Professional Documents

Culture Documents

Surface Profile

Surface Profile

Uploaded by

Peyman KhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Surface Profile

Surface Profile

Uploaded by

Peyman KhCopyright:

Available Formats

PD-4 1st

TECHNICAL DATA

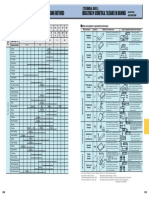

SURFACE ROUGHNESS

TECHNICAL DATA

TECHNICAL DRAWINGS

Excerpt from JIS B 0601(1994)and

JIS B 0031(1994)

Categories of surface roughness

Each grain surface position is indicated as shown in Fig. 1.This includes surface roughness,

cut-off value or reference length, processing method, symbol of direction of lay, surface waviness, etc.

Fig. 1 Legend

a :Value of Ra

b :Processing method

Typical ways for obtaining surface roughness

Arithmetical mean roughness(Ra)

Ra= r

f( x ) d x

Rv

Ry

Rp

Y V5

Yp 5

Yp4

Y V4

Y V1

Y V2

Y V3

Yp 3

Yp 2

Yp 1

Rz=

Yp1+Yp2+Yp3+Yp4+Yp 5 + Yv1+Yv 2+Yv 3+Yv 4+Yv 5

0.4

0.8

1.6

a

a

a

0.8

3.2

6.3

a

a

12.5

25

a

a

50

100

a

a

0.25

8

Max. height

Ry

0.4

3.2

12.5

50

~

~

~

~

0.2

1.6

6.3

25

100

Ten-point mean roughness

Rz

Preferred number series

0.05

0.1

0.2

0.4

0.8

s

s

s

s

s

0.05

0.1

0.2

0.4

0.8

1.6 s

3.2 s

6.3 s

1.6 z

3.2 z

6.3 z

12.5 s

25

s

12.5 z

25

z

50

100

s

s

50

100

z

z

200

400

s

s

200

400

z

z

GThe interdependence for 3 classes is not strictly enforced.

GThe evaluation length of Ra, Ry and Rz:Five times the cut-off value standard length respectively.

1167

z

z

z

z

z

Standard length

of RyCRz

r (mm)

Triangular

indication

0.08

Multidirectional intersection or nondirectional point on the projected surface

on which the direction of lay of the

cutting blade is indicated.

(ex)Rapping finished surface, super

finished surface, face milled or end

milled surface in surfacing feed

direction

Concentric circles roughly centered

on the same on the surface on which

the direction of lay of the cutting

blade is indicated.

(ex)

Facing surface

0.25

0.8

Radiating shape roughly centered

on the same point on the surface

on which the direction of lay of the

cutting blade is indicated.

0.25

8

-

Perpendicular to the projected surface on which the direction of lay of the

cutting blade is indicated.

(ex)Shaped surface( when viewed

from the side), machined or cylindrical ground surface.

(ex)

Honing finished surface

Reference:Relationship between arithmetical mean roughness(Ra)and conventional symbols

Indicating symbol of surface

Direction of lay

of cutting blade

Indicating symbol of surface requiring removal press

Indicating symbol of surface on which no removal process is permitted

Direction of lay

of cutting blade

Examples indicating the upper limits of Ra

Intersection of two diagonal lines on the

projected surface on which the direction of

lay of the cutting blade is indicated.

Yv1, Yv2, Yv3, Yv4, Yv5: Lowest 5 peaks within sample

0.012

IExamples indicating surface texture on drawing

Figure

Ry=Rp+Rv

Yp1, Yp2, Yp3, Yp4, Yp5: Tallest 5 peaks within sample

0.25

Meaning

Parallel to the projected surface on

which the direction of lay of the

cutting blade is indicated.

(ex)

Shaped surface

Indication of surface texture on drawings

c :Reference length. Evaluation length

d :Symbol of direction of lay

Note: Items other than a and f are added as necessary.

Symbol

Ten-point mean roughness(Rz)

0.08

Reference:The location of lay of e in Fig. 1.is given as the finish allowance in ISO 1302.

Note:To obtain Ry, sample only the standard length. The part, where peaks and

valleys are wide enough to be interpreted as scratches, should be avoided.

a

a

a

a

a

A section of standard length is sampled from the mean line on the

roughness chart. The distance between the peaks and valleys of the

sampled line is measured in the y direction. The value is expressed

in micrometer(Om)

.

0.012

0.025

0.05

0.1

0.2

c :Cutoff value. Evaluation length

f :Parameter other than Ra(With tp, parameter/cutoff level)

Arithmetical mean roughness

Ra

b

f

c

g

g :Surface waviness(according to JIS B 0610)

Maximum peak(Ry)

A section of standard length is sampled from the mean line on the

roughness chart. The distance between the peaks and valleys of the

sampled line is measured in the y direction.

