Professional Documents

Culture Documents

Volume 2, Welding Fabrication Procedure

Uploaded by

alouisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Volume 2, Welding Fabrication Procedure

Uploaded by

alouisCopyright:

Available Formats

LANL

Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure

WFP 2-04 AWS D1.1, Structural Welding Steel

Chapter 13, Welding & Joining

Rev. 1, 10/27/06

TABLE OF CONTENTS

Volume 2, WELDING FABRICATION PROCEDURE

WFP 2-04 AWS D1.1, STRUCTURAL WELDING STEEL .................................................................. 2

1.0

PURPOSE AND SCOPE ....................................................................................................................... 2

2.0

REFERENCES .................................................................................................................................... 2

3.0

WELDER QUALIFICATION ................................................................................................................ 2

4.0

WELDING PREREQUISITES................................................................................................................ 2

5.0

MATERIALS ...................................................................................................................................... 2

6.0

BASE MATERIAL JOINT PREPARATION ............................................................................................ 2

7.0

BASE MATERIAL JOINT CLEANING .................................................................................................. 3

8.0

JOINT FIT-UP AND ALIGNMENT ....................................................................................................... 3

9.0

PREHEAT .......................................................................................................................................... 3

10.0

TACK WELDS ................................................................................................................................... 4

11.0

BACKPURGES ................................................................................................................................... 4

12.0

INTER-PASS TEMPERATURE (IPT).................................................................................................... 4

13.0

WELDING TECHNIQUE ....................................................................................................................... 4

14.0

INSPECTOR QUALIFICATION ............................................................................................................. 5

15.0

ACCEPTANCE CRITERIA FOR COMPLETED WELDS .......................................................................... 5

16.0

WELD REPAIRS................................................................................................................................. 6

17.0

POST WELD HEAT TREATMENT ....................................................................................................... 7

18.0

ATTACHMENT WELDS ...................................................................................................................... 7

19.0

ATTACHMENTS................................................................................................................................. 7

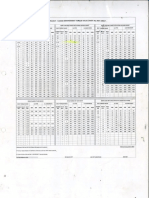

Attachment 1: Weld Profiles and Sizes..................................................................................................... 7

Attachment 2: Minimum Fillet Weld Size for Pre-qualified Joints .......................................................... 7

Attachment 3: Maximum Detailed Size of Fillet Weld Along Edges....................................................... 7

RECORD OF REVISIONS

Rev

Date

Description

POC

OIC

8/16/04

Initial issue.

Kelly Bingham,

FWO-DECS

Gurinder Grewal,

FWO-DO

10/27/06

Administrative changes only.

Organization updates from LANS

transition. IMP and ISD number

changes based on new Conduct of

Engineering IMP 341. Other

administrative changes.

Kelly Bingham,

FM&E-DES

Kirk Christensen,

CENG

Contact the Welding Standards POC for upkeep, interpretation, and variance issues

WFP 2-04

Welding POC/Committee

Page 1 of 7

LANL

Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure

WFP 2-04 AWS D1.1, Structural Welding Steel

Chapter 13, Welding & Joining

Rev. 1, 10/10/06

WFP 2-04 AWS D1.1, STRUCTURAL WELDING STEEL

1.0

PURPOSE AND SCOPE

A. This welding procedure governs the welding of components to the requirements of

AWS D1.1 (Reference 1). The Code edition and addenda for this procedure shall be the

latest in effect or as otherwise specified by engineering requirements.

B. The use of AWS standard welding procedure specifications shall be in accordance with

GWS 1-02, Administrative Control of Welding.

2.0

REFERENCES

1. AWS D1.1, Structural Welding Code

3.0

WELDER QUALIFICATION

A. Welder/welding operators shall be currently certified, having performed qualification tests in

accordance with GWS 1-05, Welder Performance Qualification & Certification.

