Professional Documents

Culture Documents

Comeval Steam Drum Level Meas

Comeval Steam Drum Level Meas

Uploaded by

sebinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comeval Steam Drum Level Meas

Comeval Steam Drum Level Meas

Uploaded by

sebinCopyright:

Available Formats

FOSSILPOWERSYSTEMSINC.

STEAMDRUMWATERLEVELMEASUREMENT

A. Introduction.Boilersteamdrumwaterlevelisoneofthemostimportantpowerplantparameters

tobothmeasureandcontrol.Controloftheproperwaterlevelintheboileriscriticalforsafe

operationoftheboiler.Ifthelevelistoolow,boilertubeswillbedamagedbyoverheating.Ifthe

levelistoohigh,steamseparatorswillnotfunctionproperly,temperaturecontrolwillbedifficult,

andthesuperheatertubesandturbinecouldbedamagedbymoistureorwatertreatment

chemicalcarryover.Inaddition,poorlevelcontrolwillalsoadverselyaffectthedrumpressure

control.Theslidingoperatingpressureofmodern3drumHeatRecoverySteamGenerators,along

withfrequentstartupandshutdown,hasaddedtothechallengeofselectingthepropermixof

instrumentsandmaintainingcorrectwaterlevelsunderallconditions.

Althoughinstrumentsfordrumwaterlevelmeasurementhavebeenaroundforwellovera

hundredyears,itisimportanttounderstandtheoperatingprinciples,installationrequirements,

strengthsandweaknessesofeachtechnology.Toignoretheseconsiderationscanleadto

misapplication,increasedmaintenance,poorinstrumentperformance,andunsafeoperation.

TheASMEBoilerandPressureVesselCodeSectionIestablishestherequirementsforsteamdrum

waterlevelmeasurementinfiredsteamdrums.Theprimaryfocusoftheserequirementsissafe

boileroperation.Maintenance,performance,andotherspecificapplicationissuesarenot

addressed.

Thereareadozenormoreleveltechnologiesthatcouldbeconsideredforthisapplication.The

purposeofthispaperistoreview5oftheproventechnologiescurrentlyavailableforhigh

pressuresteamdrumwaterlevelmeasurement.ThesewillbecomparedwiththecurrentASME

Section1requirements(2010codeedition),andalsoevaluatetheinstallation,performance

characteristics,strengthsandweaknessesofeach.

B. ASMERequirements.TheASMEBoilerandPressureVesselCodeSectionIparagraphPG60lists

themajorityoftherequirementsforwaterlevelmeasurementinstruments.Theprimaryfocusis

safeandreliabledrumlevelindicationatalltimes.Thisisanimportantconsiderationinorderto

understandwhychangestothecodearemadeslowlyanddeliberately.Otherrequirements

pertainingtolevelinstrumentsarelistedinPG5(materialsofconstruction)andPG12(water

levelindicatorsandconnectormaterial).TheASMEcoderequirementshavecontinuouslyevolved

overtheyears.Instrumentuse,incidentreportsandperformancehistoryareevaluated.In

addition,InterpretationsarepublishedannuallytoanswerquestionssubmittedtotheASME

codecommitteepertainingtovariouscodesections.Theresultsofthemostimportant

Interpretationsarelaterwrittenintothevariouscodeparagraphstopermanentlyclarify

sectionsthatmighthavebeenconfusingandmisapplied.Belowarelistedthemostimportant

coderequirements.Thisisnotacompletelisting.Iwilllaterlistanddiscussspecificrequirements

andinterpretationsapplicabletoparticularinstrumenttypes.

1|P a g e

FOSSILPOWERSYSTEMSINC.

TheprimaryrequirementsinASMEPG60(2009)areasfollows:

1. (PG60.1)Allboilershavingafixedwaterlevel(steamandwaterinterface)shallhaveatleast

onegageglass(atransparentdevicethatpermitsvisualdeterminationofthewaterlevel).

2. (PG60.1.1)Boilershavingamaximumallowableworkingpressureexceeding400psi(3MPa)

shallhavetwogageglasses.Insteadofoneofthetworequiredgageglasses,twoindependent

remotewaterlevelindicators(twodiscretesystemsthatcontinuouslymeasure,transmit,and

displaywaterlevel)maybeprovided.

3. (PG60.1.1)Whenthewaterlevelinatleastonegaugeglassisnotreadilyvisibletothe

operatorintheareawherecontrolactionsareinitiated,eitherafiberopticcable(withno

electricalmodificationoftheopticalsignal)ormirrorsshallbeprovidedtotransfertheoptical

imageofthewaterleveltothecontrolarea.Alternatively,anycombinationoftwoofthe

followingshallbeprovided:

a. Anindependentremotewaterlevelindicator

b. Anindependentcontinuoustransmissionanddisplayofanimageofthewaterlevelina

gageglass.

4. (PG60.1.1.2)Whentwoindependentremotewaterlevelindicatorsareinreliableoperation

(continuouslyindicatingwaterlevel),theonerequiredgageglassmaybeshutoff,butshallbe

maintainedintheserviceablecondition.

INTERPRETATIONSAPPLICABLETOTHESEREQUIREMENTS

NotethattheASMEcodeatonetimedistinguishedbetweenlevelindictorstypeswiththedefinition

DirectReadingforvisuallevelgagesandIndirectIndicationforallothertypesofindicators.That

languagehasbeenreplacedinthecurrentcodewithsimplygageglassandremotewaterlevel

indicator.

1. I8313Allowsgaugeglasstobeisolatedwhentworemoteindicatorsused

2. I8602AnewTechnologylevelindicatordoesnotreplacethevisualgage

3. I8650Gageindicationfortherovingoperatorisnotequaltothecontrolroomoperator.Low

wateralarmandtriparenotconsideredindirectindication.

4. I8912Theoperatorsworkareaiswherecontrolactionsareinitiated

5. I8972Anindirectleveldevicewithnopowerisnotagageglass,butcanbeconsidereda

remotelevelindicator

6. I9215Viewingagageglasswithmirrorsisconsideredadirectreading

7. I9269Amagneticlevelindicatormayprovideanindirectlevelreading

8. I9296Amagneticlevelindicatorisnotconsideredtobeagageglass

9. I9504Apressure/temperaturecompensateddpleveltransmitterisaremotelevelindicator

10. I9507ADCSCRTscreencanbearemotelevelindication.Twoareneededtoomitthegageglass,

andtheindicationsmustbecontinuous.

