Professional Documents

Culture Documents

Din 17671

Din 17671

Uploaded by

Niculescu MarianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Din 17671

Din 17671

Uploaded by

Niculescu MarianCopyright:

Available Formats

www.TubeSolution.

com

Global Marketing for Tube & Pipe

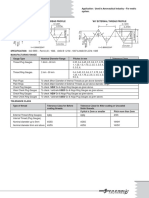

DIN 17671 Part 1 WROUGHT COPPER AND COPPER ALLOY TUBES Properties

1.Field of application

In conjunction with the technical delivery conditions specified in DIN 17671 Part 2, this standard specifies the properties of wrought copper and copper alloy tubes for the

dimensional ranges of wall thickness and for outside diameters up to 350mm, as listed in the tables.

The properties of tubes with dimensions outside the dimensional ranges specified shall be agreed at the time of ordering.

Table 1. Copper (composition in accordance with DIN 1787)

Tensile

0.2%proof

Elongation

Wall thickness

strength

stress

after fracture

mm

Rm

Rp 0.2

A5 %

N/

N/

min

Material

Designation

Number

SF-Cu

Brinell

hardness

HB

2.0090

p

.08

zh

.20

F20

To be agreed.

No strength values specified.

.10

over 3

200 to 260

max. 110

40

55

F22

.10

up to 3

220 to 270

max. 140

40

55

F25

.26

0.5 to 10

250 to 300

min. 150

20

80

F29

.30

up to 5

min. 290

min. 250

95

F36

.32

up to 3

min. 360

min 320

110

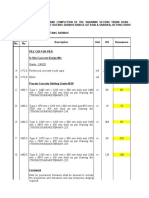

Table 2. Copper-zinc alloys without further alloying elements (Brass) (composition in accordance with DIN 17660)

Material

Designation

Number 1)

CuZn5

2.0220

Tensile

0.2%proof

Elongation

Wall thickness

strength

stress

after fracture

mm

Rm

Rp 0.2

A5 %

N/

N/

min

Brinell

hardness

HB

www.TubeSolution.com

Global Marketing for Tube & Pipe

P

.08

To be agreed.

No strength values specified.

F22

.10

up to 10

220 to 260

max.130

40

60

F26

.26

up to 10

260 to 320

min. 190

19

85

F32

.30

up to 5

min. 320

min. 260

110

.08

To be agreed.

No strength values specified.

F26

.10

up to 10

260 to 310

max.150

45

65

F31

.26

up to 10

310 to 370

min. 200

23

95

F37

.30

up to 5

min. 370

min. 290

11

120

.08

To be agreed.

No strength values specified.

F27

.10

up to 10

270 to 320

max.160

47

65

F32

.26

up to 10

320 to 390

min. 200

25

100

F39

.30

up to 5

min. 390

min. 300

13

25

.08

To be agreed.

No strength values specified.

F28

.10

up to 10

280 to 350

max.180

50

70

F35

.26

up to 10

250 to 420

min. 200

28

110

F42

.30

up to 5

min. 420

min. 320

13

130

To be agreed.

No strength values specified.

CuZn15

2.0240

CuZn20

2.0250

CuZn30

2.0265

CuZn36

2.0335

CuZn37

2.0321

P

.08

zh

.20

F29

.10

up to 10

290 to 370

max.180

50

70

F37

.26

up to 10

370 to 440

min. 200

27

110

www.TubeSolution.com

Global Marketing for Tube & Pipe

F44

.30

up to 5

440 to 540

min. 340

12

135

F54

.32

up to 2

370 to 440

min. 470

160

.08

To be agreed.

No strength values specified.

F34

.10

up to 10

min. 340

max.220

35

80

F41

.26

up to 10

min. 410

min. 220

20

115

F47

.30

up to 5

min. 470

min. 350

11

140

CuZn40

2.0360

1) The appended numbers.26, 30 and 32 do not apply for the non-stress relieved condition. No values have been specified for strain-hardened stress relieved conditions.

Table 3. Leaded copper-zinc alloys (composition in accordance with DIN 17660)

Table 4. Copper-zinc alloys with further alloying elements (special brass) (composition in accordance with DIN 17660)

Tensile

0.2%proof

Elongation

Wall thickness

strength

stress

after fracture

mm

Rm

Rp 0.2

A5 %

N/

N/

min

Material

Designation

Number

CuZn20 Al2

CuZn23Al6Mn4Fe3

HB

.08

To be agreed.

No strength values specified.