4.0

WELDING PREREQUISITES

A. All welding shall comply with the requirements specified in the Welding Procedure

Specification (WPS) or Welding Technique Sheet (WTS).

B. Welding shall not be performed when the ambient temperature in the immediate vicinity of

the weld is lower than 0 F or when surfaces are wet or exposed to rain, snow, dust, or high

wind. The welder and weld joint shall be sufficiently protected from inclement conditions.

Care shall be taken to assure that moisture has not been trapped between members that are to

be welded and that moisture has not been introduced into previously fit-up joints prior to final

welding. Preheating above the minimum specified temperature on the WPS or WTS may be

necessary to remove any entrapped moisture. The additional preheat should be applied if

there is suspicion of moisture being present.

5.0

MATERIALS

A. Base Materials

1. Only materials specified in the WPS or WTS may be welded using this procedure.

B. Filler Materials

1. Welding filler materials to be used with this procedure are specified in the WPS or WTS.

A listing of applicable welding filler materials is provided in GWS 1-07, Material

Specifications.

2. Requirements for the purchase and control of welding filler material shall be in

accordance with GWS 1-03, Welding and Brazing Material Procurement and Control.

3. Welding filler materials (electrodes, bare filler wire, etc.) must be utilized by welders

making weldments with this procedure. Welders shall not perform welds autogenously.

6.0

BASE MATERIAL JOINT PREPARATION

A. Surfaces and edges to be welded shall be smooth, uniform, and free from fins, tears, cracks,

Page 2 of 7

LANL

Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure

WFP 2-04 AWS D1.1, Structural Welding Steel

Chapter 13, Welding & Joining

Rev. 1, 10/10/06

and other discontinuities that would adversely affect the quality or strength of the weld.

B. Members to be joined may be cut to shape and size by machining, shearing, chipping,

grinding, thermal cutting, or air carbon arc gouging.

7.0

BASE MATERIAL JOINT CLEANING

A. Prior to welding, surfaces for welding shall be clean and free from paint, oil, rust, scale, slag,

grease, and other foreign materials that are detrimental to welding.

B. Solvents approved for use on the base material and weld materials are methyl alcohol, ethyl

alcohol, isopropyl alcohol, acetone, methyl ethyl ketone, toluene, Varson 4, Dowanol EB, and

Stoddard solvents.

8.0

JOINT FIT-UP AND ALIGNMENT

A. The root opening and fit-up tolerances shall be as specified in GWS 1-06, Weld Joint Design.

If the tolerances cannot be achieved, the end preparations may be built up by welding or reprepared by machining or grinding.

B. The parts to be joined by a tee or fillet weld shall be brought into as close contact as is

practicable. The maximum gap between these parts shall not exceed 3/16 in. If the separation

is greater than 1/16 in., each leg of the fillet weld shall be increased by the amount of

separation.

C. The gap between faying surfaces of lap joints or butt welds utilizing backing shall not exceed

1

/16 in.

D. Parts to be joined by butt welding shall be carefully aligned to maintain an offset not

exceeding 10 % of the thickness of the thinner part joined, but in no case more than 1/8 in.

shall be permitted as a departure from the theoretical alignment. In correcting misalignment

in such cases, the parts shall not be drawn into a slope exceeding in. in each 12 in. of

length. Measurement of offset shall be based upon centerline of parts unless otherwise shown

on the drawing. The degree of angle on the perpendicular member of the joint shall be as

specified in engineering standards/documents or drawings.

E. The parts to be joined by partial penetration groove welds parallel to the length of the

member (bearing joints excepted), shall be brought into as close contact as practicable. The

gap between parts shall not exceed 3/16 in.

9.0

PREHEAT

A. When the base material temperature is below the minimum preheat temperature specified in

the WPS or WTS, the base material shall be heated to the minimum preheat temperature prior

to welding.

B. The preheat temperature shall be maintained for a distance of at least 3 in. or the thickness of

the thicker part being joined, on each side of the weld joint and in advance of the welding.

