiln systems

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 6

ILC: In-Line Calciner

Special advantages

Features

High material and gas retention time in

calciner due to its large volume and

moderate swirl.

Regulation range of up to 30% bypass

of kiln gas using ILC-I version.

Well suited for low-grade fuels.

Long refractory life due to low thermal

kiln load and stable kiln coating.

Lowest NOx emission among traditional

calciner kiln systems.

Normal capacity range: 1500-6000 tpd,

with multiple strings > 10,000 tpd.

Ratio of firing in calciner: 55-65%.

Normal bypass of kiln gas: 0-60%.

Maximum bypass of kiln gas:

0-100% using ILC-I version.

Built-in low-NOx capabilities.

Calcination at kiln inlet: 90-95%.

-465mm WG

material

293 C

gas

fuel

1. Raw meal feed

478 C

2. Exhaust gas

3. Kiln gas by-pass, if any

4. Clinker

650 C

5. Kiln burner

6. Calciner burners

7. Tertiary air duct

799 C

8. Tertiary air duct damper

9. Cooler excess air

890 C

ILC kiln system with

five-stage preheater and

SF Cross-Bar cooler

Typical temperatures in the

system are indicated,

together with the negative

pressure in the exhaust gas

exit, based on a system

designed for minimum overall pressure drop. When

designed for bypassing 30%

or more of the kiln gases,

the layout of the system will

be slightly different, as the

tertiary air duct is connected

to the kiln riser duct at a

point below the calciner.

This system is called the

ILC-I calciner system.

(See page 13)

1000 C

280 C

Dry process kiln systems

100 C

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 7

SLC-D:

Separate Line Calciner Downdraft

Special advantages

Features

High material and gas retention times in

the calciner/ combustion chamber whose

dimensions are minimal since the kiln

gases do not pass through it.

Very well suited for all fuel types, especially low-volatile fuels, as the combustion

in the calciner takes place in hot atmospheric air and the combustion temperature in the calciner can be controlled

independently of the temperature of the

calcined material fed to the kiln.

Low NOx operation is possible.

Smallest possible tower dimensions, as

the calciner can be installed separately

from the cyclone tower.

Especially well suited for retrofits of

existing SP or ILC preheaters due to

very short down time.

Normal capacity range: 1500-6000 tpd,

with multiple strings > 10,000 tpd.

Firing in calciner: 55-60%.

Bypass of kiln gas: 0-60%.

Maximum bypass regulation range: 30%.

Calcination at kiln inlet: 90-95%.

-475mm WG

material

300 C

gas

fuel

1. Raw meal feed

487 C

2. Exhaust gas

3. Kiln gas by-pass, if any

4. Clinker

657 C

5. Kiln burner

6. Calciner burners

7. Tertiary air duct

803 C

8. Tertiary air duct damper

9. Cooler excess air

10.Raw meal dividing gate

890 C

8861100 C

SLC-D kiln system with

five-stage preheater and

SF Cross-Bar cooler

Typical temperatures in the

system are indicated,

together with the negative

pressure in the exhaust gas

exit, based on a system

designed for minimum

overall pressure drop. For

production capacities

exceeding approximately

6000 tpd, the system is

equipped with two or more

preheater strings, this also

being the case if a particularly low preheater tower is

required.

11.Slide damper

1000 C

280 C

100 C

Dry process kiln systems

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 8

SLC: Separate Line Calciner

Special advantages

High material and gas retention times in the

calciner whose dimensions are minimal

since the kiln gases do not pass through it.

Very well suited for all fuel types, even

low-volatile fuels, as the combustion in

the calciner takes place in hot atmospheric

air, and (as an option) the combustion

temperature in the calciner can be controlled independently of the temperature

of the calcined material fed to the kiln.

Long refractory life due to low thermal

kiln load and stable kiln coating.

Independent and accurate draft control

for kiln and calciner strings by adjusting

speed of individual fans.

No damper in tertiary air duct.

Production down to 40% of capacity

using kiln string only.

-445mm WG

material

294 C

gas

-350mm WG

Production down to 20% of capacity for

three-string version.

Features

Normal capacity range:

3000-7500 tpd (one C-string),

7500-12,000 tpd (two C-strings)

Firing in calciner: 55-60%.

Bypass of kiln gas: 0-100%

Maximum bypass regulation range: 30%.

Calcination at kiln inlet: 90-95%.

fuel

293 C

1. Raw meal feed

484 C

469 C

2. Exhaust gas

3. Kiln gas by-pass, if any

4. Clinker

5. Kiln burner

664 C

623 C

6. Calciner burners

822 C

7. Tertiary air duct

8. Cooler excess air

750 C

9. Raw meal dividing gate

842 C

890 C

10.Raw meal change-over gate

SLC kiln system with SF

Cross-Bar cooler and fivestage preheater in the kiln

and the calciner strings

Typical temperatures in the

system are indicated, together

with the negative pressure

in the exhaust gas exits,

based on a system designed

for minimum overall pressure

drop. The system offers the

possibility of controlling the

temperature level inside the

calciner, as part of the raw

meal from the second-lowest cyclone stage in the calciner string can be fed

directly to the kiln riser and/

or the upper portion of the

calciner vessel.

1000 C

280 C

100 C

Dry process kiln systems

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 9

SLC-I: Separate Line Calciner

with In-line Calciner

Special advantages

Features

Very well suited for all fuel types, even

low-volatile fuels, as the combustion in

the SLC calciner takes place in hot atmospheric air, and (as an option) the combustion temperature in the SLC calciner can

be controlled independently of the temperature of the calcined material fed to

the kiln.

Independent and accurate draft control

for kiln and calciner strings by adjusting

speed of individual fans.

