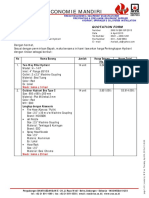

Professional Documents

Culture Documents

PN Rating Valves: Bronze, Brass & Cast Iron Valves

PN Rating Valves: Bronze, Brass & Cast Iron Valves

Uploaded by

Abdul ArifOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PN Rating Valves: Bronze, Brass & Cast Iron Valves

PN Rating Valves: Bronze, Brass & Cast Iron Valves

Uploaded by

Abdul ArifCopyright:

Available Formats

PN Rating Valves

Bronze, Brass & Cast Iron Valves

INDEX

Bronze Valves

Cast Iron Valves

Valve type

PN16 Gate Valves

PN16 Gate Valves

PN16 Gate Valves

PN25 Gate Valves

PN25 Gate Valves (Solder joint)

PN16 Globe Valves

PN25 Globe Valves

PN16 Swing Check Valves

PN25 Lift Check Valves

PN25 Y-pattern Strainers

PN16 Gate Valves

PN16 Gate Valves

PN16 Globe Valves

PN16 Swing Check Valves

PN16 Y-pattern Strainers

Page

4

4

4

5

5

5

6

6

6

7

8

8

9

9

10

Fig

272P

275P

286P

206P

207P

210P

213P

236P

230P

380P

500

501(I)

510

520

530

P-T Rating

Service Temperature ()

10 to 66

100

120

150

170

180

186

198

200

Bronze valves

PN16

PN25

16.0

25.0

13.5

9.5

7.0

21.8

16.5

12.8

11.3

10.5

Cast iron valves

PN16

16.0

14.4

13.7

13.4

13.2

12.9

12.8

DZR brass (Dezincification Resistant brass)

Water pollution and employment of new piping material have amplified valve dezincification problems.

The copper alloy used in bronze valves contains zinc, tin, and lead with copper as a base. When bronze valves are

subjected to unfavorable service conditions, the zinc component contained in the copper alloy separates from the

cooper base, and the metal corrodes. This is called dezincification.

In case of bronze valve, the body, bonnet, and other cast bronze parts hardly corrode due to the small percent of zinc

contained in the alloy. But brass valves parts such as stems, which contain 40% zinc, often corrodes due to extreme

dezincification.

The following factors cause dezincification. These factors are generally believed to occur together, rather than

independently.

1) Excessive aqueous solution in acidity.

2) Warm water containing excessive free carbonic acid with high electric conductivity.

3) High electric conductivity with excessive presence of chlorides and sulfides.

4) Copper or vinyl chloride pipes.

5) Excessive dissolved oxygen.

To struggle with dezincification corrosion, we developed DZR brass as the stem materials of bronze/brass valves. Our

test data show excellent corrosion resistance to be comparable to bronze continuous casting bars.

Bronze/brass valve have these DZR brass or bronze stems in standard specification, and offer long service life.

Notes

1) Refer to the individual specification sheet or the drawing for details of a product.

2) Main units of this catalog are shown in SI (MPa, C, millimeter) and psig.

3) Refer to the attached P-T ratings about applicable pressure and temperature.

4) The non-asbestos product is used for the gland packing and gasket of bronze, brass and cast iron valves as a

manufacturer's standard.

5) Bronze and cast iron strainers have the perforated metal screen equivalent to 12-16 meshes. Other meshes of the

screen are also available upon request.

Products guarantee

Term of guarantee: Within one year after the date of delivery from our factory to the original customer.

Contents of a guarantee: If the installations and the service conditions (such as pressure, temperature, fluid, etc.) are

proper, necessary replacement and repair of our product will be carried out without charge.

Guarantee exceptions: Please keep in mind that the above articles of guarantee will not apply to the case owing to the

following reasons:

1) Non-compliance of the customer with the technical instructions furnished by our catalog and specification sheet

2) Natural disaster incidents, such as a fire, flood damage, an earthquake, and falling stone

3) Reconstruction or repair by any third party other than us.