11. I9814Boilerswithdrumsafetyvalvessetunder400psiarenotpermittedtoshutoffthevisual

gage,evenwithtworemoteindicatorsinoperation.

2|P a g e

FOSSILPOWERSYSTEMSINC.

C. OPERATINGTEMPERATUREERRORCORRECTION(DENSITYLEVELERROR)

Levelgagesandotherremotelevelindicatorsconnectedtotheboiler(exceptdptransmitters)are

notinatotallystaticcondition.Iftheywere,thewatertemperatureinthegagewouldbenear

ambient.RefertoFIGURE1.Assteamcondensesinthegageandconnectingpiping,the

condensateflowsintothegaugeandheatsit.Asmallamountofwaterisalwaysflowingslowly

throughthegaugeandpiping.

FIGURE1

Anywaterlevelmeasurementdeviceconnectedtothesteamdrumwilloperateatatemperaturethatis

belowtheactualdrumsteam/watersaturationtemperature.Thisloweroperatingtemperaturewill

causealevelerrorwithinthemeasurementdevice.Themeasurementinstrumentwillthenalways

indicatelowerthanthetruedrumwaterlevel.Waterlevelgagesandalltypesofremotelevelindicators

areaffected.FIGURE2belowillustratesthiseffectandtheformulasusedtocalculatetheerror.

FIGURE2

3|P a g e

FOSSILPOWERSYSTEMSINC.

Thewaterdensityintheexternalinstrumentishigherthanthesteamdrumwaterdensity.The

externalmeasurementinstrumentwillalwaysindicatelowerthantheTrueDrumLevel.The

magnitudeofthelevelerrordependsonoperatingpressureandheightofthewatercolumn.The

densityofboilerwaterdecreasesasoperatingpressureincreases.Theerrorcanbesignificant,

especiallyasoperatingpressuresexceed2000psi,andonlargesteamdrumswithlongvisibility

gagessuchasusedinHRSGapplications.Althoughsomeinstrumentmanufacturesmaystatethat

theerrorsareinsignificantandchoosetoignorethem,theerrorsaresignificantunderconditions

ofhighsteampressureandhighwaterlevels,andcannotbeignored.

Thereareonlythreebasicmethodsavailabletocorrectfortheseerrors.Dependingonthelevel

technologyinuse,somemethodsaremoreorlessapplicabletovariousinstruments.These

methodsare:

1. Heatthewaterinsidetheinstrumenttoatemperatureclosetothedrumwatertemperature.

2. Physicallymovetheinstrumenttoalowerlocation.Thiswillonlyprovideacorrectionforone

operatingpressureandforonelevelposition.Althoughformultipointlevelindicatorssuchas

conductivityprobeindicators,eachprobecanbeindividuallycorrectedforagivenoperating

pressure.Correctionsarebasedonanestimateoftheinstrumentoperatingtemperature.

3. Correcttheelectricaloutputsignal.Thisistheapproachusedforpressurecompensateddp

leveltransmitters.Itcouldalsobepotentiallyusedtocorrectradarorothertypesorremote

indicatorswithanelectricaloutput.Anadditionalpressure/temperaturecorrectionsignalis

usedtocorrecttheinstrumentoutputtoindicatethetruedrumlevel.

D. LEVELINSTRUMENTSANDASSESORIES

1. VisualLevelGages,DirectlevelMeasurement

AdditionalASMERequirements:

(PG60.1)Thelowestvisiblewaterlevelinagageglassshallbeatleast2abovethelowest

permissiblewaterlevel,asdeterminedbytheboilerManufacturer.

(I9250)Theboilermanufacturerdeterminesthelowestpermissiblelevel

(I9266)SamePG60.1definition

(I8906)GageglassesarepartofBoilerExternalpiping,subjecttoPG60.Weldedgagebodies

maybeprovidedbyamanufacturerwithoutaSection1certificate.

(PG5.5)Theuseofaustenitic(series300SS)alloysteelispermittedforboilerpressureparts

thataresteamtouchedinnormaloperation.ExceptasspecificallyprovidedinPG9.1.1,PG

12,andPEB5.3,theuseofsuchausteniticalloysforboilerpressurepartsthatarewater

wettedinnormalserviceisprohibited.

(PG5.5note1).Austeniticalloysaresusceptibletointergranularcorrosionandstress

corrosioncrackingwhenusedinboilerapplicationsinwaterwettedservice.Factorsthat

affectthesensitivitytothesemetallurgicalphenomenaareappliedorresidualstressand

waterchemistry.Susceptibilitytoattackisusuallyenhancedbyusingthematerialina

stressedconditionwithaconcentrationofcorrosiveagents(e.g.chlorides,causticorreduced

sulfurspecies).Forsuccessfuloperationinwaterenvironments,residualandappliedstressed

4|P a g e

FOSSILPOWERSYSTEMSINC.

mustbeminimizedandcarefulattentionmustbepaidtocontinuouscontrolofwater

chemistry.

(PG12.1)GageglassbodyandconnectormaterialsshallcomplywithaManufacturers

standardthatdefinesthepressuretemperatureratingmarkedontheunit.Thematerialsused

mayincludeausteniticstainlesssteelsandnickelbasedalloys.

DensityErrorConsiderations:Visualgaugesaretypicallypositionedwithoutconsiderationfor

densitylevelerror.Thesewillindicatecorrectlyatlowpressure,withincreasingerroras

pressureincreases.Ifthegaugemustbedensitycorrectedthereareseveralapproaches:

1. Heatthewaterinthegaugewithanadditionalpipeconnectedtothesteamdowncomer(referred

toassteamheatingortemperatureequalization).

2. Installthegaugeinalowerposition,calculatedforonepressureandoneindicatedlevel.

3. Provideachartatthegaugeshowingtheamountofcorrectionatvariousoperatingpressures.

a. ReflexGages.SeeFIGURE3.Thesegageshavegroovedglassthatappliestheprinciplesof

lightreflectionandtransmissiontodevelopaWhite/Blackimage,indicatingthewater

level.Maximumoperatingsteampressureistypically350psi.SeeFIGURE4that

demonstratesthisoperatingprinciple.