Production up to 50% of capacity using

kiln string only (ILC or ILC-E).

Same cyclone sizes and feed systems for

both strings.

Normal capacity range: 6500-11,000 tpd.

Firing in kiln string ILC: 10-15%.

Firing in calciner string SLC: 40-50%.

Bypass of kiln gas: 0-30%.

Calcination at kiln inlet: 90-95%

material

SLC-I kiln system with SF

Cross-Bar cooler and fivestage preheaters in both

the kiln and calciner strings

Typical temperatures are

indicated, together with the

negative pressure in the

exhaust gas exits, based on

a system designed for minimum overall pressure drop.

The system has the added

advantages of having equal

cyclone sizes in both strings,

as well as increased capacity

and improved fuel consumption when only the kiln string

is in operation.

-445mm WG

304 C

gas

-445mm WG

fuel

305 C

1. Raw meal feed

483 C

486 C

2. Exhaust gas

3. Kiln gas by-pass, if any

4. Clinker

655 C

5. Kiln burner

643 C

6. Calciner burners

7. Tertiary air duct

830 C

8. Cooler excess air

774 C

9. Raw meal dividing gate

850 C

10.Raw meal change-over gate

890 C

1000 C

280 C

100 C

Dry process kiln systems

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 10

Type selection guidelines

TPD Production

Three-support kiln

Three string

Two string

One string

12000

6.00 x 95

11000

5.75 x 91

10000

5.50 x 87

9000

5.25 x 82

8000

5.00 x 78

Selecting the proper kiln system configuration

for a given project is a complicated task that

involves a number of considerations. During

the initial planning stage it will often be

useful to consult F.L.Smidth who has gained

a wealth of experience from a large variety

of cement projects. As a general guide to

choosing the most suitable new kiln system,

a number of criteria should be considered,

the most important of which are as follows:

4.75 x 74

7000

4.55 x 71

6000

4.35 x 67

5000

4.15 x 64

4000

3.95 x 60

3000

3.75 x 57

Production capacity

and investment costs

For any given production capacity, a precalcining system requires considerably smaller

rotary kiln dimensions than a simple suspension preheater system.

3.60 x 54

2000

3.30 x 49

1000

0

SP

ILC-E

ILC

SLC

SLC-I

SLC-D

Table 1a

F.L.Smidth normally recommends a rotary

kiln diameter not exceeding 6 metres to

ensure reasonably long lining life. For this

reason, it is advisable to employ a precalcining system (with tertiary air duct) for kiln

productions above 4000 tpd.

Table 1b

TPD Production

ROTAX 2 kiln, L/D~13

Two string

One string

10000

6.00 x 72

9000

5.75 x 69

5.50 x 66

8000

5.25 x 62

7000

5.00 x 60

6000

4.55 x 54

4.75 x 56

5000

4.35 x 51

4000

4.15 x 49

3.95 x 46

3000

3.75 x 44

3.60 x 42

2000

3.45 x 40

1000

0

SP

10

On the other hand, the simplicity of the

ILC-E kiln system equipped with a planetary

cooler makes it the most economical solution

for production capacities up to about 4500

tpd. Of course, the lowest-possible heat

consumption and clinker temperature are

attained by replacing the planetary cooler

with a modern SF Cross-Bar cooler. For this

reason, the grate cooler is the logical choice

for most new kiln installations particularly

when taking future expansion into account.

ILC-E

ILC

Dry process kiln systems

SLC

SLC-I

SLC-D

Single-string preheaters are preferred as

long as the cyclone diameter remains within

reasonable limits. This allows the SP and

ILC-E systems to be used as single strings

up to a production capacity of 4000-4500

tpd. Similarly, the ILC and SLC-D systems

can be used as single strings up to about

6000 tpd. In contrast, the SLC and SLC-I

1349_M_FLS_DryProcessKiln 28/11/02 11:51 Side 11

systems always have at least two

preheater strings and, therefore, will

normally only be considered for

capacities above 5000 tpd.

tion of these fuels. Special fuels,

however, require special considerations when selecting the appropriate

kiln system configuration:

Tables 1a and 1b show the six different

preheater/ precalciner configurations

as a function of production capacity

along with standard kiln sizes. The SP

kiln system is also shown for comparison, although this would not normally

be a preferred solution for a new

installation.

Low-volatile fuels

Operation and maintenance

These days, precalciner systems are

generally preferred to SP-type kiln

systems due to the fixed degree of

calcination of the material entering

the kiln and the shorter material

retention time in the system. Longer

lining life and lower kiln refractory

weight enable precalcining kiln systems to remain in operation for

longer periods than SP kilns, thus

reducing down time and refractory

costs.

Generally, the maintenance costs of

a single-string kiln system are lower

than those of a double-string kiln

system. Consequently, a singlestring preheater is always preferable

to a double-string preheater for

small-to-medium production capacities, provided there are no tower

height limitations.

Fuel types and grades

All F.L.Smidth kiln systems can be

fired with natural gas, heavy fuel oil,

standard coal grades or a combina-

Fuels such as anthracite, petroleum

coke, and other low-reactive fuels

pose no problem in the kiln which

operates at a high temperature. The

kiln burner, however, should be of

the modern flame-shaping type,

such as the DUOFLEX, which has a

suitable flow pattern that ensures

rapid and stable ignition.

The use of low-volatile fuels in calciners (that usually operate at a temperature around 900C) can cause problems unless the system is provided

with a high-temperature calciner. All

our calciner systems are suited for

the use of low-volatile fuels as they

are designed to allow raising the temperature in the combustion chamber

without affecting the rest of the system. This is accomplished by means of

a dividing gate that leads a relatively

large amount of raw meal to the calciner and/or the kiln riser duct.

