Professional Documents

Culture Documents

Tajima Machine Error List

Tajima Machine Error List

Uploaded by

Alfonso Sanchez VerduzcoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tajima Machine Error List

Tajima Machine Error List

Uploaded by

Alfonso Sanchez VerduzcoCopyright:

Available Formats

Tajima Machine Error List

_01 No 500 character function code when data set

Press RESET and set the data again.

is set

_02 Tajima tape complement error. ( The same +/-- Correct the tape

numerics are entered in a single stitch data

_03 Data is involved in the tape end code

Correct the tape

_04 Improper function code position. Or, wrong

tape format was selected.

_06 Memory writing error

Correct the tape, or select proper format.

_08 PTR tape signal trouble

Adjust reader, or replace unit

_09 PTR motion is in disorder. Reader does not

read the tape for more than 5 seconds

11 Data set incomplete

Check connection of reader cable.

12 Excessive stitch back

13 Prohibited forward ( When offset is set)

16 Tape format 5 is selected although no designs

are stored in memory.

17 After 30 designs have been stored in memory,

tape format 2, or 4 was selected.

18 After the data setting, the number of that

design is erased.

19 Memory capacity shortage during editing.

Expand memory capacity, or replace memory card.

After properly setting data, start again.

Stitch back is possible up to 71 stitches for tape operation and

starting point for memory designs.

Set the offset value to zero, or move the frame by a distance of offset

and move the frame.

Save design to memory

Only 30 designs can be stored in memory. Remove unnecessary designs.

Save design to memory again.

Erase unnecessary designs.

30 Stop command by bar switch is given during

execution of mode 5, 6, offset or home return

31 Stop command by bar switch is given

during color change

51 No stop position signal is output

Encoder or machine card trouble.

52 Frame limit switch activated.

Move the frame to its working area.

53 Stepping motor driver trouble (X, Y)

Check PMD drive units.

54 Left and right limits on the color change

are detected.

55 Color change takes over 5 seconds

Check machine card, needle position card.

56 Color change, half-turn cam signal trouble.

Check needle position card, BP card.

Check for a mechanical bind in the color change system.

Check needle position card.

Check for a mechanical bind in the color change system.

57 Needle position signal trouble

58 One turn of the main shaft motor takes over

5 seconds

59 The cap frame moves more than 75mm from

the cap frame zero point when searching

60 The embroidery space of the cap frame is

exceeded.

211 A fixed position signal is not detected.

Main shaft Z signal)

212 Needle bar is in lowering position

221 The frame has traveled left, exceeding the

position set by the frame limit

222 The frame has traveled right, exceeding the

position set by the frame limit

223 The frame has traveled up, exceeding the

position set by the frame limit

224 The frame has traveled down, exceeding the

position set by the frame limit

225 Travel outside the set embroidery area

( When the software frame limit is set, or

on cap machines)

226 Absolute origin limit (+X, -Y) detected

228 Table up/down operation was attempted although the frame was in the front side position

234 Faulty laser unit

Check machine card, BP card

Inspect the photo interrupter

Move the cap frame to the correct start point or decrease the size

of the design.

Return the main shaft to the fixed position. Check the encoder signal

Move up the needle bar by needle bar operation.

Move the frame manually so that the design fits in the embroidery area.

Correct the frame limit position(s)

Move the frame back to the rear most end before moving the table up/down.

Turn off power and wait 5 seconds. Turn on power again, if error 234

remains check the laser unit. Check chiller (cooling unit)

242 The-M-axis rotation range (+/--32 rotations) is

exceeded when using the M-axis manual

rotation function

H position

251 Low oil in the auto lube pump.

252 The status of the air valve (vacuum) does not

change

253 Lower limit of the laser protect cover is not

detected

254 Upper limit of the laser protect cover is not

detected.

255 A peripheral device is defective

TLFD

255 Manual frame travel or frame forward/back is

CE attempted when the Z-axis is not positioned at

272 Manual nipple lifting is performed during

coiling embroidery

281 The target needle position is not detected

within 15 seconds after the start of the color

change.

291 * Upper thread Breakage is detected

* Tension base card is faulty

293 Under thread breakage is detected

Press the RESET key and then manually rotate the M-axis in the reverse direction.

Or, press the RESET key and then start the machine.

Add oil to the lubrication tank.