FIGURE3

FIGURE4

AdditionalASMERequirements:

(PG60.1)Gageglassassemblieshavingmultiplesections,whetheroftubularorother

construction,shallbedesignedinsuchamannerthatwillensureaminimumof1(25mm)

5|P a g e

FOSSILPOWERSYSTEMSINC.

overlapofalladjoiningsectionsinwhichthewaterlevelmaybevisible,exceptthatported

orREFLEXgagesthatuserefractionoflighttoaidreadydeterminationoftheliquidlevel,

mayomittherequirementforoverlappingsections.

(I0438)Describessamerequirementsasabove.

b. FlatglassGagesandTubularGlassGages.FIGURE5.Thesegagesrelyontheabilitytosee

thewater/steaminterface(meniscus)insidethegageglass.Tubularglassgagesoperateat

lowpressuresandbecomefragileasglasslengthincreases.Designpressurewilllimitthe

safeglasslength.Flatglassgauges,alsocalledArmoured,canoperateathigher

pressures.

WEBNOT

PERMITTED

FIGURE5FIGURE6

AdditionalASMERequirements:FIGURE6

(PG60.1)Gageglassdesignsthatutilizetransversestructuralmembers(crosswebbing)asa

meanstostrengthenthebodyofthegage,whicharenotcontinuousovertheentirevertical

lengthofthegageglass,arenotpermitted.Note:Transverseorcrosswebstructural

strengtheningmemberswillcauseareasalongthelengthofthegageglasswheretheliquid

levelcannotbereadilydeterminedbecauseofmaskingshadowscausedbythepresenceofthe

transversemembers.Reflextypedesignsthatutilizedsolidmembersbehindtheglassthatare

continuousovertheverticallengthoftheglass,andfrontlitbyeitherambientorprojected

sourcesasapplicable,arenotprohibited.

c. PortedGages.FIGURE7.Thesegaugescanoperateatveryhighsteampressuresbecause

thewindowareaisreduced.Thegagebodyisconstructedinatrapezoidshape.The

6|P a g e

FOSSILPOWERSYSTEMSINC.

illuminatorwillprojectaREDandGREENlightthroughtheportstoprovideaRED/GREEN

indicationofdrumwaterlevel.

FIGURE7

AdditionalASMERequirements:

(PG60.1)Portedgagesorreflexgagesthatuserefractionoflighttoaidready

determinationoftheliquidlevel,mayomittherequirementforoverlappingsections.

FIGURE8illustratesthisoperatingprincipleandtheimageddisplayed.

FIGURE8

7|P a g e

FOSSILPOWERSYSTEMSINC.

(I0708)Ahandheldlightsource(flashlight)heldbehindaportedgagedoesnotsatisfy

therequirementthatthegagebeequippedtoprovideobviousvisualdiscrimination

betweenwaterandvaporintheindividualsections.

Note:ARED/GREENilluminatordesignedforproperdisplayofthelevelinthebicolour

gaugeMUSTbeusedtosatisfythisASMErequirement.

2. WaterColumns.FIGURE9.ThisillustrationisfromASMESectionI,figurePG60.These

columnsareusedasaninterfacebetweenthesteamdrumandthevisualgaugeandprovide

thefollowingbenefits:

a. Allowsformismatchbetweendrumandvisualgageconnectioncenters

b. Providesafixedandrigidpointtoinstallthegageisolationvalves

c. Preventsexcessivecondensatefromflowingthroughthegageandoverthegage

window,reducingorobscuringthevisibility.

FIGURE9

AdditionalASMERequirements:

(PG60.2.3)EachwatercolumnshallbefurnishedwithaconnectionofatleastNPS3/4

(DN20)toinstallavalveddraintoasafepointofdischarge.

PG60.3.1)GageglassesthatarerequiredbyPG60.1shallbeconnecteddirectlytothe

shellordrumoftheboilerortoaninterveningwatercolumn.Whentwogageglassesare

required,bothmaybeconnectedtoasinglewatercolumn.

8|P a g e

FOSSILPOWERSYSTEMSINC.

(PG60.3.2)Theloweredgeofthesteamconnectionbetweenawatercolumn,gageglass

orausteniticstainlesssteelornickelbasedalloywaterlevelsensingdeviceintheboiler

shallnotbebelowthehighestvisiblewaterlevelinthegageglass.Thereshallbenosagor

offsetinthepipingthatwillpermittheaccumulationofwater.

(PG60.3.3)Theupperedgeofthewaterconnectionbetweenawatercolumn,gageglass,

orausteniticstainlesssteelofnickelbasedallowwaterlevelsensingdeviceandtheboiler

shallnotbeabovethelowestvisiblewaterlevelinthegageglass.Nopartofthispipe

connectionshallbeabovethepointofconnectionatthewatercolumn.

(PG60.3.4)ConnectionsfromtheboilertothewatercolumnshallbeatleastNPS1(DN25)

3. ConductivityProbeSystems.FIGURE10Thesedevicesmeasurelevelusingtheprinciplethat

theconductivityofwaterandsteamaresignificantlydifferent.Theconductivityprobeacts

likeanon/offswitch.Alowvoltageisappliedtotheprobetipthatisinsulatedfromthe

columnbody.Thereturnsignalismeasuredbyanelectroniccircuit.Steamappearsasan

opencircuit,whilewatershortstheprobetogroundandappearsasaclosedcircuit.The

conductivityprobesarelocatedatvariouslocationsinaprobecolumntoprovidediscrete

indicationsofdrumwaterlevel.

FIGURE10

9|P a g e

FOSSILPOWERSYSTEMSINC.

AdditionalASMERequirements:

(I0122)Austeniticmaterials(series300SS)cannotbeusedforlevelindicators

(I0125)Conductivityprobetypelevelcolumnscannotuseausteniticmaterials.

DensityErrorConsiderations.Asdiscussedearlier,watertemperatureintheprobe

columnwillbelowerthanthedrumwatertemperature,causingadensitylevelerror.

