Professional Documents

Culture Documents

Electrostatic Precipitators

Electrostatic Precipitators

Uploaded by

Durai SivamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrostatic Precipitators

Electrostatic Precipitators

Uploaded by

Durai SivamCopyright:

Available Formats

Air quality control SOLUTIONS

Electrostatic Precipitators

Effectively improving the environment

Alstoms wide range

of Electrostatic

Precipitators (ESP)

designs offer the best

fit for all applications,

optimising emission

compliance and

saving power.

Customer benefits

HIGH PARTICULATE REMOVAL

EFFICIENCY

Emission levels less than 10 mg/Nm3.

CUSTOMISATION

Choice of discharge electrodes

customised to specific demands of

various applications.

Meeting the most stringent regulation

with the lowest cost

Electrostatic Precipitators (ESP) are widely accepted across the world as an

effective system for particulate emissions control. Alstom Electrostatic

Precipitators, offer a reliable solution to the demands of increasingly strict

regulations for particulate matter emissions worldwide, at the lowest

lifecycle cost.

ESPs work by creating a high voltage electrical field (corona) around the discharge

electrodes, which causes the gases and the dust particles being carried by the gases,

to get ionised. The dust particles, once charged, migrate to and deposit themselves

on the neutral collecting plates, from which they are dislodged by periodic rapping and

guided to dust hoppers for removal.

Alstom offers a wide range of ESP designs, with a choice of discharge electrodes and

rapping systems, to provide the most cost effective, technically reliable solution for

every application.

Applications

Power and industrial boilers firing coal, lignite, oil, orimulsion, biomass and

other fuels

Various processes in iron and steel and non-ferrous metallurgical industries,

cement industry, incineration plants, glass smelting and pulp & paper plants, etc.

INCREASED AVAILABILITY

Robust design and construction

ensures reliability.

TPW/BPROS/ESPBRC12/EN/ECS/10.13/CH/7709

REDUCED COMPLIANCE COSTS

Integrated control system optimises

power savings while maximising

performance.

LOWER INVESTMENT

Easy to install due to flexible layout

and modular design.

PROVEN DESIGN

Proven technology fine tuned with

global experience and a large installed

base.

ALSTOM 2013. All rights reserved. Information contained in this document is indicative only. No representation or warranty is given or should be

relied on that it is complete or correct or will apply to any particular project. This will depend on the technical and commercial circumstances. It is

provided without liability and is subject to change without notice. Reproduction, use or disclosure to third parties, without express written authority,

is strictly prohibited. Photo credits: ALSTOM 2013. All rights reserved. Printed on environmentally friendly paper.

Air quality control SOLUTIONS

Electrostatic Precipitators

3 STEPS TO MAXIMISE PERFORMANCE

1 Optimum charging of the dust is fundamental to effective ESP performance and

this is achieved by perfectly matching the choice of the discharge electrode design

to the demands of the application.

The Alstom spiral discharge electrodes ensure uniform corona current distribution

and is universally recognised as the most effective solution for medium and high

resistivity dust.

The Alstom multi-peak discharge electrodes are best suited for applications

involving low resistivity dusts or dusts having large amounts of fine particles.

Scope options

EPC Option

Design, engineering, supply, erection and

commissioning with or without civil works

Design, engineering and supply with advisory

service during erection and commissioning

2 Effective Cleaning System design helps prevent dust building up on the collecting

plates, minimising the back corona effect, which otherwise diminishes the

efficiency of the ESP, especially if the dust resistivity is high.

Alstom uses a robust tumbling hammer design which is most effective in

dislodging even the most resistant dust from the electrodes, to ensure consistently

high efficiency of the ESP.

Alstom also offers, Electric Impact Rapping (EIR) for applications involving low

resistivity dust, where relatively mild rapping is sufficient. The design of the EIR

is simple and easy to maintain as all the moving parts are accessible from outside

the flue gas path.

3 High quality Integrated ESP Control systems ensure optimised performance of

the ESP

Alstoms Electrostatic Precipitator Intelligent Controller (EPIC III) is a 3rd

generation state-of-the-art ESP control system that delivers

optimum performance and power savings thanks to a range of operating modes

rapping sequence optimisation and power controlled rapping as well as selfoptimisation algorithms (EPOQ)

Alstom also offers the Switch Integrated Rectifier (SIR) high frequency output

power supplies, which ensures maximum power injection without sparking and

is highly effective for low and medium resistivity dusts.

