Professional Documents

Culture Documents

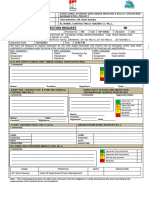

Fuxin Steel Buildings Co.,Ltd: Welding Procedure Specification (WPS) Qms-Wps-V1 FCAW-001

Fuxin Steel Buildings Co.,Ltd: Welding Procedure Specification (WPS) Qms-Wps-V1 FCAW-001

Uploaded by

imsovanara5310Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuxin Steel Buildings Co.,Ltd: Welding Procedure Specification (WPS) Qms-Wps-V1 FCAW-001

Fuxin Steel Buildings Co.,Ltd: Welding Procedure Specification (WPS) Qms-Wps-V1 FCAW-001

Uploaded by

imsovanara5310Copyright:

Available Formats

FUXIN STEEL BUILDINGS Co.

,Ltd

WELDING PROCEDURE SPECIFICATION (WPS)

QMS-WPS-V1

FCAW-001

Identification : _________________________________

Company Name : _____________________________

_______________________________

Welding Process(es) : __________________________

Supporting PQR No.(s) : _______________________

Revision : _________ Date : _____________________

By Mr. ____________________________________

Authorized By : _______________ Date : ____________

Type : Manual

Semi-Automatic

Machine

Automatic

-

JOINT DESIGN USED

Type : ________________________________________

Single

Double Weld

Backing : Yes

No

Backing Material : _____________________________

Root Opening : _________ Root Face : ____________

Groove Angle : ___________ Radius(J-U) : _________

Back Gouging : Yes

No

Method: _________

POSITION

Position of Groove : ___________ Fillet : __________

Vertical Progression : Up

Down

-

BASE METALS

Material Spec : _______________________________

Type or Grade : _______________________________

Thickness ; Groove : ___________ Fillet : ___________

Diameter (Pipe) : ______________________________

FILLER METALS

AWS Specification : ___________________________

AWS Classification : ___________________________

F-No : _____________________________________

SHIELDING

Flux : ________________ Gas : _________________

Composition : _________

Electrode-Flux(Class) : ______ Flow Rate : ___________

Gas Cup Size : ________________________________

PREHEAT

Preheat Temp., Min : ____________________________

Interpass Temp., Min : __________ Max : ___________

WELDING PROCEDURE

Filler Metals

Current

Pass /

Process

Dia

Type /

Amps/

Layer

Class

(mm) Polarity Wire Feed

ELECTRICAL CHARACTERISTICS

Transfer Mode (GMAW)

Short-Circuiting

Globular

Spray

Current : ____________________________________

Other : _____________________________________

Tungsten Electrode(GTAW)

Size : ___________________________________

Type : __________________________________

TECHNIQUE

Stringer or Weave Bead : _______________________

Multi-pass or Single pass(per side) : _______________

Number of Electrodes : ________________________

Electrode Spacing

Longitudinal : ____________________________

Lateral : _________________________________

Angle : __________________________________

Interpass Cleaning : ___________________________

Contact Tube to Work Distance : __________________

Peening : ____________________________________

POST WELD HEAT TREATMENT

Temp : ______________________________________

Time : ______________________________________

Volts

Special Introductions:

1) The welding surface area shall be free from contamination

2) Tack weld shall be avoid crack and remove prior to welding

Travel

Speed

(cm/min)

Joint Details

You might also like

- Sample Welding Procedure Specification (WPS) FormDocument1 pageSample Welding Procedure Specification (WPS) Formfallalovaldes50% (4)

- QIR 121 Bolts Torque ReportDocument1 pageQIR 121 Bolts Torque ReportSamer BayatiNo ratings yet

- Sample PQRDocument2 pagesSample PQRudaysrp33% (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Welding Procedure Specification (WPS) Form: Pt. Idogama - Engineering - Fabrication - ConstructionDocument1 pageWelding Procedure Specification (WPS) Form: Pt. Idogama - Engineering - Fabrication - ConstructionbayuNo ratings yet

- Brazing Procedure SpecificationsDocument5 pagesBrazing Procedure Specificationssajay2010100% (1)

- Nuclear Power Corporation of India Litd.: Quality Assurance GroupDocument4 pagesNuclear Power Corporation of India Litd.: Quality Assurance GroupviswamanojNo ratings yet

- Wps Short FormDocument2 pagesWps Short FormsrinivasanNo ratings yet

- F4-WPS PQR Stud WeldingDocument1 pageF4-WPS PQR Stud WeldingBernardo LeorNo ratings yet

- WPS VarillaDocument2 pagesWPS Varillalabingles89No ratings yet

- Asme BPVC IxDocument7 pagesAsme BPVC IxNVTVNNo ratings yet

- Joint (QW-402)Document3 pagesJoint (QW-402)MuhammadNajibNo ratings yet

- Welder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingDocument1 pageWelder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingReza100% (1)

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNavanitheeshwaran SivasubramaniyamNo ratings yet

- B2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFDocument2 pagesB2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFNavanitheeshwaran SivasubramaniyamNo ratings yet

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Document2 pagesSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzNo ratings yet