Check the air pressure supplied to the air valve.

Check/replace the lower limit sensor, check/adjust air pressure

Check/replace the upper limit sensor, check/adjust air pressure

Check the peripheral device and the connection to it.

Set the Z-axis to H position

Press the RESET key

Turn the shaft of the color change box to check to see if needle position

display is correct. Correct display, action complete.

Incorrect display, check color change sensor(s)

* Check the upper/under thread

* Replace the tension base card

Check the bobbin thread

2B1 No response is received for 5 seconds since

the operation was started using a serial I/F

( Serial I/F device is not correctly connected)

2B2 TAJIMA code complement error. Same + and

* Check connection of serial device (TFD, PC, etc.)

* Repair or correct the design data

2B3 Data exists in an end code

Correct the design data

2B4 Code format error (A stitch code does not

exist at the third character.)

2B5 Reading error, stitch data over 5.1 mm

Correct the design data

2B6 The serial interface is not ready

Set the serial interface to the Communications mode.

Correct the design data

Correct data

2B7 The machine was started or frame forward

was performed although data was not input

2B8 When the pre-reading buffer becomes empty

Perform data set

2B9 Memory write error

During operation: Lower main shaft speed.

During frame forward operation: Wait until all of the design data is read.

Check the CPU or memory card. Replace if necessary

2BA Memory capacity Exceeded

Delete unnecessary designs registered in memory

2BB Frame back exceeded the allowable range

Do not perform further frame back

2BC *No design is registered in memory

*An attempt was made to erase from memory

the current design being embroidered

*An attempt was made to edit data

(clean-upP.4-14) during embroidery

2BD Either a stop code or end code is detected

before the 3rd stitch data.

2BE Start code and end code are not set to be a

pair in satin convers., sequin, and boring code

2C1 The machine is started or frame forward/back

is executed during setting the panel

2C2 Incorrect option setting

*Register design in memory

*To erase from memory a design currently being embroidered, either set another design

or data set the same design

* Do not edit (cleanup) design during embroidery

2C2 ON is set for both boring and laser unit)

TLFD

2C3 "Pack" is not designated

Correct the design data

Set again to make start code and end code be a pair if necessary.

Do not attempt to operate the machine while performing setting on the panel

Set correctly

Set OFF for DSW2-2 boring device and turn on the power after turning it off once

Designate packed designs

2C4 The design stitch count is exceeded

Confirm the number of stitches in the design

2C5 An attempt was made to carry out laser

processing during laser preheating

2C6 Machine operation was attempted, although

the bobbin changer was running

2CB The design is too large to be displayed within

the designated software frame limit

2CD Power supply is turned OFF during design

Wait until preheating is complete.

Do not operate bobbin changer when the machine is running.

Reduce the design to be within the designated software frame limit.

Rewrite data to the memory

deletion or edit mode processing

2CE Remote interlock activates

Reset the remote interlock

2CF An immediate stop came in from an external

device

2D1 Initial setting of laser power is not complete.

Check the external device or the connection to the external device.

(TMLG, connector joint 16 JH08

Complete initial setting of laser power. (Teaching)

_2E3 Power supply has been interrupted during

embroidery

311 *Encoder A signal status does not change for

5 seconds

*Motor or belt failure

312 Encoder z signal status does not change

for 5 seconds

313 Clutch stopper disengaged

314 Main shaft rotation failure

316 A main shaft driver error is detected

Turn ON the power and perform "Power Resume" operation.

*Check encoder and encoder signal lines

*Check the main shaft driver for excitation

Check the main motor and belt

*Check the encoder and encoder signal lines

Engage clutch stopper

Check the encoder/encoder signal line, main motor and belt.

Main breaker.

Replace the main shaft driver unit or mainn shaft motor

317 The take-up lever clutch has received an

abnormal signal

321 PMD failure

Check or replace the joint-25 card.

322 An X-axis pulse motor driver error signal is

detected

323 A Y-axis pulse motor driver error signal is

detected

324 Frame feed output when the needle penetrates

the fabric

32A Hidden Error, usually occurs when the ATH

functions.

32F Hidden Error

Replace the X-axis driver unit

325 *Absolute origin could not be detected on the X

or Y axis

*Cap machine origin search error

Check driver and motor.

Replace the Y-axis driver unit

Decrease the machine operating speed. Check the rotary encoder and encoder

wiring.