Then, the average peak is obtained among 5 tallest peaks(Yp)

, as

is the average valley between 5 lowest valleys(Yv).

The sum of these two values is expressed in micrometer(Om).

Ra

A section of standard length is sampled from the mean line on the

roughness chart. The mean line is laid on a Cartesian coordinate

system wherein the mean line runs in the direction of the x-axis and

magnification is the y-axis.The value obtained with the formula on

the right is expressed in micrometer

(Om)when y=f(a)

.

Cut-off value

c(mm)

Excerpt from

JIS Z B 0031(1994)

Positions of respective indicating symbols relative to indicating symbol of surface

Definitions and indications for surface roughness parameters(for industrial products)are specified. They are arithmetical mean roughness(Ra),

maximum height(Ry), ten-point mean roughness(Rz), mean spacing of profile irregularities(Sm), mean spacing of local peaks of the profile(S)

and profile bearing length ratio(tp). Surface roughness is given as the arithmetical mean value for a randomly sampled area. [Mean center line

roughness(Ra 75)is defined in the annexes of JIS B 0031 and JIS B 0061].

Preferred number series

METHOD OF INDICATING SURFACE

TEXTURE ON DRAWINGS

(a)

(b)

(c)

25

6.3

25

25

6.3

25

Direction of lay

of cutting blade

Examples indicating direction of lay

Examples indicating the upper limit and lower limit of Ra

(a)

(b)

6.3

1.6

6.3

1.6

Examples indicating processing method

(b)

(a)

Front milled

3.2

M

3.2

1168

You might also like

- Asme 14.5M 2009Document25 pagesAsme 14.5M 2009aguiladezcalza69100% (5)

- Combinatorics - Brilliant - AnswersDocument6 pagesCombinatorics - Brilliant - AnswersPikachuNo ratings yet

- Finish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019Document5 pagesFinish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019JoshNo ratings yet

- International Standard: Aerospace - MJ ThreadsDocument11 pagesInternational Standard: Aerospace - MJ ThreadsCristian Rodeghel100% (1)

- PMI Testing - Limitations With XRFDocument3 pagesPMI Testing - Limitations With XRFArun Kumar Kar100% (2)

- Part 01 - Review of EN ISO 9606-1Document26 pagesPart 01 - Review of EN ISO 9606-1Turbo Snail RNo ratings yet

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument7 pagesFord Worldwide Fastener Standard: Printed Copies Are Uncontrolledferhat aydoganNo ratings yet

- Steel Rivets and Bars For Rivets, Pressure VesselsDocument4 pagesSteel Rivets and Bars For Rivets, Pressure VesselsxaviereduardoNo ratings yet

- Surface RoughnessDocument1 pageSurface Roughnessapi-3848892100% (2)

- Problem Set 1 - SolutionDocument10 pagesProblem Set 1 - SolutionAgen KolarNo ratings yet

- XTRACT Calculul Unui Perete de B.ADocument1 pageXTRACT Calculul Unui Perete de B.AHDu13No ratings yet

- UKCDocument10 pagesUKCRoshan de Silva0% (1)

- EN10034 Beams Rolling TolerancesDocument2 pagesEN10034 Beams Rolling Tolerancesrameshdatta100% (1)

- ISO 1302 DIN 4768 Comparison of Surface Roughness Values - Stainless Steel T PDFDocument2 pagesISO 1302 DIN 4768 Comparison of Surface Roughness Values - Stainless Steel T PDFgalvaosilva33% (3)

- Din 2393-1Document6 pagesDin 2393-1alextentwentyNo ratings yet

- Control Procedures For The Calibration and Measurement of The Welding Power Supplies For PDFDocument11 pagesControl Procedures For The Calibration and Measurement of The Welding Power Supplies For PDFNenad NedeljkovicNo ratings yet

- EN 10025: 2004 Is The New European Standard For Structural Steel.Document6 pagesEN 10025: 2004 Is The New European Standard For Structural Steel.Alin DavidNo ratings yet

- Domex Welding PDFDocument16 pagesDomex Welding PDFAgourame Abderrahmane100% (1)

- Astm A519Document3 pagesAstm A519Eko SuherNo ratings yet

- Spot Weld Mech PropDocument57 pagesSpot Weld Mech PropWeld Bro SandeepNo ratings yet

- SAE J1926, MS 16142 - CuttersDocument11 pagesSAE J1926, MS 16142 - CutterspbsurfNo ratings yet

- ASME B1.13M - 2005 (Reaffirmed 2010) PDFDocument84 pagesASME B1.13M - 2005 (Reaffirmed 2010) PDFKristin JonesNo ratings yet

