Professional Documents

Culture Documents

Destructive Testing Production Welds

Destructive Testing Production Welds

Uploaded by

Akhilesh KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Destructive Testing Production Welds

Destructive Testing Production Welds

Uploaded by

Akhilesh KumarCopyright:

Available Formats

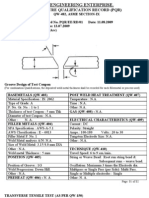

PROCESS FOR DESTRUCTIVE TESTING PRODUCTION WELDS

Reference : API Standard 1104, 5.2

PROCEDURE SPECIFICATION NO.: INDCON-PJPL-STN-MECH-WPS-15

For welding of

: Process Pipe and fittings

Process

: SMAW

Material

: API 5 L x 52, Group : b

Diameter and wall thickness

: 10.75 OD x 0.365 WT

Joint design

: V Groov

Filter material & No. of beads

: A 5.1,

4 ( Four)

Electrical or flame characteristics : Electrical

Position

: 6G

Direction of welding

: Uphill - Vertical

No. of welders

: One

Time lapse between passes

:

Type and removal of line up clamp : External Clamp

Cleaning and/or grinding

: Cleaning with power brush and grinding

Preheat stress relief

:

N/A

Shielding gas and flow rate

:

N/A

Shielding flux

:

N/A

Speed of travel

:

Plasma gas flow rate :

N/A

Plasma gas composition

:

N/A

Plasma gas orifice size

:

N/A

Sketch and tabulations attached :

YES

Tested

Welder

Approved

Welding supervisor

Adopted

Chief engineer

Standard V-Bevel Butt Joint

Bead Number

Sequence of Beads

ELECTRODE SIZE AND NUMBER OF BEADS

Electrode size

Voltage

Amperage and

and type

polarity

Speed

COUPON TEST REPORT

Date

Location

State

Welder

Welding time

Mean temperature

Weather conditions

Test no.

Voltage

Welding machine type

Filler material

Reinforcement size

Pipe type and grade

Wall thickness

Amperage

Welding machine size

Weld position

Mark

Time of day

Wind break used

Roll

Fixed

Outside diameter

1

Coupon stenciled

Original specimen dimensions

Original specimen area

Maximum load

Tensile strength

Fracture location

Procedure

Qualifying test

Qualified

Welder

Line test

Disqualified

Maximum tensile :

Remarks on tensile strength tests :

1

2

3

4

Remarks on bend tests :

1

2

3

4

Remarks on nick-break tests :

1

2

3

4

Minimum tensile :

Average tensile :

Test made at :

Dated :

Tested by :

Supervised by :

Note:

Use back for additional remarks. This form can be used to report either a procedure qualification test or a welder

qualification test.

You might also like

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Welding Procedure Specification Pipe - 6GDocument3 pagesWelding Procedure Specification Pipe - 6Gdndudc97% (29)

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Subsea Pipeline Design, Analysis, and InstallationFrom EverandSubsea Pipeline Design, Analysis, and InstallationRating: 3 out of 5 stars3/5 (1)

- Welding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauDocument5 pagesWelding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauTharakeshNo ratings yet

- Preliminary Welding Procedure Specification: Code: EN ISO 15609-1Document2 pagesPreliminary Welding Procedure Specification: Code: EN ISO 15609-1wentropremNo ratings yet

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezNo ratings yet

- Alu WpsDocument4 pagesAlu WpsdselvakuuNo ratings yet

- WPS 8 To 1-3-1 Rev2 (10-1-13)Document5 pagesWPS 8 To 1-3-1 Rev2 (10-1-13)ERA SSNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalPeter Johnston100% (3)

- MIS-M-DS-04045 Closed Drain Drum Data Sheet-BDocument3 pagesMIS-M-DS-04045 Closed Drain Drum Data Sheet-Bhappale2002No ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Welder Cirt TotalDocument78 pagesWelder Cirt TotalNguyễn ChâuNo ratings yet

- WPS Form - A - ENGDocument1 pageWPS Form - A - ENGdavidemolNo ratings yet

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- WPS-PQR For Split TeeDocument9 pagesWPS-PQR For Split TeemaheshmalaichamyNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- TopCorbelco - WPS FCAW Sa 516 GR 70Document6 pagesTopCorbelco - WPS FCAW Sa 516 GR 70miltonangulomorrisNo ratings yet

- WPQ CS SmawDocument1 pageWPQ CS Smawniket0No ratings yet

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsjacquesmayolNo ratings yet

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Document2 pagesWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyNo ratings yet

- Clad PQRDocument5 pagesClad PQRRinshadNo ratings yet

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- Approved Welding Procedures-Rebar Indirect Butt Joint With Splice AngleDocument8 pagesApproved Welding Procedures-Rebar Indirect Butt Joint With Splice Anglecipele12No ratings yet

- WPQR6Document3 pagesWPQR6Dimitris NikouNo ratings yet

- Essar Constructions Ltd. Hazira.: List of FormatsDocument68 pagesEssar Constructions Ltd. Hazira.: List of Formatsravi00098No ratings yet