- Tata Consulting Engineers Limited: P Q T R (PQR)Document2 pagesTata Consulting Engineers Limited: P Q T R (PQR)Rajat KoleyNo ratings yet

- WPS TemplateDocument1 pageWPS TemplateMatt De Hoog100% (1)

- WPS SampleDocument2 pagesWPS Sampleeetua100% (1)

- Uail - Pin Li-Cqa-213-F-01 WPS FormatDocument2 pagesUail - Pin Li-Cqa-213-F-01 WPS FormatKarthikNo ratings yet

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFDocument1 pageAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajNo ratings yet

- JushDocument2 pagesJushg6vhdytsyzNo ratings yet

- M/S SPML Infra LTDDocument6 pagesM/S SPML Infra LTDyouuuuyNo ratings yet

- Report of Magnetic-Particle Examination of WeldsDocument1 pageReport of Magnetic-Particle Examination of WeldsSathish KumarNo ratings yet

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- WPQDocument1 pageWPQChava TejaNo ratings yet

- B2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormDocument1 pageB2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormtuanNo ratings yet

- SGB WPS Al 01Document2 pagesSGB WPS Al 01Ahmed GomaaNo ratings yet

- FM-NM-014 ECN - NoticeDocument1 pageFM-NM-014 ECN - Noticephutthawongdanchai041215No ratings yet

- Solderer Performance Qualification (SPQ) - Sample Form: Qualification, AWS B2.3/B2.3MDocument1 pageSolderer Performance Qualification (SPQ) - Sample Form: Qualification, AWS B2.3/B2.3MBernardo LeorNo ratings yet

- QA-QC Inspection Request FormDocument1 pageQA-QC Inspection Request FormShaikh Ubaid Ur RehmanNo ratings yet

- CS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Document2 pagesCS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Nazar Abdul KareemNo ratings yet

- PQRDocument2 pagesPQRRavi KumaranNo ratings yet

- Sample Report of Magnetic-Particle Examination of WeldsDocument1 pageSample Report of Magnetic-Particle Examination of WeldsNavanitheeshwaran SivasubramaniyamNo ratings yet

- Ir-Cw-0101 Tie BeamDocument1 pageIr-Cw-0101 Tie BeamAnwar SadathNo ratings yet

- BPQ SampleDocument1 pageBPQ Samplesudeep_singh1No ratings yet

- Excavation CertificateDocument1 pageExcavation CertificateEmmanuel Ezekiel-Hart EdemNo ratings yet

- Ir-Cw-0102 Pile CapDocument1 pageIr-Cw-0102 Pile CapAnwar SadathNo ratings yet

- Form N3 PDFDocument1 pageForm N3 PDFTavo RojasNo ratings yet

- Form Blank Kelengkapan Data SampleDocument1 pageForm Blank Kelengkapan Data SampleVin DieselNo ratings yet

- D1.3 D1.3M 2018 Annexb1 PQR FormDocument1 pageD1.3 D1.3M 2018 Annexb1 PQR FormAkihiko TakagiNo ratings yet

- Job Order and Document Review Format (Document93 pagesJob Order and Document Review Format (Ami AluminiumNo ratings yet

- Descon Engineering Ltd. Visit Report: Doc No: Rev: DateDocument2 pagesDescon Engineering Ltd. Visit Report: Doc No: Rev: Dateanon_909403619No ratings yet

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- WPS & PQR FORMATE AS PER BPVC Sec-IX QW-482Document6 pagesWPS & PQR FORMATE AS PER BPVC Sec-IX QW-482Umesh Sakhareliya100% (1)

- Appendix DDocument1 pageAppendix DDelta akathehuskyNo ratings yet

- Procedure Qualification Record (PQR) NoDocument3 pagesProcedure Qualification Record (PQR) NoMohamed elrefaeyNo ratings yet

- Welding Procedure Qualification Log - Rev2Document8 pagesWelding Procedure Qualification Log - Rev2HoangNo ratings yet

- Attachment D (SAEP 316)Document1 pageAttachment D (SAEP 316)imtiazNo ratings yet

- Hacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)From EverandHacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)No ratings yet

- Wiley Practitioner's Guide to GAAS 2017: Covering all SASs, SSAEs, SSARSs, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2017: Covering all SASs, SSAEs, SSARSs, and InterpretationsNo ratings yet

- Codification of Statements on Auditing Standards: Numbers 122 to 133, January 2018From EverandCodification of Statements on Auditing Standards: Numbers 122 to 133, January 2018No ratings yet

- Wiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsNo ratings yet

- Codification of Statements on Standards for Attestation Engagements, January 2018From EverandCodification of Statements on Standards for Attestation Engagements, January 2018No ratings yet

- Codification of Statements on Standards for Accounting and Review Services: Numbers 1 - 23From EverandCodification of Statements on Standards for Accounting and Review Services: Numbers 1 - 23No ratings yet

- Codification of Statements on Standards for Accounting and Review Services: Numbers 21-24From EverandCodification of Statements on Standards for Accounting and Review Services: Numbers 21-24No ratings yet