Professional Documents

Culture Documents

NV10USB Field Service Manual

NV10USB Field Service Manual

Uploaded by

Apple PieCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NV10USB Field Service Manual

NV10USB Field Service Manual

Uploaded by

Apple PieCopyright:

Available Formats

SECTION

NV10 USB

MANUAL SET

FIELD SERVICE

MANUAL

NV10 USB Manual Set Section 2

NV10 USB MANUAL SET SECTION 2

2.

FIELD SERVICE MANUAL

2.1

Cleaning

2.2

Belt Cleaning

2.3

Belt Changing

2.4

Re-Initialisation

2.5

Fault Finding - Flash Codes

2.6

Technical Specifications

2.7

Fault Finding Flow Chart

2.8

Frequently Asked Questions

11

2.9

Spare Parts

12

Copyright Innovative Technology Ltd 2013

GA00450-4

NV10 USB Manual Set Section 2

2.

FIELD SERVICE MANUAL

This section is one part of a complete manual set: typically, a field service engineer

who is maintaining the product would use this section.

This section contains the essential information that the field engineer needs to clean,

maintain and fault find an NV10 USB Validator that is installed in a host machine.

The NV10 USB Validator has been designed to minimise any problems or performance

variations over time. This has been achieved by careful hardware and software

design; this attention to the design means there is very little user maintenance

required.

2.1

Cleaning

The NV10 USB Validator has been designed in a way to prevent damage and airborne

contamination reaching the optical sensors; however, depending upon the

environment the NV10 USB may require occasional cleaning or belt changing.

Caution!

Do not use solvent based

cleaners on any part of the

NV10 USB unit.

Do not use solvent based cleaners such as

alcohol, petrol, methylated spirits, white spirit or

PCB cleaner. Using these solvents can cause

permanent damage to the unit; only use a mild

detergent solution as directed below.

Release

catches

To clean the NV10 USB, release the

bezel, open the note path by pushing

downwards on both Red catches and

the inwards towards the body of the

NV10 USB (see Figure 10) and lift and

expose the note paths, place them on

a clean dry surface. The note path

will now be exposed for cleaning,

(see Figure 11).

Figure 10 NV10 USB Release Catches

Copyright Innovative Technology Ltd 2013

GA00450-4

NV10 USB Manual Set Section 2

Carefully wipe the surfaces with a soft lint free cloth that has been dampened with a

water and mild detergent solution (i.e. household washing up liquid). Take particular

care around all sensor lenses (see Figure 11), ensuring they are clean and dry. If a

lens has become badly scratched do not attempt to polish it. Contact ITL for further

advise as there may be damage to the optical properties of the lens.

CUTION: WHEN CLEANING THE RECESSED FRONT SENSOR, USE A SMALL

SOFT BRUSH OR COTTON WOOL BUD.

Optical Sensors

Figure 11 NV10 USB Sensor Location

WARNING!

Disconnect power BEFORE

any cleaning operation

Unless stated otherwise, you should disconnect

the power BEFORE carrying out any cleaning

operations to avoid the risk of causing damage

to the validator.

Copyright Innovative Technology Ltd 2013

GA00450-4

NV10 USB Manual Set Section 2

2.2

Belt Cleaning

Ensure the validator is enabled (i.e. Bezel lights are illuminated).

Remove bezel.

Insert a piece of paper, narrower than the width between the two red belts, in the

centre of the note path to activate the drive motor.

Use a lint free cloth dampened with water and mild detergent solution; such as

household washing up liquid, and hold it against each drive belt as it turns.

Repeat steps 3 and 4 until all dust and debris has been removed from both belts.

Repeat step 3 using a DRY lint free cloth to remove any excess moisture.

Insert Paper Here

Figure 12 Belt Access

Copyright Innovative Technology Ltd 2013

GA00450-4

NV10 USB Manual Set Section 2

2.3

Belt Changing

With the NV10 note paths exposed (see Error! Reference source not found.)

place the unit on a clean dry surface.

Remove the lower cover plate by lifting up the retention catch and carefully

sliding it back (see Error! Reference source not found.).

Push the 2 belt tension springs inwards then slide each belt off the drive unit

body, smallest wheels first.

