Professional Documents

Culture Documents

Procedure Qualification Record (PQR) : Joint Design Used

Procedure Qualification Record (PQR) : Joint Design Used

Uploaded by

Alexander Muñoz SánchezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure Qualification Record (PQR) : Joint Design Used

Procedure Qualification Record (PQR) : Joint Design Used

Uploaded by

Alexander Muñoz SánchezCopyright:

Available Formats

Sheet 1 of 4

Procedure Qualification Record (PQR)

Code: AWS D1.1

Company Name: www.WPSAmerica.com

PQR No.:

Address: info@WPSAmerica.com, 1 (877) WPS-WELD

Welding Process:

Process Type:

SMAW

DEMO-PQR

Manual

Base Metal Part I (Material Spec., type or grade):

WPS No.:

Position:

DEMO-WPS

Flat

Base Metal Part II (Material Spec., type or grade):

ASTM A 516 Grade 60

ASTM A 516 Grade 60

Thickness and Diameter (Pipe):

Filler Metals:

AWS Classification/AWS Specification:

Thickness of Test Coupon: 60 mm (2.36 in.), Plates

E7018

Diameter of Test Coupon: N/A

A5.1

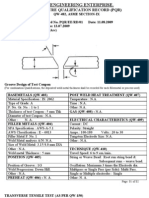

Joint Details/Sketch:

Joint Design Used:

Root Opening G: mm (in) 0 to 1/8 in.

Root Face RF : 3 mm (1/8 in.)

Weld Type:

Back-gouge to sound metal

Radius (J-U): N/A

Joint Type:

Complete Joint Penetration Groove Weld

Backing Option:

Groove Angle: 60 (both sides)

Butt Joint

Backing Material:

N/A

Back Gouging Method:

Mechanical (Grinding)

PQR No.: DEMO-PQR

Sheet 2 of 4

Electrical Characteristics:

Current Type/Polarity:

Transfer Mode (GMAW):

Tungsten Electrode (GTAW):

Shielding:

DCEP

Gas Composition (Flux for SAW):

N/A

Gas Flow Rate: N/A

Gas Cup Size: N/A

Type: N/A

Size: N/A

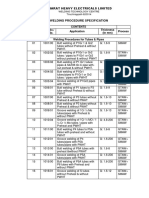

Welding Procedure

Weld

Layer(s)

Pass

No.

Process

Filler Metal

Classification

1 to 2

2 to n

1 to 3

4 to n

SMAW

SMAW

E7018

E7018

Filler

Metal

Diameter

mm(in)

4.0 mm (5/32)

4.8 mm (3/16)

Current

Amps

Current Wire Feed

Type &

Speed

Polarity (in/min)

Volts

Travel

Speed (in/min)

Remarks [Heat Input]

160-200

220-250

DCEP

DCEP

24-26

24-26

5-10 (in/min)

5-10 (in/min)

Root Pass

Fill and Cap Passes

N/A

N/A

Technique:

Stringer or Weave Bead: Stringer and Weave Bead

Contact Tube to Work Distance: N/A

Initial/ Interpass Cleaning: Wire Brush, Grinding

Peening: Not Required

Number of Electrodes: Single

Electrode Spacing: Longitudinal: N/A

Lateral: N/A

Angle: N/A

Heat Treatment:

Preheat Temp. Min C (F): 150 C

Interpass Temp. Min/ Max: 150 C

Postweld Heat Treatment:

Time: 1 Hour per in.

Temp. C (F): 600 to 620 C

Additional Notes:

See Postweld Heat Treatment (PWHT) Specification No. PWHT-SMAW-01

Manufacturer/ Contractor

Welding Engineer :

Authorized by:

Name: Jim Clark

Name: John Smith

Title: Welding Engineer

Title: QA Manager

Date: 12,12,2005

Date: 12,13, 2005

PQR No.: DEMO-PQR

Sheet 3 of 4

PQR Heat Treatment (AWS Code's Guideline):

PREHEAT:

AWS D1.1, Table 3.2 Prequalified Minimum Preheat and Interpass Temperature F (C):

Thickness 3 to 20 mm (1/8 to 3/4 in.) incl.: 32F (0C)

Over 20 thru 38 mm (3/4 to 1-1/2 in.) incl.: 50F (10C)

Over 38 thru 65 mm (1-1/2 to 2-1/2 in.) incl.: 150F (65C)

Over 65 mm (2-1/2 in): 225F (110C)

For SMAW process, above preheat data is with low hydrogen electrodes.

When the base metal temperature is below 32F (0C), preheated to a minimum of 70F (20C)

Preheat and interpass temperature shall be sufficient to prevent cold cracking.