- Datasheet For Ball ValveDocument16 pagesDatasheet For Ball ValveDamu JankerboyNo ratings yet

- Aluminim WPSDocument2 pagesAluminim WPSKarthikeyan ShanmugavelNo ratings yet

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationFranklin londono0% (1)

- Asme PQR DemoDocument3 pagesAsme PQR DemoMuthusamy AyyanapillaiNo ratings yet

- AL Wps PDFDocument4 pagesAL Wps PDFprem nautiyalNo ratings yet

- WpsDocument1 pageWpssathi_mechNo ratings yet

- Qw-482 Welding Procedure Specification (WPS) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocument2 pagesQw-482 Welding Procedure Specification (WPS) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86No ratings yet

- Welding Qualification SeminarDocument66 pagesWelding Qualification SeminarsoparlNo ratings yet

- Prequalified X Qualified by Testing Procedure Qualification Records (PQR) YES .Document2 pagesPrequalified X Qualified by Testing Procedure Qualification Records (PQR) YES .Midhun K ChandraboseNo ratings yet

- Annex BDocument14 pagesAnnex BPercy Junior Berrios Muñoz100% (1)

- 13205-PPE-DS-V-003-1 - DataSheet - CVDocument7 pages13205-PPE-DS-V-003-1 - DataSheet - CVAnggun RushNo ratings yet

- Welding FormDocument4 pagesWelding FormAnand SomanNo ratings yet

- Project Standards and Specifications Pipeline Construction Rev01Document15 pagesProject Standards and Specifications Pipeline Construction Rev01hiyeonNo ratings yet

- API-1000-11 Rev 0Document3 pagesAPI-1000-11 Rev 0Mahesh MishraNo ratings yet

- Sample Forms AWS, ASME and APIDocument14 pagesSample Forms AWS, ASME and APIaamirtec301No ratings yet

- Wps For Ss Welding in Pump Room: Phase-3A Development at Indira Gandhi International AirportDocument5 pagesWps For Ss Welding in Pump Room: Phase-3A Development at Indira Gandhi International Airportamit rajputNo ratings yet

- Welding Presentation by NoreastDocument78 pagesWelding Presentation by Noreastravi00098No ratings yet

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- Gas Pipeline SpecDocument4 pagesGas Pipeline SpecA_bener100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDDocument14 pagesProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarNo ratings yet

- 15 ConcretingDocument22 pages15 ConcretingAkhilesh KumarNo ratings yet

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDDocument16 pagesProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarNo ratings yet

- PaintingDocument6 pagesPaintingAkhilesh KumarNo ratings yet

- 12 Form WorkDocument7 pages12 Form WorkAkhilesh KumarNo ratings yet

- Procedure For Plumbing Sanitary WorkDocument5 pagesProcedure For Plumbing Sanitary WorkAkhilesh Kumar100% (1)

- Anti TermiteDocument30 pagesAnti TermiteAkhilesh KumarNo ratings yet

- WaterproofingDocument5 pagesWaterproofingAkhilesh KumarNo ratings yet

- 11-Backfiling at Station NoDocument7 pages11-Backfiling at Station NoAkhilesh KumarNo ratings yet

- 06-Earthwork in ExcavationDocument7 pages06-Earthwork in ExcavationAkhilesh KumarNo ratings yet

- Procedure For Fencing WorksDocument3 pagesProcedure For Fencing WorksAkhilesh KumarNo ratings yet

- Procedure For Horticulture WorksDocument4 pagesProcedure For Horticulture WorksAkhilesh KumarNo ratings yet

- Procedure For Flooring WorksDocument4 pagesProcedure For Flooring WorksAkhilesh Kumar0% (1)

- Procedure For Area Grading and Development WorksDocument3 pagesProcedure For Area Grading and Development WorksAkhilesh KumarNo ratings yet

- Procedure For Steel Door Windows and VentilatorsDocument3 pagesProcedure For Steel Door Windows and VentilatorsAkhilesh KumarNo ratings yet

- Procedure For ScafoldingDocument4 pagesProcedure For ScafoldingAkhilesh KumarNo ratings yet

- Procedure For Roof Water ProofingDocument4 pagesProcedure For Roof Water ProofingAkhilesh KumarNo ratings yet

- Procedure For Surveying and Levels FixingDocument3 pagesProcedure For Surveying and Levels FixingAkhilesh KumarNo ratings yet

- Roof Treatment Proc.Document4 pagesRoof Treatment Proc.Akhilesh KumarNo ratings yet

- Proedure For PlasteringDocument4 pagesProedure For PlasteringAkhilesh KumarNo ratings yet

- Reinforcement Work Proc.Document5 pagesReinforcement Work Proc.Akhilesh Kumar0% (1)

- WBM For Road Work Proc.Document3 pagesWBM For Road Work Proc.Akhilesh KumarNo ratings yet