Set parameter N-23 to 0 mm. If problem continues install software version BD or later.

Change IMM card.

Make sure machine has at least version BD or later.

If problem persists, change IMM card.

*Find faulty origin sensor and adjust or replace.

* Check cap origin sensor and harness

331 Bobbin Changer error

341 D-axis origin error

CE/LE

341 An M-axis base point signal is not detected

LG

342 An M-axis PMD abnormal signal is detected.

345 The M-axis clutch driver has received an

abnormal signal

346 The zig-zag PMD has received an abnormal

signal

347 An M-axis PMD abnormal signal is detected

352 The sequin driver has issued abnormal signals

371

CE/LE

371

LG

372

CE

372

LG

373

Check bobbin changer components.

Replace the M-axis base point sensor or its harness.

Check the mechanical parts related to the M-axis for abnormalities. Check/replace

the M-axis incremental encoder or M-axis drive assembly.

Check/replace the joint-25 card.

Check the parts related to the zigzag swing mechanism. After adjustment, reset the

machine.

Check the parts related to the M-axis for abnormalities. After adjustment, press the

RESET key.

Check/replace sequin card.

Needle height position error

Check BP card and needle position card

Either an upper or lower position signal cannot

be input

ZB Signal error

Adjust the nipple lifter. Check/replace the sensor.

The nipples do not move more than 1 second

Press the RESET key. Then check/replace the nipple lifting motor and/or the

nipple position sensor.

Press the reset key. Then change the nipple stroke by using the keys from 1 to 5.

and the return key. Check/replace the nipple position sensor.

The nipple position sensor issued an abnormal

signal

373 No input to position sensors

LE

374 Nipple sensor signal abnormality, both inputs

have signals

375 The Z-axis driver (Z-axis release solenoid) has

received an abnormal signal.

381 *The FX head needle position input data has

an error

*The FX head needle position signal is not

input while the main shaft is rotating

382 The needle position signal status during

Check/replace the joint-25 card.

* Set the number of needles at system software correctly. Check/replace

color change sensor

*Check/replace color change sensor

*Check the color change motor and power supply circuit

color change does not change for 1 second

or more

383 *Incorrect input of needle position

*No needle position signal is detected during

rotation of the main shaft

383 Control error of the D-axis drive motor

CE

384 No 1 rotation signal is given while the main

shaft is running

384 Control error of the looper shaft drive

CE motor

385 Lens does not move to the designated position

when during lense switching

385 Z-axis operation failure

CE

391 Thread release input signal error

LE

3A1 The thread trimming driver has issued abnormal

signals

3A2 Thread trimming output time exceeded

*Check the potentiometer (Needle position sensor)

3A6 Incorrect ATH movable knife retract position

Check the position of the ATH movable knife

3A8 A thread holding driver error signal is detected.

3B5 Communication error in the controller

Check thread holding inverter LED. If re LED is lit, change the inverter.

If not, check the harness.

Turn ON the power again

3B6 Communication problem

Check connection IDM and LM1 and LU1 cards.

3C1 The power switch was turned on in the state

the machine has been stopped by keeping

the bar switch pressed to the left

3D1 There is abnormality in a battery backup signal

Turn off the power switch, and then turn it on. If code 3C1 is still displayed, check

the bar switch and the switch harness.

3D1 There is abnormality in a battery backup signal

CE

3D2 There is abnormality in a battery backup signal

*Check the setting for number of needles in the parameter settings

*Check the potentiometer (needle position sensor)

Turn off the power, and then turn it on again. If code 383 is still displayed, replace

the head card of the corresponding CE head.

Check color change sensor(s)

Turn off the power, and then turn it on again. If code 384 is still displayed, replace

the head card of the corresponding CE head.

Check/adjust/replace: compressor pressure, sensor, sensor wiring, electromagnetic

valve & wiring, lens fulcrum axis and shaft

Adjust the Z-axis position of the corresponding head.

Check the thread trimming drive card and/or the joint -21 card.

Check/replace joint card

Charge the battery by turning on the power of the machine. Check settings, parameters

IDM Card, and design settings.

Charge the battery by turning on the power of the machine. Check master card

Charge the battery by turning on the power of the machine. Check settings, parameters

3D3 There is abnormality in a battery backup signal

CE

3D3 NMI signal error

3D4 A ROM data check sum is abnormal

3D5 There is an abnormality in the RAM data

checksum

3D6 There is abnormality in the program or

CPU card

The software is not correctly installed.