Probelocationscanbeindividuallycorrectedtoimprovetheaccuracyoftheindicated

drumlevelataspecificoperatingpressure.Probesathighlevelsreceivemorecorrection

thanprobesatlowlevels.Measurementerrorsareintroducedwhenoperatingat

pressuresotherthanthenormaloperatingpressure,andinparticularwhenatcoldstartup

conditions.

4. DifferentialPressure(dp)Transmitters.FIGURE11.Theseproductsprovidea420mAsignalto

indicatedrumlevelandaremostcommonlyusedfordrumlevelcontrol.Theyoperateby

measuringthedifferenceinpressurebetweenthelevelofwaterinthedrumandthewaterin

astaticcolumn,alsocalledtheReferenceLeg.Ascanbeseenfromthediagram,lowdrum

waterlevelsproducehighdeltap,andhighdrumwaterlevelsproducelowdeltap.Accurate

andrepeatablemeasurementsthatareunaffectedbychangesinboilerpressureare

challengingsincetheinstrumentsoperateatthousandsofpsiboilerpressure,butmust

measureonlyinchesofwaterpressuredifferential,oftenlessthanonepsidifferential.To

achieveaccuracy,highpressuresystemsmustbePressureCompensated,meaningthatthe

operatingpressureismeasuredandtheindicateddrumleveliscorrected.Multivariable

densitycompensatedtransmittersarealsoavailablethatmeasuredifferentialpressure,

absolutepressure,andprocessorwetlegtemperature.Measurementsandcalculations

withinonedeviceshouldreduceerrors.

FIGURE11

10|P a g e

FOSSILPOWERSYSTEMSINC.

AdditionalASMERequirements

(I9263)Acomputerterminalleveldisplaycanbeselectedondemand,providedthe

secondremotelevelindicatoriscontinuous,withonevisualgaugeinserviceandvisibleto

theoperator.

(I0119)Thesamesignalalgorithmcanbeusedfortworemoteindicators

DensityErrorConsiderations:FIGURE12Thedrumlevelindicatedtotheoperatorisa

calculatedvaluebasedonthefollowingmeasurementsandassumptions:

a. dptransmittermeasurement

b. Pressuretransmittermeasurement(requiredforpressurecorrection)

c. Referencelegheight

d. Referencelegtemperature

e. Variablelegtemperature

f. Steamandwaterdensitycalculationattheoperatingpressure

LP=

HP=

DP=

DP=

DP=

H1D1 + H2D2 + H4D4

H3D3 + H4D4

HP - LP

(H3D3 + H4D4) - (H1D1 + H2D2 + H4D4)

H3D3 - H1D1 - H2D2

D1= STEAM DENSITY

D2= DRUM WATER DENSITY

D3= REFERENCE LEG DENSITY

NOTE: DISTANCE X MUST BE SUFFICIENT SO

THAT T IS AT AMBIENT TEMPRATURE

FIGURE12

Significantlevelindicationerrorsareintroducedwhentheassumptionsusedinthelevel

calculationformulasdonotagreewiththeactualparameters.Errorsarealsointroduced

duetoinstallationmistakes.Thesensinglinesfromtheboilertothedpinstrumentshould

beslopedtopreventformationofgaspocketsanderroneouslevelreadings.Toobtainthe

bestaccuracy,temperaturesinthereferenceandvariablelegsmustaccuratelyestimated.

FIGURE12showstheidealdptransmitterinstallationthatintroducestheminimum

numberofvariablesintotherequiredequations.

11|P a g e

FOSSILPOWERSYSTEMSINC.

Inaddition,FIGURE13belowillustratesthatthedensityofwateranddensityofsteam

approacheachotheraspressureincreases.Thiswillexacerbateanyerrorsinthedrum

waterlevelcalculation.

FIGURE13

TABLE1belowwillbeusedtoillustrateanumberofexamplesofdptransmittererrors

introducedbyinaccurateassumptions.

LINE

NO.

1

2

3

LINE

NO.

4

5

6

7

REF

LEG

TEMP

DEGF

120

120

120

STM

PRESS

PSIA

2500

20

2500

STM

TEMP

DEGF

668

228

668

H1

INCH

12

12

12

D1

LB/FT3

7.658

0.0498

7.658

H2

INCH

36

36

24

D2

LB/FT3

34.97

59.42

34.97

H3

INCH

48

48

48

D3

LB/FT3

61.71

61.71

61.71

Y

INCH

0

0

12

TEMP

TY

DEGF

0

0

565

DP

INCHES

25.86

25.86

25.86

25.86

REF

LEG

TEMP

DEGF

120

50

120

120

STM

PRESS

PSIA

2500

2500

20

2500

STM

TEMP

DEGF

668

668

228

668

D1

LB/FT3

7.658

7.658

0.0498

7.658

D2

LB/FT3

34.97

34.97

59.42

34.97

H3

INCH

48

48

48

48

D3

LB/FT3

61.7

62.4

61.7

61.7

Y

INCH

0

0

0

12

DY

LB/FT3

0

0

0

44.96

H2

INCH

36.01

37.24

22.72

16.25

12|P a g e

DY

LB/FT3

0

0

44.96

DP

INCHES

25.86

13.20

22.46

FOSSILPOWERSYSTEMSINC.

FromFIGURE12,Theformulaforthetransmitterdpis:

1) Dp=H3D3H1D1H2D1

Notethat:H1=H3H2

ReplacingH1intheDpformula,theformulacanbesimplifiedas:

2) Dp=[H3(D3D1)+H2(D1D2)]/62.3

IftheDpisknown,theheightofwaterinthedrumcanbecalculatedfrom:

3) H2=[62.3(DP)H3(D3D1)]/D1D2

Theunitsintheseformulasare:

Dpinchesofwaterpressure

Height(H):Inches

Density(D):lb/ft3

Conversionfactor:62.3

EXAMPLE1:Referencelegtemperaturelowerthanestimated.Comparelines1,4,andline

5intheTABLE1.Theassumptionsare:

Steamdrumpressure:2500psia

Reflegheight,H3,48inches

Referencelegtemperature:120F

Drumwaterlevel,H2,36inches

Thecalculateddpmeasurementis25.86inchesofwater(TABLEline1).Thisisconfirmed

inline4.Ifthemeasureddpis25.86,thecalculateddrumlevel(H2)is36.01

But,iftheactualreferencelegtemperatureis50Finsteadoftheassumed120F,theeffect

ofthiserrorisshowninline5ofthetable.Withthedptransmittermaintainingdrumlevel

controlat25.86,theactualdrumlevelwillbeat37.24.Anerrorof1.23.