- ISO-10664Document10 pagesISO-10664Daniel Quijada LucarioNo ratings yet

- General Tolerances To DIN ISO 2768 T1 and T2Document2 pagesGeneral Tolerances To DIN ISO 2768 T1 and T2manageieNo ratings yet

- Harmonized "Cluster" Document: Fasteners Property Classes of Special ServiceDocument7 pagesHarmonized "Cluster" Document: Fasteners Property Classes of Special ServiceIBRNo ratings yet

- DIN en 462-1 Image Quality of Radiographs (Wire Type)Document10 pagesDIN en 462-1 Image Quality of Radiographs (Wire Type)QA QC100% (2)

- JIS G3445 STKM 11A Steel TubesDocument11 pagesJIS G3445 STKM 11A Steel TubesshantyNo ratings yet

- Thread Gages PDFDocument35 pagesThread Gages PDFpatitay036817No ratings yet

- ISO 9692 3 2002 Joint PreparationDocument16 pagesISO 9692 3 2002 Joint PreparationLHYT NTUANo ratings yet

- Aisi 1018Document1 pageAisi 10188085roNo ratings yet

- Vdocuments - MX Din 405 Universo For Knuckle Thread Din 405Document7 pagesVdocuments - MX Din 405 Universo For Knuckle Thread Din 405wauwio1906No ratings yet

- Properties and Grades of FastenersDocument3 pagesProperties and Grades of Fastenerschez ezNo ratings yet

- Ilnas-En Iso 19598:2016Document8 pagesIlnas-En Iso 19598:2016Victor ParvanNo ratings yet

- F 1789 - 17Document15 pagesF 1789 - 17Acilasac 2018No ratings yet

- Mechanical Properties - Bolt, Nut, FastenersDocument4 pagesMechanical Properties - Bolt, Nut, FastenersmegatornadoNo ratings yet

- E155-00 Aluminum & Magnesium CastingsDocument4 pagesE155-00 Aluminum & Magnesium CastingsSander Duque100% (1)

- As 1897-1976 Electroplated Coatings On Threaded Components (Metric Coarse Series)Document11 pagesAs 1897-1976 Electroplated Coatings On Threaded Components (Metric Coarse Series)SAI Global - APACNo ratings yet

- Bsen25817 PDFDocument18 pagesBsen25817 PDFdzat_sudrazat0% (1)

- En 10139Document2 pagesEn 10139releone11No ratings yet

- Locking Fasteners HandbookDocument48 pagesLocking Fasteners HandbookMomchil YordanovNo ratings yet

- 0526 16 2004 07 en - enDocument6 pages0526 16 2004 07 en - envtsusr fvNo ratings yet

- JIS B0419-1991 (Dung Sai Kich Thuoc)Document1 pageJIS B0419-1991 (Dung Sai Kich Thuoc)Giang Nguyễn BáNo ratings yet

- New StandardsWELDING STANDARDS - VOLVODocument22 pagesNew StandardsWELDING STANDARDS - VOLVORadivojJovanovNo ratings yet

- Iso 4287-1997 PDFDocument21 pagesIso 4287-1997 PDFmikadoturkNo ratings yet

- Method of Shearing Test For Lap Joint Welded: Nissan Engineering StandardDocument5 pagesMethod of Shearing Test For Lap Joint Welded: Nissan Engineering StandardRicardo F.A.No ratings yet

- Astm B446 - 2003 - 2008Document5 pagesAstm B446 - 2003 - 2008isaque300984No ratings yet

- Asme 46.1 2001Document25 pagesAsme 46.1 2001jr_satish6965No ratings yet

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocument4 pagesForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinNo ratings yet

- General Tolerances For MTB: July 2012 Accuracy of ShapeDocument9 pagesGeneral Tolerances For MTB: July 2012 Accuracy of ShapeAkmal NizametdinovNo ratings yet

- Din en 10139 1997 PDFDocument28 pagesDin en 10139 1997 PDFYogesh AnapNo ratings yet

- Auditing Oof Welding Under ASME Section IXDocument21 pagesAuditing Oof Welding Under ASME Section IXsabahiraqNo ratings yet

- Microindentation Hardness of Materials: Standard Test Method ForDocument40 pagesMicroindentation Hardness of Materials: Standard Test Method ForRichard Alcalde100% (1)

- Ford 970Document4 pagesFord 970amanNo ratings yet

- Cqi-9 Heat Threatment DetailsDocument34 pagesCqi-9 Heat Threatment DetailshaydarkasnaklarNo ratings yet

- ISO 4033 Class 12 NutsDocument1 pageISO 4033 Class 12 NutssubsubtwoNo ratings yet

- A923Document7 pagesA923Fakrul HasanNo ratings yet

- Surface Roughness Drawing Indications of Surface TextureDocument1 pageSurface Roughness Drawing Indications of Surface TextureSIVA 1010No ratings yet