3D7 There is abnormality in the main shaft motor

speed control data

_3E2 The p24R power supply is abnormal

3F1 Improper tension (looseness) error

CE-100

3F1 Thread tension control failure

CE-600

3F2 Improper tension (tightness) error

IMM Card, and design settings.

Charge the battery by turning on the power of the machine. Check master card

Check/replace IMM/IDM/joint/CPU and/or harnesses.

Replace the PROM

Reload data to memory, or check/replace the IDM2 card.

Check the CPU card, IDM

Install software

Check/replace the IDM or IMM card

Check/replace the P24R AVR or capacitor. Check/replace joint-25 card.

Adjust/replace the tension potentiometer

3F3 The thread tension release driver has received

an abnormal signal

B01 Floppy disk format has an error. The error

occurred during read/write operation.

B02 Floppy disk management information

has an error

B03 The write protect window of the floppy

disk is open

B04 No floppy disk has been inserted

Chek/replace the joint-25 card.

BC1 Selected design is not found on the floppy

disk or no design is registered on the disk

BC2 The design number specified as the writing

destination already exists on the floppy disk

BC4 Design data was not correctly written from

Select other design

*Format the floppy disk, or use a new formatted floppy disk

*Copy other deigns to a new floppy disk and dispose of the old floppy disk.

Copy data of the floppy disk to a new floppy disk and dispose of the old floppy disk.

Close the write protect window

Insert a floppy disk

Change the design number

Retry writing

the memory to the floppy disk

BC5 Available capacity of the floppy disk is not

sufficient

C01 The FDD is diconnected or faulty

CE1 Communication speed set for the external device connected serially does not match the

communication speed set for the machine.

Use a floppy disk that has enough available capacity

Select correct design number: 2DD 1 to 111, 2HD 1 to 223

Check the FDD cable and connection. If there is no problem with the connection

then replace the FDD unit.

Check the communication speed setting.

Temporary Stops

1B1 Stop due to frame stepping code

These stop codes are not caused by abnormality or failure. Continue operation by

1B2 Stop due to stop code

pressing the START key or by conducting the frame back/forward operation, or press

1B3 Stop due to end code 1

any operation key (except the manual frame travel keys)

1B4 Stop due to thread trimming code

1B6 Stop due to automatic free setting offset code

1B5 Stop due to a sequin code.

Manually move the sequin device up/down and then start the machine.

1C1 Stop occurred because bar switch was

pressed during frame stepping

1C2 Stop by manual ATH operation

Either start the machine or coduct frame back/forward

1D1 Stop at the start of all-head embroidery due to

the stop setting

1D2 Stop by preset halt

Reatart the machine

OIL Halt for lubrication

Supply oil to the necessary parts, and pree the retuen key to reset the code number.

Either start the machine or coduct frame back/forward

Press return khey to reset the code number

Neo Maintenance Stop

**MAINT. REQUIRD**

One drop of oil

As per Inst. Manual

When this messsage is displyed on the screen, supply oil to the specified spots (p. 13 - 7). After

lubrication, press the stop button to release the maintenance mode to continue working

!CAUTION: Grease Cams

Take-up, Presser

As per Inst. Manual

When this messsage is displyed on the screen, grease the specified spots (p. 13 - 8). After

greasing, press the stop button to release the maintenance mode to continue working

!CAUTION: Grease Cams

Take-up, Presser, Trim

Needle Case Drive

As per Inst. Manual

When this messsage is displyed on the screen, grease the specified spots (p. 13 - 8). After

greasing, press the stop button to release the maintenance mode to continue working

You might also like

- Tajima TMFX User ManualDocument6 pagesTajima TMFX User ManualCesar Espinoza0% (5)

- Manual TajimaDocument151 pagesManual TajimaBordados Fx100% (5)

- Apelio Operation Manual 1 PDFDocument174 pagesApelio Operation Manual 1 PDFParvezNo ratings yet

- Tajima Tme-Dc, TMFD-DC User ManualDocument7 pagesTajima Tme-Dc, TMFD-DC User ManualFilibor Bordados Eletronicos33% (6)