EXAMPLE2:Nopressurecompensationofthedptransmitter.

Assumethesameconditionsasabove,withthedptransmittersettomaintainadrumlevel

of36whentheboilerisat2500psi.(Line1andline4).

Ifnopressurecompensationwasavailableduringboilerstartup(Tableline6),atadrum

pressureof20psithedrumwaterlevelwouldbeat22.72,anerrorof13.3.

13|P a g e

FOSSILPOWERSYSTEMSINC.

EXAMPLE3:DPtransmittervariablelegconnectedtothebottomofthedrum.TheFIGURE

14belowshowsthisinstallationmethod.

FIGURE14.Variablelegoffbottomofdrum

LP=

HP=

DP=

DP=

DP=

H1D1 + H2D2 + H4D4

H3D3 + H4D4

HP - LP

(H3D3 + H4D4) - (H1D1 + H2D2 + H4D4)

H3D3 - H1D1 - H2D2

D1= STEAM DENSITY

D2= DRUM WATER DENSITY

D3= REFERENCE LEG DENSITY

Assumingthesameboilerconditionsasthefirsttwoexamples,butH2drumlevelnow

includestheYcomponentthatwillbeatalowertemperaturethanthesteamdrum

watersaturationtemperature.

AssumeforthisinstallationthatYis12inches,andthiswaterinthislineissubcooled

100Fbelowthesaturateddrumwatertemperature(waterat565F).Theeffectofthis

changeisshowninLines#3and#7.

ThedrumlevelfromLine#7willbethetotalofYandthecalculatedH2,or28.25.This

isanerrorof7.75fromthesetpoint(36).

5. MagneticFloatIndicators.FIGURE15.Thesedevicesconsistofastainlesssteel(orothernon

magneticmaterial)pipechamberandaninternalfloat.Thefloatisalsononmagnetic,but

containsaringofmagnets.Themagnetswithinthefloatoperateamagneticindicatorlocated

ontheoutsideofthepressurechamber.Theindicatoriseitherasinglefollower,oraseries

offlagsthatrotateandchangecolourasthefloatmagnetspassby.Thefloatmagneticring

willcollectcorrosionparticles(iron/steel)fromthewaterandthefloatmustberemovedand

cleanedperiodically,dependingonwaterquality.Floatsmustbecomelargeraspressure

increasesduetothereductioninwaterdensity.

14|P a g e

FOSSILPOWERSYSTEMSINC.

STAINLESS STEEL

CHAMBER WALL

INDICATING

FLAGS

FLUX

RING

LIQUID

LEVEL

FLOAT

MAGNETS

FLOAT

FIGURE15

AdditionalASMERequirements:

(PG60.1.1.4)Independentremotelevelindicatorsthatcontainsensingdevicesthat

includeamagneticallycoupledfloatinsideanonmagneticcylindricalpressurechamberto

utilizethroughthewallsensingoffloatpositionshallberestrictedtotherequirementsof

PG12.2.Thedesignandconstructionofsuchdevicesshallincludeprovisionsforeaseof

cleaningandmaintenance.Attachmentofanycontroldevicesforuseotherthan

indicatingwaterlevelisprohibited.

(PG12.2)Boilershavingamaximumallowableworkingpressurenotexceeding900psi(6

MPa)mayusealternativemethodsforindependentremotewaterlevelindicatorsorwater

levelsensingdevices(seePG60).Thesensingdevicesmayincludeamagneticallycoupled

floatinsideanonmagneticcylindricalpressurechambertoutilizethroughthewallsensing

offloatposition.Thepressurechamberstressesshallmeettheappropriaterequirements

ofPG27andPartPW,andshallberestrictedtothematerialgradeslistedinPG12.3

DensityErrorConsiderations:Aswithothermanometertypeindicators,thedifference

indensitybetweenthewaterinthedrumandthewaterinthemagneticfloatcolumnwill

causealevelindicationerror.Theerrorincreasesasthemeasuredlevelincreases.Higher

pressuresandlongervisibilitieswillcreatelargererrors.Itispossibletocorrectforthis

erroratoneoperatingpressureandoneindicatedlevel(typicallythezeroposition)by

calculatingacorrectedfloatpositionbasedonfloatweight,floatdisplacedvolume,and

15|P a g e

FOSSILPOWERSYSTEMSINC.

averagewatertemperaturewithinthechamber.However,errorsareintroducedatother

operatinglevelsandotheroperatingpressures.

Example:OperatingPressuredifferentthancalculation.

FIGURE16

Assumethatthemagneticfloatpositionisdesignedforanoperatingpressureof900psia.

Assume:Steamdrumlevel(Hd)of36inches.

MagGaugesubcoolingof100Ffromthedrumwatertemperature.

Theheightofthewaterinthegaugeis:

Hg=Hd(DdDs)/(DgDs)

Thetablebelowshowstheindicationerrorwhenoperatedat300psia

PRESS

PSIA

900

300

TEMP

F

532

417

Hd

INCH

36

36

Dd

LB/FT3

47.10

52.92

Ds

LB/FT3

2.00

0.65

TEMP

GAUGE,Tg

F

432

317

Dg

LB/FT3

52.36

56.75

Hg

INCH

32.24

33.54

Thistableshowsthatthelevelinthefloatchamberwillchangeby:

33.5432.24=1.30

Inaddition,thebuoyancyofthefloatwillincrease,raisingthepositionofthefloat,andadding

furthererror.

16|P a g e

FOSSILPOWERSYSTEMSINC.