C. Preheat temperature above 125 F shall be checked by a surface pyrometer, Tempilstik, or

non-mercury-type thermometer. Temperature indicating crayons shall not be used directly in

the weld zone.

Page 3 of 7

LANL

Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure

WFP 2-04 AWS D1.1, Structural Welding Steel

Chapter 13, Welding & Joining

Rev. 1, 10/10/06

10.0 TACK WELDS

A. Tack welds shall be made by a qualified welder in accordance with an approved WPS or

WTS.

B. Acceptable tack welds may be incorporated into the final weld.

C. Defective tack welds shall be removed or repaired prior to welding.

11.0 BACKPURGES

Not applicable.

12.0 INTER-PASS TEMPERATURE (IPT)

A. Inter-pass temperature shall not exceed the maximum value specified in the WPS or WTS

and shall be checked on the surface of the component using a surface pyrometer,

Tempilstick, or non-mercury-type thermometer. Temperature indicating crayons shall not

be used directly in the weld zone.

B. If the temperature of the weld is above the maximum inter-pass temperature specified in the

WPS or WTS, the weld shall be allowed to cool to below the maximum inter-pass

temperature, but not below the minimum preheat temperature, prior to resumption of welding.

13.0 WELDING TECHNIQUE

A. Welding voltage and amperage shall be in accordance with the limits specified in the WPS or

WTS. Specified voltage ranges are not mandatory for AWS purposes. Voltage and amperage

range gages located on the welding power supply are for reference only and are not

mandatory check or hold points. Voltage and amp range checks for documentation purposes

shall be performed by a qualified (CWI or equivalent) inspector using calibrated voltage and

amp meters or approved welding parameter recording equipment.

B. Cracks or blowholes that appear on the surface of a weld bead shall be removed by filing,

grinding, chipping, or air carbon arc gouging before depositing the next bead. Oxygen

gouging shall not be used on quenched and tempered steel.

C. Before welding over previously deposited material, all slag and flux shall be removed, and

the weld and adjacent base material within 1 on either side of the weld shall be brushed

clean.

D. For double-welded butt joints, the second side to be welded, shall be prepared by suitable

methods such as chipping, grinding, or air carbon arc gouging to sound material before

welding.

E. The minimum size of a root pass shall be sufficient to prevent cracking but not less than 1/8.

F. The maximum thickness of root passes in groove welds shall be in.

G. The maximum size of single-pass fillet welds and root beads of multiple-pass fillet welds

shall be:

/8 in. for the flat (1F) position

/16 in. for the horizontal (2F) and overhead (4F) positions

in. for the vertical (3F) position.

5

Page 4 of 7

LANL

Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure

WFP 2-04 AWS D1.1, Structural Welding Steel

Chapter 13, Welding & Joining

Rev. 1, 10/10/06

H. The maximum thickness of layers subsequent to root passes of groove and fillet welds shall

be:

I.

/8 in. for the flat (1G & 1F) position

/16 in for vertical (3G & 3F), overhead (4G & 4F), and horizontal (2G & 2F)

positions.

3

Peening

1. Peening of Group l materials may be used to control distortion or to relieve residual

stresses. Peening shall not be performed until 3/8 in. of the joint thickness has been

deposited. Peening shall not be applied to cover passes, base material, or weld layers

requiring nondestructive examination. Peening shall not be used to mask a defect.

J.

Control of Distortion and Shrinkage

1. In assembling and joining parts of a structure or of built-up members and in welding

reinforcing parts to members, the procedure and sequence shall only be performed to

minimize distortion and shrinkage.

2. Insofar as practicable, welds shall be deposited in a sequence that will balance the applied

heat of welding while the welding progresses.

3. The welding sequence applied, in conjunction with the WPS or WTS and overall

fabrication methods, shall produce members or structures meeting the specified quality

requirements.