F22

.10

up to 10

330

120

35

85

up to 20

780

540

190

F78

2.0500.88

2.0490

(CuZn31Si)

(CuZn35Ni)

hardness

2.0460

CuZn31Si 1

CuZn35Ni2

Brinell

.08

To be agreed.

No strength values specified.

F44

.27

1 to 8

440

200

30

120

F49

.31

1 to 8

490

290

15

160

2.0540

www.TubeSolution.com

Global Marketing for Tube & Pipe

P

.08

To be agreed.

No strength values specified.

F49

.27

3 to12

490

290

18

130

F54

.31

3 to 8

540

390

14

150

.08

To be agreed.

No strength values specified.

F39

.09

3 to12

390

150

25

110

F44

.27

3 to 8

440

200

20

120

F59

.31

3 to 8

490

260

15

140

.08

To be agreed.

No strength values specified.

F44

.27

4 to 12

540

230

15

150

F49

.31

4 to10

590

250

10

160

.08

To be agreed.

No strength values specified.

F44

.27

3 to12

440

180

20

125

F49

.31

3 to 8

490

270

18

140

.08

To be agreed.

No strength values specified.

F39

.09

3 to12

390

150

22

110

F44

.27

3 to 8

440

180

18

125

F49

.31

2 to 5

490

290

15

140

CuZn40 Al1

2.0561

CuZn40 Al2

2.0550

CuZn40Mn

2.0572

(CuZn40Mn)

CuZn40Mn 1Pb

2.0580

(CuZn40MnPb)

1) Some designations have been amended in accordance with DIN 17660. The previous designations are given in brackets for the purposes of information.

Table 5. Copper-tin alloys (tin bronze) (composition in accordance with DIN 17662)

www.TubeSolution.com

Global Marketing for Tube & Pipe

Tensile

0.2%proof

Elongation

Wall thickness

strength

stress

after fracture

mm

Rm

Rp 0.2

A5 %

N/

N/

min

Material

Designation

Number

CuSn6

Brinell

hardness

HB

2.1020

P

.08

To be agreed.

No strength values specified.

F34

.10

up to 5

340 to 400

max.260

55

85

F40

.26

up to 5

400 to 490

min. 220

30

135

F49

.30

up to 2

490 to 610

min. 390

12

155

F61

.32

up to 2

min. 610

min. 510

185

.08

To be agreed.

No strength values specified.

F34

.10

up to 5

390 to 450

max.290

60

90

F40

.26

up to 5

450 to 540

min. 250

28

145

F46

.30

up to 2

min. 540

min. 460

10

170

CuSn8

2.1030

Table 6. Copper-nickel-zinc alloys (nickel siver) (composition in accordance with DIN 17663)

Material

Designation

Number

CuNi12Zn20

Tensile

0.2%proof

Elongation

Wall thickness

strength

stress

after fracture

mm

Rm

Rp 0.2

A5 %

N/

N/

min

Brinell

hardness

HB

2.1020

P

.08

To be agreed.

No strength values specified.

F34

.10

up to 3

340 to 420

max.290

45

85

F42

.26

up to 3

420 to 490

min. 240

28

125

F49

.30

up to 2

min. 490

min. 390

12

150

.08

To be agreed.

No strength values specified.

F37

.10

up to 3

370 to 440

40

95

CuNi18Zn20

2.1030

max.290

www.TubeSolution.com

Global Marketing for Tube & Pipe

F44

.26

up to 3

440 to 540

min. 290

20

135

F54

.30

up to 2

min. 540

min. 470

150

Table 7. Copper-nickel alloys (composition in accordance with DIN 17 664)

Tensile

0.2%proof

Elongation

Wall thickness

strength

stress

after fracture

mm

Rm

Rp 0.2

A5 %

N/

N/

min

Material

Designation *)

Number

CuNi10Fe1Mn

Brinell

hardness

HB

2.0872

(CuNi10Fe)

P

.08 To be agreed.

No strength values specified.

F34

.10 up to 5

min. 290

.08 To be agreed.

No strength values specified.

F36

.10 up to 5

360 to 490

CuNi30Mn1Fe

min. 90

30

80

30

100

2.0882

(CuNi30Fe)

min. 120

*) Some designations have been amended in accordance with DIN 17 664. The previous designations are given in brackets for the purposes of information.