6. GuidedWaveRadarLevelIndicators.FIGURE17Comparedwiththeothertechnologiesinuse,

thisoneisrelativelynew.Guidedwavetechnologysendsaradarpulsedownaprobeinstalled

inanexternalcolumn.Thepulsereflectsoffthesurfaceofthewaterbackuptheprobeand

tothesensor.Thetransittimeistranslatedintoadistance,andbasedondimensionsofthe

installation,thewaterleveliscalculated.Thisdeviceproducesacontinuousreading(420mA

signal)ofthewaterlevel.Theadvantageofthismethodoverothertypesofradarsensorsis

thattheprobeguidestheradarpulseandconcentratesboththepulseandthereturnsignal

energy.Effectivelytransmittingtheradarpulsethroughthelongguideandthroughthe

pressurecontainmentboundarytotheelectronicsrequiresspecializedsealsandconstruction.

FIGURE17

DensityErrorConsiderations.Aswithotherdevicesusingawatercolumnconnectedtothe

steamdrum,thewaterinthecolumnwillbecolderandconsequentlyatalowerlevelthanthe

steamdrumtemperature.Iftheactualwatertemperatureinthecolumnismeasured,it

wouldbepossiblefortheelectronicstocalculateandapplyacorrectionfactortotheindicated

level.

Anadditionalconsiderationaffectingindicationaccuracyisthesignificantchangethatoccurs

indielectricconstantsofwaterandsteamaspressureandtemperaturechanges.Theradar

pulsereflectionisactuallycausedbydetectingtheimpedancechangebetweenthewater

andsteam.Anychangeinthesevalueswillaffectthepulsetransittime,andtheindicated

level.Thetablebelowshowsthisaffect.

17|P a g e

FOSSILPOWERSYSTEMSINC.

TEMP(F) PRESSURE LIQDENS. VAPOR

DIELECTRIC DIELECTRIC ERROR

(PSIA)

(LB/FT3) DENSITY CONS,LIQ CONS,VAP %

(LB/FT3)

100

0

61.99

0.0029 73.95

1.001

0.0

400

247

53.65

0.537

34

1.069

3.4

600

1543

42.32

3.74

18.04

1.461

21

ThedielectricconstantsofWaterandSteamapproacheachotheraspressureincreases.Programswithin

theelectronicscancompensateforthischangeandmaintainthelevelindicationaccuracy.

E. CONCLUSION

TheASMEBoilerandPressureVesselCodeliststherequirementsforsteamdrumlevelgauges

andindicatorstoensuresafeoperationoftheboiler.Directreadingvisuallevelgaugesare

requiredoneveryboiler.Thesecanbecomplimentedwithotherindirectinstrumentsto

attainthegoalofsafeandefficientboileroperation.Buttoattainthisgoal,instrumentsmust

beproperlyselectedforthedesignconditions,installedproperly,calibratedproperly,and

maintained.Ifanyoneoftheserequirementsisignored,performancewillbedegraded.All

instrumentshaveinherentstrengthsandweaknessesbasedonthetechnologyemployedto

measurelevel.Theseinstrumentcharacteristicsshouldbethoroughlyunderstoodbytheuser,

orindicationswillbemisleading.Aprudentandconservativeapproachistousesome

combinationofthedifferentproventechnologies.Theindependentindicationsthese

instrumentsgivewillthenprovideconfidencethattheboilerisalwaysoperatedinasafe

condition.

F. REFERENCES

1. Liptak,BelaG.,InstrumentEngineersHandbook,ThirdEdition1969

2. Kalix,D.A,DensityLevelErrorandItsCorrectioninBoilerDrumLevelIndication,ISA

ConferenceOctober1995

3. Boyes,W.SomeThingsdoexactlywhattheyaresupposedto,ControlMagazineFeb2004

4. Evely,D.P.,HeatRecoverySteamGeneratorDrumLevelMeasurementSourcesofError,ISA

jointPOWID/EPRIconference,2004

5. Gilman,J.BoilerDrumLevelControl,ISAJuly/August2010

DavidKalix,P.E.

FossilPowerSystemsInc.

10MosherDrive,Dartmouth,

NovaScotia,Canada

B3B1N5

(902)4682743

26July2011

18|P a g e

You might also like

- Flow of Fluids Through Valves, Fittings and Pipe (Crane)Document133 pagesFlow of Fluids Through Valves, Fittings and Pipe (Crane)kangsungjin100% (1)

- Analysis of Boiler Efficiency - CaseDocument89 pagesAnalysis of Boiler Efficiency - CaseSaritha Yadav100% (5)

- Deaerator Volume Calculation ReportDocument1 pageDeaerator Volume Calculation Reportpsk.pranesh5520No ratings yet

- PolyIT InstallationDocument36 pagesPolyIT Installationuriel vazquezNo ratings yet

- Xal Price List 2020: Xal GMBH Auer-Welsbach-Gasse 36 8055 Graz T +43.316.3170 F +43.316.3170.9000Document24 pagesXal Price List 2020: Xal GMBH Auer-Welsbach-Gasse 36 8055 Graz T +43.316.3170 F +43.316.3170.9000Shadi AbdelsalamNo ratings yet

- Engineering Bulletin No 1: Boiler and Furnace TestingFrom EverandEngineering Bulletin No 1: Boiler and Furnace TestingRating: 4.5 out of 5 stars4.5/5 (2)

- Boiler CirculationDocument7 pagesBoiler CirculationaruntpeNo ratings yet

- Density Error and Correction in Drum LevelDocument8 pagesDensity Error and Correction in Drum Levelvai123_bodNo ratings yet

- Boiler Performance & Technical Data JT-K13467-E01-0Document15 pagesBoiler Performance & Technical Data JT-K13467-E01-0Puntanata Siagian0% (1)

- BoilBal SpreadsheetDocument16 pagesBoilBal SpreadsheetZulkarnain NasrullahNo ratings yet

- 7.steam Headers and OfftakesDocument6 pages7.steam Headers and Offtakessandeep kumarNo ratings yet

- Natural Circulation in BoilerDocument9 pagesNatural Circulation in BoilerSajjad AhmedNo ratings yet

- DLT 5054-1996Document245 pagesDLT 5054-1996ecsuperalNo ratings yet

- Turbine Bypass ValvesDocument6 pagesTurbine Bypass ValvesadehriyaNo ratings yet

- Catalog INDIRA 2019-CompressedDocument8 pagesCatalog INDIRA 2019-CompressedIDM BOILERNo ratings yet

