Professional Documents

Culture Documents

Sheave

Sheave

Uploaded by

vikasgahlyan0 ratings0% found this document useful (0 votes)

0 views8 pagesSheaves and Pulley

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSheaves and Pulley

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

0 views8 pagesSheave

Sheave

Uploaded by

vikasgahlyanSheaves and Pulley

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

Sheave Design Manual

“Partners to the Crane Industry”

The Nycast Advantage

Nycast Custom Cast sheaves offer some very

important advantages to the equipment designer

searching for ways to recuce component

waights, improve service life, and provide protec-

tion against corrosive environments at a cost

which is competitive with other sheave materials.

Nycast sheaves are custom formulated and cast

from anionically polymerized Nylon Type 6,

yielding a technologically advanced part, ire

from localized stresses which occur in most

other plastics processing methods. In addition,

Nycast sheaves can be specifically formulated

with modifiers and internal lubricant packages

appropriate to the end use which further en-

hance performance.

Advantage #1- Reduced Component Weight

Nycast nylon castings are approximately one-

seventh the weight of cast steel sheaves of the

same dimension, and approximately one-half the

weight of aluminum sheaves. The use of Nycast

sheaves results in reduced dead weight at the

end of a boom and thus increased working

capacity, and lower inertial loads in operation.

Component weight reductions in the crane trans-

late to lower gross vehicle weights. an important

consideration in mobile crane design. Further:

more, reduced woight Nycast sheaves aro oasior

to handle during installation and replacement

than their metallic counterparts.

Advantage #2- Improved Service Life

Nycast Nylon Type 6 custom cast sheaves not

only provide exceptional durability and perfor-

mance in demanding applications, their unique

combination of physical properties significantly

improve wire rope lite in operation. In addition to

high tensile and compressive strength, Nycast

sheaves possess oxcellent toughness and high

elongation properties normally associated with

(One steot sheave weighs as mucti

2a soven Nyeast Nylon sheaves.

less-rigid, elastomeric materials. This provides

a cushioning effect in the groove areas which

contact the rope strands, which has proven to

significantly extend wire rope life. Due to the

ability of Nycast nylon to undergo a reversible,

non-permanent deformation around the indi-

vidual rope strands making contact with the

groove surface, contact pressures at the rope-

groove interface are almost 12 times less than a

steel sheave of the same configuration. Nycast

nylon sheaves provide a cushioned bedding

area for the wire rope which translates into

improved field performance, increased safety in

‘operation, and reduced expense associated

with wire rope replacement

Advantage #3- Corrosion Protection

Nycast nylon sheaves are impervious to rust

and salt water corrosion. This corrosion

resistance is a property of the material itself,

and does not rely on the integrity of a paint or

similar thin coating applied to the sheave

to maintain protection,

In addition, Nycast sheaves are resistant to

attack from most organic chemicals including

solvents, degreasers, and clean-up solvents

Advantage #4- Custom Engineered

All Nycast sheaves are produced in molds

custom engineered to the application. This

optimal design for service and production re-

sults in components which outperform their

metallic counterparts at a competitive cost.

Custom designed molds reduce material waste

in production, and Nycast sheaves require

minimal machining after casting to arrive at the

finished part. Proper mold design also ensures

that material properties are optimized and

casting stresses are eliminated, resulting ina

superior component.

Nycast Custom Sheave design begins with an

analysis of some basic key dimensions and

load requirements. These are detailed below

and on the Sheave Design Worksheet. Cast

Nylons Ltd. provides an experienced Engineer-

ing Staff in place to assist in the design of

Custom Cast Sheaves and Components.

Groove Configuration

A correct groove angle and groove radius are

required to provide maximum support to the

wire rope and minimize wear on both the rope

and the sheave. Experience has shown that

Nycast nylon sheaves with an included groove

angle of 20 deg. provide optimum rope support.

The depth of the rope groove is generally speci-

fied to be a minimum of 1.75 times the rope

diameter. American and European standards

recommend a groove diameter approximately

5% larger than the wire rope itself to accornmo-

date rope tolerances and stil provide adequate

‘spport. Nycast nylon Custom Cast Sheaves

“ate designed with these guidelines in mind.

Recommended groove radius based on rope

diameter is presented in Table

Table | ]

Rope Diameter and Groove Radius

for Nycast Custom Sheaves.