Low-calorific fuels

Fuels with high ash content rarely

cause problems in the calciner

because the ash is intimately mixed

into the raw meal as a consequence

of the turbulence and high material

retention time. However, the use of

such fuels for kiln firing can cause

problems such as (1) the inability to

reach sufficiently high flame temperature, and (2) the non-homogeneous mixing of ash into the kiln

charge which is already nodulised

DUOFLEX Kiln burner.

and partially fused. For this reason,

a precalcining system is always preferred when using low-grade coals

because the total input ash content

to the kiln burning zone is greatly

reduced. Each type of fuel should

be considered separately. Typically,

the lower limit for net heating value

can be 3800 kcal/kg for the calciner

and 4000 kcal/kg for the kiln.

Alternative fuels

Combustible waste products can be

used in all kiln systems as a substitute for fossil fuels, provided that

such substitution does not result in

negative consequences for the kiln

system operation.

Each type of waste product must

therefore be assessed on an

individual basis, by evaluation of the

impact on clinker quality, production

capacity, kiln system stability and

emissions. Also health and safety

issues must be taken into consideration.

For many solid waste products, the

physical size may be a challenge. For

slow-reacting waste products the

SLC-D system might be suitable,

due to the possibility of high-temperature calciner operation.

However, high temperature operation can also be introduced in the

SLC type of calciners.

Some solid waste products must

always be pretreated before feeding to the kiln or calciner. The

traditional method is to operate

costly shredding and grinding systems, but for the ILC system a HOTDISC reactor may be used instead.

This is a combustion chamber integrated with the calciner, allowing

for direct firing of lumpy waste

products at high substitution rates.

Dry process kiln systems

11

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 12

Type selection guidelines

Heat efficiency

Table 2: Heat consumption, pressure drop & power consumption ( no kiln bypass )

Heat balance in (kcal/kg clinker)

SLC-kiln 5000 t/d

ILC kiln 3000 t/d

(SF Cooler)

(SF Cooler)

5-stage

6-stage

5-stage

6-stage

153

132

149

130

+ radiation loss from preheater

34

39

31

35

+ radiation loss from kiln

19

19

23

23

+ heat of reaction

405

405

405

405

107

109

113

115

+ heat of clinker at amb. temp.

- heat in raw meal, air and fuel

30

30

30

30

- combustibles in raw meal

688

674

691

678

K-C

K-C

Exhaust gas temperature (C)

294

256

293

258

Pressure loss preheater (mmWG)

305

360

305

360

Pressure loss in the rest of the system

45-140

45-140

160

160

Total pressure loss (mmWG)

350-445

405-500

465

520

ID fan(s)

5,0

5,4

5,3

5,7

Cooler (drive + fans+ crusher)

5,5

5,5

5,5

5,5

Kiln drive

2,1

2,1

2,1

2,1

Primary air fan

1,0

1,0

1,0

1,0

Heat in exhaust gas and dust

+ free water

+ VDZ cooler loss

= Net specific heat consumption

Power consumption (kWh/t clinker)

Cooler vent system

1,4

2,2

1,7

1,1

Total specific power consumption

15,0

16,2

15,6

15,4

(1)

(2)

(2)

(1)

Table 2: Typical process values of SLC and ILC kilns

with five and six-stage preheaters.

(1) Includes electrostatic precipitator, vent fan and

dust conveying system.

(2) Includes fabric filter, heat exchanger, vent fan

and dust conveying system.

The specific heat consumption of the various kiln systems depends mainly on the size

of the kiln, the number of preheater stages,

the rate of kiln bypass (if any), the raw mix

composition, and the fuel type.

Table 2 shows typical heat balances for fivestage and six-stage SLC and ILC kiln systems.

As shown, the specific heat consumption of

the six-stage preheater system is 10 kcal/kg

clinker lower than that of the equivalent

five-stage system. By comparison, the specific

heat consumption of the five-stage preheater

system is 20-25 kcal/kg clinker lower than

that of the equivalent four-stage system.

Pressure drop and

power consumption

The most power-consuming parts of a kiln

system are the Induced Draft gas fan

motor(s), the cooler fan motors and the kiln

drive motor.

The power consumption of the ID gas fan(s)

mainly depends on the total pressure drop in

the kiln system. Most of this pressure drop

occurs in the preheater. Increasing the preheater cyclone dimensions will reduce the

pressure drop, but for any given preheater

geometry stable preheater operation (without raw meal falling through the riser ducts)

requires a certain minimum pressure drop.

The Low Pressure (LP) cyclone, a standard

component in all FLS kiln systems, was developed to ensure a low pressure drop in the

preheater while maintaining high efficiency

and reasonably small cyclone dimensions.

The table compares the specific power consumption of an SLC and an ILC kiln system,

both equipped with LP cyclone preheaters.

12

Dry process kiln systems

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 13

It also shows a comparison between the two

modern types of cooler venting systems

(electrostatic precipitator versus fabric filter

and heat exchanger).

volatile concentration in the gases of a precalcining system which is caused by the

lower specific gas flow through the kiln, see

table 3.

For many years, costs have favoured the use

of electrostatic precipitators (EP) for this purpose because of the higher running costs of

fabric filters (FF) in terms of power consumption and maintenance (bag replacement).

However, with the tightening of emission

standards, FF will tend to be preferred for

cooler venting installations, because the EP

size increases proportionately with tighter

emission standards, while the FF size remains

constant.

If the volatile components in the raw mix

(and fuel) are higher than these upper limits,

the kiln system must be equipped with a

bypass that enables extracting some of the

kiln gas from the system before it reaches

the preheater. In this way, internal circulation of volatile components is reduced.