Guideline on Alternative Methods for Determining Preheat/Interpass: See Annex I of AWS D1.1

POSTWELD HEAT TREATMENT:

PWHT requirements shall be based on Welding Procedure Specification (WPS).

AWS D1.1, 5.8 Stress-Relief Heat Treatment: Where required by the contract

drawings or specifications, welded assemblies shall be stress relieved by heat treating.

(See AWS D1.1, 5.8.1, Requirements for stress-relief treatment;

Table 5.2, Minimum Holding Time; Table 5.3, Alternate Stress-Relief Heat Treatment)

See AWS D1.1, 5.8.3, Steels Not Recommended for PWHT

PQR Qualified Range (AWS Code's Guideline):

Qualified Position: F (CJP/PJP Groove, Fillet) on Plate, Pipe, Box Tube (Table 4.1 AWS D1.1)

Qualified Thicknesses (CJP Groove): 1/8 in. (3 mm) Min., Unlimited

Plus any size of fillet or PJP groove weld for any thicknesses (Table 4.2 AWS D1.1)

WPS Base Metal Group Allowed by PQR: Any Group I Steels to Any Group I Steels in Table 3.1 of AWS D1.1

(Table 4.8 AWS D1.1)

Qualified WPS Filler Metal Allowed by PQR: For SMAW process, only same electrode type (change from

low hydrogen to non-low hydrogen is not allowed).

Also same (or lower) strength electrode tested in PQR for SMAW process.

No increase in diameter from size tested in PQR allowed, except that an increase on electrode size of only 1/32

in. (0.8 mm) in SMAW is acceptable for use in WPS.

(Table 4.5 AWS D1.1)

PQR No.: DEMO-PQR

Sheet 4 of 4

PROCEDURE QUALIFICATION RECORDS

Test Results

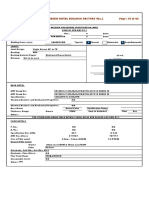

TENSILE TEST

Specimen No.

Area

Width Thickness

Ultimate Tensile Load

Ultimate Unit Character of Failure

sq. mm

mm (in) mm (in)

kg (lb)

Stress, MPa (psi)

and Location

(in)

TA1

TA2

TB1

TB2

25,1

25,1

25

25,1

30

30

30

30

753

753

750

753

36212 Kg

36712 Kg

35712 Kg

35612 Kg

471 (MPa)

477 (Mpa)

466 (MPa)

463 (MPa)

Ductile out Weld

Ductile out Weld

Ductile out Weld

Ductile out Weld

GUIDED BEND TEST

Specimen No.

Type of Bend

Results

Remarks

T1

T2

T3

T4

Side bend

Side bend

Side bend

Side bend

Satisfactory

Satisfactory

Satisfactory

Satisfactory

Ductile

Ductile

Ductile

Ductile

Radiographic-ultrasonic examination:

VISUAL INSPECTION:

Appearence: Good appearance

RT report no: 1230-RT

UT report no: 2310-UT

Undercut: No

Result: O.K.

Result: O.K.

Piping porosity: No

Convexity: Acceptable

FILLET WELD TEST RESULTS:

Test Date: 11,11, 2005

Max. size single pass:

Macrotech

Min. size multiple pass:

Macrotech

1: N/A

1: N/A

2: _

2: _

3: _

3: _

Witnessed By: Jim Clark

Other Tests (Notes):

All-weld-metal tension test:

Tensile strength, MPa (psi): N/A

Yield point/strength, MPa (psi): _

Elongation in 2 in.,%: _

Laboratory test no.: _

Welders name: Welder Guy

Tests conducted by: Quality Weld Lab, Inc.

Laboratory Tests Number: TN-46547

Clock No.: 123-12-1234

Stamp No.: JS-02

Per: WPSAmerica.com

We, the undersigned, certify that the statements in this record are correct and that the test welds were

prepared, welded, and tested in conformance with the requirements of Section 4 of AWS D1.1, (Year:2004)

Structural Welding Code Steel.

Signed (Manufacturer):

Name:

Title:

Date:

John Smith

QA Manager

12,12,2005

You might also like

- Welding Qusetion and AnswersDocument9 pagesWelding Qusetion and AnswersSunil100% (1)

- AWS D1.1 Guides PDFDocument8 pagesAWS D1.1 Guides PDFwidada_marjiNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Question Paper For Snr. WeldingDocument3 pagesQuestion Paper For Snr. WeldingThulasi Ram100% (1)

- Company Name Key Information Questions Answers File Reference Reviews & ApprovalsDocument7 pagesCompany Name Key Information Questions Answers File Reference Reviews & ApprovalsMAT-LIONNo ratings yet

- Cswip - Section 09-Welding SymbolsDocument14 pagesCswip - Section 09-Welding SymbolsNsidibe Michael Etim100% (1)