Wire Rope Diameter heave Groove Radius.

vaio, ost in

ae ist

76 set

v2 iret

ane ttt

38 206

34 236

cn iss

fi rd

Bore Configuration

Needle type roller bearings are recommended for

heavy duty applications involving heavy loads.

It press fit is the method of bearing retention,

‘sufficient stock must be left in the bore to main-

tain an acceptable press {it and eliminate bearing

movement within the bore. Press fit allowance

can be determined by the relationship:

PF = .009 VBearing OD

The press fit allowance is subtracted from the

bearing OD to obtain the required bore diameter.

This relationship takes into consideration the

thermal expansion of Nycast nylon from -10 to

140°F operating temperatures. If temperatures

outside this range are to be encountered,

consult Cast Nylons Ltd. for the proper press

fit allowance.

Steel sleeves can be utilized in conjunetion with

bearings to increase load handling capacity in

heavy duty applications due to the resultant

increase in bore diameter. Bronze bushings are

not recommended for applications involving

higher than moderate loads as an alternative to

bearings. In lightly loaded applications, it is

possible to take advantage of Nycast nylons

inherent bearing properties; the bore may be

machined to provide the bearing surface.

The PV limits of the material selected must not

be exceeded, and the proper running clearances

must be taken into account. Table II below indi-

cates recommended shaft running clearances.

Table Il

Shaft Diameters and Recommended

Running Clearances, Plain Bored Nycast Sheaves

Shaft bi Funning Clearance

n o.g0sin

o.008

002

Boia

00:7

010

S021

024

Bore surface finishes of 32 RMS or better

are recommended in plain bored sheave

applications.

All bore machined tolerances are +/- 0.002"

Bearing Retention

Bearings can be retained on the circummterence

through press fit directly into the bore of a Nycast

sheave. By following the formula shown under

the Bore Configuration section, suffucient inter-

ference can be achieved between the bearing

and the bore to hold the bearing in place. Instal-

lation can be achieved with a hydraulic press, or

through the use of heat to expand the bore at

180-200.

Side retention of bearings is required to restrict

movement which may result trom side forces in

operation, Thrust plates or washers can be

placed on either side of the hub to restrict move-

ment. Internal enap rings which lock into grooves

machined into the bore of the hub have also

been utilized successfully in Nycast sheaves

Bearing olained in sheave bore

with nap rings

Idler sheaves fitted with bronze bearings, which

are allowed to move freely from side to side on

the shaft, and two-row, doublo-cup bearings

require different methods of bearing retention

Bronze idler bearings can be retained through

the use of external snap rings placed outboard

of the sheave hub. Similarly, a steel sleeve insert

can be retained with external snap rings to

accommodate two row double cup bearings

which are pressed into the sleeve.

Basic Sheave Dimensions

Load Capacity of Sheaves

Industry standards identity the sheave pitch to

rope diameter ratio (Dp/Dr) and the cesign factor

(Fd) as important variables in the safe design of

load bearing crane sheave applications. ANSI

standarcs specify a minimum Dp/Dr of 18:1, and

a minimum Fd of 8.5 for live or running wire

ropes. The user should determine the values of

these important design criteria based on the

demands of the specific application as the initial

step in custom sheave design.

Sheaves with Bearings

The load capacity of Nycast sheaves, which

incorporate a bearing in the hub, is limited to the

maximum allowable groove pressure and bore

pressure of 3500 psi, The maximum load capac-

ity of a sheave (Lmax) would be the lower of

these two values as calculated below.

9500 pai x D, xD,

$600 psi x D, x W,

Loa

where: D, = Rope diameter in.)

D, = Tread diameter (in.

D,-D,

D, =Pitsh diameter fin.)

Dy, = Bore diametar (in.)

1W, = Bore width in contact with bearing

(Pet Fg. 1)

Lax is chesan as the smaller of

Loe 84 Looe,

‘The actual groove pressure (P,) may be calculated as foliows:

P.=2(UIF)

DxD,

where: U = Breaking strength of

wire 196 (Ib.)

and —UIF, = Maximum single line

pull (b.)

The actual bore pressure (P,) may be caleulated as folows:

Pe2WiFy

Ox Ww,

The load capacity limits recommended above are

based on intermittent cyclic loading at 70°F. If the

application involves continuous loading or cy-

cling, heavy impact forces, high speeds and

acceleration, or operation at temperatures signifi-

cantly higher or lower than ambient, the applica-

tion should be evaluated thoroughly and the

limits should be reduced. Consult Cast Nylons

Lig, for Engineering asistance in these cases.