4. The direction of the general progression in welding on a member shall be from points

where the parts are relatively fixed in position with respect to each other toward points

where they have a greater relative freedom of movement.

5. Joints expected to have significant shrinkage should usually be welded before joints

expected to have lesser shrinkage. Such joints should be welded with as little restraint as

possible.

6. In making welds under conditions of severe external shrinkage or restraint, the welding

shall be continuous to completion or to a point that will ensure freedom from cracking

before the joint is allowed to cool below the minimum-specified preheat temperature.

K. All welding processes may be single pass or multiple passes per side unless otherwise

specified in the WPS or WTS.

L.

Welding shall be performed single arc unless otherwise specified in the WPS or WTS.

14.0 INSPECTOR QUALIFICATION

A. The Inspector who performs welding inspection for acceptance to this procedure shall be an

AWS-CWI, and authorized by the LANL WPA.

15.0 ACCEPTANCE CRITERIA FOR COMPLETED WELDS

A. Butt Welds

1. As-welded surfaces are permitted; however, the surface of welds shall be sufficiently free

from coarse ripples, grooves, overlaps, abrupt ridges, and valleys.

Page 5 of 7

LANL

Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure

WFP 2-04 AWS D1.1, Structural Welding Steel

Chapter 13, Welding & Joining

Rev. 1, 10/10/06

2. The surface condition of the finished welds shall be suitable for the proper interpretation

of radiographic and other nondestructive examinations when nondestructive examinations

are required. In those cases where there is a question regarding the surface condition, the

film shall be compared to the actual weld surface for interpretation and determination of

acceptability.

3. Undercuts shall not exceed 0.01 in. (0.5 mm) and shall not encroach on the minimum

required section thickness for sheer moment connections and primary members cyclically

loaded in tension. For other than sheer moment and primary connections cyclically

loaded in tension, undercut shall not exceed 1/32 in. (0.8 mm) and shall not encroach on

the minimum required section thickness.

4. Reinforcement shall not exceed 1/8 in. in height and shall have gradual transition to the

plane of the base material surface.

5. Groove welds shall be terminated at the ends of a joint in a manner that will ensure sound

welds. This shall be done by use of extension bars or runoff plates or by grinding starts

and stops. After the weld is completed, the extension bars or runoff plates shall be

removed and the junction ground flush.

B. Fillet Welds

1. As-welded surfaces are permitted; however, the surface of welds shall be sufficiently free

from coarse ripples, grooves, overlaps, abrupt ridges, and valleys.

2. The surface condition of the finished welds shall be suitable for the proper interpretation

of nondestructive examinations.

3. Undercuts shall not exceed 0.01 in. (0.5 mm) and shall not encroach on the minimum

required section thickness for primary members cyclically loaded in tension. For joints

other than cyclically loaded in tension, undercut shall not exceed 1/32 in. (0.8 mm) and

shall not encroach on the minimum required section thickness.

4. Fillet welds may vary from convex to concave. The size of a fillet weld is determined as

shown in Attachment 1.

5. Weld beads shall be continuous through high stress areas such as corners.

6. The minimum fillet weld size, except for fillet welds used to reinforce groove welds,

shall be in accordance with Attachment 2.

7. The minimum length of an intermittent fillet weld shall be 1 in.

8. The maximum fillet weld size detailed along edges of material shall be in accordance

with Attachment 3.

C. Arc Strikes

1. Cracks or blemishes outside of the area of permanent welds resulting from arc strikes

shall be ground to a smooth contour and checked to ensure soundness.

16.0 WELD REPAIRS

A. Weld repairs shall be performed using the original WPS or WTS or an approved repair WTS

to restore a weld to an acceptable condition.

