Professional Documents

Culture Documents

Filled Wps Multi Gmaw Fcaw

Filled Wps Multi Gmaw Fcaw

Uploaded by

ukavathekarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filled Wps Multi Gmaw Fcaw

Filled Wps Multi Gmaw Fcaw

Uploaded by

ukavathekarCopyright:

Available Formats

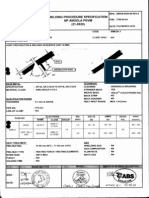

Sample Form (GMAW & FCAW)

WELDING PROCEDURE SPECIFICATION (WPS)

RED Inc.

______

____________

M-N-O____

_____

__0__ 12/01/2014

Company Name

WPS No.

E. M. Ployee (Q.C. Mgr.) _________ 12/01/2014

789 __________________________

Authorized by

Supporting PQR(s)

BASE METALS

Base Material

Welded To

Backing Material

Other

Date

Specification

ASTM A131

ASTM A131

ASTM A131

Type or

Grade

A

A

A

AWS

Group No.

I

I

I

Rev. No.

BASE METAL

THICKNESS

CJP Groove Welds

CJP Groove w/CVN

PJP Groove Welds

Fillet Welds

DIAMETER

JOINT DETAILS

Groove Type

Groove Angle

Root Opening

Root Face

Back Gouging

Method

As-Welded

3/4 -1

5/8 -1

Unlimited

Unlimited

24 min.

Date

_

With

PWHT

3/4 min.

5/8 min.

Unlimited

Unlimited

24 min.

JOINT DETAILS (Sketch)

single V groove butt weld

35 included

1/4

none

-

POSTWELD HEAT TREATMENT

Temperature

Time at Temperature

Other

1100 - 1150F

1 hr/in., 1 hr minimum

WPS may be used with or without PWHT

PROCEDURE

Weld Layer(s)

Weld Pass(es)

Process

Type (Semi-Auto./Machine/Auto.)

Position

Vertical Progression

Filler Metal AWS Spec.

AWS Classification

Diameter

Manufacture/Trade Name

Shielding Gas (Composition)

Flow Rate

Nozzle Size

Preheat Temperature

Interpass Temperature

Electrical Characteristics

Current Type & Polarity

Transfer Mode

Power Source Type

Amps

Volts

Wire Feed Speed

Travel Speed

Maximum Heat Input*

Technique

Stringer or Weave

Multi or Single Pass (per side)

Oscillation (Machine/Automatic)

Number of Electrodes

1-2

1-3

1-2

1-3

1-2

1-3

3-bal.

4-n

3-bal.

4-n

3-bal.

4-n

3-bal.

4-n

3-bal.

4-n

GMAW

GMAW

GMAW

FCAW

FCAW

FCAW

FCAW

FCAW

semi-auto.

semi-auto.

semi-auto.

semi-auto.

semi-auto.

semi-auto.

semi-auto.

semi-auto.

F,V,OH

up

A5.18

ER70S-6

F,V,OH

up

A5.18

ER70S-6

F,V,OH

up

A5.18

ER70S-6

F,V,OH

up

A5.20

E70T-7

F,V,OH

up

A5.20

E70T-7

F,V,OH

up

A5.20

E70T-7

F,V

up

A5.20

E70T-7

F

A5.20

E70T-7

1/16

1/32

1/8

0.045

1/16

5/64

3/32

1/8

s-wire

s-wire

s-wire

t-wire

60 min.

60-350

--DCEP

spray

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

t-wire

60 min.

60-350.

--DCEP

spray

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

t-wire

60 min.

60-350

--DCEP

spray

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

t-wire

60 min.

60-350

--DCEP

spray

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

100 % CO2

100 % CO2

100 % CO2

45-55 cfh

#4

60 min.

60-350

--DCEP

globular

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

45-55 cfh

#4

60 min.

60-350

--DCEP

globular

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

45-55 cfh

#4

60 min.

60-350

--DCEP

globular

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

t-wire

60 min.

60-350

--DCEP

spray

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

42.9 KJ/in.

42.9 KJ/in.

42.9 KJ/in.

42.9 KJ/in.

42.9 KJ/in.

42.9 KJ/in.

42.9 KJ/in.

42.9 KJ/in.

--stringer

multipass

1

None

--stringer

multipass

1

None

--stringer

multipass

1

None

--stringer

multipass

1

None

--stringer

multipass

1

None

--stringer

multipass

1

None

--stringer

multipass

1

None

--stringer

multipass

1

None

wire brush

wire brush

Peening

wire brush

wire brush

wire brush

wire brush

wire brush

wire brush

Interpass Cleaning

Other

*Maximum heat input limit does not apply for non impact tested applications.