Sheaves without Bearings

\n applications involving sheaves without the use

of bearings, the load capacity of a Nycast

sheave is limited by the ability of the bore to act

asa bearing. This limit is established by the

maximum recommended pressure (P) loading

and velocity (V) at the bore surface, and the

product of the two, the limiting PV of the

material

PV =Design Load lbs) X V

D,xW,

The calculated PV must not exceed the limiting PV licted

in the Physical Properties table.

To determine load capacity, first obtain the limitng PV of

the material. Calculate the bore suriace velocity (V):

V=.262 x RPMxD,

where D, = Bore diameter (in)

The velue of V should not exceed 400 fpm. Next, deter:

mine the bare pressure P,

P, = Limiting PV

V

‘The maximum recommended bore pressure loading is

1,000 psi. Use the calcuated Pb or 1,000 psi, whichever Is

less, to determine load capacity as follows:

Lmax =P, xD, x1,

whore: Lma

W,

Load capacity (Ibs.)

jore width in contact

with shaft (in)

Excessive loads or speeds above the recommended

limits may cause accelerated wear and increased

bore clearance.

Nycast Sheave Design Worksheet

In reference to the drawing above, the following need to be determined to calculate load

capacities: (assume a bearing is to be used)

D, = Rope diameter = in

D,=D,+D,=___in.

D,=Treaddiameter=____in.

Check: Is D,/ D, equal to or greater than 18? If not, change D, or D, to achieve

this ratio. © e

D, = Bore diameter = in, W, = Bore wicth = in,

Maximum load capacities are then:

MAX Lggie~ 3500 x D, x D, Ibs.

MAX Ly. = 3500 x D, x WY, Ibs.

Choose maximum load to be the smaller of the two quantities above. This is the Maxi-

mum Load in pounds the sheave can carry. To optimize the choice of rope and sheave

dimensions, use the actual groove and bore pressure equations and choose values that

maximize the P, and P, at or near 3500 psi

U=Broaking strongth of rope —_F, = Safety factor = 3.5,

size chosen (Ibs.)

P, MAX = 8500 psi. P, MAX = 3500 psi.

D, /D, = 18 (minimum recommended)

Substituting and simplitying:

Minimum D,= V .0028_x U

and

Minimum W, = 1.47 x 104 x U

Ds

‘The remaining items shown in the drawing above are required for an accurate quote of the part cost.

(aaEEERniiieeemmmeemmememmmeinieinnmmmmmenseeneesaeeeneee ed

———$——]$—_[_{[{[{[{

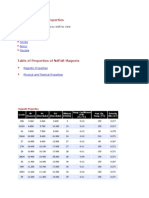

Material Properties

ASTMTEST | NYCASTSPA

PROPERTY UNITS —NETHOD-—_NYCAST6FA-COLORS" NYCASTEPA-MoS2 NYCASTNYLOIL HYCASTXHA

Sresie Geaniy : one 416447 1184.47 1aets 1151.17

Tensile Strength pst ese +2,000-13600 apo0r3.sco —@an0-9.600 12000-13500

Tensile Elongation % ese 2045, 2500 4558 20.00

“Tenste teats ps fd 485-550.000 s20-80.000 390-409,009 _485-580,000

Comprossve Stiengh psi 606 16-1800 16-1800 :

(@ 1% ote)

Floral Sanath ps 0730 15,600-17,500 15500-17500 130043,500 _15.000-15,000,

Floral ods pa 700 0.440.000 420-840 000 so-86n,000 420.140 000

Shear Srength pa ore +10,000-1,000 10000-11,900 0005.60 70,000-11,000

Netchee io pec —tebsin 286 m8 a9 1418 ne

Hardness, Rockwell FL vas 115-120 115-120 40518 110-115

Hovdnose, Shere DD bere 7081 e199 878 7678

Meting Port * o7ee 450-4410 eso se0 4504/10 460-410

Coe efLiearThemal —intinsF D696, Bx to ex 108 36x10" 45x10

Expansion

Doemaen UndeLead — % vezi 102s sta oe a0

Detection Temp,

‘204 ps * bese ss0-anu 330-400 30-409 330-400

pei * pee 400.430 00-420 400499 400-430

Coninuous Serco Temp. 230 290 230 250

Intent Soni Tero. °F 390 30 0 330

Flarmaiity : ves Soltexing Satanting Sotexirg Settting

Water Abeomton

24 Hous rs ps0 ae a4 a4 ad

Saturation % bore 9080 20-80 2025 5060

Limiting PY

Unturieared pstumin = 3600 3.600 16,000 3.609

Lutricatod peittnin 44,000 +4000 318,009 14000

This informations presented 2s a quie for material comparison only. No cuarante® is mace of hei accuracy, however