Replace the belts by fitting them over the drive unit body legs, smallest wheels

first.

Place the lower cover plate into the locating slots (2 each side) pushing forward

and down, the plate will click confirming correct insertion.

Connect the upper and lower note path back together.

Retention Catch

Lower Cover Plate

Belts

Locating

Slots

Drive Unit

Body

Drive Belts

2.4

Belt Tension Springs

Re-Initialisation

The NV10 USB has an in-built self-calibration system that maintains the optical

sensors at their best operating point. However if the NV10 USB is disassembled for

any reason it will need to be re-calibrated. Re-calibration may only be performed

under license from ITL, contact support@innovativetechnology.co.uk for further

details.

Copyright Innovative Technology Ltd 2013

GA00450-4

NV10 USB Manual Set Section 2

2.5

Fault Finding - Flash Codes

The NV10 USB Validator has inbuilt fault detection. If there is a configuration or other

error the NV10 USB front bezel will flash in a particular sequence to indicate the

problem; a summary of the Bezel Flash Codes for the NV10 USB is shown below:

Flashes

Long

Short

0

0

1

2

None

Note path jam

Unit not initialised

Internal sensor

unable to calibrate

Firmware checksum

error

Interface checksum

error or unable to

set programmed

interface

EEPROM checksum

error

Dataset checksum

error

Power supply too

low

Power supply too

high

2

3

3

4

1

4

Indicated Error

Copyright Innovative Technology Ltd 2013

Comments

Remove obstruction and

follow the cleaning

procedure in subsection 2.1

of this manual

Contact ITL technical

support

Ensure note path is firmly

closed, then cycle the

power to the unit. If the

problem persists contact ITL

technical support

Download new firmware

Check power supply

GA00450-4

NV10 USB Manual Set Section 2

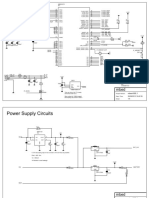

2.6

Technical Specifications

The full technical specifications for the NV10 USB Validator can be found in Section 6,

Appendix B of this manual set. A brief summary is given here:

DC Voltage

Absolute limits

Absolute limits (when fitted

with IF5 interface)

Supply ripple voltage

Minimum

10.8 V

18 V

Nominal

12 V

---

0V

0V

Maximum

14.2 V

48 V DC or 34 V

AC

0.25 V @ 100 Hz

Supply Current

Standby

Running

Peak (motor stall)

200 mA

1A

1.5 A

Interface Logic Levels

Logic Low

Logic High

Inputs

Outputs (2.2 k pull-up)

+0 V to +0.5 V

+0.6 V

+3.7 V to +12 V

Pull-up voltage of host

interface

50 mA per output

Maximum current sink

WARNING!

Use suitable power supply

Ensure that the supply voltage to the NV10 USB is

not lower than 10.8 V and that the power supply

can provide sufficient current to avoid incorrect

operation and excessive note rejects.

We recommend that your power supply is capable of supplying 12V DC at 3 A.

For 12V operation, use TDK Lambda model SWS50-12. This power supply is

available from a variety of suppliers including Farnell (stock code 1184645) and

RS (stock code 466-5869).

Copyright Innovative Technology Ltd 2013

GA00450-4

NV10 USB Manual Set Section 2

2.7

Fault Finding Flow Chart

Please use this flow chart with the Flash Codes in subsection 2.2 as an aid to help

resolve any configuration or start up problems you might have after installing the

NV10 USB validator

Incorrect currency

file

Check the required dataset is programmed using the

Validator Manager Software (see Section 3 of this

manual set).

Notes not included in

currency file

Check the required note denomination and issue is

included in the currency file using the Validator Manager

Software (see Section 3 of this manual set).

Notes inhibited by

host machine

Check the host machine is ready to accept notes and

that the maximum allowed credit hasnt been exceeded.

If a coin hopper is fitted, make sure it isnt empty.

Bill path obstructed

Check there is sufficient clearance for note ejection after

acceptance (see Section 4 of this manual set).

No power

Check there is power to the validator, and that it is

within the tolerances specified in the Technical

Specification (see Sections 1 or 6 of this manual set).