Bypassing a few per cent of the kiln gases is

sufficient to reduce the internal circulation

of chloride in the kiln system to an acceptable level.

Raw materials

To produce low-alkali cement it may also be

desirable to remove large quantities of alkalis

through a kiln bypass. This requires a high

bypass rate, and a precalcining system with

tertiary air duct will be appropriate. For a

given amount of kiln gas extracted, higher

alkali reduction is obtained in a precalcining

system than in a SP kiln system. A certain

reduction of alkali in the clinker can be

attained by the lowest-possible increase in

the specific fuel consumption.

The content of volatile components in the

raw materials is an important factor when

choosing the appropriate kiln system.

Volatile components in connection with kiln

operation are usually understood as minerals

containing the elements potassium (K),

sodium (Na), sulphur (S), and chloride (Cl).

Small quantities of these components will

inevitably enter the kiln system with the raw

mix and the fuel. On reaching the kiln burning zone, some of the volatile components

evaporate and are carried with the kiln gas

to the preheater where they condense.

The resulting internal circulation of volatile

matter in the kiln system and the concentration of these components in the kiln gases

flowing to the preheater eventually reaches

such levels that it affects kiln operation. The

higher concentration of volatile matter

increases dust stickiness which in turn causes

coating formation and cyclone blockages.

The type of process selected sets an upper

limit to the acceptable content of the various

volatile components in the raw mix (and the

fuel) used in a preheater kiln system without

a bypass. The upper limit is lower with a precalcining system (with tertiary air duct) than

with an SP kiln system due to the higher

Maximum by-pass version ILC-I

The ILC-I and SLC kiln systems allow bypassing up to 100% of the kiln gas while the

other kiln systems can be equipped with a

bypass carrying a maximum 25-60% of the

kiln gas, which in most cases will suffice to

ensure smooth operation, even with lowgrade raw materials.

Table 3: The normal limit applies to

a raw mix of good burnability and

an ideal sulphur/alkali ratio

Table 3: Allowable total input of volatile components for kiln systems

without bypass on LOI free basis.

Normal limit

ILC, SLC & SLC-I

Chlorine as CI

Sulphur as S-total

0.023%

1.25%

SP & ILC-E

Chlorine as CI

0.029%

Sulphur as S-total

1.5%

Dry process kiln systems

13

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 14

Cyclone preheater

All six kiln systems are supplied with a fourstage, five-stage, or six-stage cyclone preheater equipped with Low Pressure (LP)

cyclones.

The unique design of the LP cyclone ensures

high thermal efficiency and low pressure drop

while enabling moderate preheater tower

dimensions.

The segmented central

pipe (thimble).

A four-stage preheater can be designed for

a pressure drop down to 250 mm WG across

the preheater itself, while a five-stage preheater can be designed for a pressure drop

down to 305 mm WG at nominal capacity.

Even with these low nominal pressure drops,

the preheaters operate smoothly down to

70-80% of rated capacity without increasing

the percentage of excess air.

Since the LP cyclones have no horizontal

surfaces on the inside, no material will accu-

14

Dry process kiln systems

mulate and this, in turn, ensures smooth

operation.

The lowermost cyclone (exposed to gas

temperatures of about 900C) is equipped

with a cast, segmented central pipe (thimble)

of special alloy which maximizes thermal

efficiency while ensuring long life.

The central pipe is easy to install and, because

it consists of segments, will fit any size of

cyclone both in new and existing preheaters.

To prevent the gas from bypassing up through

the material chutes between the individual

cyclone stages, the chutes are equipped

with tipping valves. Distribution boxes with

adjustable spreader plates ensure correct

material distribution in the individual riser

ducts. Change-over gates and dividing gates

are used to efficiently distribute the raw meal.

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 15

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 16

In the following pages, the three

basic types of calciners (In-Line,

Separate-Line, and Downdraft

calciners) offered by F.L.Smidth

are discussed in detail.

Low NOx Calciners

All F.L.Smidth calciners are

specifically designed to meet

today's most stringent emissions

limits by minimizing NOx and

CO emissions among other pollutants. This is best accomplished

through the use of a cylindrically-shaped vessel with a conical

bottom. The cylindrical design

ensures ample internal volume

while minimizing calciner weight

and surface heat loss.

All F.L.Smidth low NOx calciners

are designed for (1) localized

reducing conditions and/or (2)

high temperature zone both of

which are proven to significantly minimize NOx emissions. The

elevated temperature designs

are also particularly suited for

the use of low volatile fuels.

In fact, many F.L.Smidth calciner

designs are specifically tailored

for today's demands for the firing of low-reactive and hard-toburn fuels. All calciners can be

fired with liquid, gaseous or

pulverized fuels. The calciner

burners are placed so that the

fuel is evenly distributed across

the calciner cross section

enabling it to ignite rapidly in

the presence of tertiary air.

The downdraft calciner, for

example, is equipped with a

vertical burner that makes it

particularly well suited for low

volatile fuels.

All F.L.Smidth calciners (and

preheaters) are lined with

wear-resistant refractory bricks

on all cylindrical and conical

surfaces. The irregularly shaped

areas are lined with castable.

The wear-resistant lining is fitted

on a back lining of insulated

blocks, which ensures a very

low heat loss from the calciner

and/or preheater surface.

16

ILC Calciner

In-Line Calciners:

In-Line calciners are generally known to

generate lower NOx emissions than SeparateLine calciners since all of the kiln exhaust

gases must pass through the calciner.

