Professional Documents

Culture Documents

4.30 - Co Metabolic Processes PDF

Uploaded by

Michael HuffmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.30 - Co Metabolic Processes PDF

Uploaded by

Michael HuffmanCopyright:

Available Formats

4.

30 CO-METABOLIC PROCESSES

Description:

Co-metabolism is one form of secondary substrate transformation in which

enzymes produced for primary substrate oxidation are capable of degrading the

secondary substrate fortuitously, even though the secondary substrates do not

afford sufficient energy to sustain the microbial population. An emerging

application involves the injection of water containing dissolved methane and

oxygen into groundwater to enhance methanotrophic biological degradation.

This class of microorganisms can degrade chlorinated solvents, such as vinyl

chloride and TCE, by co-metabolism.

4-30 TYPICAL CO-METABOLIC BIOREMEDIATION SYSTEM (IN SITU) FOR

CONTAMINATED GROUNDWATER

Applicability: Target contaminants for co-metabolic processes are VOCs and SVOCs. The process

may also have some effectiveness in treating fuels and pesticides. As with other

biological treatments, treatability is highly dependent upon the biodegradability of the

contaminants.

Limitations:

Factors that may limit the applicability and effectiveness of the process include:

This technology is still under development.

Where the subsurface is heterogeneous, it is very difficult to circulate the

methane solution throughout every portion of the contaminated zone.

Higher permeability zones are cleaned up much faster because

groundwater flow rates are greater.

Safety precautions (such as removing all ignition sources in the area)

must be used when handling methane.

MK01\RPT:02281012.009\compgde.430

4-121

08/21/95

IN SITU WATER TREATMENT TECHNOLOGIES

Data Needs:

A detailed discussion of these data elements is provided in Subsection 2.2.2

(Data Requirements for Groundwater, Surface Water, and Leachate).

Characteristics that should be addressed prior to system design include aquifer

permeability, site hydrology, dissolved oxygen content, pH, and depth, type,

concentration, and biodegradability of contaminants.

Performance

Data:

While ex situ bioreactors for methanotrophic TCE biodegradation are being

used in full-scale remediation, in situ application has not yet been demonstrated

at a practical scale. A field demonstration project has been conducted at DOD's

Moffett Naval Air Station, and another is being conducted at DOE's Savannah

River site.

The DOE pilot-scale demonstration was performed at the Savannah River site's

abandoned seepage basin and process sewer line employed for disposal of

solvents used to degrease nuclear fuel target elements. Contamination is mostly

TCE and PCE with concentrations of 10,000 ppb in soil and 1,000 ppb in

groundwater. Extensive soil and groundwater monitoring has demonstrated that

when methanotroph densities increased five orders of magnitude, TCE and PCE

concentrations declined to less than 2 ppb.

Cost:

For the DOE Savannah River demonstration, capital investment costs were

$150K and 200 manhours for site preparation, setup, and assembly. The

operation is low maintenance, requiring only one technician at 25% time (10

hours per week); other operational costs are for electricity, natural gas, and

equipment maintenance.

O&M costs can be significant because a continuous source of methane solution

must be delivered to the contaminated groundwater.

References:

EPA, 1993. In Situ Bioremediation: Biodegradation of Trichloroethylene and

Tetrachloroethylene by Injection of Air and Methane, Innovative Remedial

Technology Information Request Guide.

DOE, 1991. "Modeling Bioremediation Experiments at SRS ID," FY92

Technical Task Description, TTP No. AL 1211-02.

DOE, 1992. "SRS Integrated Demo: Remediation Tasks," FY92 Technical Task

Description, TTP Reference Number: SR 1211-06.

DOE-SR, 1993. Technical Name: Methanotrophic In Situ Bioremediation

Using Methane/Air and Gaseous Nutrient Injection Via Horizontal Wells,

Technology Information Profile, Rev. 2, DOE ProTech Database, TTP

Reference Number: SR-1211-06.

DOE, 1991. "VOCs in Non-Arid Soils Integration Demonstration, Analysis,

and Evaluation Task," FY92 Technical Task Summary/Description, TTP

Reference Number: SF 2111-01.

MK01\RPT:02281012.009\compgde.430

4-122

08/21/95

4.30 CO-METABOLIC PROCESSES

Site Information:

Site Name

Tinker AFB

and ORNL

DOE Savannah

River Site

Aiken, SC

Contact

Summary

Alison Thomas

AL/EQW-OL

139 Barnes Drive

Tyndall AFB, FL 32403

(904) 283-6303

Ex situ methanotrophic

bioreactor

Terry C. Hazen

Westinghouse Savannah

River Co.