Incorrect interface

programmed

Check which interface the validator is programmed for by

pressing the configuration button twice the displayed

code indicates which interface is programmed (see

Section 1 of this manual set).

All notes rejected

(bezel LEDs ON)

Notes not accepted

(bezel LEDs OFF)

Power supply out of

specification

Notes accepted but

no credit given

Rear note detect

sensor obscured

Copyright Innovative Technology Ltd 2013

Check voltage and current supplied to the validator are

within the tolerances specified in the Technical

Specification (see Sections 1 or 6 of this manual set).

Check there is sufficient clearance for note ejection after

acceptance (see Section 4 of this manual set).

Check there are no foreign objects obstructing the

sensors (see subsection 2.1 of this manual).

Check the back security flap moves freely (this is the

black plastic flap at the rear underside of the validator

head)

GA00450-4

NV10 USB Manual Set Section 2

Foreign objects in

note path

Acceptor runs slowly

or intermittently

Incorrect supply

voltage

Unit damage

Bezel LEDs are

flashing

Motor continues to

run

Various reasons

Foreign object or

note in the note path

10

Check and clean the note path (see subsection 2.1 of

this manual).

Check drive belts are fitted correctly and that there is no

debris underneath the belts.

Check voltage and current supplied to the validator are

within the tolerances specified in the Technical

Specification (see Sections 1 or 6 of this manual set).

If possible, replace damaged components (see Section 4

of this manual set).

IF YOU HAVE ANY DOUBTS, RETURN THE UNIT TO ITL

FOR REPAIR

Check the flash code tables for an understanding of the

issue (see subsection 2.2 of this manual).

Check and clean the note path (see subsection 2.1 of

this manual), then reset the validator.

In some cases you may also need to reset the host

machine.

If you are unsure about the cause or how to resolve the problem, please contact ITLs

technical support department. Support contact details can be found on the ITL

website (www.innovative-technology.co.uk), or on the last page of this section.

Copyright Innovative Technology Ltd 2013

GA00450-4

NV10 USB Manual Set Section 2

2.8

11

Frequently Asked Questions

a. Why are there no DIP switches on the unit?

The NV10 USB has no dipswitches. The unit is configured with the

configuration button mounted on right hand side of the unit see subsection

1.3 of this manual for more information.

b. In what orientation can I use the NV10 USB validator?

The NV10 USB can only be mounted horizontally. See subsection 1.1 1.3 of

this manual for more information on mounting the validator check the ITL

website

c. Some or all notes are not accepted

Check that no inhibits are set in the Validator Manager software (see Section 3

of this manual set). If the problem persists, contact ITL Support for further

assistance.

d. How do I clean the validator?

Follow the instructions given in subsection 2.1 of this manual.

Copyright Innovative Technology Ltd 2013

GA450-4

NV9 USB Manual Set Section 2

2.9

12

Spare Parts

Full details of the interface cable connector pinouts, connector types / makes and other related information can be found in Section 4

of this manual set. The user can obtain the following parts for the NV10 USB validator:

ITL Part Number

Description

Details

CN392

Power and USB Communication Cable

USB 2.0 Compliant Type A to 16 way header cable

Copyright Innovative Technology Ltd 2012

GA550-2

NV10 USB Manual Set Section 2

13

Bezels

ITL Part

Number

Description

PA231

Standard Small Bezel

PA266

Extended Small Bezel

Information

Check website for options.

There are a couple of variants of bezel available for

the NV10 USB validator. Please check the ITL

website (www.innovative-technology.co.uk) for up to

date information on the options available.