EP Option

Services Only

Operation and maintenance services

Technical specifications

PM removal efficiency

approx. 99.95%

Emission level

<10 mg/Nm3

Corona power consumption

110 W/m2

Typical ESP layout and key components

Gas distribution

screens

TPW/BPROS/ESPBRC12/EN/ECS/10.13/CH/7709

Bottom arrangement

(pyramid hoppers,

trough hoppers

or scrapers, baffles)

Rapping mechanism

for discharge and

collecting electrodes

Power supply

Casing

Discharge electrode

system

Collecting electrodes

State-of-the-Art Laboratory and Testing Facilities

Highly-skilled engineers and technicians from Alstoms R&D Execution Centre in

Vxj, Sweden support our customers and the further development of our ESP

technology solutions.

ALSTOM 2013. All rights reserved. Information contained in this document is indicative only. No representation or warranty is given or should be

relied on that it is complete or correct or will apply to any particular project. This will depend on the technical and commercial circumstances. It is

provided without liability and is subject to change without notice. Reproduction, use or disclosure to third parties, without express written authority,

is strictly prohibited. Photo credits: ALSTOM 2013. All rights reserved. Printed on environmentally friendly paper.

LOWERING

ENVIRONMENTAL FOOTPRINT

<10mg/Nm3

emissions achievable using our

ESP Solutions and Technology.

Alstom has a strong reference

base of more than 4,500

successful ESP installations

worldwide including 230 GW

eqv. in power generation.

To find out more about Alstoms

ESP technology and applications,

please contact your local Alstom

representative:

Alstom Power

Brown Boveri Strasse 7

5401 Baden

Switzerland

Visit us online: www.alstom.com

You might also like

- Electrostatic PrecipitatorsDocument2 pagesElectrostatic PrecipitatorsHaraprasad SNo ratings yet

- Data SheetDocument5 pagesData SheetPaolo S. ContrerasNo ratings yet

- Technical Report Rso & ResistanceDocument5 pagesTechnical Report Rso & Resistanceari anggawanNo ratings yet

- PCS-985G - X - Instruction Manual - EN - Domestic General - X - R1.00 - (EN - YJBH2641.0086.0001) PDFDocument316 pagesPCS-985G - X - Instruction Manual - EN - Domestic General - X - R1.00 - (EN - YJBH2641.0086.0001) PDFDoan BaoNo ratings yet

- Vacuum Circuit BreakerDocument6 pagesVacuum Circuit BreakerMd Rodi BidinNo ratings yet

- 11 Electrabel Maxima Power PlantDocument29 pages11 Electrabel Maxima Power Plantpartha6789No ratings yet

- Case Study Electrical MachineDocument31 pagesCase Study Electrical MachineMuneerAhmed0% (2)

- Alstom Gen TOPACK PDFDocument6 pagesAlstom Gen TOPACK PDFcynaidu100% (2)

- Aarti Steel WHR PDDDocument34 pagesAarti Steel WHR PDDKvvPrasadNo ratings yet

- DC Link InductorsDocument14 pagesDC Link InductorsManguishNo ratings yet

- Auma Button Type Manual PDFDocument80 pagesAuma Button Type Manual PDFMotorola AndroidNo ratings yet

- Faults CompediumDocument109 pagesFaults CompediumDevas ShuklaNo ratings yet

- 5M3/H Water Electrolysis Hydrogen Production Equipment Overhauling PlanDocument17 pages5M3/H Water Electrolysis Hydrogen Production Equipment Overhauling Plandanang harimurtiNo ratings yet

- AF09 ... AF30 3-Pole Contactors Up To 25 HP / 600 VAC: Contactors and Overload RelaysDocument33 pagesAF09 ... AF30 3-Pole Contactors Up To 25 HP / 600 VAC: Contactors and Overload RelaysJohn LorenzoNo ratings yet

- lm6000 Business Unit Igt Packaging PDFDocument10 pageslm6000 Business Unit Igt Packaging PDFEDBNo ratings yet

- Brochure2010 en LDocument70 pagesBrochure2010 en Lbharat_22nandula100% (1)