P.O. Box 616

Bldg. 773-42A

Aiken, SC 29802

(803) 725-5178

Methane and air injected

into seepage basin by

horizontal wells

Bendix

Corp./Allied

Automotive

St. Joseph, MI

NA

Beginning

Levels

Levels

Attained

Costs

NA

NA

NA

TCE/PCE

<2 ppb

$150K cap

NA

CERCLA Lead Predesign - TCE, DCE, DCA,

anaerobic cycle to treat

VC

TCE

NA

NA

Note: NA = Not Available.

Points of Contact:

Contact

Government Agency

Phone

Location

Ronald Lewis

EPA RREL

(513) 569-7856

Fax: (513) 569-7620

26 West M.L. King Dr.

Cincinnati, OH 45268

Technology

Demonstration and

Transfer Branch

USAEC

(410) 671-2054

Fax: (410) 612-6836

SFIM-AEC-ETD

APG, MD 21010-5401

Kurt Gerdes

DOE

(301) 903-7289

EM-551, Trevion II

Washington, DC 20585

MK01\RPT:02281012.009\compgde.430

4-123

08/21/95

You might also like

- Lecture 8 MetalsDocument53 pagesLecture 8 MetalsManga 01No ratings yet

- Labor Productivity Output RateDocument12 pagesLabor Productivity Output RateCarl Manzano100% (1)

- 2008 CAPE Chemistry Unit 1 Paper 1Document10 pages2008 CAPE Chemistry Unit 1 Paper 1Michael Huffman0% (1)

- Tundish RefractoryDocument15 pagesTundish RefractoryMashiur RahmanNo ratings yet

- Membrane Technology in Water Treatment ApplicationsDocument11 pagesMembrane Technology in Water Treatment ApplicationsleechulmiuNo ratings yet

- Direct Methane to Methanol: Foundations and Prospects of the ProcessFrom EverandDirect Methane to Methanol: Foundations and Prospects of the ProcessNo ratings yet

- NALCO Optimized Desalting As A Key in Development of A Refinery Profitability and ReliabilityDocument11 pagesNALCO Optimized Desalting As A Key in Development of A Refinery Profitability and Reliabilitysaleh4060No ratings yet

- CH2M HILL Wastewater Treatment Design OperationDocument10 pagesCH2M HILL Wastewater Treatment Design OperationpennywiserNo ratings yet

- Overview of The Cost of Desalinated Wate PDFDocument14 pagesOverview of The Cost of Desalinated Wate PDFAhmed AnsariNo ratings yet

- Grounwater RemediationDocument6 pagesGrounwater RemediationCarlos AponteNo ratings yet

- Conversion of CO2 To Formic Acid Using A SolidDocument7 pagesConversion of CO2 To Formic Acid Using A Solidsigit cahyonoNo ratings yet

- InTech-Drilling Fluid Technology Performances and Environmental Considerations PDFDocument30 pagesInTech-Drilling Fluid Technology Performances and Environmental Considerations PDFshuvo134No ratings yet

- Aloe VeraDocument10 pagesAloe VeraIrvany PetitNo ratings yet

- CH 058Document6 pagesCH 058MapeixNo ratings yet

- 10 1016@j Desal 2006 09 007 PDFDocument6 pages10 1016@j Desal 2006 09 007 PDFMimi TanNo ratings yet

- Bio#324NicholsPaper FinalDocument8 pagesBio#324NicholsPaper FinalJim LetourneauNo ratings yet

- sg5000 CasestudyDocument8 pagessg5000 CasestudyPetronio MontezumaNo ratings yet

- CLAIRE RP3 MembersOnlyDocument77 pagesCLAIRE RP3 MembersOnlyNatalia RuizNo ratings yet

- Bioreactor Landfills For Sustainable Solid Waste ManagementDocument12 pagesBioreactor Landfills For Sustainable Solid Waste Managementdhriti9No ratings yet

- Application of The Combined Ultrafiltration and Reverse Osmosis For Refinery Wastewater Reuse in Sinopec Yanshan PlantDocument11 pagesApplication of The Combined Ultrafiltration and Reverse Osmosis For Refinery Wastewater Reuse in Sinopec Yanshan PlanteducacionNo ratings yet

- Recent Progress in Syngas Production Via Catalytic CO2 Hydrogenation ReactionDocument11 pagesRecent Progress in Syngas Production Via Catalytic CO2 Hydrogenation Reactionkishore dasmunshiNo ratings yet

