Professional Documents

Culture Documents

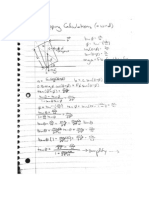

Hinge Stress and Tipping Calculations

Uploaded by

api-269308188Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hinge Stress and Tipping Calculations

Uploaded by

api-269308188Copyright:

Available Formats

Hinge

Stress

Calculations

Variable

A

rn

ci

co

ce

F

Formula

ht

d/ln(ro/ri)

rn-ri

ro-rn

rc-rn

Prc/t

A

cross

section

of

a

hinge.

In

this

case,

t

is

the

metal

thickness

and

h

is

the

hinge

height.

!! !

!

!! !

!

! = !!! !! + ! = 56

! = !!! !! + ! = 57

(1,2

! !

! !

The

yield

stress

of

aluminum

is

approximately

145MPa,

giving

a

safety

factor

of

about

3.

Wind

Load

Calculations

Assumptions:

Wind

speed

in

a

tropical

storm

V

=

32m/sec

Drag

coefficient

C

=

1.2

Panels

45

per

side,

A

=

2.61m2

!"#$%

!"#$% =

!"! !

!.!

= 2

= 0.5 cos +

= sin +

!!

= arctan !

Condition

for

tipping:

!"

tan + = !!

!"# ! !!"# !

!!!"# ! !"# (!)

!"

!!

(3

(4

(5

(6

(7

(8

(9

Tipping angle as a function of n, the number of stacked units:

!"#!!!"!

tan = !!"!!"#!

(10

This

graph

shows

the

number

of

stacked

units

on

the

x-axis

and

the

tipping

angle

on

the

y-

axis.

This

is

calculated

with

32m/sec

(tropical

storm

force)

winds

blowing

against

the

side

of

the

stack.

An

approximation

was

made

to

apply

this

total

force

only

at

the

very

top

of

the

stack

as

a

worst-case

scenario,

even

though

the

force

will

actually

be

distributed

across

the

entire

height

of

the

stack.

Number

of

Tipping

Number

of

Tipping

Stacked

Angle

in

Stacked

Angle

in

Units

(n)

Degrees

Units

(n)

Degrees

1

29.1

6

7.0

2

19.7

7

5.9

3

14.2

8

5.0

4

10.8

9

4.3

5

8.9

10

3.8

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Volvo Partx HandoutDocument2 pagesVolvo Partx Handoutapi-269308188No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 4 14 15Document2 pages4 14 15api-269308188No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Volvo CalculationsDocument2 pagesVolvo Calculationsapi-269308188No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Partx Fabrication StepsDocument10 pagesPartx Fabrication Stepsapi-269308188No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Tipping CalculationsDocument3 pagesTipping Calculationsapi-269308188No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 4 2 15Document2 pages4 2 15api-269308188No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Meeting Minutes 3/2/15 BTH, Stanford, and MartinDocument2 pagesMeeting Minutes 3/2/15 BTH, Stanford, and Martinapi-269308188No ratings yet

- Winter PresentationDocument27 pagesWinter Presentationapi-269308188No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Design Decisions 4 8Document1 pageDesign Decisions 4 8api-269308188No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- System StepsDocument1 pageSystem Stepsapi-269308188No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Volvo Corporate HandoutDocument1 pageVolvo Corporate Handoutapi-269308188No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Volvo Springplan HandoutDocument2 pagesVolvo Springplan Handoutapi-269308188No ratings yet

- Volvo FunkdesignhandoutDocument2 pagesVolvo Funkdesignhandoutapi-269308188No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Winter BrochureDocument2 pagesWinter Brochureapi-269308188No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Visionconcept Handout 1Document3 pagesVisionconcept Handout 1api-269308188No ratings yet

- Panel SizeDocument1 pagePanel Sizeapi-269308188No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Modularxconcept Handout-1Document2 pagesModularxconcept Handout-1api-269308188No ratings yet

- Darkhorse Prototype BTH Handout v3Document2 pagesDarkhorse Prototype BTH Handout v3api-269308188No ratings yet

- Dispenser Subsystem Prototype HandoutDocument4 pagesDispenser Subsystem Prototype Handoutapi-269308188No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 2 9 15Document1 page2 9 15api-269308188No ratings yet

- Functional B HandoutDocument2 pagesFunctional B Handoutapi-269308188No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- O Address Money IssueDocument1 pageO Address Money Issueapi-269308188No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Functional A HandoutDocument2 pagesFunctional A Handoutapi-269308188No ratings yet