Table 8. Copper-aluminum alloys (aluminum bronze) (composition in accordance with DIN 17665)

Material

Tensile

Designation *)

Number 1)

Wall thickness

strength

mm

Rm

N/

0.2%proof

stress

Rp 0.2

N/

min

CuAl8

Elongation

after fracture

A5 %

min

Brinell

hardness

HB

2.0920

P

.08

To be agreed.

No strength values specified.

F37

.10

2 to10

370 to 450

130

35

90

F49

.30

2 to 8

min. 490

270

15

130

www.TubeSolution.com

Global Marketing for Tube & Pipe

CuAl8Fe

2.0932

(CuAl8Fe)

P

.08

To be agreed.

No strength values specified.

F39

.10

4 to12

390 to 490

150

30

110

F54

.30

4 to 8

min. 540

270

12

145

.08

To be agreed.

No strength values specified.

F64

.98

4 to 8

min. 640

10

165

.08

To be agreed.

No strength values specified.

F44

.27

3 to12

440

180

20

125

F49

.31

3 to 8

490

270

18

140

.08

To be agreed.

No strength values specified.

F64

.97

4 to 12

min. 640

10

180

.08

To be agreed.

No strength values specified.

F69

.97

2 to 5

490

15

140

CuAl10FeMn2

2.0936

(CuAl10Fe)

CuAl9Mn2

290

2.0960

(CuAl9Mn)

CuZn40Mn 1Pb

2.0580

(CuZn40MnPb)

CuAl11Ni6Fe5

340

2.0978

(CuAl11Ni)

290

*) Some designations have been amended in accordance with DIN 17665. The previous designations are given in brackets for the purposes of information.

1) The appended number. 30 does not apply for the non-stress relived condition. If, subject to a particular agreement, the tubes are to be supplied in the stress relived in

the stress relieved condition, the appended number is to be changed into 3.1.

You might also like

- ASTM Material Changes: CCFSS Technical BulletinDocument6 pagesASTM Material Changes: CCFSS Technical BulletinkfctcoNo ratings yet

- Bucket Elevator CatalogDocument20 pagesBucket Elevator CatalogLeonardo De la CruzNo ratings yet

- 1 2312 PDFDocument4 pages1 2312 PDFFrancisco CarrascoNo ratings yet

- Metal matrix composites: Processing and InterfacesFrom EverandMetal matrix composites: Processing and InterfacesR EverettNo ratings yet

- ASTM A 192A 192M 02 Standard Specification For Seamless Carbon Steel Boiler Tubes For High Pressure Service1 PDFDocument3 pagesASTM A 192A 192M 02 Standard Specification For Seamless Carbon Steel Boiler Tubes For High Pressure Service1 PDFjromero_rpgNo ratings yet

- Super Duplex Stainless Steel: Excellent Engineering SolutionsDocument4 pagesSuper Duplex Stainless Steel: Excellent Engineering SolutionsTXUSNo ratings yet

- Carbon Steel Tee Rails: Standard Specification ForDocument7 pagesCarbon Steel Tee Rails: Standard Specification ForAAYNo ratings yet

- Simmerrings PDFDocument152 pagesSimmerrings PDFGogyNo ratings yet

- 25CrMo4 (EN 10083 3)Document2 pages25CrMo4 (EN 10083 3)mohsen_267No ratings yet

- Of The Nuclear Safety Standards Commission (KTA)Document123 pagesOf The Nuclear Safety Standards Commission (KTA)smallik3No ratings yet

- Data Sheet REMALOX (ENG)Document1 pageData Sheet REMALOX (ENG)anggada satriaNo ratings yet

- A743A743MDocument7 pagesA743A743MAnonymous ggwJDMh8No ratings yet

- Design Requirements of Precoat Filters For Water FiltrationDocument445 pagesDesign Requirements of Precoat Filters For Water FiltrationYesi CeballosNo ratings yet

- Iso 148-1-2009Document33 pagesIso 148-1-2009alecuNo ratings yet

- QU AL ITY: Material Data SheetDocument5 pagesQU AL ITY: Material Data SheetAlex007No ratings yet

- Material Comparison F316L Vs F321Document1 pageMaterial Comparison F316L Vs F321Vivi OktaviantiNo ratings yet

- PPT: Materials Used in Mechanical DesignDocument50 pagesPPT: Materials Used in Mechanical DesignMuhammad afzal100% (1)

- SC470-P Four Inch STUB Cyclone 2016Document2 pagesSC470-P Four Inch STUB Cyclone 2016Tobias De Somer100% (1)