B. The removal of weld material or portions of the base material may be done by machining,

grinding, chipping, or air carbon arc gouging. It shall be done in such a manner that the

remaining weld material or base material is not nicked or undercut. Oxygen gouging shall

not be used in quenched and tempered steel. Unacceptable portions of the weld shall be

Page 6 of 7

LANL

Engineering Standards Manual ISD 341-2

Volume 2, Welding Fabrication Procedure

WFP 2-04 AWS D1.1, Structural Welding Steel

Chapter 13, Welding & Joining

Rev. 1, 10/10/06

removed without substantial removal of the base material. Additional weld material to

compensate for any deficiency in size shall be deposited using an electrode preferably smaller

than that used for making the original weld, and preferably not more than 5/32 in. in diameter.

The surfaces shall be cleaned thoroughly before welding.

C. The weld shall be corrected as follows:

1. Overlap or Excessive Convexity - Remove excess weld material.

2. Excessive Concavity of Weld or Crater, Undersize Welds, Undercutting - Prepare

surfaces and deposit additional weld material using the original Welding Procedure

Specification (WPS) or Weld Technique Sheet (WTS).

3. Excessive Weld Porosity, Excessive Slag Inclusions, Incomplete Fusion - Remove

unacceptable portions and re-weld.

4. Cracks in Weld or Base Material - Determine the extent of the crack by use of magnetic

particle or liquid penetrant (PT) examination. Remove the crack, using the boat

technique to sound material 2 in. beyond each end of the crack, and re-weld.

D. The repaired weld shall be reexamined by the method and technique originally used, with the

same acceptance criteria.

17.0 POST WELD HEAT TREATMENT

A. Post weld heat treatment, when indicated in the engineering specification or in the WPS or

WTS, shall be performed in accordance with GWS 1-08, Post Weld Heat Treatment.

18.0 ATTACHMENT WELDS

A. Attachment welds shall be performed in accordance with an approved WPS or WTS.

B. Materials used for welded attachments shall be equal to, or compatible with the base material.

C. When applying attachments to materials of different thicknesses, the preheat and inter-pass

requirements of the thicker material shall be observed.

D. When the specification requires temporary attachments to be removed, a method of removal

that will not damage the base material shall be utilized; i.e., cut, grind, or air carbon arc

gouge the attachment off and grind the area flush.

19.0 ATTACHMENTS

Attachment 1: Weld Profiles and Sizes

Attachment 2: Minimum Fillet Weld Size for Pre-qualified Joints

Attachment 3: Maximum Detailed Size of Fillet Weld Along Edges

Page 7 of 7

You might also like

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument9 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureJovanni RodriguezNo ratings yet

- WFP 2-01 ASME B31 Piping Welding ProcedureDocument8 pagesWFP 2-01 ASME B31 Piping Welding Procedureleodavid87No ratings yet

- Arc StrikeDocument9 pagesArc StrikeBulut YildizNo ratings yet

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument11 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureJaveed A. Khan100% (1)

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument7 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication Proceduremabrouk2013No ratings yet

- Fabrication Weld ManualDocument12 pagesFabrication Weld ManualChaidir Transmission100% (2)

- Welding Fabrication Procedure API 650 TankDocument6 pagesWelding Fabrication Procedure API 650 TankMenad SalahNo ratings yet

- Shop Welding InspectionDocument4 pagesShop Welding InspectionIndra Nath MishraNo ratings yet

- Field Welding ProceduresDocument102 pagesField Welding Procedureslaz_k100% (2)

- Method Statement For Structural Fabrication & ErectionDocument11 pagesMethod Statement For Structural Fabrication & ErectionBinay94% (16)

- Asme B31.8Document8 pagesAsme B31.8deepndeepsi100% (1)

- Procedure For Visual InspectionDocument4 pagesProcedure For Visual InspectionAkhilesh Kumar100% (4)

- Fab & Erection Pro 20000klR1Document17 pagesFab & Erection Pro 20000klR1Gandhi OnoNo ratings yet

- 5 Clamps Connectors 220 400kv SsDocument12 pages5 Clamps Connectors 220 400kv SsJaswanth SaiNo ratings yet

- HFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ADocument14 pagesHFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ANashaat DhyaaNo ratings yet

- 8a. Insulating Joint - PDF 2 PDFDocument9 pages8a. Insulating Joint - PDF 2 PDFBalasubramanian AnanthNo ratings yet

- Fabrication Inspection ProcedureDocument11 pagesFabrication Inspection Procedurewill_herry100% (6)

- Fabrication - Assembly & ErectionDocument83 pagesFabrication - Assembly & ErectionRengga Andryastama100% (2)

- SOP - 03C Rev 1 Weld Shop PDFDocument9 pagesSOP - 03C Rev 1 Weld Shop PDFGohilakrishnan Thiagarajan100% (1)

- 1 Engg DBD ST 010Document11 pages1 Engg DBD ST 010sanketNo ratings yet

- Fabrication Procrdure Metering SkidDocument11 pagesFabrication Procrdure Metering SkidgstketutNo ratings yet

- Cable Tray Technical SpecificationDocument11 pagesCable Tray Technical SpecificationVikas TanejaNo ratings yet

- Weld Repair ProcedureDocument15 pagesWeld Repair Proceduremohd as shahiddin jafriNo ratings yet

- Spec - WeldingDocument6 pagesSpec - Weldingprasad_kcpNo ratings yet

- Low Temp Design Note 1 Ed 1.0Document4 pagesLow Temp Design Note 1 Ed 1.0Kendra TerryNo ratings yet

- G3ir 1000 50 SP 9015 - R3Document20 pagesG3ir 1000 50 SP 9015 - R3Ramu NallathambiNo ratings yet

- Standard Pipe Support DrawingDocument137 pagesStandard Pipe Support DrawingAob AprilNo ratings yet

- Q210 Welding of Power PipingDocument7 pagesQ210 Welding of Power Pipingpragmatix100% (2)

- Centralizer Spec. IIDocument5 pagesCentralizer Spec. IIsatyendraNo ratings yet

- Welding Manual R01 Nov 2006Document184 pagesWelding Manual R01 Nov 2006SHIVAJI CHOUDHURY100% (5)

- Weld Manual 4 PowerDocument77 pagesWeld Manual 4 PowerGyanendra Narayan NayakNo ratings yet

- Apron FeederDocument10 pagesApron FeederKenny Ruiz100% (1)

- Field Welding SpecsDocument15 pagesField Welding SpecsRaimundo LimaNo ratings yet

- Site Welding Instruction Sheet (SWIS) HandbookDocument36 pagesSite Welding Instruction Sheet (SWIS) HandbookNuwan RanaweeraNo ratings yet

- Shell US 2GS-57 Pipe With Internal Weld OverlayDocument16 pagesShell US 2GS-57 Pipe With Internal Weld OverlaySudarshan Narasipura100% (1)

- 1.1.5 WPSDocument15 pages1.1.5 WPSDominic Apollo RoblesNo ratings yet

- Facility Piping Construction SpecificationDocument18 pagesFacility Piping Construction SpecificationAmanSharmaNo ratings yet

- JJ Sietas Workinstructions For OffshoreDocument12 pagesJJ Sietas Workinstructions For OffshoreDimitris NikouNo ratings yet

- Expansion Joint Technical Specification and Data SheetDocument9 pagesExpansion Joint Technical Specification and Data SheetAhmad Dzulfiqar RahmanNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- Insulator SpecificationDocument22 pagesInsulator SpecificationtanujaayerNo ratings yet

- Department of Infrastructure, Energy and Resources, Tasmania Bridgeworks Specification B22 - Erection of Structural Steelwork April 2003Document6 pagesDepartment of Infrastructure, Energy and Resources, Tasmania Bridgeworks Specification B22 - Erection of Structural Steelwork April 2003Safarudin RamliNo ratings yet

- TGN-BC-01 Tack Welding of Reinforcement BarDocument8 pagesTGN-BC-01 Tack Welding of Reinforcement Barnaseema1No ratings yet