- Parts Listing and Wiring Diagram Autobend 7 HurcoDocument162 pagesParts Listing and Wiring Diagram Autobend 7 HurcoRenato HernandezNo ratings yet

- Parts List: Original Instructions P-GN14-E (2012.05)Document88 pagesParts List: Original Instructions P-GN14-E (2012.05)Shahrooz RahmaniNo ratings yet

- MT S4000 EngDocument8 pagesMT S4000 Engsamet gozubolNo ratings yet

- BARUDAN BEKS-KY Quick Reference Guide - EnglishDocument16 pagesBARUDAN BEKS-KY Quick Reference Guide - EnglishbethNo ratings yet

- Tajima TME-DC (Type 2) Wide Cap Tubular Goods Frame Instruction ManualDocument43 pagesTajima TME-DC (Type 2) Wide Cap Tubular Goods Frame Instruction Manualalma.vega8994100% (2)

- TTD 101002 eDocument30 pagesTTD 101002 eWaheed Ahmed100% (3)

- M100780A MX1 LX1 For Yasnac ManualDocument8 pagesM100780A MX1 LX1 For Yasnac ManualChu Leo100% (1)

- TDA16888 Power SupplyDocument1 pageTDA16888 Power SupplycocolisoteNo ratings yet

- HP Pavilion 15 N Series Quanta U82 R1A DA0U82MB6D0 REV D SchematicsDocument40 pagesHP Pavilion 15 N Series Quanta U82 R1A DA0U82MB6D0 REV D SchematicsRakesh BhattaNo ratings yet

- Rittal Compact Cooling Units Manual ENDocument13 pagesRittal Compact Cooling Units Manual ENAdil Chaudhary50% (2)

- EMC 10-12T Technical Manual Model Num 008410-01 Serial Num 10100xxDocument140 pagesEMC 10-12T Technical Manual Model Num 008410-01 Serial Num 10100xxCesar EspinozaNo ratings yet

- Sales Force Motivation and CompensationDocument38 pagesSales Force Motivation and CompensationTemple TurtleNo ratings yet

- Tajima CordingDocument45 pagesTajima CordingWilsonGutierrezNo ratings yet

- SunStarFortunaServo - MotorSeriesVUser 5Document99 pagesSunStarFortunaServo - MotorSeriesVUser 5Heriberto Flores Ampie100% (1)

- Card Od SWF MachineDocument5 pagesCard Od SWF MachineGeo GarciaNo ratings yet

- Zero B Axis On Amada Laser With Fanuc 160i ControlDocument1 pageZero B Axis On Amada Laser With Fanuc 160i ControlmagnetomaxNo ratings yet

- Painel SWFDocument152 pagesPainel SWFEdu ÁvilaNo ratings yet

- Color Change Rotary SW To Absolute Encoder 0011 TTD 2000 10 PDFDocument16 pagesColor Change Rotary SW To Absolute Encoder 0011 TTD 2000 10 PDFAlonso IbarraNo ratings yet

- SWF Multi Head Embroidery Machine Control PartsDocument78 pagesSWF Multi Head Embroidery Machine Control PartsLuis Caba Ramirez100% (1)

- Error Code 104 - 105Document8 pagesError Code 104 - 105joecentroneNo ratings yet

- Tajima TMM User ManualDocument5 pagesTajima TMM User ManualdanielNo ratings yet

- VIPROS 368 QUEEN (Ab Ser - Nr.36730014 - EU) PDFDocument334 pagesVIPROS 368 QUEEN (Ab Ser - Nr.36730014 - EU) PDFDima Trushkin100% (1)

- TMEG-X LimistopDocument71 pagesTMEG-X LimistopkratmelNo ratings yet

- Troubleshooting: Paper GuillotineDocument21 pagesTroubleshooting: Paper GuillotineAmro FaisalNo ratings yet

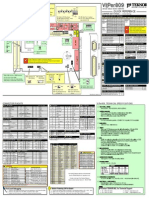

- Viper809 Motheboard Pinout DiagramDocument2 pagesViper809 Motheboard Pinout DiagramAnonymous 60esBJZIjNo ratings yet

- 59Document79 pages59jroyal692974No ratings yet

- Citizen M16 - 2Document112 pagesCitizen M16 - 2Favoreel Patrick50% (2)

- Redsail Cutting Plotter TroubleDocument6 pagesRedsail Cutting Plotter TroublezaharimanNo ratings yet