Drive Belts

FD107

NV10 USB Red Drive Belt

Copyright Innovative Technology Ltd 2013

GA450-4

NV10 USB Manual Set Section 2

14

Accessories

ITL Part

Number

Description

CN392

ITL to USB Cable

PM599

Anti Strim Shield

PA258

NV4 to NV10 USB Adaptor

Plate

Copyright Innovative Technology Ltd 2013

GA450-4

NV10 USB Manual Set

MAIN HEADQUARTERS

Innovative Technology Ltd

Derker Street Oldham England - OL1 4EQ

Tel: +44 161 626 9999 Fax: +44 161 620 2090

E-mail: support@innovative-technology.co.uk

Web site: www.innovative-technology.co.uk

BRAZIL

suporte@bellis-technology.com.br

CHINA

support@innovative-technology.co.uk

GERMANY

supportDE@innovative-technology.eu

SPAIN

supportES@innovative-technology.eu

UNITED KINGDOM

support@innovative-technology.co.uk

UNITED STATES OF AMERICA

supportusa@bellis-technology.com

REST OF THE WORLD

support@innovative-technology.co.uk

Copyright Innovative Technology Ltd 2013

GA450-4

You might also like

- PowerStore+Concepts+and+Features+ +Participant+Guide (PDF) +Document72 pagesPowerStore+Concepts+and+Features+ +Participant+Guide (PDF) +LadislauNo ratings yet

- Utility Software: User ManualDocument15 pagesUtility Software: User ManualLUATNo ratings yet

- HOWTO - Snort, Fail2ban and UFW CombinationDocument3 pagesHOWTO - Snort, Fail2ban and UFW CombinationToby LimNo ratings yet

- Candy Ced110 37Document104 pagesCandy Ced110 37drdrb2100% (2)

- TDM 900 2003 ServiceManualDocument110 pagesTDM 900 2003 ServiceManualRadu PopNo ratings yet

- Avdi Common User S Manual English-2203Document53 pagesAvdi Common User S Manual English-2203Miguel VegaNo ratings yet

- NV200 Manual Set - Section 2 - Field Service ManualDocument13 pagesNV200 Manual Set - Section 2 - Field Service ManualBogicevic DejanNo ratings yet

- NV200 Manual Set - Section 2 - Field Service ManualDocument13 pagesNV200 Manual Set - Section 2 - Field Service ManualBogicevic DejanNo ratings yet

- Service Mapping - Business - Service - Data Gathering - Questionnaire - Draft - v1 - 3Document5 pagesService Mapping - Business - Service - Data Gathering - Questionnaire - Draft - v1 - 3Nidhi KaleNo ratings yet

- Digsi 4 V4.87: Product InformationDocument64 pagesDigsi 4 V4.87: Product InformationMohit PhadnisNo ratings yet

- NV10Document39 pagesNV10Marian BaciuNo ratings yet

- Manual HPVFV ModbusDocument16 pagesManual HPVFV ModbusZohra ElNo ratings yet

- 6SL3130 6ae15 0aa0 Smart Line Module Sinamics S120 Siemens ManualDocument7 pages6SL3130 6ae15 0aa0 Smart Line Module Sinamics S120 Siemens ManualdalyNo ratings yet

- Multi-Motor DrivesDocument6 pagesMulti-Motor DrivessriabolfazlNo ratings yet

- Manual Book UPS Lieber T APM 150Document97 pagesManual Book UPS Lieber T APM 150Harry CulNo ratings yet

- Microcontroller Based Constant Speed Low Cost Energy Efficient BLDC Motor Drive Using Proteus VSM SoftwareDocument7 pagesMicrocontroller Based Constant Speed Low Cost Energy Efficient BLDC Motor Drive Using Proteus VSM SoftwaremakroumNo ratings yet

- 3 Phase Ac Motor Control With VHZ Speed Closed Loop Using The 56f800eDocument36 pages3 Phase Ac Motor Control With VHZ Speed Closed Loop Using The 56f800ePrabhu RajNo ratings yet

- Ups Kstar-1-3kva 120V 0.9PFDocument5 pagesUps Kstar-1-3kva 120V 0.9PFoscar mauricio caballero camachoNo ratings yet

- Alarm Code OverzichtDocument36 pagesAlarm Code OverzichtMihuța NarcisaNo ratings yet

- Lectures 6 & 7 - Uncontrolled (Diode) Rectifier Circuits: Single-Phase Center-Tapped RectifierDocument21 pagesLectures 6 & 7 - Uncontrolled (Diode) Rectifier Circuits: Single-Phase Center-Tapped RectifierTommy ManNo ratings yet