rl the products are sold without warranty express or pied, anc upon the condions that purchasers shall conduct ther

dn teas to termine suitably for thai intended use

Available in raiual, blue, black, re6, orange, ard yellow. Call fr olor samples.

a NE

Your Complete Source For

Nylon Crane Components.

4300 Hamann Pkwy + Willoughby, Ohio 44094.

216-269-2300 © 1-800-543-3619

You might also like

- Sibre Crane Wheel Systems PDFDocument13 pagesSibre Crane Wheel Systems PDFZehNo ratings yet

- NORD Universal Worm Gear Units CatalogueDocument101 pagesNORD Universal Worm Gear Units CatalogueJ Jick PerSeiNo ratings yet

- Timco Sheave DesignDocument10 pagesTimco Sheave DesignAyman SaadNo ratings yet

- MASTER - Publications 24 PDFDocument1 pageMASTER - Publications 24 PDFgioNo ratings yet

- SKF Plain BearingDocument36 pagesSKF Plain Bearinga04205No ratings yet

- Sheaves : With Cylindrical Roller BearingsDocument3 pagesSheaves : With Cylindrical Roller BearingsInhake AutechreNo ratings yet

- Rear AxleDocument108 pagesRear AxleSlobodanNo ratings yet

- Loads Acting On Crane Structure During TravelDocument11 pagesLoads Acting On Crane Structure During Travelaiyubi2No ratings yet

- Spur Gear Design by IIT MadrasDocument28 pagesSpur Gear Design by IIT MadrasC.S.ABHILASHNo ratings yet

- Brugg Catalog enDocument28 pagesBrugg Catalog enSinoj V AntonyNo ratings yet

- Shafts and BearingsDocument43 pagesShafts and BearingsMario AndrewNo ratings yet

- Design of Bearings & Miscellaneous ElementsDocument14 pagesDesign of Bearings & Miscellaneous ElementsjvanandhNo ratings yet

- C1 30 - 3 EN Crane Wheel SystemsDocument16 pagesC1 30 - 3 EN Crane Wheel SystemsKovács EndreNo ratings yet

- 250 KW Soalr SparesDocument1 page250 KW Soalr SparesRAJENDRA PRASADNo ratings yet

- Insulated Conductor Rail Single Powerline Program 0812: WWW - Conductix.UsDocument36 pagesInsulated Conductor Rail Single Powerline Program 0812: WWW - Conductix.UsHéctor FuentesNo ratings yet

- Loading Factors Within The Strength Calculation Procedure For Involute Marine Gears With Parallel AxesDocument12 pagesLoading Factors Within The Strength Calculation Procedure For Involute Marine Gears With Parallel AxesNenad VulićNo ratings yet

- Ring FederDocument0 pagesRing Federrudolf_laszlokNo ratings yet

- Universal Joint and Theory-Basic PDFDocument17 pagesUniversal Joint and Theory-Basic PDFPrasadNo ratings yet

- Sizes of Different Motor FramesDocument2 pagesSizes of Different Motor FramesVijay Raghavan0% (1)

- Bhatkar (2015) - Finite Element Analysis of Crane Hook and Optimization Using Taguchi ApproachDocument5 pagesBhatkar (2015) - Finite Element Analysis of Crane Hook and Optimization Using Taguchi ApproachGogyNo ratings yet

- Emm 3506 - Group 3Document132 pagesEmm 3506 - Group 3Griffin ThomasNo ratings yet

- Review On Structural Analysis of Bevel GearDocument3 pagesReview On Structural Analysis of Bevel GearEditor IJTSRDNo ratings yet

- 0340 Peinersmagde-21022003-P-Peiner-Greifer-OperatingDocument94 pages0340 Peinersmagde-21022003-P-Peiner-Greifer-OperatingHui ChenNo ratings yet