F.L.Smidth's patented Low NOx ILC design is

based on dividing the meal from the second

lowest preheater cyclone to (1) the kiln riser

and (2) the calciner, which are separated by

an expanded riser duct that forms a reducing

NOx zone. That is, the calcining chamber is

built (at least partially) into the kiln riser. In

this way, a very simple means of creating low

NOx emissions without splitting of tertiary air

is attained. 100% of the fuel is fired to the

kiln riser duct. As a result, it is possible to

obtain both reducing conditions and high

Dry process kiln systems

temperature zone in one simple system (without multiple firing points) for the lowest

possible NOx emissions. The combustion air

is drawn either through the kiln or through a

separate tertiary air duct. Because the kiln

combustion gases are drawn through the

calciner, the calciner size is necessarily larger

to attain the required gas velocity and

retention time. Following the reduction

zone, the calciners cylindrical section is

sequentially tapered. The resultant rapid

changes in cross-sectional areas create

strong vortexes ensuring effective mixing of

fuel, raw meal, and gas. The top of the calciner is most often provided with a loop duct

to ensure optimum gas retention time, mixing and complete combustion of the fuel.

In the ILC-E configuration, kiln exhaust gas

enters the calciner axially through the bottom

cone and the calciner exhaust gas leaves the

calciner through a side outlet at the top. In

the ILC configuration, kiln exhaust gas enters

the calciner axially through the bottom cone

and leaves through an outlet connected to

a central outlet pipe. The mixing of the fuel,

raw meal and gas is further enhanced by

the tertiary air duct being fitted tangentially

on the calciner. This causes a moderate swirl

in the calciner which further increases particle retention time. When designed for

bypassing 60% or more of the kiln gases,

the tertiary air duct is connected to the kiln

riser (in an ILC-I configuration page 13)

rather than tangentially connected to the

calciner.

Separate-Line Calciners

Separate-line calciners are also known as

air-only calciners since the calcining

chamber is at least partially offset from the

kiln riser. The combustion air is always

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 17

drawn through a separate tertiary air duct.

Because the kiln combustion gases do not

pass through the calciner, the calciner size

can be reduced to attain the required gas

velocity and retention time. This often

results in a shorter preheater structure (and

a shorter erection period for retrofits) since

the calciner can be readily situated outside

of the preheater structure.

In the SLC configuration, the hot tertiary air

from the cooler enters the calciner through

the central inlet in the bottom cone and

leaves through either a side outlet or (in

case high temperature operation is planned)

through an outlet cone connected to a central outlet pipe.

In the SLC-I configuration, a SLC calciner

is built parallel to the kiln riser duct as

described above and a second ILC calciner

is built into the kiln riser duct. This design

effectively destroys thermal NOx generated

in the burning zone of the kiln. Fuel NOx

generated in the calciner is effectively minimized through high temperature operation.

A unique feature of the high temperature

calciner system is the fact that the temperature inside the calciner is independently

controlled by the position of the gate that

divides the raw meal flow to the calciner

and to the kiln riser duct, respectively.

So, by feeding a relatively larger amount of

raw meal to the kiln riser duct and keeping

the fuel input to the calciner constant, the

mean temperature in the calciner vessel can

be brought up to 9500 10500C. The temperature of the exit gas and the degree of

calcination of the raw meal leaving the calciner will increase accordingly. However, when

mixing with the kiln exhaust gas that contains

uncalcined raw meal, the temperature of the

gas/particle suspension falls to approximately

900oC. So a normal temperature level is

maintained in the calciner cyclone. Similarly,

a normal degree of calcination of 90-95%

is maintained for the raw meal supplied to

the kiln.

The higher temperature in the calciner

ensures effective combustion of even lowreactive fuels and helps to greatly minimize

fuel NOx formation.

The calciners of the SLC and SLC-I systems

are characterized by a vortex formation in

the bottom cone, ensuring effective mixing

of raw meal, fuel and tertiary air for a high

particle-to-gas retention time ratio.

SLC Calciner

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 18

Low NOx Calciners

multi-channel vertical burner located in the

roof of the DDC under high temperature

conditions to minimize fuel NOx. In the

SLC-D configuration, raw meal entrained in

hot tertiary air enters the DDC at the top

through a 180 degree involute (similar to an

LP cyclone) and exits through a truncated

cone which forms a circular duct transition

to the kiln riser duct. The 180 degree involute ensures that the majority of the calcined

meal is detained along the walls of the DDC.

This effectively protects the refractory lining

while promoting hot core conditions for

optimum combustion characteristics in the

centre of the calciner.

Downdraft Calciners

The downdraft calciner is specifically tailored

to low-reactive fuels since the combustion

air for the downdraft calciner (DDC) is

drawn solely from the clinker cooler. The

separate-line features of this calciner design

minimize the height of the preheater structure since a substantial portion of the total

retention time is located parallel to the kiln

riser duct. The placement of the combustion chamber outside the preheater structure makes this calciner design well suited

for retrofits since down time is minimized.

The SLC-D configuration combines the

advantages of the well-known Separate-line

calciners with the low NOx features of the

In-line calciner when a portion of the calciner

fuel is directed to the kiln riser duct. This

effectively destroys thermal NOx formed in

the kiln. Most of the fuel is introduced via a

18

Dry process kiln systems

For the same production capacity, the calciner

of the SLC-D system has smaller dimensions

than the ILC calciner since no kiln exhaust

air is led through the calciner. This makes

the SLC-D system well suited for retrofit

applications even when low reactive fuels

are not planned.

SLC-D Calciner

1349_M_FLS_DryProcessKiln 28/11/02 9:16 Side 19

State-of-the-art systems

State-of-the-art systems

Designing equipment and systems for the

manufacture of cement has always been a

challenging task due to the variations in raw

materials, the multitude of cement products

required for the marketplace, and the need

to minimize investment costs. In addition,

integrating high-efficiency concepts with

the requirement for reliability has tended to

inhibit the development of new machinery

and systems. However, widespread acceptance of preheater and precalciner systems

has created the opportunity to evolve to the

present high level of efficiency and reliability.