- EnertorkDocument22 pagesEnertorkTj Bro BroNo ratings yet

- Turbo GeneratorDocument7 pagesTurbo GeneratorSagar Khandelwal100% (1)

- Training Catalogue November 2017 PDFDocument140 pagesTraining Catalogue November 2017 PDFRohit KumarNo ratings yet

- ACS 800 ParametersDocument82 pagesACS 800 ParametersMike CerreroNo ratings yet

- 01 Auma Sar1 Am1 en PDFDocument60 pages01 Auma Sar1 Am1 en PDFAnurag PandeyNo ratings yet

- S705 E-43 (A) 6E2831101 MAIN GENERATORDocument24 pagesS705 E-43 (A) 6E2831101 MAIN GENERATORSagar TamhankarNo ratings yet

- H.V Rectifier Device Use ManualDocument50 pagesH.V Rectifier Device Use Manualatulbrmhnkr100% (1)

- TX2/RX2 Remote Controller With Five Functions: FeaturesDocument8 pagesTX2/RX2 Remote Controller With Five Functions: FeaturesRambo333No ratings yet

- Ka26 Combined Cycle Gas Power Plant UpgradeDocument2 pagesKa26 Combined Cycle Gas Power Plant UpgradepaulwaNo ratings yet

- AEGIS Presentation - Preventing Bearing Fluting Failure in VFD Driven Motors-ASHRAEDocument31 pagesAEGIS Presentation - Preventing Bearing Fluting Failure in VFD Driven Motors-ASHRAEshekarpNo ratings yet

- Small-Scale Hydropower System: 1 PrefaceDocument4 pagesSmall-Scale Hydropower System: 1 PrefaceAnonymous LHGQqOBNo ratings yet

- Generator-Transformer Unit Protection (RCS-985BT) PDFDocument261 pagesGenerator-Transformer Unit Protection (RCS-985BT) PDFJennerous100% (1)

- HTTP WWW - Trenchgroup.com Ps Tools Download - PHP File Docudb Psfile Doc 83 Import4cd7ff1c2563f.pdf&Name Transformer Bushings COTA 25kV To 765kvDocument12 pagesHTTP WWW - Trenchgroup.com Ps Tools Download - PHP File Docudb Psfile Doc 83 Import4cd7ff1c2563f.pdf&Name Transformer Bushings COTA 25kV To 765kvhenny_el3306No ratings yet

- Dry Cleaning & Inspet Esp #1Document16 pagesDry Cleaning & Inspet Esp #1ShahNo ratings yet

- Jaquet FT 1400 eDocument4 pagesJaquet FT 1400 eAnonymous AeIfk4RKnNo ratings yet

- Se-4e15 Avr Manual 2021Document10 pagesSe-4e15 Avr Manual 2021Kostas Ioannou50% (2)

- CB76 3261Document7 pagesCB76 3261rodruren01No ratings yet

- Advantages of Star Delta StarterDocument1 pageAdvantages of Star Delta StarterMoiz HasanNo ratings yet

- SHPMDocument14 pagesSHPMvikasoza100% (1)

- Site Comp End 02Document66 pagesSite Comp End 02Parameswararao BillaNo ratings yet

- SOP For TOSHIBA VFDDocument8 pagesSOP For TOSHIBA VFDJoseph Jojo100% (1)

- Heat Shrink Cable Joints & Cable Terminations LV HV, 6.6kV 11kV 33kV SPS CatalogueDocument63 pagesHeat Shrink Cable Joints & Cable Terminations LV HV, 6.6kV 11kV 33kV SPS CatalogueBasman GeorgeNo ratings yet

- APH Brochure PDFDocument10 pagesAPH Brochure PDFdillipsh123No ratings yet

- ABB Catalogue For LT MotorDocument6 pagesABB Catalogue For LT MotorNavneet Singh0% (1)

- Operating Instructions and Maintenance Manual For LV AC Induction MotorsDocument22 pagesOperating Instructions and Maintenance Manual For LV AC Induction MotorsAlwyzz Happie RaamzzNo ratings yet

- Self Dehydrating BreatherDocument12 pagesSelf Dehydrating BreatherJOSE DANIEL PEREZNo ratings yet

- Magnetics Corporation of India-Brochure (New) .Document8 pagesMagnetics Corporation of India-Brochure (New) .Mk BhatNo ratings yet