- GTL Conversion ProcessesDocument4 pagesGTL Conversion Processesslidey1No ratings yet

- Seminários 7Document6 pagesSeminários 7Angeline MoraisNo ratings yet

- 1 s2.0 S2666016423001366 MainDocument10 pages1 s2.0 S2666016423001366 MainChan Yong SoonNo ratings yet

- Kao 2008Document8 pagesKao 2008Julio Cesar Lopez UrregoNo ratings yet

- Copper Doped ZnODocument12 pagesCopper Doped ZnOkarthik tvkNo ratings yet

- 2018, Fu Et Al., Surface Reduced CeO2 Nanowires For Direct Conversion of CO2 and Methanol To Dimethyl CarbonateDocument11 pages2018, Fu Et Al., Surface Reduced CeO2 Nanowires For Direct Conversion of CO2 and Methanol To Dimethyl CarbonateDanielNo ratings yet

- 2020 Geron SpeekLIZDocument16 pages2020 Geron SpeekLIZGeronimo Perez HerreroNo ratings yet

- Bioreactor LandfillDocument23 pagesBioreactor LandfillMayuri Yadav100% (1)

- WaterSA 2002 01 1418aDocument14 pagesWaterSA 2002 01 1418aCleto TundumulaNo ratings yet

- Aniket and ChetanDocument18 pagesAniket and ChetanPrajakta NanoteNo ratings yet

- We Air Oxidation As A Pretreatment Option For Selective Biodegradability Enhancement and Biogas Generation Potential From Complex Effluent BTDocument8 pagesWe Air Oxidation As A Pretreatment Option For Selective Biodegradability Enhancement and Biogas Generation Potential From Complex Effluent BTsarath6142No ratings yet

- Long-Term Evaluation of A Forward Osmosis-Nanofiltration Demonstration Plant For Wastewater Reuse in AgricultureDocument39 pagesLong-Term Evaluation of A Forward Osmosis-Nanofiltration Demonstration Plant For Wastewater Reuse in Agriculturesamson.idabuNo ratings yet

- Advanced Oxidation ProcesssesDocument25 pagesAdvanced Oxidation ProcesssesDHANANJAY RAJNIKANTBHAI BODANo ratings yet

- Galeano Et Al 2020-3Document14 pagesGaleano Et Al 2020-3Arturo MeloNo ratings yet

- 116CH0120 RP ReportDocument12 pages116CH0120 RP ReportAscender ZeusNo ratings yet

- Photocatalytic Degradation of P-Nitrophenol in An Annular Column Photoreactor and The IntermediatesDocument7 pagesPhotocatalytic Degradation of P-Nitrophenol in An Annular Column Photoreactor and The Intermediatessulihah12No ratings yet

- Desalination: Marcel Melo, Helga Schluter, Jailton Ferreira, Rosana Magda, Agenor Júnior, Oswaldo de AquinoDocument3 pagesDesalination: Marcel Melo, Helga Schluter, Jailton Ferreira, Rosana Magda, Agenor Júnior, Oswaldo de AquinoAhmed AliNo ratings yet

- Research Papers On Fuel Cell TechnologyDocument4 pagesResearch Papers On Fuel Cell Technologypqltbarif100% (1)

- 01 EST CHCSourceRemediation Stroo Et Al 2012Document10 pages01 EST CHCSourceRemediation Stroo Et Al 2012Fabiano Rodrigues dos SantosNo ratings yet

- 11 TechLeaders v9n3 FINALDocument3 pages11 TechLeaders v9n3 FINALvishesh0211No ratings yet

- Fraga Dubreuil2006Document8 pagesFraga Dubreuil2006Phuong Duy Nguyen HoangNo ratings yet

- Biweekly 2 SeminarDocument6 pagesBiweekly 2 SeminarShailendra ChaudekarNo ratings yet

- ICES 2017 - DRAFT Number 166Document10 pagesICES 2017 - DRAFT Number 166GIUSEPPE BONZANONo ratings yet

- 1 s2.0 S2212827114012219 MainDocument5 pages1 s2.0 S2212827114012219 MainRezkiTriNurrachmadNo ratings yet

- Quantifying The Inhibitory Impact of Soluble Phenolics On Anaerobic Carbon Mineralization in A Thawing Permafrost PeatlandDocument19 pagesQuantifying The Inhibitory Impact of Soluble Phenolics On Anaerobic Carbon Mineralization in A Thawing Permafrost PeatlandkshariqmNo ratings yet