Table 4 clearly reflects the trend towards

large single production lines and previously

unheard-of low levels of fuel consumption

for the modern dry processes.

In the case of F.L.Smidth, the evolution of

our designs has been driven by the continuing

performance evaluation of existing systems,

coupled with feedback which has identified

the obstacles to achieving optimum performance of every system component. This has

been particularly true for kiln system upgrades and modernisation projects. It is commonplace for F.L.Smidth to audit the performance of kiln systems before and after

modification. In the process of establishing

the potential modification scenarios, each

preheater stage, the kiln, cooler and other

system auxiliaries are analysed and compared

to the standards of performance being

achieved by the most modern systems that

have been installed by F.L.Smidth worldwide.

Some of the more notable achievements of

these projects are shown in table 4.

Table 4: Examples of F.L.Smidth plants operating with low heat consumption

Heat balance (kcal/kg clinker)

Plant location

Heat in exhaust gas and dust

Heat in free water evaporation

Plant A

Mexico

Plant B

Indonesia

Plant C

USA

Plant D

Thailand

134

184

135

182

Heat in bypass gas

39

Radiation loss from preheater

37

22

48

35

Radiation loss from kiln

28

31

44

25

Total cooler loss

132

125

113

124

Heat of reaction

374

384

320

360

Free heat from air, fuel and feed

-30

-29

-31

-33

Net specific heat consumption

677

719

673

697

(651 w/o bypass)

Plant

Plant

Plant

Plant

A 6-stage ILC preheater w/2-support kiln and conventional cooler (3000 MTPD)

B 4-stage SLC-I preheater w/conventional cooler (7800 MTPD)

C 6-stage ILC preheater w/SF Cross-Bar cooler and 15% operating bypass (3700 MTPD)

D 5-stage SLC preheater w/ conventional cooler (10,000 MTPD)

By utilising its extensive mechanical and

plant design capabilities, F.L.Smidth has

been able to implement the necessary modifications with minimum interruption to

the plant's normal operations. In this way,

the state of the art has been advanced

for existing plants as well as greenfield

facilities.

Dry process kiln systems

19

1349_M_FLS_DryProcessKiln 28/11/02 9:17 Side 20

www.flsmidth.com

Up-to-date addresses of worldwide

subsidiaries and sales offices are

available from our website

DENMARK

INDIA

USA

F.L.Smidth A/S

Vigerslev All 77

DK-2500 Valby

Copenhagen

Tel: +45 36 18 10 00

Fax: +45 36 30 18 20

E-mail: info@flsmidth.com

Fuller India Limited

Capital Towers

180, Kodambakkam High Road

Nungambakkam

Chennai 600 034

India

Tel: +91 44-827-6030/8228623

Fax: +91 44-827-9393

E-mail: fil@fullerindia.co.in

F.L.Smidth Inc.

2040 Avenue C

Bethlehem, PA 18017-2188

Tel: +1 610-264-6011

Tel: +1 800-523-9482

Fax: +1 610-264-6170

E-mail: info@flsmidth.com

12-02-271 Gramstrup Design ApS

Data in this brochure is intended for preliminary project planning only. Manufacturer reserves the right to modify equipment details and/or specifications without notice.

You might also like

- SJ6832RT Service Manual PDFDocument144 pagesSJ6832RT Service Manual PDFszerelNo ratings yet

- (1.3) - Pyro Process Theory & Kiln System DesignDocument63 pages(1.3) - Pyro Process Theory & Kiln System DesignMuhammed Emami100% (1)

- Ball Mill PresentationDocument34 pagesBall Mill PresentationISLAM I. Fekry100% (18)

- Doosan Diesel Engine Service Manual B3.3Document240 pagesDoosan Diesel Engine Service Manual B3.3thuan71% (7)

- Kohler DieselDocument80 pagesKohler DieselLeigh Galloway50% (2)

- How To Measure False Air PDFDocument3 pagesHow To Measure False Air PDFharyantoaditNo ratings yet

- Nose Ring & Retaining Ring - Cooling & Refractory DesignDocument69 pagesNose Ring & Retaining Ring - Cooling & Refractory Designzementhead100% (3)

- Kiln Systems - ProcessDocument172 pagesKiln Systems - ProcessOki100% (1)

- Day 1 - 5 - BALL Mill Internals - MBu PDFDocument80 pagesDay 1 - 5 - BALL Mill Internals - MBu PDFTELEGBIASIA100% (4)

- VRM Operation and OptimizationDocument39 pagesVRM Operation and OptimizationJitendra Jangid100% (5)

- 10 Basic Fact About ClinkerDocument52 pages10 Basic Fact About ClinkermngyooNo ratings yet

- Raw Meal Suspension in CalcinerDocument48 pagesRaw Meal Suspension in CalcineremadsabriNo ratings yet

- Brochure Gas Turbine SGT-400 For Power Generation PDFDocument4 pagesBrochure Gas Turbine SGT-400 For Power Generation PDFfrdnNo ratings yet

- Ball MillDocument14 pagesBall MillISLAM I. Fekry95% (20)

- Installation - Gocht 2015Document208 pagesInstallation - Gocht 2015vũ minh tâm100% (1)

- Cement Tech BooksDocument7 pagesCement Tech Booksrat12345No ratings yet

- Mass and Heat Balances Grinding PDFDocument46 pagesMass and Heat Balances Grinding PDFAhmad Nil100% (1)

- VRM Heat and Mass BalanceDocument1 pageVRM Heat and Mass BalanceRajeshRockNo ratings yet