- Astm A 27 PDFDocument4 pagesAstm A 27 PDFRyan LasacaNo ratings yet

- Normas Sistemas de Transmicion de PotenciaDocument10 pagesNormas Sistemas de Transmicion de PotenciaCristian Gonzalez ThomasNo ratings yet

- Cracks in High-Manganese Cast Steel: Archives of Foundry EngineeringDocument6 pagesCracks in High-Manganese Cast Steel: Archives of Foundry EngineeringAgil SetyawanNo ratings yet

- RJR PMMTDocument16 pagesRJR PMMTArun PrasadNo ratings yet

- Rema Tip Top Unigrip CR L 215Document2 pagesRema Tip Top Unigrip CR L 215dedison_rNo ratings yet

- ASTM A356 A356M - 07 Steel CastingsDocument6 pagesASTM A356 A356M - 07 Steel CastingsMacario LeyvaNo ratings yet

- Mat 3422 For Suppliers PDFDocument3 pagesMat 3422 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Norma de Rosca Metrica MJDocument1 pageNorma de Rosca Metrica MJXANANo ratings yet

- Astm A204 A204m PDFDocument3 pagesAstm A204 A204m PDFKaterynaNo ratings yet

- Brass MachiningDocument68 pagesBrass MachiningVaibhav ShuklaNo ratings yet

- Nfa 49 310 Grade Tu 52 B Tubes PDFDocument1 pageNfa 49 310 Grade Tu 52 B Tubes PDFMitul MehtaNo ratings yet

- Datasheet Sandvik 2re69 enDocument9 pagesDatasheet Sandvik 2re69 enMuzammilNo ratings yet

- Pulp and PaperDocument8 pagesPulp and PaperDevanshGoenkaNo ratings yet

- Astm A307Document1 pageAstm A307SAlman Khan100% (1)

- MssDocument8 pagesMssGuillermo Gonzales AmayaNo ratings yet

- Astm A24 (2001) PDFDocument4 pagesAstm A24 (2001) PDFJim FrostNo ratings yet

- Iso 9445 2 2009Document9 pagesIso 9445 2 2009Kerem ErtemNo ratings yet

- ASTM A-802 - Falhas de FundiçãoDocument3 pagesASTM A-802 - Falhas de FundiçãoCristian RodeghelNo ratings yet

- Oliver Equation Paper-1928Document38 pagesOliver Equation Paper-1928dps32100% (1)

- Nickel Al Bronze Guide Engineers PDFDocument100 pagesNickel Al Bronze Guide Engineers PDFSenakeNo ratings yet

- Din 7623Document2 pagesDin 7623Racha Amel100% (1)

- General Documentation - RecrystallizationDocument11 pagesGeneral Documentation - RecrystallizationAlbokeaNo ratings yet

- UHMW-PE (Ultra High Molecular Weight - Polyethylene)Document2 pagesUHMW-PE (Ultra High Molecular Weight - Polyethylene)Gaurav PatilNo ratings yet

- Držači Osovina DIN 15058 PDFDocument1 pageDržači Osovina DIN 15058 PDFMartin JurmanNo ratings yet

- HASLE Datasheet OverviewDocument2 pagesHASLE Datasheet OverviewkINGNo ratings yet

- 1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFDocument2 pages1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFrabmusukeNo ratings yet

- Gear FailuresDocument12 pagesGear FailuresAnshuman RoyNo ratings yet

- Supply Flange ANSI B16.5 Slip On Flange, SORF Flange, Class 150LBS To 1500LBS - Jinan Hyupshin Flanges Co., LTDDocument3 pagesSupply Flange ANSI B16.5 Slip On Flange, SORF Flange, Class 150LBS To 1500LBS - Jinan Hyupshin Flanges Co., LTDSandipNo ratings yet

- Kisssoft Tut 003 E KeyDocument11 pagesKisssoft Tut 003 E KeyJorge Ronald Cabrera ÑaupaNo ratings yet

- Sepction - 3Document3 pagesSepction - 3k koradiaNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- En 10028 P355GHDocument2 pagesEn 10028 P355GHEvriMert RüzgArdaNo ratings yet

- Boliya Ji (Electric Lay Out)Document11 pagesBoliya Ji (Electric Lay Out)alive computerNo ratings yet

- Rubber Expansion Joint Double Sphere (Flanged End) PN16 911-2Document2 pagesRubber Expansion Joint Double Sphere (Flanged End) PN16 911-2Ariane Joy LucasNo ratings yet

- WELDING SPREADER Electrode KALMAR PDFDocument1 pageWELDING SPREADER Electrode KALMAR PDFArtin HykoNo ratings yet