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- QCF309 Welding Summary ReportDocument1 pageQCF309 Welding Summary Reportminhnn100% (5)

- Welding Processes Fcaw, Gmaw, Gtaw, Smaw, SawDocument2 pagesWelding Processes Fcaw, Gmaw, Gtaw, Smaw, SawiaftNo ratings yet

- Saep 1102Document6 pagesSaep 1102Francis ReyesNo ratings yet

- Advandced Welding SymbolsDocument24 pagesAdvandced Welding Symbolswvandamme100% (1)

- Fitup Check For WeldingDocument1 pageFitup Check For WeldingVijay Kant SharmaNo ratings yet

- FMDS0706 Plasitc TanksDocument10 pagesFMDS0706 Plasitc Tanksdaniela hritucNo ratings yet

- Asme Section Ix InterpretationsDocument77 pagesAsme Section Ix Interpretationsippon_osoto100% (1)

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationFranklin londono0% (1)

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- Welding ImpuritiesDocument11 pagesWelding ImpuritiesapNo ratings yet

- ER80S Ni1 PDFDocument2 pagesER80S Ni1 PDFebastien2No ratings yet

- Api - 1104 - 1Document2 pagesApi - 1104 - 1aditya bhideNo ratings yet

- P91 Profile WpsDocument6 pagesP91 Profile WpsManzar KhanNo ratings yet

- Acknowledgements: Welded Connection Design & Cost EstimationDocument20 pagesAcknowledgements: Welded Connection Design & Cost EstimationJessica JacksonNo ratings yet

- 2.WIS5 Course Notes 501 699Document199 pages2.WIS5 Course Notes 501 699nani356No ratings yet

- Hardox 450Document3 pagesHardox 450Marko RisticNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Welding Positions: Section 2 PA PB PC PF PG PE PDDocument15 pagesWelding Positions: Section 2 PA PB PC PF PG PE PDPeter Beckwith100% (1)

- GPI Price List Welding MachineDocument4 pagesGPI Price List Welding MachineBudi SantonyNo ratings yet

- Cswip3.1 Question 1Document9 pagesCswip3.1 Question 1mohammed dallyNo ratings yet

- Welding Guidelines CuNiDocument8 pagesWelding Guidelines CuNiRadu-Gabriel GhergheNo ratings yet

- CSWIP Plate Tr5. WPK Rev2Document4 pagesCSWIP Plate Tr5. WPK Rev2razormeback100% (1)

- Cigweld-Deposited Rates PDFDocument7 pagesCigweld-Deposited Rates PDFNam_HitechNo ratings yet

- Specification No: LMB-COI-TRG-001 Rev No. R0 Page ofDocument16 pagesSpecification No: LMB-COI-TRG-001 Rev No. R0 Page ofApoorv MathurNo ratings yet

- Welding Defect - ISO6520Document3 pagesWelding Defect - ISO6520manojballaNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- SMAW Electrode IdentificationDocument2 pagesSMAW Electrode IdentificationAsim AliNo ratings yet

- CSWIP NotesDocument32 pagesCSWIP NotesKhaled FatnassiNo ratings yet

- MMAWDocument21 pagesMMAWAkash PandeyNo ratings yet

- 03 Welding Imperfections 30-03-07 (2Document20 pages03 Welding Imperfections 30-03-07 (2geokovoorNo ratings yet

- Fabrication - Assembly & ErectionDocument83 pagesFabrication - Assembly & ErectionRengga Andryastama100% (2)

- Asme PQR DemoDocument3 pagesAsme PQR DemoMuthusamy AyyanapillaiNo ratings yet

- Inspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusDocument18 pagesInspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusoberaiNo ratings yet

- Metal Core WireDocument30 pagesMetal Core WireHuỳnh TrươngNo ratings yet

- Preguntas AwsDocument7 pagesPreguntas AwsRoman Roa MachucaNo ratings yet

- CSM-QR-02-2, Medical Gas BPS TablesDocument8 pagesCSM-QR-02-2, Medical Gas BPS TablesaadmaadmNo ratings yet

- WPSPQRDocument11 pagesWPSPQR0502raviNo ratings yet

- WPS, PQR, WPQDocument2 pagesWPS, PQR, WPQESL100% (1)

- Mce Gulf Contracting Co. Welder Performance QualificationDocument2 pagesMce Gulf Contracting Co. Welder Performance QualificationhamidjoyiaNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- ASME AcceptanceDocument46 pagesASME AcceptanceSteelera EngineersNo ratings yet

- Sample of Procedure Qualification Record (PQR) : Joint DetailsDocument4 pagesSample of Procedure Qualification Record (PQR) : Joint Detailshancur_27No ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Weld Matrix Format 1Document7 pagesWeld Matrix Format 1Arslan WaheedNo ratings yet