( see aws.org/forms for more examples )

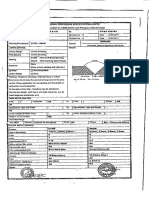

Sample Form (GMAW & FCAW)

WELDING PROCEDURE SPECIFICATION (WPS)

RED Inc.

______

____________

M-N-O____

_____

__1__ 12/01/2014

Company Name

WPS No.

E. M. Ployee (Q.C. Mgr.) _________ 12/01/2014

789 __________________________

Authorized by

Supporting PQR(s)

BASE METALS

Base Material

Welded To

Backing Material

Other

Date

Specification

ASTM A131

ASTM A131

Any

Type or

Grade

A

A

Any

AWS

Group No.

I

I

I

Rev. No.

BASE METAL

THICKNESS

CJP Groove Welds

CJP Groove w/CVN

PJP Groove Welds

Fillet Welds

DIAMETER

JOINT DETAILS

Groove Type

Groove Angle

Root Opening

Root Face

Back Gouging

Method

As-Welded

3/4 -1

5/8 -1

Unlimited

Unlimited

24 min.

Date

_

With

PWHT

3/4 min.

5/8 min.

Unlimited

Unlimited

24 min.

JOINT DETAILS (Sketch)

single V groove butt weld

35 (or as shown on production drawings)

1/4 (or as shown on production drawings)

as shown on production drawings

See Production Drawings

none

-

POSTWELD HEAT TREATMENT

Temperature

Time at Temperature

Other

1100 - 1150F

1 hr/in., 1 hr minimum

WPS may be used with or without PWHT

PROCEDURE

Weld Layer(s)

Weld Pass(es)

Process

Type (Semi-Auto./Machine/Auto.)

Position

Vertical Progression

Filler Metal AWS Spec.

AWS Classification

Diameter

Manufacture/Trade Name

Shielding Gas (Composition)

Flow Rate

Nozzle Size

Preheat Temperature

Interpass Temperature

Electrical Characteristics

Current Type & Polarity

Transfer Mode

Power Source Type

Amps

Volts

Wire Feed Speed

Travel Speed

Maximum Heat Input*

Technique

Stringer or Weave

Multi or Single Pass (per side)

Number of Electrodes

Any

Any

Any

Any

GMAW

FCAW

semi-automatic

F,V,OH

up

A5.18

ER70S-6

semi-automatic

F,V,OH

up

A5.20

E70T-7

F,V

up

A5.20

E70T-7

F

A5.20

E70T-7

1/16

1/32

1/8

0.045

1/16

5/64

3/32

1/8

s-wire

s-wire

s-wire

t-wire

-

t-wire

-

t-wire

-

DCEP

spray

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

DCEP

spray

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

100 % CO2

100 % CO2

100 % CO2

45-55 cfh

#4

45-55 cfh

#4

DCEP

globular

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

45-55 cfh

#4

60 min.

60-350

--DCEP

globular

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

t-wire

-

DCEP

globular

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

DCEP

spray

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

DCEP

spray

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

t-wire

60 min.

60-350

--DCEP

spray

CV

180 - 220

25 - 26

(Amps)

8-12 ipm

42.9 KJ/in.

42.9 KJ/in.

42.9 KJ/in.

42.9 KJ/in.

42.9 KJ/in.

42.9 KJ/in.

42.9 KJ/in.

42.9 KJ/in.

stringer

multipass

1

None

--stringer

multipass

1

None

stringer

multipass

1

None

--stringer

multipass

1

None

stringer

multipass

1

None

stringer

multipass

1

None

wire brush

wire brush

stringer

multipass

1

None

stringer

multipass

1

None

Peening

wire brush

wire brush

wire brush

wire brush

wire brush

wire brush

Interpass Cleaning

Other

*Maximum heat input limit does not apply for non impact tested applications.

( see aws.org/forms for more examples )

You might also like

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- QCF309 Welding Summary ReportDocument1 pageQCF309 Welding Summary Reportminhnn100% (5)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Welding Consumables Control RegisterDocument5 pagesWelding Consumables Control RegisterAli Mhaskar100% (2)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- WPS MigDocument3 pagesWPS MigAJOJOY00960% (5)

- Asme Sec V Article 9 Visual ExaminationDocument11 pagesAsme Sec V Article 9 Visual ExaminationRamesh R100% (1)

- Welder Qualification Form (API 1104) : M/S Chamunda Engineering & Fabrication WorkDocument1 pageWelder Qualification Form (API 1104) : M/S Chamunda Engineering & Fabrication WorkMahendra singhNo ratings yet

- Sa 516 GR 70 WPSDocument5 pagesSa 516 GR 70 WPSRajesh Owaiyar71% (7)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline SungahidNo ratings yet