- Cep HandoutDocument2 pagesCep Handoutapi-269308188No ratings yet

- Darkhorse2 HandoutDocument2 pagesDarkhorse2 Handoutapi-269308188No ratings yet

- Background - Observations and Identified Needs: Prevent The Occupation of Space?Document2 pagesBackground - Observations and Identified Needs: Prevent The Occupation of Space?api-269308188No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- 1 7 15Document1 page1 7 15api-269308188No ratings yet

- Darkhorse1 HandoutDocument2 pagesDarkhorse1 Handoutapi-269308188No ratings yet

- Sida1 1Document2 pagesSida1 1api-269308188No ratings yet

- Interview QuestionsDocument7 pagesInterview QuestionssangeethadurjatiNo ratings yet

- Shading DevicesDocument4 pagesShading DevicesAyush TyagiNo ratings yet

- Antioxidant Activity by DPPH Radical Scavenging Method of Ageratum Conyzoides Linn. LeavesDocument7 pagesAntioxidant Activity by DPPH Radical Scavenging Method of Ageratum Conyzoides Linn. Leavespasid harlisaNo ratings yet

- Team Leader WorkbookDocument171 pagesTeam Leader Workbooktousah2010No ratings yet

- Reg0000007635187Document2 pagesReg0000007635187Amal JimmyNo ratings yet

- CIRCUITS EXERCISE 03 MINIMUM CURRENT SOURCE VALUEDocument2 pagesCIRCUITS EXERCISE 03 MINIMUM CURRENT SOURCE VALUENiño John JaymeNo ratings yet

- Donor Selections..Document17 pagesDonor Selections..OmamaNo ratings yet

- Abortion Guide: Types, Causes and TreatmentDocument46 pagesAbortion Guide: Types, Causes and TreatmentNikhil TyagiNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- GDRatingDocument13 pagesGDRatingdgzaquinojcNo ratings yet

- RNYM02-1120A-12Document2 pagesRNYM02-1120A-12bastian silvaNo ratings yet

- Flexi Edge Bts SystemDocument25 pagesFlexi Edge Bts SystemMuty Koma67% (3)

- IMSP 21 Operational Control EMSDocument3 pagesIMSP 21 Operational Control EMSEvonne LeeNo ratings yet

- Range Brochure Wardrobes 2012Document23 pagesRange Brochure Wardrobes 2012Uci DutzuNo ratings yet

- đề 3Document12 pagesđề 3Vi CầmNo ratings yet

- Principles of Synthetic BiologyDocument21 pagesPrinciples of Synthetic BiologyOpale PapaleNo ratings yet

- REST API For Oracle Fusion Cloud HCMDocument19 pagesREST API For Oracle Fusion Cloud HCMerick landaverdeNo ratings yet

- What is Strategic Human Resource ManagementDocument8 pagesWhat is Strategic Human Resource ManagementYashasvi ParsaiNo ratings yet

- Quotes About Homework Being BannedDocument7 pagesQuotes About Homework Being Bannedafeuhyxst100% (1)

- ZDocument6 pagesZDinesh SelvakumarNo ratings yet

- Pre CRM at RelianceDocument3 pagesPre CRM at RelianceSonali SinghNo ratings yet

- Adrenergic SystemDocument6 pagesAdrenergic SystemdocsNo ratings yet

- Case Study Assignment Sime Darby-R.M.A.Hasan Chowdhury (ID-1600061) PDFDocument13 pagesCase Study Assignment Sime Darby-R.M.A.Hasan Chowdhury (ID-1600061) PDFRaihan Mahmood50% (6)

- Analysis of NOx in Ambient AirDocument12 pagesAnalysis of NOx in Ambient AirECRDNo ratings yet

- WMA14 01 Rms 20220199 UNUSEDDocument17 pagesWMA14 01 Rms 20220199 UNUSEDVanessa NgNo ratings yet

- Trading Rules Strategies William F EngDocument290 pagesTrading Rules Strategies William F EngDheeraj Suntha100% (10)

- Mathematics Form 1Document339 pagesMathematics Form 1JacintaRajaratnam67% (9)

- DepEd Tayo Training Series Accomplishment Report Sapang Maragul Integrated School JHS DepartmentDocument6 pagesDepEd Tayo Training Series Accomplishment Report Sapang Maragul Integrated School JHS DepartmentTeng SevillaNo ratings yet

- Business and Tech Mock Exam (8Document11 pagesBusiness and Tech Mock Exam (8Jack PayneNo ratings yet

- Sources of FundsDocument22 pagesSources of FundsImtiaz RashidNo ratings yet

- The Best Chicken Quesadillas - Mel's Kitchen Cafe 4Document1 pageThe Best Chicken Quesadillas - Mel's Kitchen Cafe 4Yun LiuNo ratings yet