- Power Electronics Application in DC Motor Drives - Case Study - ss03595 - Sarwan Shah PDFDocument6 pagesPower Electronics Application in DC Motor Drives - Case Study - ss03595 - Sarwan Shah PDFMehdi Raza KhorasaniNo ratings yet

- MP Series HMIDocument74 pagesMP Series HMIalfoteNo ratings yet

- ESC201T L23 Power Supply Part-1Document28 pagesESC201T L23 Power Supply Part-1Rachit MahajanNo ratings yet

- An Serv 002 PDFDocument20 pagesAn Serv 002 PDFMario TapiaNo ratings yet

- 2.3.7. PGM1 and PGM2 (Programmable) Output ConnectionsDocument15 pages2.3.7. PGM1 and PGM2 (Programmable) Output ConnectionsSuperNova xNo ratings yet

- Vsi Csi With Various LoadsDocument56 pagesVsi Csi With Various LoadsDeependra RastogiNo ratings yet

- ED1000Document4 pagesED1000Mohamed TahounNo ratings yet

- BTS Huawei LTEDocument41 pagesBTS Huawei LTEAkoo Mera100% (1)

- Advanced Power Electronics DC DC Converters: DR Taosif IqbalDocument71 pagesAdvanced Power Electronics DC DC Converters: DR Taosif IqbalTaosif IqbalNo ratings yet

- Controlling Stepper Motors With A PIC MicrocontrollerDocument16 pagesControlling Stepper Motors With A PIC Microcontrollervasudeva yasasNo ratings yet

- Why Do Some Motors Have Constant Load Torque and Some Have Variable?Document5 pagesWhy Do Some Motors Have Constant Load Torque and Some Have Variable?Charles RobiansyahNo ratings yet

- Yaesu FT-890 Operating ManualDocument25 pagesYaesu FT-890 Operating ManualYayok S. AnggoroNo ratings yet

- EJ-03 Jednopolna Shema Ormara RO-HMD - Ovo - KORISTITI - Hamdija7 PDFDocument1 pageEJ-03 Jednopolna Shema Ormara RO-HMD - Ovo - KORISTITI - Hamdija7 PDFDzananMujicNo ratings yet

- GSM Pots AdapterDocument9 pagesGSM Pots AdapterdagskarlsenNo ratings yet

- Four - Quadrant Control SystemsDocument4 pagesFour - Quadrant Control SystemsRICHARDNo ratings yet

- Baldor Basics PDFDocument6 pagesBaldor Basics PDFSHUBHAM SINHANo ratings yet

- S10 Face Access Controller-Hardware Manual - SESAMEDocument17 pagesS10 Face Access Controller-Hardware Manual - SESAMEDaniel Jesus LozanoNo ratings yet

- Introduction To Introduction To Power Electronics Ipvs T in PV SystemsDocument36 pagesIntroduction To Introduction To Power Electronics Ipvs T in PV SystemsKhiem NguyenNo ratings yet

- Braking of Electric Motors: Need..... ?Document8 pagesBraking of Electric Motors: Need..... ?Ramesh VeerNo ratings yet

- How To Drive DC Motors With Smart Power IcsDocument14 pagesHow To Drive DC Motors With Smart Power IcsGoran ŽivkovićNo ratings yet

- Vacon NX Inverters FI9 14 User Manual DPD00909A enDocument106 pagesVacon NX Inverters FI9 14 User Manual DPD00909A enTanuTiganuNo ratings yet

- Cnc-210S User Manual VER.F668-R15: DOC NO:001229Document23 pagesCnc-210S User Manual VER.F668-R15: DOC NO:001229CarlosNo ratings yet

- Position ControlDocument3 pagesPosition Controls k sahuNo ratings yet

- Melfa Basic Iv: Main Main Characteristics of Characteristics of RV-2AJDocument8 pagesMelfa Basic Iv: Main Main Characteristics of Characteristics of RV-2AJAntonio SánchezNo ratings yet

- D3 Remote ManualDocument2 pagesD3 Remote ManualbobanmiNo ratings yet

- LFR Tutorial CompleteDocument22 pagesLFR Tutorial CompleteTraic Club0% (1)