- 6GR WPS PQRDocument15 pages6GR WPS PQRKiukStaks100% (6)

- FIT UP ReportDocument2 pagesFIT UP Reportsiva8000No ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Bend AllowanceDocument2 pagesBend AllowancewentropremNo ratings yet

- GN-11 Declaration of Conformity TemplateDocument1 pageGN-11 Declaration of Conformity TemplateIstu PataiNo ratings yet

- Internal Audit Checksheet EMS-OHSASDocument32 pagesInternal Audit Checksheet EMS-OHSASRambir KaushikNo ratings yet

- Sample of Welding Quality ManualDocument5 pagesSample of Welding Quality ManualwentropremNo ratings yet

- Mil DTL 1222jDocument51 pagesMil DTL 1222jwmish7419No ratings yet

- Electronics by Sir JoelDocument47 pagesElectronics by Sir JoelDann SarteNo ratings yet

- Engineering Standards: Autodeposition Coating For SteelDocument3 pagesEngineering Standards: Autodeposition Coating For SteelMuthu GaneshNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- Specification Type or Grade AWS Group No. Thickness Size (NPS) Schedule DiameterDocument3 pagesSpecification Type or Grade AWS Group No. Thickness Size (NPS) Schedule Diametercentaury2013No ratings yet

- Wps Magi Tig ExempleDocument6 pagesWps Magi Tig ExempleDanem HalasNo ratings yet

- WPS-PQR Gmaw LtiDocument2 pagesWPS-PQR Gmaw Ltibgonzalez198150% (2)

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- PQR SAW ProcessDocument1 pagePQR SAW Processdevendrasingh202133% (3)

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WQT - WPS 01Document71 pagesWQT - WPS 01Gururaj P Kundapur100% (1)

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsDocument1 pageTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014No ratings yet

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- Sample Welder ID As Per ASME Section IXDocument99 pagesSample Welder ID As Per ASME Section IXVivek Jadhav100% (1)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- Sample API 1104 WpsDocument6 pagesSample API 1104 Wpsjacquesmayol100% (2)

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- Qualified Welder List Valid Until - 03-12-2019Document2 pagesQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarNo ratings yet

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (2)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- WPS 304L &316LDocument2 pagesWPS 304L &316LShakeel Memon100% (1)

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- As Run Sheet-Pqr-051Document14 pagesAs Run Sheet-Pqr-051Anonymous rYZyQQot550% (1)

- PN06CB1S01 PDFDocument5 pagesPN06CB1S01 PDFpololamkaNo ratings yet

- Class 1CB1S01 (Pip PN01CB1S01 - 2005)Document5 pagesClass 1CB1S01 (Pip PN01CB1S01 - 2005)Zvonko Bešlić100% (2)

- Internal Audit Checksheet EMS-OHSASDocument32 pagesInternal Audit Checksheet EMS-OHSASwentropremNo ratings yet

- Bolt Torque SpecsDocument2 pagesBolt Torque SpecswentropremNo ratings yet

- 2.5 SLMTA Receipt Checklist v1Document2 pages2.5 SLMTA Receipt Checklist v1wentropremNo ratings yet

- Metric FastenersDocument5 pagesMetric FastenerswentropremNo ratings yet

- Ultrasonic Testing FormulasDocument4 pagesUltrasonic Testing FormulasNavneet Singh100% (1)

- What Is The Best Way To Clean Aluminum Before WeldingDocument1 pageWhat Is The Best Way To Clean Aluminum Before WeldingwentropremNo ratings yet

- Astm b210mDocument13 pagesAstm b210mwentropremNo ratings yet

- Your Company Name: Suggestion SheetDocument2 pagesYour Company Name: Suggestion Sheetwentroprem100% (1)

- Quality Management System Audit Checklist: Department: Email: Locations Sampled: Phone: Fax: NameDocument7 pagesQuality Management System Audit Checklist: Department: Email: Locations Sampled: Phone: Fax: NamewentropremNo ratings yet

- Staff Suggestion FormDocument1 pageStaff Suggestion FormwentropremNo ratings yet

- ISO Standards On WeldingDocument6 pagesISO Standards On WeldingwentropremNo ratings yet

- On Site Assessment TemplateDocument8 pagesOn Site Assessment TemplatewentropremNo ratings yet

- Stand RdsDocument23 pagesStand RdswentropremNo ratings yet

- PSI First Article Inspection ReportDocument3 pagesPSI First Article Inspection ReportwentropremNo ratings yet

- Page - of - : (A Copy of This Report Is To Remain at Job-Site. Use Additional Sheets If Necessary.)Document7 pagesPage - of - : (A Copy of This Report Is To Remain at Job-Site. Use Additional Sheets If Necessary.)wentropremNo ratings yet