- ESP Operation and MaintenanceDocument42 pagesESP Operation and MaintenanceWahyu ßagus TriwiyonoNo ratings yet

- Air Circuit Breakers - AH TypeDocument6 pagesAir Circuit Breakers - AH TypeAchmad Furqon Syaifullah100% (1)

- 10 Generator EbookDocument15 pages10 Generator EbookPurryWidiarko100% (1)

- High Vacuum Insulating Oil Purifier Series ZYDocument10 pagesHigh Vacuum Insulating Oil Purifier Series ZYMartha BenavidesNo ratings yet

- MCBDocument18 pagesMCBEko Nugroho PranunggoroNo ratings yet

- Calibration of Tr-Rec ESPDocument17 pagesCalibration of Tr-Rec ESPNuris ApriyantoNo ratings yet

- Zorc PresentationDocument18 pagesZorc PresentationAyman AboudNo ratings yet

- DTR 1000 KvaDocument7 pagesDTR 1000 KvaAbhinav TewariNo ratings yet

- ALSTOM Australia FactsheetDocument5 pagesALSTOM Australia FactsheetRAJAMANICKAMNo ratings yet

- Alstom Vajh13 Relay ManualDocument3 pagesAlstom Vajh13 Relay ManualNaveen Prasad100% (1)

- 3.digital Electric HydraulicDocument35 pages3.digital Electric HydraulicBui Vanluong100% (1)

- 505 Digital Governor For Steam Turbines With Single or Split-Range ActuatorsDocument124 pages505 Digital Governor For Steam Turbines With Single or Split-Range ActuatorsramkrishnaNo ratings yet

- 30 Full Turnkey CapabilitiesDocument12 pages30 Full Turnkey CapabilitiesMahazan Ab. GhaniNo ratings yet

- Alstom EPIC III ControllerDocument2 pagesAlstom EPIC III Controlleradehriya50% (6)

- Gas Power Plants AlstomDocument28 pagesGas Power Plants AlstomNo Pi100% (2)

- Gas Insulated Switchgear For High Voltage Substations SiemensDocument10 pagesGas Insulated Switchgear For High Voltage Substations SiemenspcelisNo ratings yet

- Eco 80 Wind Turbine PlatformDocument2 pagesEco 80 Wind Turbine PlatformKarthick Velayutham0% (2)

- Sae 1000 PsiDocument6 pagesSae 1000 PsiAnonymous uL3JlWfhNo ratings yet

- High-Performance Decanter: Applications Working PrincipleDocument4 pagesHigh-Performance Decanter: Applications Working PrincipleAnonymous uL3JlWfhNo ratings yet

- B AlstonDocument176 pagesB AlstonAnonymous uL3JlWfhNo ratings yet

- Norit Brochure Ac Gas and AirDocument11 pagesNorit Brochure Ac Gas and AirAnonymous uL3JlWfhNo ratings yet

- CJC Off-Line Fine Filter Insert: ApplicationDocument1 pageCJC Off-Line Fine Filter Insert: ApplicationAnonymous uL3JlWfhNo ratings yet

- Moody DiagramDocument18 pagesMoody DiagramAnonymous uL3JlWfh100% (1)

- Celebrating: Y E A R SDocument6 pagesCelebrating: Y E A R SAnonymous uL3JlWfhNo ratings yet

- Exact Ratio: Ab C Defg H J K L MNDocument1 pageExact Ratio: Ab C Defg H J K L MNAnonymous uL3JlWfhNo ratings yet

- Electrostatic Precipitation PDFDocument10 pagesElectrostatic Precipitation PDFAnonymous uL3JlWfhNo ratings yet

- MGE Comet S31: Three Phase / Single PhaseDocument4 pagesMGE Comet S31: Three Phase / Single PhasevrymanNo ratings yet

- Air Charge-Air Cooling: Diesel Engine-Generator SetDocument4 pagesAir Charge-Air Cooling: Diesel Engine-Generator SetredaNo ratings yet

- Quotation For Solar Street LightDocument3 pagesQuotation For Solar Street LightDebabrata GhoshNo ratings yet

- 3000W True Sine Wave DC-AC Inverter: SeriesDocument2 pages3000W True Sine Wave DC-AC Inverter: Serieshassoun01No ratings yet