- Operating Instructions For Metal and Rubber Hose Lines: 1. Packaging / Storage / TransportationDocument4 pagesOperating Instructions For Metal and Rubber Hose Lines: 1. Packaging / Storage / TransportationFabio TemporiniNo ratings yet

- Kuwait Oil Company (K.S.C.) : Engineering GroupDocument14 pagesKuwait Oil Company (K.S.C.) : Engineering GroupRELLA ROSHAN KUMARNo ratings yet

- MOS Roof Truss InstallationDocument19 pagesMOS Roof Truss InstallationMohammad Hadoumi Saldan100% (9)

- AMS2411Document9 pagesAMS2411Pankaj Shah100% (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesFrom EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesRating: 1 out of 5 stars1/5 (1)

- PADALDocument24 pagesPADALalouisNo ratings yet

- Volume 1 of The Poem of The Man-GodDocument461 pagesVolume 1 of The Poem of The Man-GodKonstantinos Konstantinidis100% (1)

- Volume 2 of The Poem of The Man-God PDFDocument459 pagesVolume 2 of The Poem of The Man-God PDFalouis0% (1)

- Liza Torque Value ChartDocument1 pageLiza Torque Value ChartalouisNo ratings yet

- URA Exclusion ListDocument1 pageURA Exclusion ListalouisNo ratings yet

- Cswip Wis20Document91 pagesCswip Wis20alouis100% (3)

- Visual Examination ReportDocument47 pagesVisual Examination ReportalouisNo ratings yet

- Flare Tower StatusDocument6 pagesFlare Tower StatusalouisNo ratings yet

- Fpso Piping Material Datasheet SO17033 PESDMCPF999001 A2 10 of 23Document1 pageFpso Piping Material Datasheet SO17033 PESDMCPF999001 A2 10 of 23alouisNo ratings yet

- ASNT L3 Required FormsDocument6 pagesASNT L3 Required FormsErick PachasNo ratings yet

- Joint DesignDocument4 pagesJoint DesignalouisNo ratings yet

- E7007A - Thickness Report (From External)Document2 pagesE7007A - Thickness Report (From External)alouisNo ratings yet

- API 510 Exam Study GuideDocument5 pagesAPI 510 Exam Study Guideanthonyaz100% (2)

- 2 GDocument5 pages2 GalouisNo ratings yet

- Api 570Document116 pagesApi 570alouisNo ratings yet

- Magnetic Particle InspectionDocument7 pagesMagnetic Particle InspectionalouisNo ratings yet

- ASNT Basic Exam Study PlanDocument1 pageASNT Basic Exam Study Planalouis50% (2)

- Visual Examination ReportDocument47 pagesVisual Examination ReportalouisNo ratings yet

- Joint DesignDocument4 pagesJoint DesignalouisNo ratings yet

- EN Standard Welding ParametersDocument1 pageEN Standard Welding ParametersalouisNo ratings yet

- Inspector Calc Part 1Document10 pagesInspector Calc Part 1Abbas RizviNo ratings yet

- Question MTDocument11 pagesQuestion MTrajaksekar100% (3)

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- MT Level IDocument12 pagesMT Level Iidealparrot100% (1)

- API 570 Exam CalculationsDocument2 pagesAPI 570 Exam Calculationssnehal.deshmukhNo ratings yet

- MT Level IDocument12 pagesMT Level Iidealparrot100% (1)

- BA ExamDocument7 pagesBA Examalouis0% (1)

- MT Level IDocument12 pagesMT Level Iidealparrot100% (1)

- Ndtreportsampleandanswercswip3 150207032256 Conversion Gate01 PDFDocument18 pagesNdtreportsampleandanswercswip3 150207032256 Conversion Gate01 PDFalouisNo ratings yet

- API 570 FormulasDocument2 pagesAPI 570 FormulasArif Mokhtar89% (9)