- Surface RoughnessDocument1 pageSurface RoughnesswholenumberNo ratings yet

- Surface Texture SymbolDocument1 pageSurface Texture SymbolSrinivas RaoNo ratings yet

- Measuring Surface Roughness: Drawing Symbols (DIN EN ISO 1302:2002)Document1 pageMeasuring Surface Roughness: Drawing Symbols (DIN EN ISO 1302:2002)SudhagarNo ratings yet

- Surface Roughness JIS B 0601 (1994)Document1 pageSurface Roughness JIS B 0601 (1994)Tú Nguyễn MinhNo ratings yet

- pr1169 1170 PDFDocument1 pagepr1169 1170 PDFrahulmuleNo ratings yet

- Scrap Retention DiesDocument1 pageScrap Retention DiesPeter NomikosNo ratings yet

- CH 10Document71 pagesCH 10Ilda KhakiNo ratings yet

- Study Aid - Coriolis EffectDocument4 pagesStudy Aid - Coriolis EffectXu BaoNo ratings yet

- API Operator Manual Practical DistillationDocument17 pagesAPI Operator Manual Practical DistillationUsman NaseemNo ratings yet

- PDS 55910Document2 pagesPDS 55910daimaheshNo ratings yet

- Asme Viii Uhx Tubesheet CalcsDocument3 pagesAsme Viii Uhx Tubesheet CalcsjdfdfererNo ratings yet

- Process Simulation EssentialsDocument26 pagesProcess Simulation EssentialsaalbuhseNo ratings yet

- Math Cement PackageDocument26 pagesMath Cement PackageKarthik Vk100% (1)

- Progress On Iec 60034-18-42Document7 pagesProgress On Iec 60034-18-42manojpathak24No ratings yet

- Reversible LogicDocument4 pagesReversible LogicAbhinand SkNo ratings yet

- Diff EQ SoltionsDocument242 pagesDiff EQ SoltionsLake LoweNo ratings yet

- A Detailed Lesson Plan in Mathematics 9 Grade 9 - Pinta Flores I. ObjectivesDocument10 pagesA Detailed Lesson Plan in Mathematics 9 Grade 9 - Pinta Flores I. ObjectivesRosemarie Velasco DalupangNo ratings yet

- Examples3 PDFDocument2 pagesExamples3 PDFManuel OosNo ratings yet

- Inosindt PDF Extended Surface Tubes 3-1Document32 pagesInosindt PDF Extended Surface Tubes 3-1Hoover OrtizNo ratings yet

- Passive and ACTIVE VentilationDocument12 pagesPassive and ACTIVE VentilationHimanshu Ruhilla50% (4)

- Effect of Preload On Natural Frequency of Bolted Joint Under Impact LoadingDocument4 pagesEffect of Preload On Natural Frequency of Bolted Joint Under Impact LoadingInternational Journal of Innovative Science and Research Technology100% (1)

- Human Body ExergyDocument19 pagesHuman Body ExergyAtakanNo ratings yet

- HSE P COW 06 Leak Testing ProcedureDocument19 pagesHSE P COW 06 Leak Testing Procedurehzq1e100% (1)

- Solving Systems of Equations by Substitution or EliminationDocument5 pagesSolving Systems of Equations by Substitution or EliminationSijey ManingasNo ratings yet

- Nmat Review Physics 1 (Module 1 Exercise) : DIRECTIONS: Select The Best Answer To Each of TheDocument3 pagesNmat Review Physics 1 (Module 1 Exercise) : DIRECTIONS: Select The Best Answer To Each of TheMia0% (1)

- Centre of MassDocument32 pagesCentre of MassR.Yashwanth Raj XBNo ratings yet

- Aegis UG Drill&BlastDocument30 pagesAegis UG Drill&BlastIsabel ChoqueNo ratings yet

- Beers and Lambart Law Lab ReportDocument4 pagesBeers and Lambart Law Lab ReportErinNo ratings yet

- Sheet 2 - ME 211TDocument4 pagesSheet 2 - ME 211Tsophia haniNo ratings yet

- GTA-26 (P-II) Physics ABD: ABC BC Abcd Abcd BD 3 3.2 2 360 0.05 1 10 16 D C B DDocument10 pagesGTA-26 (P-II) Physics ABD: ABC BC Abcd Abcd BD 3 3.2 2 360 0.05 1 10 16 D C B Dabhi kalathiyaNo ratings yet

- Num Block 1 Unit 3Document37 pagesNum Block 1 Unit 3Ramesh KonakallaNo ratings yet

- Suspension Bridge Unit: Technical Teaching EquipmentDocument4 pagesSuspension Bridge Unit: Technical Teaching EquipmentMeraSultanNo ratings yet