- A0595 016 0000 H2 001 D B Installation Guideline CompleteDocument216 pagesA0595 016 0000 H2 001 D B Installation Guideline CompleteLong Lê100% (2)

- 03 QualityDocument22 pages03 QualityMKPashaPasha67% (3)

- Red RiverDocument16 pagesRed RiverNael100% (1)

- Raw Mix Design SoftwareDocument7 pagesRaw Mix Design Softwarevvijaybhan90% (10)

- 4.0 Air Separators 4.1Document31 pages4.0 Air Separators 4.1Dilnesa Ejigu100% (1)

- Flow MeasurementsDocument19 pagesFlow MeasurementsHazem DiabNo ratings yet

- RMH & GrindingDocument132 pagesRMH & Grindingmkpq100% (1)

- Kiln Golden RulesDocument19 pagesKiln Golden RulesWisnu Indriyanto50% (2)

- Precalciners: Cement Manufacturing Course 2003Document29 pagesPrecalciners: Cement Manufacturing Course 2003Salud Y Sucesos100% (1)

- Alkali CyclesDocument14 pagesAlkali CyclesElwathig BakhietNo ratings yet

- Cement MannualDocument30 pagesCement MannualPushpendra Kumar Kushwaha100% (10)

- Loesche Round Table VICATDocument20 pagesLoesche Round Table VICATrecaiNo ratings yet

- 8 - 9 - Mill Optimisation Part 1 and 2Document82 pages8 - 9 - Mill Optimisation Part 1 and 2bulentbulutNo ratings yet

- Pyro ProcessingDocument29 pagesPyro ProcessingMKPashaPasha100% (2)

- Rotaflam PillardDocument34 pagesRotaflam PillardRogério CorreiaNo ratings yet

- Cement Mill - Ball Mill DynamicsDocument36 pagesCement Mill - Ball Mill DynamicsRohit Manglik100% (1)

- Brick CaclulatorDocument7 pagesBrick CaclulatorAbul QasimNo ratings yet

- Pet Coke Fuel Experience in Rotary KilnDocument7 pagesPet Coke Fuel Experience in Rotary KilnP.S.J.Sarma100% (1)

- Refractories For The Cement IndustryDocument28 pagesRefractories For The Cement Industrysteve chollenkNo ratings yet

- The Effects of Limestone Addition, Clinker Type and Fineness PDFDocument5 pagesThe Effects of Limestone Addition, Clinker Type and Fineness PDFHazem DiabNo ratings yet

- Cyclone DPDocument2 pagesCyclone DPTamer Fathy0% (1)

- Atox Coal MillDocument8 pagesAtox Coal MillLijosh JamesNo ratings yet

- Raw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Document6 pagesRaw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Bùi Hắc HảiNo ratings yet

- Cement Process Engineering Vade-Mecum: 3. QualityDocument22 pagesCement Process Engineering Vade-Mecum: 3. QualityRaúl Marcelo Veloz100% (1)

- Cement Mill Control DB MSDocument30 pagesCement Mill Control DB MSShakil Ahmad100% (2)

- The Chemistry of Kiln Feed and ClinkerDocument19 pagesThe Chemistry of Kiln Feed and Clinkermahendra sen100% (1)

- Kiln Heat-Up, Optimun Kiln OperationDocument42 pagesKiln Heat-Up, Optimun Kiln OperationJoko Dewoto100% (11)

- Presentasi Build UpDocument13 pagesPresentasi Build UpJoko Dewoto100% (1)

- DAY1 - DA - 10 Rules For Clinker QualitiesDocument30 pagesDAY1 - DA - 10 Rules For Clinker Qualitiestricky77792% (12)

- Clinker FormationDocument120 pagesClinker FormationDragos PlaesuNo ratings yet

- Common Problems in Cement Plant: One Issue From Each SectionDocument7 pagesCommon Problems in Cement Plant: One Issue From Each SectionYhaneNo ratings yet

- ILC SLC-D Kiln SystemDocument45 pagesILC SLC-D Kiln SystemAndris Risyat100% (1)

- Alk-SO3-Cl Balance - v2.1Document4 pagesAlk-SO3-Cl Balance - v2.1shani5573100% (4)

- Precalciner Kilns Systems & OperationDocument58 pagesPrecalciner Kilns Systems & OperationYhaneNo ratings yet

- Cement MillDocument28 pagesCement Millsaji kumar100% (2)

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Preheater Calciner SystemsDocument8 pagesPreheater Calciner SystemsDanni SulaimanNo ratings yet

- Preheater Calciner SystemsDocument8 pagesPreheater Calciner SystemsPaknubkNo ratings yet

- Preheater Lores PDFDocument8 pagesPreheater Lores PDFamjed_de_enimNo ratings yet

- Operational Strategies For Flexing in Thermal PlantsDocument27 pagesOperational Strategies For Flexing in Thermal PlantsSanjay NandalNo ratings yet

- Upgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L SmidthDocument7 pagesUpgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L Smidthmail2quraishi3084No ratings yet

- Chapter - Chap 9Document35 pagesChapter - Chap 9SimphiweNo ratings yet

- Special Issue: An Exchange of Technical Information About Carrier Transicold Container ProductsDocument4 pagesSpecial Issue: An Exchange of Technical Information About Carrier Transicold Container ProductsCarlosAlbertoMirandaAndradesNo ratings yet

- Series R™ Helical Rotary Liquid Chillers: Product CatalogDocument140 pagesSeries R™ Helical Rotary Liquid Chillers: Product CataloggabyorNo ratings yet

- Thermo-Chemistry Enthalpy Changes in Chemical Process Part 2Document20 pagesThermo-Chemistry Enthalpy Changes in Chemical Process Part 2ISLAM I. FekryNo ratings yet