- Zhao (2020) - Research On Jib Performance of Crane in Hoisting Wind GeneratorDocument9 pagesZhao (2020) - Research On Jib Performance of Crane in Hoisting Wind GeneratorGogyNo ratings yet

- Method For Combining Valves With Symmetric and Asymmetric Cylinders For Hydraulic Systems PDFDocument15 pagesMethod For Combining Valves With Symmetric and Asymmetric Cylinders For Hydraulic Systems PDFRichard De Medeiros CastroNo ratings yet

- Operating Manual For Bevel Gear Boxes: DrehmoDocument16 pagesOperating Manual For Bevel Gear Boxes: DrehmohamzaNo ratings yet

- ISO Gear StandardsDocument6 pagesISO Gear StandardsEslam YehiaNo ratings yet

- Din 471 Ext CirclipsDocument5 pagesDin 471 Ext Circlipschaitanya_kumar_13No ratings yet

- R 27Document668 pagesR 27Adan Arribasplata SeguinNo ratings yet

- Steel Rope Technical Information: Pressures Between Ropes and Sheaves or DrumsDocument1 pageSteel Rope Technical Information: Pressures Between Ropes and Sheaves or Drumskumaras1No ratings yet

- Me-331 Design of Machine Elements Unit Iv Design of Basic ElementsDocument25 pagesMe-331 Design of Machine Elements Unit Iv Design of Basic ElementsMuthuvel MNo ratings yet

- Design of Power ScrewsDocument13 pagesDesign of Power ScrewstogibabusNo ratings yet

- FEM9.311 EnglDocument6 pagesFEM9.311 EnglPınar SunNo ratings yet

- Ejemplo Sepson-manual-EN-dec - 2014 PDFDocument91 pagesEjemplo Sepson-manual-EN-dec - 2014 PDFAngelNo ratings yet

- 22 PDFDocument25 pages22 PDFgavin kennedyNo ratings yet

- Design of Hyd. CylindersDocument10 pagesDesign of Hyd. CylindersVinod YbNo ratings yet

- Spline CalculationsDocument3 pagesSpline CalculationsUfuk KılıçNo ratings yet

- Modeling of Welded Connections in SolidWDocument5 pagesModeling of Welded Connections in SolidWCleyton L. AlvesNo ratings yet

- Comparison of Theoretical & ANSYS FEADocument26 pagesComparison of Theoretical & ANSYS FEArbachalliNo ratings yet

- Joints and Pains of Hydraulic CylindersDocument16 pagesJoints and Pains of Hydraulic CylindersVinaySeeba100% (1)

- TGN 11 Clip Spacing 09-12Document2 pagesTGN 11 Clip Spacing 09-12kayakeras3335No ratings yet

- D155E 10.02 (DOWMAX English)Document50 pagesD155E 10.02 (DOWMAX English)Nastase Dan NicusorNo ratings yet

- Flat Belt CalculationDocument19 pagesFlat Belt CalculationAstri NgentNo ratings yet

- Slewing Bearings CatDocument33 pagesSlewing Bearings CatbennyfergusonNo ratings yet

- ECE-111-Sabra A.S. 2011/ ADR RegulationDocument1 pageECE-111-Sabra A.S. 2011/ ADR RegulationSabra A.S.No ratings yet

- Hydraulic Power Pack Minipack HPM TG2 XXX X S N N 05S C18CDDocument1 pageHydraulic Power Pack Minipack HPM TG2 XXX X S N N 05S C18CDjuniorNo ratings yet

- Austenitic Cast IronDocument2 pagesAustenitic Cast Ironkatchani123No ratings yet

- HSD PDFDocument3 pagesHSD PDFDavid AguilarNo ratings yet

- Rima Rolamentos Versão1 PDFDocument114 pagesRima Rolamentos Versão1 PDFCarlos Alberto de OliveiraNo ratings yet

- Stress Analysis of Tractor Trolley Chassis With Effect of Various Thickness and Design Optimization For Weight Reduction Ijariie1894Document7 pagesStress Analysis of Tractor Trolley Chassis With Effect of Various Thickness and Design Optimization For Weight Reduction Ijariie1894anil sajjanarNo ratings yet

- Technical Information: 1. Hoist RopesDocument17 pagesTechnical Information: 1. Hoist RopesvikasgahlyanNo ratings yet