- F. Rocket Engine Design Lect 2Document29 pagesF. Rocket Engine Design Lect 2Black HunterNo ratings yet

- Kalkulasi KHA & CB ListrikDocument30 pagesKalkulasi KHA & CB ListrikTanaka Fikry Hi-tsuichiNo ratings yet

- LV Switch - Schneider Electric - Vario - V4Document24 pagesLV Switch - Schneider Electric - Vario - V4Chris WolfNo ratings yet

- Siel Evo Ups 20 200KVADocument83 pagesSiel Evo Ups 20 200KVAIoannis PerperisNo ratings yet

- Rankine CycleDocument15 pagesRankine Cycleitezaz ahmedNo ratings yet

- Understanding Air Preheater Performance: Storm Technologies, IncDocument4 pagesUnderstanding Air Preheater Performance: Storm Technologies, IncMahesh MishraNo ratings yet

- Lecture 1 Thermodynamics Review: Dr. Ronald M. Levy Ronlevy@temple - EduDocument7 pagesLecture 1 Thermodynamics Review: Dr. Ronald M. Levy Ronlevy@temple - EduAracelly CortesNo ratings yet

- 188-MS Kashmir Bricks Co.Document1 page188-MS Kashmir Bricks Co.muhammad bilal ahmedNo ratings yet

- Chimney Liners For FGD PlantDocument19 pagesChimney Liners For FGD PlantAnonymous gr5Pr9AV100% (1)

- INTRODUCTIO1Document75 pagesINTRODUCTIO1Raj KumarNo ratings yet

- Malaysia Matriculation Programme and SyllabusDocument4 pagesMalaysia Matriculation Programme and Syllabuspoundslee73% (11)

- Federal Technology Alert: Refrigerant SubcoolingDocument24 pagesFederal Technology Alert: Refrigerant SubcoolingVeera ManiNo ratings yet

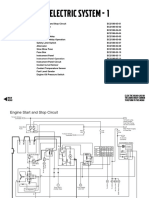

- Electric System - 1: Master Switch Battery RelayDocument18 pagesElectric System - 1: Master Switch Battery RelayLeopoldo Del Campo100% (5)

- Full Wave Voltage Multiplier: Voltage Multipliers Are Similar in Many Ways To Rectifiers in That They ConvertDocument5 pagesFull Wave Voltage Multiplier: Voltage Multipliers Are Similar in Many Ways To Rectifiers in That They ConvertRex Albert Tejadilla100% (2)

- Compressed Natural Gas in Transport SectorDocument13 pagesCompressed Natural Gas in Transport SectorAnurag RayNo ratings yet

- Chapter2 TransformersDocument63 pagesChapter2 Transformerssudeshna sonkar100% (1)

- Dragan Radovic Fitness 4x4 The Way of Dragan PDFDocument150 pagesDragan Radovic Fitness 4x4 The Way of Dragan PDFLonginus Venturus100% (1)

- Focus3 2E Unit Test Vocabulary Grammar UoE Unit5 GroupA B ANSWERSDocument1 pageFocus3 2E Unit Test Vocabulary Grammar UoE Unit5 GroupA B ANSWERSdenys d100% (2)

- Acti9 RCCB Katalog Indonesia PDFDocument3 pagesActi9 RCCB Katalog Indonesia PDFarnosyNo ratings yet

- Proposal For Solar Powered Car Park: With Charging Points For Electric CarsDocument8 pagesProposal For Solar Powered Car Park: With Charging Points For Electric CarsCheerag DuggalNo ratings yet

- EMD June 2012Document2 pagesEMD June 2012kmnath1965No ratings yet

- Component Cost 380 KV LineDocument65 pagesComponent Cost 380 KV LineRague Miuei100% (2)

- TNO 2022 OffshoreDocument43 pagesTNO 2022 OffshoreEirinaios ChatzillariNo ratings yet

- Patterns of DevelopmentDocument5 pagesPatterns of DevelopmentRyan Bustillo100% (3)

- 10 HP Solar Water PumpDocument10 pages10 HP Solar Water PumpPower gamingNo ratings yet

- About Smps and Troubleshooting: To Check Wether Smps Is Working or NotDocument2 pagesAbout Smps and Troubleshooting: To Check Wether Smps Is Working or NotSelvasundar KumarNo ratings yet