- Book TotDocument39 pagesBook TotwentropremNo ratings yet

- Fine-Grain Structural Steels, Normalised Rolled: Mechanical PropertiesDocument2 pagesFine-Grain Structural Steels, Normalised Rolled: Mechanical PropertieswentropremNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- Datasheet For Steel Grades Carbon Steel Sae j403Document5 pagesDatasheet For Steel Grades Carbon Steel Sae j403Ranjeet DongreNo ratings yet

- Introduction To Process Control: Chapter ContentsDocument14 pagesIntroduction To Process Control: Chapter ContentsBe VerchNo ratings yet

- SRM 2014Document28 pagesSRM 2014YogendraKumarNo ratings yet

- Statement of CB612 - Food Contact 2014 06 25 PDFDocument2 pagesStatement of CB612 - Food Contact 2014 06 25 PDFAmaranTa Jollhe Wissar100% (1)

- Case Study MTPS Dr. Jagannath Munda DVCDocument21 pagesCase Study MTPS Dr. Jagannath Munda DVCLakshmi NarayanNo ratings yet

- Lab 2Document7 pagesLab 2api-250979087No ratings yet

- k2s-Ng01007551-Gen-ra7754-00004 Specification For Line Pipe Protective Coating RepairDocument15 pagesk2s-Ng01007551-Gen-ra7754-00004 Specification For Line Pipe Protective Coating Repairadeoye_okunoyeNo ratings yet

- Download textbook Descriptive Inorganic Chemistry 6Th Edition Geoff Rayner Canham ebook all chapter pdfDocument51 pagesDownload textbook Descriptive Inorganic Chemistry 6Th Edition Geoff Rayner Canham ebook all chapter pdfelizabeth.johnson229100% (9)

- 8.lectures Blend Dyeing 3-05-04-11Document2 pages8.lectures Blend Dyeing 3-05-04-11Shoaib WahabNo ratings yet

- Module 15 PlanetsDocument32 pagesModule 15 PlanetsJensen Ryan Lim100% (1)

- TextileTreatments e PDFDocument20 pagesTextileTreatments e PDFoverlord5555No ratings yet

- ScaDocument16 pagesScaAndres CarrascoNo ratings yet

- Global Marketing For Tube & Pipe: JIS G 4903 Seamless Nickel-Chromium-Iron Alloy PipesDocument9 pagesGlobal Marketing For Tube & Pipe: JIS G 4903 Seamless Nickel-Chromium-Iron Alloy PipesGerardo Emmanuel Romana BrianoNo ratings yet

- CHAPTER 7 9th CLASS Long QuestionsDocument12 pagesCHAPTER 7 9th CLASS Long Questionssomerakhan2023No ratings yet

- The Binding Mode of The Ambidentate Ligand DicyanaDocument7 pagesThe Binding Mode of The Ambidentate Ligand Dicyanapyare08041996No ratings yet

- (Doc 1396) 3-26-2015 FBI David McCollum Explosives TestimonyDocument46 pages(Doc 1396) 3-26-2015 FBI David McCollum Explosives TestimonyTrial DocsNo ratings yet

- SR 12 11684 - Materials - Selection - Guideline - For - Producer - and - Injector - Wells (2) - SignedDocument61 pagesSR 12 11684 - Materials - Selection - Guideline - For - Producer - and - Injector - Wells (2) - SignedMustafa AlrikabiNo ratings yet

- CW July 2013Document72 pagesCW July 2013Clint FosterNo ratings yet

- Catalog Rubber Lining (HD)Document15 pagesCatalog Rubber Lining (HD)imam dianiNo ratings yet

- CHAPTER 2 Acids, Bases and SaltsDocument14 pagesCHAPTER 2 Acids, Bases and Saltsvijusutar31No ratings yet

- Drytec - Refrigerated Compressed Air DryersDocument8 pagesDrytec - Refrigerated Compressed Air DryersJoanaRicardo FigueiredoNo ratings yet

- Chemistry Project To Prepare Rayon ThreadsDocument8 pagesChemistry Project To Prepare Rayon Threadsbharathrajan0% (1)

- Comparative Efficacy of Non-Sedating Antihistamine Updosing in Patients With Chronic UrticariaDocument6 pagesComparative Efficacy of Non-Sedating Antihistamine Updosing in Patients With Chronic UrticariadregleavNo ratings yet

- Automotive Air Conditioning Training Manual 1Document49 pagesAutomotive Air Conditioning Training Manual 1Intan Risky100% (1)

- Fanbeam 4.2 Manual Issue 09Document92 pagesFanbeam 4.2 Manual Issue 09Mohamad HapizNo ratings yet

- Usfda Method ValidationDocument28 pagesUsfda Method ValidationredkarNo ratings yet