- Compile Inventory 400kv Srinagar For August21 2192021Document48 pagesCompile Inventory 400kv Srinagar For August21 2192021priyanka k lNo ratings yet

- En8m and En24Document5 pagesEn8m and En24amh.fpdNo ratings yet

- Equivalent SpecificationsDocument4 pagesEquivalent SpecificationscvssbvNo ratings yet

- Web Datasheet A6.2Document4 pagesWeb Datasheet A6.2wolf_nsNo ratings yet

- Pier Pilecap MeasurementDocument103 pagesPier Pilecap MeasurementLiew Kuet KongNo ratings yet

- Ductile Iron Pipes General Information PDFDocument15 pagesDuctile Iron Pipes General Information PDFfernandoNo ratings yet

- Rifeng PAP 2Document37 pagesRifeng PAP 2Sota KarunaNo ratings yet

- JIS G 4314 S S S W: Tainless Teel Pring IREDocument2 pagesJIS G 4314 S S S W: Tainless Teel Pring IREVinaya Almane DattathreyaNo ratings yet

- Part 2 Navy e July10Document226 pagesPart 2 Navy e July10Marco MorrisNo ratings yet

- Seamless and Welded Copper-Nickel Tubes For Water Desalting PlantsDocument6 pagesSeamless and Welded Copper-Nickel Tubes For Water Desalting PlantsphuongqcNo ratings yet

- Crane Copper Tub Evie GaDocument22 pagesCrane Copper Tub Evie GaonspsnonsNo ratings yet

- Ms 01 180Document88 pagesMs 01 180FabricioNo ratings yet

- Astm A200 PDFDocument3 pagesAstm A200 PDFgaminNo ratings yet

- MS 01 180Document88 pagesMS 01 180DucVikingNo ratings yet

- EEMUA Publication CatDocument36 pagesEEMUA Publication CatLamija Lamy67% (3)

- Pressure Drop AdjustmentsDocument2 pagesPressure Drop AdjustmentsFaheem MushtaqNo ratings yet

- SS Tubing Technical Data - Pressure RatingDocument1 pageSS Tubing Technical Data - Pressure Rating채원종No ratings yet

- 3 ConduitsDocument9 pages3 ConduitsAlsayed Rabiea MiesalamNo ratings yet

- ASTM B188-2002 Tubos de CobreDocument10 pagesASTM B188-2002 Tubos de Cobrelinealmen100% (1)

- Autoclave CatalogueDocument12 pagesAutoclave CataloguecristianoclemNo ratings yet

- Sa 226Document4 pagesSa 226Raju SkNo ratings yet

- Astm A178Document0 pagesAstm A178flaviodellatorre0% (1)

- Sa 423Document6 pagesSa 423Widya widyaNo ratings yet

- 2 .875 Spec.Document35 pages2 .875 Spec.Daniel VanLiereNo ratings yet

- Copper Tube HandbookDocument92 pagesCopper Tube HandbookNivaldo100% (1)

- Aalco Stainless Steel Tube TubeDocument18 pagesAalco Stainless Steel Tube Tubearun100% (1)

- Astm A210 PDFDocument2 pagesAstm A210 PDFgaminNo ratings yet

- Astm A271 PDFDocument3 pagesAstm A271 PDFgaminNo ratings yet

- HTTP WWW - Wermac.org Fittings Buttweld Fittings Part5Document4 pagesHTTP WWW - Wermac.org Fittings Buttweld Fittings Part5prabu prasad100% (1)

- Stainless Steel CatalogDocument114 pagesStainless Steel CatalogSiva KumarNo ratings yet

- 04 - MDS Selection SoftwareDocument62 pages04 - MDS Selection SoftwarechinithNo ratings yet

- 2009 City Multi Modular Engineering ManualDocument676 pages2009 City Multi Modular Engineering ManualNiong DavidNo ratings yet

- Gooluck Steel TubesDocument15 pagesGooluck Steel TubesVelu SamyNo ratings yet

- Jis G3472 o Stam 440G PDFDocument13 pagesJis G3472 o Stam 440G PDFAxel TorresNo ratings yet

- Catalago ParkerDocument242 pagesCatalago ParkerandgomesvieiraNo ratings yet

- Sans657 3Document17 pagesSans657 3johndupNo ratings yet

- Tubes and SdfspipesDocument19 pagesTubes and SdfspipesScumfucOutlawNo ratings yet