- LNAPLs Spill Makati 2Document9 pagesLNAPLs Spill Makati 2Mohammad NamaeeNo ratings yet

- Groundwater Remediation TechnologiesDocument108 pagesGroundwater Remediation TechnologiesjoesuhreNo ratings yet

- Physical Solvent Compare PDFDocument6 pagesPhysical Solvent Compare PDFHyungwoong AhnNo ratings yet

- Advanced Treatment of Shale Gas Fracturing Water To Produce Re-Use or Discharge Quality Water ... (PDFDrive)Document98 pagesAdvanced Treatment of Shale Gas Fracturing Water To Produce Re-Use or Discharge Quality Water ... (PDFDrive)سعيد الهاديNo ratings yet

- 2022 - Efficacies of Nitrogen Removal and Comparisons of Microbial Community in Full ScaleDocument16 pages2022 - Efficacies of Nitrogen Removal and Comparisons of Microbial Community in Full Scalesupaporn.phanNo ratings yet

- Chapter 1Document27 pagesChapter 1Isha MeshramNo ratings yet

- Li 2021Document21 pagesLi 2021yogaNo ratings yet

- Module 21: Anaerobic Wastewater Treatment Processes Lecture 33: Anaerobic Wastewater Treatment ProcessesDocument12 pagesModule 21: Anaerobic Wastewater Treatment Processes Lecture 33: Anaerobic Wastewater Treatment ProcessesSabhari NatarajanNo ratings yet

- Accepted Manuscript: Ultrasonics SonochemistryDocument24 pagesAccepted Manuscript: Ultrasonics SonochemistrySiddhartha MoulikNo ratings yet

- Liu 2021Document10 pagesLiu 2021Zoran VranesevitchNo ratings yet

- Technical Economic Analyses The Development Bioremediation ProcessesDocument14 pagesTechnical Economic Analyses The Development Bioremediation ProcessesRodolfo Angulo OlaisNo ratings yet

- Aali-Paper, November, With D.reference 2013Document25 pagesAali-Paper, November, With D.reference 2013Ali Abdul-RahmanNo ratings yet

- Field Application of Glycerol To Enhance Reductive Dechlorination - 2022 - ChemoDocument9 pagesField Application of Glycerol To Enhance Reductive Dechlorination - 2022 - ChemoDana MateiNo ratings yet

- Ijee 6 (2) - 07Document8 pagesIjee 6 (2) - 07Ali Abdul-RahmanNo ratings yet

- Highly-Defective Fe-N-C Catalysts Towards pH-Universal Oxygen Reduction ReactionDocument24 pagesHighly-Defective Fe-N-C Catalysts Towards pH-Universal Oxygen Reduction Reactionliuyimin20100201No ratings yet

- Thermophilic Versus Mesophilic Anaerobic DigestionDocument14 pagesThermophilic Versus Mesophilic Anaerobic DigestionatmanebensaidNo ratings yet

- 4.applied Catalysis BDocument8 pages4.applied Catalysis BCristianAtanasiuNo ratings yet

- Technologies and Costs For Coalbed Methane Produced Water TreatmentDocument25 pagesTechnologies and Costs For Coalbed Methane Produced Water TreatmentManash MudoiNo ratings yet

- Route of The Catalytic Oxidation of Phenol in Aqueous PhaseDocument17 pagesRoute of The Catalytic Oxidation of Phenol in Aqueous Phaseedgarpinzon21No ratings yet

- DustBoss ManualDocument33 pagesDustBoss ManualMichael Huffman100% (1)

- PERSONAL PROTECTION Half Mask RespiratorsDocument1 pagePERSONAL PROTECTION Half Mask RespiratorsMichael HuffmanNo ratings yet

- Intro To Hydraulics PDFDocument28 pagesIntro To Hydraulics PDFsurjitvarmaNo ratings yet

- Innovative TechDocument200 pagesInnovative TechMichael HuffmanNo ratings yet

- Bio SpargingDocument40 pagesBio SpargingMichael HuffmanNo ratings yet

- Types of BeltsDocument5 pagesTypes of BeltsMichael Huffman50% (2)

- 4.22 - Hot Gas DecontaminationDocument3 pages4.22 - Hot Gas DecontaminationMichael HuffmanNo ratings yet

- 4.44 - Air StrippingDocument4 pages4.44 - Air StrippingMichael HuffmanNo ratings yet