- Boiler Efficiency CalculationsDocument6 pagesBoiler Efficiency CalculationsRobert BarrettNo ratings yet

- HRSG Supplier's Chemistry IonDocument11 pagesHRSG Supplier's Chemistry IonJoe Schroeder100% (1)

- Understanding Waterhammer in Pumping Systems and Surge Suppression OptionsDocument20 pagesUnderstanding Waterhammer in Pumping Systems and Surge Suppression OptionsdeepakmathilakathNo ratings yet

- TEWI AnalysisDocument63 pagesTEWI Analysismirali74No ratings yet

- 12-Design Fundamentals of BoilerDocument12 pages12-Design Fundamentals of BoilerVishalVaishNo ratings yet

- HRSG ReportDocument46 pagesHRSG Reportoverlord5555No ratings yet

- Shrink and SwellDocument3 pagesShrink and SwellAkshay SetlurNo ratings yet

- Drum Level Measurement 5689463fb873aDocument49 pagesDrum Level Measurement 5689463fb873aSteve WanNo ratings yet

- Desuperheater Catalog of DAEJU CONTROL CO., LTD.Document28 pagesDesuperheater Catalog of DAEJU CONTROL CO., LTD.Ki Ho ChungNo ratings yet

- DesuperheaterDocument14 pagesDesuperheatervon18100% (1)

- Basic Desuperheater Types PDFDocument17 pagesBasic Desuperheater Types PDFLiège CostaNo ratings yet

- Boiler CirculationDocument5 pagesBoiler Circulationsugumar100% (1)

- Air HeatersDocument34 pagesAir HeatersNaveen KamatNo ratings yet

- Application Data: Combustion Management Solutions Full-Metered, Cross-Limited ControlDocument6 pagesApplication Data: Combustion Management Solutions Full-Metered, Cross-Limited Controlsprotkar100% (1)

- Boiler Design Step 2Document2 pagesBoiler Design Step 2Amad TaupiqNo ratings yet

- Boiler FundamentalsDocument63 pagesBoiler Fundamentalsakrverma2011100% (1)

- Pressurised Deaerator Head-Technical Information PDFDocument2 pagesPressurised Deaerator Head-Technical Information PDFel doctolNo ratings yet

- 1996 - Misplon - Pinhole Grate Conversions ofDocument4 pages1996 - Misplon - Pinhole Grate Conversions ofmchoi23No ratings yet

- Properly Employ Overhead Condensers For Vacuum ColumnsDocument8 pagesProperly Employ Overhead Condensers For Vacuum ColumnsmrtiemannNo ratings yet

- Alum DosingDocument3 pagesAlum DosingsandiprkutheNo ratings yet

- JBC Common Boiler FormulasDocument12 pagesJBC Common Boiler Formulasnesrine10No ratings yet

- Is 14164 2008Document45 pagesIs 14164 2008Pukhraj DagaNo ratings yet

- Boiler Excess Air Tune-UpDocument15 pagesBoiler Excess Air Tune-UpAlif Nur FirdausNo ratings yet

- Boiler Dissolved Oxygen ControlDocument12 pagesBoiler Dissolved Oxygen Controltrieu100% (1)

- Claver Brooks General Boiler InformationDocument10 pagesClaver Brooks General Boiler Informationnecio77No ratings yet

- Cathotic ProtectionDocument5 pagesCathotic Protectionkrishna_swaroop99100% (1)

- Title: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectDocument24 pagesTitle: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectRamalingam PrabhakaranNo ratings yet

- WH Vacuum in Steam TurbineDocument2 pagesWH Vacuum in Steam Turbinemiths_0087No ratings yet

- Parameters Affecting Turbine PerformanceDocument8 pagesParameters Affecting Turbine PerformancePrakash DoraNo ratings yet

- 23 09 13.33 - Control ValvesDocument25 pages23 09 13.33 - Control Valvesforevertay2000No ratings yet

- Delivering Excellence in Combustion and Process HeatingDocument11 pagesDelivering Excellence in Combustion and Process HeatingsajjadyasinNo ratings yet

- Steam TablesDocument6 pagesSteam TablesRichard Olawoyin100% (1)

- DeaeratorDocument18 pagesDeaeratorSouvik DeNo ratings yet

- Acid Dew Point Calculation For CFB Boilers Parameters Formula Value UnitsDocument2 pagesAcid Dew Point Calculation For CFB Boilers Parameters Formula Value UnitsUsman NaseemNo ratings yet

- Acid Gas Dew PointDocument8 pagesAcid Gas Dew Pointzubair195No ratings yet

- Chapter 2 FiretubeDocument18 pagesChapter 2 FiretubeWael Abdel-MageedNo ratings yet

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4From EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Rating: 5 out of 5 stars5/5 (1)

- Materials and Processes for CO2 Capture, Conversion, and SequestrationFrom EverandMaterials and Processes for CO2 Capture, Conversion, and SequestrationNo ratings yet

- Energy and Process Optimization for the Process IndustriesFrom EverandEnergy and Process Optimization for the Process IndustriesNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Chemistry and Metallurgy: Second Revised and Enlarged EditionFrom EverandChemistry and Metallurgy: Second Revised and Enlarged EditionA. SherryNo ratings yet

- Advanced Distillation Technologies: Design, Control and ApplicationsFrom EverandAdvanced Distillation Technologies: Design, Control and ApplicationsNo ratings yet

- A Review of Explicit Approximations of Colebrook's EquationDocument5 pagesA Review of Explicit Approximations of Colebrook's EquationkangsungjinNo ratings yet

- Environmental, Health, and Safety General GuidelinesDocument99 pagesEnvironmental, Health, and Safety General GuidelineskangsungjinNo ratings yet

- FAC and Cavitation: Identification, Assessment, Monitoring, PreventionDocument7 pagesFAC and Cavitation: Identification, Assessment, Monitoring, PreventionkangsungjinNo ratings yet

- Low Temperature CatalystDocument29 pagesLow Temperature CatalystkangsungjinNo ratings yet

- Environmental, Health, and Safety Guidelines For Thermal Power Plant - FilesDocument33 pagesEnvironmental, Health, and Safety Guidelines For Thermal Power Plant - FileskangsungjinNo ratings yet