- Welding Bevel Design 3.1 Bevels For Other Than GTAW Root PassDocument2 pagesWelding Bevel Design 3.1 Bevels For Other Than GTAW Root PassaezeadNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- Enrollment Form - How To Fill UpDocument3 pagesEnrollment Form - How To Fill UpRaja Guru100% (1)

- Electrode Backing RegisterDocument4 pagesElectrode Backing RegisterSimbu Arasan100% (1)

- WPQ Flux CoreDocument1 pageWPQ Flux Corealberto jayaNo ratings yet

- MODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsDocument7 pagesMODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsNsidibe Michael EtimNo ratings yet

- WPS Updated PDFDocument2 pagesWPS Updated PDFRaja Muaz Ahmad KhanNo ratings yet

- Asme Ix - Welder Id Rev.2Document5 pagesAsme Ix - Welder Id Rev.2Joseph Peter100% (1)

- ASME P Material Numbers: P No. EN288 Base MetalDocument6 pagesASME P Material Numbers: P No. EN288 Base Metalsagar1503100% (1)

- Piping Inspection 22.01.2020Document72 pagesPiping Inspection 22.01.2020KarthikNo ratings yet

- WpsDocument2 pagesWpsjsmargate100% (1)

- Submerged Arc Welding Fluxes BasicityDocument3 pagesSubmerged Arc Welding Fluxes Basicitylram70No ratings yet

- WPS 1aDocument2 pagesWPS 1aPrasenjit BhanjaNo ratings yet

- G12MF TypeDocument1 pageG12MF Typeosto72No ratings yet

- Welder NIMI Q 2Document30 pagesWelder NIMI Q 2Mahesh SonarNo ratings yet

- CV Painting InsulationDocument3 pagesCV Painting Insulationhamza brahmiNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Handbook - Calculations 4 PDFDocument1 pageHandbook - Calculations 4 PDFSmith SivaNo ratings yet

- Wis 5 Eoca AnswersDocument34 pagesWis 5 Eoca AnswersAli ClubistNo ratings yet

- Aumr + Cadx-A Series: Split Air ConditionersDocument24 pagesAumr + Cadx-A Series: Split Air ConditionersAhmad SalahNo ratings yet

- PQR 005-50-NLG PWHT (Icas)Document2 pagesPQR 005-50-NLG PWHT (Icas)Atilio BarriosNo ratings yet

- Welding Visual ReportDocument6 pagesWelding Visual ReportFerdie OSNo ratings yet

- Aalborg EH: Versatile Booster, Auxiliary Oil and Water HeaterDocument3 pagesAalborg EH: Versatile Booster, Auxiliary Oil and Water HeaterRafaell SantaNo ratings yet

- PACSDocument33 pagesPACSphilipnart100% (1)

- Contract Provison of Hook-Up and Commisioning of Petronas Carigali For YEAR 2012-2018Document6 pagesContract Provison of Hook-Up and Commisioning of Petronas Carigali For YEAR 2012-2018Faiz IshakNo ratings yet

- Gmaw Terminal Report 3Document1 pageGmaw Terminal Report 3Artdik PacificNo ratings yet

- Cylinder Unit Hydrobox FTC BoxDocument14 pagesCylinder Unit Hydrobox FTC BoxkjulenNo ratings yet

- Schubert PDFDocument66 pagesSchubert PDFdattu33No ratings yet

- Welder Certification: MethodDocument2 pagesWelder Certification: MethodChakka ChakkaNo ratings yet

- Mig Welding HistoryDocument4 pagesMig Welding HistorykecikhernyNo ratings yet

- WPS Format For AWS D1.1 - WPS - SAWDocument1 pageWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityNo ratings yet

- WPS Understanding: By: Eng. Mohamed Farouk BayomiDocument11 pagesWPS Understanding: By: Eng. Mohamed Farouk BayominwohaNo ratings yet

- WPS Variables Asme IX 2019Document2 pagesWPS Variables Asme IX 2019RedzuanNo ratings yet

- Weldindssdvg Part 2Document55 pagesWeldindssdvg Part 2sbs271187No ratings yet

- BMP (Class 13) WeldingDocument9 pagesBMP (Class 13) WeldingAsesh PramanikNo ratings yet

- Aires Acondicionados BARDDocument14 pagesAires Acondicionados BARDJMiguel RCNo ratings yet

- Table 6.3 Welder Qualification-Number, Types of Test, Production Welds, and Positions Qualified (See 6.3)Document8 pagesTable 6.3 Welder Qualification-Number, Types of Test, Production Welds, and Positions Qualified (See 6.3)Lassaad ZarraaNo ratings yet