- Troubleshooting Manual For I/O Link Communication Alarm: (System Alarm PC050/PC150/971)Document22 pagesTroubleshooting Manual For I/O Link Communication Alarm: (System Alarm PC050/PC150/971)huutan12345No ratings yet

- PLC Onboard Instruction ManualDocument91 pagesPLC Onboard Instruction ManualKarthick RNo ratings yet

- Diagrama HCD-EC59-51800Document8 pagesDiagrama HCD-EC59-51800Luis Cansino100% (1)

- Galaxy Series Machine Install Elevating Capping System InstructionDocument10 pagesGalaxy Series Machine Install Elevating Capping System InstructiondarkenelNo ratings yet

- Tajima Usb Linker User's GuideDocument35 pagesTajima Usb Linker User's GuideFermin MuñozNo ratings yet

- Manual Mantenimiento VJ1604 MutohDocument448 pagesManual Mantenimiento VJ1604 MutohjavierNo ratings yet

- P 43 MSLL 3 enDocument13 pagesP 43 MSLL 3 enROSU FLORIAN MIRCEANo ratings yet

- Mutoh Rock Hopper 3-65-90Document319 pagesMutoh Rock Hopper 3-65-90Koki SmokiNo ratings yet

- IRT 1300 Drive ManualDocument54 pagesIRT 1300 Drive Manualcontrol tejidoNo ratings yet

- Philips 32pfl2508 f8Document118 pagesPhilips 32pfl2508 f8Victor Hugo PiedrahitaNo ratings yet

- JPL J: Hitachi Seiki Micon 8 Maintenance ManualDocument144 pagesJPL J: Hitachi Seiki Micon 8 Maintenance ManualВячеславГрузевскийNo ratings yet

- Manual de Servicio Haas VF-1 1996Document246 pagesManual de Servicio Haas VF-1 1996Alejandro Rivera Vega100% (1)

- Cosmo Converter PDFDocument11 pagesCosmo Converter PDFSulistyo TaufikNo ratings yet

- Como Se Genera Un Rayo LaserDocument51 pagesComo Se Genera Un Rayo Laseryoyo5050% (2)

- TD981014Document10 pagesTD981014Flavio SanchezNo ratings yet

- FTP Server With Letter HeadDocument25 pagesFTP Server With Letter HeadPham LongNo ratings yet

- 5000VG7S Series: Instruction ManualDocument97 pages5000VG7S Series: Instruction ManualsunhuynhNo ratings yet

- Tajima TMFD-C IIDocument73 pagesTajima TMFD-C IIVictor Thiago PrissaoNo ratings yet

- Click Here To The Previous PageDocument4 pagesClick Here To The Previous PageNGUYEN HUU DAONo ratings yet

- Delem: Documentation CollectionDocument61 pagesDelem: Documentation CollectionRMK BrothersNo ratings yet

- AP74700 Troubleshooting GuideDocument94 pagesAP74700 Troubleshooting Guidegass2100% (2)

- ArcWelding OM 3HAC028931-EnDocument142 pagesArcWelding OM 3HAC028931-EnMihail AvramovNo ratings yet

- Fanuc 6M Alarm CodesDocument7 pagesFanuc 6M Alarm CodesKrassi GlogovskiNo ratings yet

- SMC4-4-16A16B Four-Axis Motion Controller Instruction ManualDocument14 pagesSMC4-4-16A16B Four-Axis Motion Controller Instruction ManuallucaNo ratings yet

- March 2002 3035 - All Active SolutionsDocument38 pagesMarch 2002 3035 - All Active SolutionsMario de OzNo ratings yet

- SM300 ManualDocument32 pagesSM300 ManualdeivisroseroNo ratings yet

- Manual BC 2000Document15 pagesManual BC 2000CosăuValentinNo ratings yet

- BC-2000 enDocument15 pagesBC-2000 enpaberge3458No ratings yet

- Cititor Stand Alone Interior Sebury Cartele Proximitate Cod ControllerDocument7 pagesCititor Stand Alone Interior Sebury Cartele Proximitate Cod ControllerAndrei PantaNo ratings yet

- R2D2 PDFDocument5 pagesR2D2 PDFCesar EspinozaNo ratings yet

- WarhawkDocument24 pagesWarhawkCesar EspinozaNo ratings yet

- Steampunk Plague Doctor PDFDocument5 pagesSteampunk Plague Doctor PDFCesar EspinozaNo ratings yet