- How A Cyclone Dust Collector WorksDocument2 pagesHow A Cyclone Dust Collector WorksMichael HuffmanNo ratings yet

- Materials: Steel Gold Wood Plastic Glass CeramicDocument4 pagesMaterials: Steel Gold Wood Plastic Glass Ceramicedison sebastian buitragoNo ratings yet

- Metal Technology Aluminium Casement WindowsDocument6 pagesMetal Technology Aluminium Casement WindowsmuzNo ratings yet

- Concrete 22Document11 pagesConcrete 22Kurt CargoNo ratings yet

- A Comparative Study of Sodium Hydrogen Titanate Nanotubes 2017 Journal of CDocument10 pagesA Comparative Study of Sodium Hydrogen Titanate Nanotubes 2017 Journal of CDes RiliNo ratings yet

- Visual Classification of SoilDocument11 pagesVisual Classification of SoilTISHA ANNE DE GRACIANo ratings yet

- 68-0003-B09-0005 - Cold Room CeilingDocument30 pages68-0003-B09-0005 - Cold Room CeilingBahia El RefaiNo ratings yet

- The Structure of The Blue Starch - Iodine ComplexDocument2 pagesThe Structure of The Blue Starch - Iodine ComplexBryan Mesala Rhodas GarciaNo ratings yet

- Form 4 Chapter 2 Paper 1Document82 pagesForm 4 Chapter 2 Paper 1FakhriahNo ratings yet

- Form 3 Chemistry Assignment (WK 8)Document3 pagesForm 3 Chemistry Assignment (WK 8)JOSEPH MWANGINo ratings yet

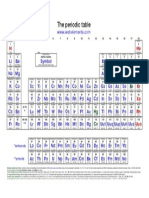

- Periodic Table PDFDocument0 pagesPeriodic Table PDFStetson TurnerNo ratings yet

- Operation and Maintenance of Hydro TunnelsDocument49 pagesOperation and Maintenance of Hydro TunnelsAbhushan NeupaneNo ratings yet

- Rubber Standards in Today's World Economy: Special ReportDocument5 pagesRubber Standards in Today's World Economy: Special ReportMina RemonNo ratings yet

- Guide To Photographic Paper Surfaces CharacteristicsDocument61 pagesGuide To Photographic Paper Surfaces CharacteristicsJorgeCamachoNo ratings yet

- AQA Level 1/2 Certificate in Chemistry - IGCSE' (Draft) - Atoms and BondingDocument3 pagesAQA Level 1/2 Certificate in Chemistry - IGCSE' (Draft) - Atoms and BondingFarahAlAsaadNo ratings yet

- Hot-Rolled - Plate: Data SheetDocument2 pagesHot-Rolled - Plate: Data SheetRichard Vica CalvoNo ratings yet

- Interpretation of Cyclic Potentiodynamic Polarization Test ResultsDocument15 pagesInterpretation of Cyclic Potentiodynamic Polarization Test ResultsPedroSoucasauxNo ratings yet

- BS115Document7 pagesBS115Virendra vishwakarmaNo ratings yet

- Warren Concrete LimitedDocument18 pagesWarren Concrete LimitedCaleb ChegeNo ratings yet

- Tile Grout CalculationDocument1 pageTile Grout CalculationMarivic D. SantosNo ratings yet

- Powercrete R-65/F1: Product Data SheetDocument2 pagesPowercrete R-65/F1: Product Data SheetFernando Ytozu TairaNo ratings yet

- Ladd Casagrande 2003Document57 pagesLadd Casagrande 2003DIJ Ingeniería y Servicios S.A.SNo ratings yet

- Eccu 211 Manual T10Document36 pagesEccu 211 Manual T10Flow a ThousandNo ratings yet

- Stainless 316, 316L, 317, 317L: Element Percent by Weight Maximum Unless Range Is Specified 316 316L 317 317LDocument3 pagesStainless 316, 316L, 317, 317L: Element Percent by Weight Maximum Unless Range Is Specified 316 316L 317 317LAvijit SharmaNo ratings yet

- Study of The Arc Interruption Performance of SF6 Alternative Gases in Load SwitchDocument5 pagesStudy of The Arc Interruption Performance of SF6 Alternative Gases in Load Switchs201291072No ratings yet

- Catalogus 2014 Compleet - LR PDFDocument215 pagesCatalogus 2014 Compleet - LR PDFJacob ReedNo ratings yet

- Jain International School Rate of Evaporation of LiquidsDocument14 pagesJain International School Rate of Evaporation of LiquidsGAUNo ratings yet