- Design of TEE Sections in BendingDocument3 pagesDesign of TEE Sections in BendingJimmyNo ratings yet

- Isis DriveDocument18 pagesIsis DriveTms ArnNo ratings yet

- Shaft LayoutDocument21 pagesShaft LayoutAmmar SafwtNo ratings yet

- Charles D Ghilani - Paul R Wolf - Elementary Surveying - An Introduction To Geomatics-Pearson Prentice Hall (2012) - ExtractoDocument19 pagesCharles D Ghilani - Paul R Wolf - Elementary Surveying - An Introduction To Geomatics-Pearson Prentice Hall (2012) - ExtractoRodrigo DelBarrioNo ratings yet

- 101 Problems in AlgebraDocument160 pages101 Problems in AlgebraTrishaii Cuaresma96% (28)

- 2020Document14 pages2020mintrikpalougoudjoNo ratings yet

- Elec 4 BlackDocument1 pageElec 4 Blackyudo08No ratings yet

- Cicuta Tibia - TubaDocument2 pagesCicuta Tibia - TubaYohan Octavio Vera DelgadoNo ratings yet

- Mix Serpiente - BandaDocument53 pagesMix Serpiente - BandaJohn Carlos Vilca VelizNo ratings yet

- Safety Engineering IIDocument2 pagesSafety Engineering IIChusnadiNo ratings yet

- Buku PUIL Keselamatan Dan Pemasangan Instalasi Listrik Voltase RendahDocument240 pagesBuku PUIL Keselamatan Dan Pemasangan Instalasi Listrik Voltase Rendahlamenty55100% (1)

- Behavior Theory ABC Model by Thomas KrausDocument28 pagesBehavior Theory ABC Model by Thomas KrausChusnadiNo ratings yet

- Safety Health and Environmental EbookDocument1 pageSafety Health and Environmental EbookChusnadiNo ratings yet

- Fatality Assessment and Control EvaluationDocument2 pagesFatality Assessment and Control EvaluationChusnadiNo ratings yet

- Welding Standard For Formula StudentDocument1 pageWelding Standard For Formula StudentChusnadiNo ratings yet

- Magnet Materials PropertiesDocument6 pagesMagnet Materials PropertiesChusnadiNo ratings yet

- Design of Pressure VesselDocument137 pagesDesign of Pressure VesselAnand Bhandarkar75% (4)

- MSA American Eagle V-Gard Freedom Series Hard Cap With Fas-Trac SuspensionDocument2 pagesMSA American Eagle V-Gard Freedom Series Hard Cap With Fas-Trac SuspensionChusnadiNo ratings yet

- Marine Safety Guidance Marine Engineering Practice Series Vol 1 Part 5Document1 pageMarine Safety Guidance Marine Engineering Practice Series Vol 1 Part 5ChusnadiNo ratings yet

- Oq &gs - L : Orleans, LA. Cincinnati, OH: U.S. Department of Health, Education, and Welfare, Public Health ServiceDocument3 pagesOq &gs - L : Orleans, LA. Cincinnati, OH: U.S. Department of Health, Education, and Welfare, Public Health ServiceChusnadiNo ratings yet

- Popov E P, Mechanical of Material, Prentice Hall, Inc. 1952 Mechanical of Material by Popov E.P, Prentice Hall Inc 1952Document1 pagePopov E P, Mechanical of Material, Prentice Hall, Inc. 1952 Mechanical of Material by Popov E.P, Prentice Hall Inc 1952ChusnadiNo ratings yet

- Construction Criteria Base WBDG Whole Building Design GuideDocument3 pagesConstruction Criteria Base WBDG Whole Building Design GuideChusnadi100% (1)

- Din 15061 Translate EngDocument1 pageDin 15061 Translate EngMaey Akim50% (2)

- Index of Materials Science and Engineering HandbookDocument1 pageIndex of Materials Science and Engineering HandbookChusnadiNo ratings yet

- Handbook of HYTOPS15000rev10-09Document182 pagesHandbook of HYTOPS15000rev10-09ChusnadiNo ratings yet

- McKissick - 431 Super Champion Snatch Block W Shackle Specs Lengkap Dengan PerhitungannyaDocument9 pagesMcKissick - 431 Super Champion Snatch Block W Shackle Specs Lengkap Dengan PerhitungannyaChusnadiNo ratings yet