- Release Notes For Melco Control Panel Software Release 2001-10Document5 pagesRelease Notes For Melco Control Panel Software Release 2001-10Cesar EspinozaNo ratings yet

- Dinacell LoadweigherDocument24 pagesDinacell LoadweigherkieranNo ratings yet

- A Study of Audience Perception About The PDFDocument12 pagesA Study of Audience Perception About The PDFRahat HaneefNo ratings yet

- The Ants and The PenDocument27 pagesThe Ants and The PenNi NiNo ratings yet

- Spanish Football Federation Soccer Camps in Madrid, SpainDocument7 pagesSpanish Football Federation Soccer Camps in Madrid, SpainKerine HeronNo ratings yet

- Technical Sheet: Generating Set QLS13TDocument1 pageTechnical Sheet: Generating Set QLS13Tdjef djefNo ratings yet

- 103 - Table Saw Panel SledDocument2 pages103 - Table Saw Panel SledRob PierceNo ratings yet

- Sassetta Dinner MenuDocument1 pageSassetta Dinner MenueaterdcNo ratings yet

- Full Merchant Shipping Act Plus AmendmentsDocument245 pagesFull Merchant Shipping Act Plus AmendmentsVaishnavi JayakumarNo ratings yet

- Chapter 3 - Rules On Gross Gift (Notes)Document11 pagesChapter 3 - Rules On Gross Gift (Notes)Angela Denisse FranciscoNo ratings yet

- Setting Up Axis Camera Edge Storage: GuideDocument9 pagesSetting Up Axis Camera Edge Storage: GuideRicardo ChavezNo ratings yet

- Euler Diagrams and ReasoningDocument4 pagesEuler Diagrams and ReasoningDanica MamontayaoNo ratings yet

- Group Report - Team InclusionDocument16 pagesGroup Report - Team InclusionShimulAhmedNo ratings yet

- UntitledDocument39 pagesUntitledLaurice AndresNo ratings yet

- T 1M J&J Ty - 1: 'PhilhealthDocument1 pageT 1M J&J Ty - 1: 'PhilhealthBulan HospitalNo ratings yet

- A Program of Studies For New MuslimDocument75 pagesA Program of Studies For New MuslimMuhammad AsadNo ratings yet

- What Are The 25 Consonant SoundsDocument3 pagesWhat Are The 25 Consonant SoundsvidyapostNo ratings yet

- 2010 Senate Minority ReportDocument321 pages2010 Senate Minority Reportthecynicaleconomist100% (1)

- The Mona Lisa: by Leonardo Da VinciDocument2 pagesThe Mona Lisa: by Leonardo Da VinciJoseph Anjodel GumbocNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityvenkat naiduNo ratings yet

- Mise en Scene (Inc Lighting)Document41 pagesMise en Scene (Inc Lighting)Dee WatsonNo ratings yet

- Development PlanDocument8 pagesDevelopment PlanuyunamanNo ratings yet

- 2011 Paraquat: Unacceptable Health Risks For UsersDocument67 pages2011 Paraquat: Unacceptable Health Risks For UsersRudmar Luiz Pereira dos SantosNo ratings yet

- Bound To Fail: The Rise and Fall of The Liberal International OrderDocument44 pagesBound To Fail: The Rise and Fall of The Liberal International OrderShu'eib HassenNo ratings yet

- Morgan FULL-1357-1425Document69 pagesMorgan FULL-1357-1425Sya RifahNo ratings yet

- Jack Robinson Resume 2015Document2 pagesJack Robinson Resume 2015api-281993498No ratings yet

- Fluid Power SystemDocument2 pagesFluid Power SystemVijay Shakar0% (1)

- Zikhali Thobeka Y 2016Document91 pagesZikhali Thobeka Y 2016Anonymous XSiAvXNo ratings yet

- ADM - Masonry - Q1 - M2Document23 pagesADM - Masonry - Q1 - M2joanduermeNo ratings yet

- Shariff Kabunsuan College, Inc. 136-Bagua 1, Cotabato CityDocument5 pagesShariff Kabunsuan College, Inc. 136-Bagua 1, Cotabato CityRuby Jane VerdeflorNo ratings yet