- Kivy TutorialDocument5 pagesKivy TutorialShashwat PandeyNo ratings yet

- Diode Circuits or Uncontrolled Rectifier: EE 435-Electric Drives Dr. Ali M. EltamalyDocument21 pagesDiode Circuits or Uncontrolled Rectifier: EE 435-Electric Drives Dr. Ali M. EltamalyNaga Surya PrakashNo ratings yet

- TR Load Cell ManualDocument4 pagesTR Load Cell ManualGopal Hegde0% (1)

- NCE T FaultDataCollectionGuide (RTN)Document15 pagesNCE T FaultDataCollectionGuide (RTN)KSumiteshNo ratings yet

- AmplidyneDocument10 pagesAmplidynearkaprava243100% (4)

- UntitledDocument52 pagesUntitledVedranL84No ratings yet

- FluidicsDocument18 pagesFluidicsDINESH DHANABALANNo ratings yet

- Gysmi Tig 160 HFDocument6 pagesGysmi Tig 160 HFAugustoferreira Ferreira100% (1)

- TL-WR844N (EU) 1.0 DatasheetDocument5 pagesTL-WR844N (EU) 1.0 DatasheetCarlos Alberto100% (1)

- ICL7107 Assembly GuideDocument9 pagesICL7107 Assembly GuideLaurentiu IacobNo ratings yet

- ARM Mbed LPC1768 SchematicDocument5 pagesARM Mbed LPC1768 Schematicmyacine16No ratings yet

- Omron Cqm1 Oc222 PDFDocument2 pagesOmron Cqm1 Oc222 PDFHeatherNo ratings yet

- T3806Document1 pageT3806Eong Huat Corporation Sdn BhdNo ratings yet

- Installation Manual W465H, W475H/M, W4105H/M, W4130H/M, W4180H/M, W4240H, W4250M, W4300H, W4330M Clarus ControlDocument52 pagesInstallation Manual W465H, W475H/M, W4105H/M, W4130H/M, W4180H/M, W4240H, W4250M, W4300H, W4330M Clarus ControlAgustin FernandezNo ratings yet

- Positioning Basic PosDocument41 pagesPositioning Basic PosGuilhermeCuninghanNo ratings yet

- Eltek CTRL Web Interface - CompressedDocument364 pagesEltek CTRL Web Interface - CompressedTan100% (1)

- Load Inertia Motor SelectionDocument3 pagesLoad Inertia Motor Selectiondanferreiro8318100% (1)

- NV10USB Manual Set - Section 2 PDFDocument15 pagesNV10USB Manual Set - Section 2 PDFElvis LinaresNo ratings yet

- NV9USB Quick Start Manual Section 1Document16 pagesNV9USB Quick Start Manual Section 1oplaza.airis7No ratings yet

- NV9 Spectral 5Document2 pagesNV9 Spectral 5Bogicevic DejanNo ratings yet

- NV200 SpectralDocument2 pagesNV200 SpectralBogicevic DejanNo ratings yet

- JCM Uba ProDocument2 pagesJCM Uba ProBogicevic DejanNo ratings yet

- Spectral Payout DRAFTDocument2 pagesSpectral Payout DRAFTBogicevic DejanNo ratings yet

- BNFDocument2 pagesBNFBogicevic DejanNo ratings yet

- UPC1Document24 pagesUPC1Bogicevic DejanNo ratings yet

- SSP ManualDocument272 pagesSSP ManualBogicevic Dejan100% (1)

- Versions Available:: Aeterna Programming and UpdateDocument10 pagesVersions Available:: Aeterna Programming and UpdateBogicevic DejanNo ratings yet

- CR-158 Coupon Printer ManualDocument14 pagesCR-158 Coupon Printer ManualBogicevic DejanNo ratings yet

- Necta Wittenborg Brio-250 PDFDocument27 pagesNecta Wittenborg Brio-250 PDFBogicevic DejanNo ratings yet

- B Currenzac Spider enDocument2 pagesB Currenzac Spider enBogicevic Dejan100% (1)

- Domaći Kuhar - Deserti I Slana Jela - Fererro RocherDocument2 pagesDomaći Kuhar - Deserti I Slana Jela - Fererro RocherBogicevic DejanNo ratings yet