- Environmental, Health, and Safety General Guidelines - 2008Document33 pagesEnvironmental, Health, and Safety General Guidelines - 2008kangsungjinNo ratings yet

- 8.8 Chemical Reactors: Batch SequencingDocument24 pages8.8 Chemical Reactors: Batch SequencingkangsungjinNo ratings yet

- Ml12335a508 PDFDocument279 pagesMl12335a508 PDFkangsungjinNo ratings yet

- An Experimental Study of Swirling Supercritical Hydrocarbon Fuel JetsDocument9 pagesAn Experimental Study of Swirling Supercritical Hydrocarbon Fuel JetskangsungjinNo ratings yet

- Guideline ForDetermination of Good Engineering Practice Stacl Height (Technical Support Document For The Stack Height Regulations)Document100 pagesGuideline ForDetermination of Good Engineering Practice Stacl Height (Technical Support Document For The Stack Height Regulations)kangsungjin100% (1)

- JEGTP 1983 Vol 105 N4Document242 pagesJEGTP 1983 Vol 105 N4kangsungjinNo ratings yet

- High Strength, Ductile Braze Repairs For Stationary Gas Turbine Components-Part IIDocument10 pagesHigh Strength, Ductile Braze Repairs For Stationary Gas Turbine Components-Part IIkangsungjinNo ratings yet

- JEGTP 1980 Vol 102 N1Document228 pagesJEGTP 1980 Vol 102 N1kangsungjinNo ratings yet

- A Modeling Approach To Predict Fretting Fatigue On Highly Loaded Blade RootsDocument9 pagesA Modeling Approach To Predict Fretting Fatigue On Highly Loaded Blade RootskangsungjinNo ratings yet

- Development of Double Gear Fuel Pump For Heat Management ImprovementDocument9 pagesDevelopment of Double Gear Fuel Pump For Heat Management ImprovementkangsungjinNo ratings yet

- 1081app A 8Document26 pages1081app A 8kangsungjinNo ratings yet

- 2.15 Model-Free Adaptive (MFA) Control: G. S. ChengDocument10 pages2.15 Model-Free Adaptive (MFA) Control: G. S. ChengkangsungjinNo ratings yet

- HandyChecker (Ver 3) - Laptop Install ManualDocument8 pagesHandyChecker (Ver 3) - Laptop Install ManualAlex Robledo OlarteNo ratings yet

- 40 412M PDFDocument42 pages40 412M PDFpaulpuscasuNo ratings yet

- HM70 User Guide in EnglishDocument83 pagesHM70 User Guide in EnglishAbdelouahd Ben MohamedNo ratings yet

- Installation Guide T-Marc 3306 MN100280 Revision ADocument43 pagesInstallation Guide T-Marc 3306 MN100280 Revision AMarco Ur100% (1)

- Arb FrizzerDocument83 pagesArb FrizzerFrancisco ChaoNo ratings yet

- Test 1: Aircraft English TestsDocument45 pagesTest 1: Aircraft English Testshunganhngoc100% (2)

- PROTEL DXP - Getting Started With PCB DesignDocument35 pagesPROTEL DXP - Getting Started With PCB DesignIvana KlapačNo ratings yet

- W01 358 9414Document29 pagesW01 358 9414MROstop.comNo ratings yet

- Ad 4329 AexDocument56 pagesAd 4329 AexRahmat GunawanNo ratings yet

- Irc5 PDFDocument326 pagesIrc5 PDFHuỳnh Gia Vũ100% (1)

- KSE User ManualDocument45 pagesKSE User ManualprekNo ratings yet

- General Catalogue HMIDocument180 pagesGeneral Catalogue HMIjavivi_75No ratings yet

- Catálogo VARIOKIT PERI PDFDocument44 pagesCatálogo VARIOKIT PERI PDFHenry MorenoNo ratings yet

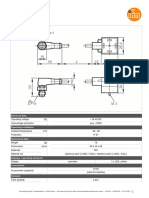

- Jumper Cable With Valve Plug: VVSAB041MSS00,6A03STAH030VASDocument2 pagesJumper Cable With Valve Plug: VVSAB041MSS00,6A03STAH030VASJhon Elmer ChoqueNo ratings yet

- C18 Marine Auxiliary Engine Electrical System: Harness and Wire Electrical Schematic SymbolsDocument2 pagesC18 Marine Auxiliary Engine Electrical System: Harness and Wire Electrical Schematic SymbolsDammiam GaticaNo ratings yet

- Topaz AM1 User Manual EnglishDocument8 pagesTopaz AM1 User Manual English106trNo ratings yet

- Ele Boqce BMM Staff - 31-07-12rDocument10 pagesEle Boqce BMM Staff - 31-07-12rKrm ChariNo ratings yet

- Dell Precision 3520: Owner's ManualDocument82 pagesDell Precision 3520: Owner's ManualncharalaNo ratings yet

- Basic PLC Cp1lDocument51 pagesBasic PLC Cp1lQuang Huy Doan NgocNo ratings yet

- Factors of A Safe Residential Electrical InstallationDocument32 pagesFactors of A Safe Residential Electrical InstallationjporangecubeNo ratings yet

- User Manual DRC-40DK/41DKDocument14 pagesUser Manual DRC-40DK/41DKEhsan pour sarabiNo ratings yet

- FU50 Steering Lever ManualDocument28 pagesFU50 Steering Lever Manualmfazioli100% (1)

- MX-ProDV UserManualDocument198 pagesMX-ProDV UserManualYo TuNo ratings yet

- 773 G Plano ElectricoDocument26 pages773 G Plano Electricoandres gomezNo ratings yet

- Keyence 1Document20 pagesKeyence 1prasadrokadeNo ratings yet

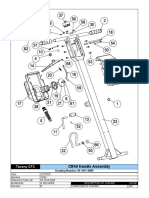

- Cimex 48 Parts DrawingDocument9 pagesCimex 48 Parts DrawingCoffee. copylahNo ratings yet

- YPG 625 Eng Manual PDFDocument142 pagesYPG 625 Eng Manual PDFvpandya1981No ratings yet

- Radio (Gamma)Document6 pagesRadio (Gamma)Istina GubitnikNo ratings yet