- ELECTROCHEMISTRYDocument10 pagesELECTROCHEMISTRYISLAM I. Fekry100% (2)

- Sodium HydroxideDocument3 pagesSodium HydroxideISLAM I. Fekry100% (2)

- Joule Thomson Expansion J TDocument6 pagesJoule Thomson Expansion J TISLAM I. Fekry100% (2)

- Environmental Implications On The Oxygenation of Gasoline With Ethanol in The Metropolitan Area of Mexico CityDocument10 pagesEnvironmental Implications On The Oxygenation of Gasoline With Ethanol in The Metropolitan Area of Mexico CityISLAM I. FekryNo ratings yet

- The Influence of Air-Fuel Ratio On Engine Performance and Pollutant Emission of An SI Engine Using Ethanol-Gasoline-Blended FuelsDocument8 pagesThe Influence of Air-Fuel Ratio On Engine Performance and Pollutant Emission of An SI Engine Using Ethanol-Gasoline-Blended FuelsISLAM I. Fekry100% (1)

- Engine Performance and Pollutant Emission of An SI Engine Using Ethanol-Gasoline Blended FuelsDocument8 pagesEngine Performance and Pollutant Emission of An SI Engine Using Ethanol-Gasoline Blended FuelsISLAM I. FekryNo ratings yet

- Tube MillsDocument44 pagesTube MillsISLAM I. Fekry100% (2)

- Molar Enthalpy of Vaporization of Ethanol-Gasoline Mixtures and Their Colloid StateDocument5 pagesMolar Enthalpy of Vaporization of Ethanol-Gasoline Mixtures and Their Colloid StateISLAM I. FekryNo ratings yet

- Separators of Different GenerationsDocument46 pagesSeparators of Different GenerationsISLAM I. Fekry100% (8)

- Latest Technology of Mill DiaphragmsDocument17 pagesLatest Technology of Mill DiaphragmsISLAM I. Fekry100% (5)

- Transmission (ZF16S151/221)Document20 pagesTransmission (ZF16S151/221)pankituna54870% (1)

- LNG Vehicle Fuel Tank Installation and Operation Manual: Manual P/N 7950-8359 Publication # TW-359Document29 pagesLNG Vehicle Fuel Tank Installation and Operation Manual: Manual P/N 7950-8359 Publication # TW-359caligula9955No ratings yet

- Urbino ElectricDocument9 pagesUrbino ElectricPhilippine Bus Enthusiasts Society0% (1)

- Fire Technology and Arson InvestigationDocument29 pagesFire Technology and Arson InvestigationEM ONNo ratings yet

- ECU List 6 8 0 New Features ListDocument23 pagesECU List 6 8 0 New Features ListAdeelNo ratings yet

- Specification: Specification & General Com Ponent Kode Unit D7G: - D: Dozer - 7: Size Unit - G: ModifikasiDocument3 pagesSpecification: Specification & General Com Ponent Kode Unit D7G: - D: Dozer - 7: Size Unit - G: ModifikasiAgus DaniNo ratings yet

- Sumerset 14 X 78 Sample SurveyDocument56 pagesSumerset 14 X 78 Sample Surveyjtipton178No ratings yet

- Swot AnalysisDocument22 pagesSwot AnalysisUddish BagriNo ratings yet

- Generator Set Performance: ApplicationDocument8 pagesGenerator Set Performance: Applicationpurnomno sidiNo ratings yet

- Di650i t3 Specification Sheet EnglishDocument3 pagesDi650i t3 Specification Sheet EnglishjiaozhongxingNo ratings yet

- Dec 2014Document1,694 pagesDec 2014Avadhoot JoshiNo ratings yet

- Tentative CatalogueVIJ20191226206Document42 pagesTentative CatalogueVIJ20191226206VamshiNo ratings yet

- Gaskets - Graphite PDFDocument4 pagesGaskets - Graphite PDFSH1961No ratings yet

- Wheel Loader 988GDocument24 pagesWheel Loader 988GChristian Kari100% (1)

- Cetane Number PDFDocument6 pagesCetane Number PDFadame_udsNo ratings yet

- Asxxmobil Delvac MX F3 15W40Document3 pagesAsxxmobil Delvac MX F3 15W40Noche de EstrellasNo ratings yet

- Problem Set GEASDocument9 pagesProblem Set GEASDarthRevan23No ratings yet

- I 3648Document4 pagesI 3648Ajazuddin MohammedNo ratings yet

- Flywheel Housing & AlternatorsDocument9 pagesFlywheel Housing & AlternatorsLukman ChairkiandraNo ratings yet

- WSS ProductCatalogue2015 LowresDocument664 pagesWSS ProductCatalogue2015 LowresJuriandi Saputra100% (1)

- EHS Questions 1Document21 pagesEHS Questions 1Fahd KhanNo ratings yet

- Boiler 2Document57 pagesBoiler 2azmisabran100% (1)

- British Petroleum LimitedDocument593 pagesBritish Petroleum Limitedjk kumarNo ratings yet

- Ferti JetDocument19 pagesFerti JetCèsar Daniel Linares QuirozNo ratings yet

- Tankers Dry Bulk: Published by Fearnresearch 18. September 2013Document3 pagesTankers Dry Bulk: Published by Fearnresearch 18. September 2013SimmarineNo ratings yet

- Potential Oil Areas of VenezuelaDocument3 pagesPotential Oil Areas of VenezuelaAngelica PintoNo ratings yet

- SSP 055 20 110kw 16 85kw Fsi EngineDocument58 pagesSSP 055 20 110kw 16 85kw Fsi EngineutfNo ratings yet