- Nv9 Usb ManualDocument40 pagesNv9 Usb ManualBogicevic DejanNo ratings yet

- IBM FlashSystem A9000 12.2.1 CLIDocument748 pagesIBM FlashSystem A9000 12.2.1 CLIvikrantp1008No ratings yet

- Log2021-11-11 0Document3 pagesLog2021-11-11 0Adeyemi A. OluwadamilolaNo ratings yet

- Advanced Web Scraping - Bypassing - 403 Forbidden, - Captchas, and More - SangalineDocument12 pagesAdvanced Web Scraping - Bypassing - 403 Forbidden, - Captchas, and More - SangalineLop MangNo ratings yet

- Rake ReceiverDocument48 pagesRake ReceiverIk Ram100% (1)

- ADSL Line ProfileDocument3 pagesADSL Line ProfileمنصورالمغربيNo ratings yet

- CCR1036 8G 2S+Document3 pagesCCR1036 8G 2S+Ayrton TicseNo ratings yet

- 8830 HW Installation ManualDocument132 pages8830 HW Installation ManualCarlos GaldamezNo ratings yet

- Casestudy Community HealthDocument2 pagesCasestudy Community Healthالمسافر من الحياةNo ratings yet

- Wire Shark Report 2011Document28 pagesWire Shark Report 2011Balaji VenkataramanNo ratings yet

- Introduction To Parallel ComputingDocument34 pagesIntroduction To Parallel ComputingJOna Lyne0% (1)

- Online News Portal: Sach Ke Teh TakDocument15 pagesOnline News Portal: Sach Ke Teh Takmuhammad aamirNo ratings yet

- How To Crack WEPDocument44 pagesHow To Crack WEPHari CahyadiNo ratings yet

- Computer Networks Larry L Peterson Bruce S Davie Full ChapterDocument51 pagesComputer Networks Larry L Peterson Bruce S Davie Full Chapterjose.ferguson966100% (17)

- CnPilot Enterprise Wi Fi Access Points 4.2 User Guide Meltec CambiumDocument263 pagesCnPilot Enterprise Wi Fi Access Points 4.2 User Guide Meltec CambiumCamilo CruzNo ratings yet

- Stackoverflow Com Questions 17095443 How To Use Simple AjaxDocument7 pagesStackoverflow Com Questions 17095443 How To Use Simple AjaxmenberNo ratings yet

- Eaton XConfortDocument16 pagesEaton XConfortRebbelliyonNo ratings yet

- 17ec741 Module - 1Document54 pages17ec741 Module - 1Chinmay NaikNo ratings yet

- Nss Labs Security Controls in The Us EnterpriseDocument16 pagesNss Labs Security Controls in The Us EnterpriseYoel ArmasNo ratings yet

- GRZ200 Brochure - 12032-0.BDocument44 pagesGRZ200 Brochure - 12032-0.BRuly TonapaNo ratings yet

- Zeus4-Mc Ver7 GprsDocument1 pageZeus4-Mc Ver7 GprsxyzNo ratings yet

- 9.2.6 Lab - Using Wireshark To Observe The TCP 3-Way HandshakeDocument7 pages9.2.6 Lab - Using Wireshark To Observe The TCP 3-Way HandshakePrince NagacNo ratings yet

- Quick Start Guide: Cisco Wap150 Wireless-Ac/N Dual Radio Access Point With PoeDocument12 pagesQuick Start Guide: Cisco Wap150 Wireless-Ac/N Dual Radio Access Point With PoeHamza AbdelsalamNo ratings yet

- Elcomsoft Wireless Security Auditor Standard + Professional Edition Serial Keys - On HAXDocument3 pagesElcomsoft Wireless Security Auditor Standard + Professional Edition Serial Keys - On HAXAhmad اكملNo ratings yet

- ANC-120e RSLinx Classic USB To DH+ Configuration SetupDocument5 pagesANC-120e RSLinx Classic USB To DH+ Configuration SetupAutomation Networks & Solutions LLCNo ratings yet

- Game Cities For RSD MembersDocument8 pagesGame Cities For RSD MembersAyo Heart AnimashaunNo ratings yet

- Netbsd InstallDocument6 pagesNetbsd InstallAndreNo ratings yet