4) Deterioration (such as rust, degradation, chemical changes, etc.)

5) Any other matter resulting from the damage not being regarded as manufacturer's responsibility

In addition, you will be required necessary charge for repair or exchange of parts on failure or damage by the guarantee exceptions. Please contact our sales staff or agency for details.

The specification and the performance term of our product indicated in this catalog are based on the internationally

governed standards and specifications, our products experience or the design calculation and our in-house examination.

When using the product beyond the service conditions mentioned in this catalog, users are requested to consult us

for further advice in advance, or to conduct the verification or evaluation for the performance under user's responsibility. We shall not be liable for any damages resulting from lack of aforementioned procedures by the customer.

Item mentioned in this catalog are subject change without prior notice to the customers.

Don't use our products in flammable or toxic gas service.

Bronz e & B r a s s Va l v e s

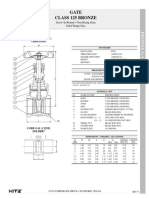

272P

Gate Valve

PN16 Cast Bronze Gate Valve

Non-rising Stem, Solid Wedge Disc.

16 bar at 100C, 7 bar at 170C, P-T rating : See page 02

Materials

Parts

Body

Bonnet

Stem

Disc

Gland Packing

Material

Gunmetal

Gunmetal

Special Brass*1

Gunmetal

Aramid Fibers Graphite

*1: Dezincification Resistand Brass

Dimensions

12

34

DN

15

20

L

H

D

Fig. 272P

Threaded ends: BS21(JIS B0203)

275P

inch

43

76

48

48

86

55

114

32

1

25

53

98

63

Gate Valve

60

118

70

112

40

63

126

80

2

50

71

154

90

212

65

87

180

90

Unit : mm

3

80

96

211

100

PN16 Cast Bronze Gate Valve

Non-rising Stem, Solid Wedge Disc.

16 bar at 100C, 7 bar at 170C, P-T rating : See page 02

Materials

Parts

Body

Bonnet

Stem

Disc

Gland Packing

Material

Bronze

Bronze

Special Brass*1

Bronze

Aramid Fibers Graphite

*1: Dezincification Resistand Brass

Dimensions

L

H

D

Fig. 275P

Threaded ends: BS21(JIS B0203)

286P

inch

12

34

DN

15

20

43

76

48

48

86

55

114

32

1

25

53

98

63

Gate Valve

60

118

70

112

40

63

126

80

2

50

71

154

90

212

65

87

180

90

Unit : mm

3

80

96

211

100

PN16 Cast Bronze Gate Valve

Non-rising Stem, Solid Wedge Disc.

16 bar at 100C, 7 bar at 170C, P-T rating : See page 02

Materials

Parts

Body

Bonnet

Stem

Disc

Gland Packing

Material

Bronze

Brass

Special Brass*1

Brass

Aramid Fibers Graphite

*1: Dezincification Resistand Brass

Dimensions

Fig. 286P

Threaded ends: BS21(JIS B0203)

L

H

D

inch

12

34

DN

15

20

42

76

48

47

86

55

1

25

50

98

63

114

32

60

118

70

112

40

63

126

80

Unit : mm

2

50

72

154

90

Bro n z e & Bra s s Va l ves

206P

Gate Valve

PN25 Cast Bronze Gate Valve

Non-rising Stem, Solid Wedge Disc.

25 bar at 100C, 10.5 bar at 186C, P-T rating : See page 02

Materials

Parts

Body

Bonnet

Stem

Disc

Gland Packing

Material

Bronze

Bronze

Special Brass*1

Special Brass*1*2/Bronze

Aramid Fibers Graphite

*1: Dezincification Resistand Brass

*2: Size 1/2 only

Dimensions

12

34

DN

15

20

L

H

D

Fig. 206P

Threaded ends: BS21(JIS B0203)

207P

inch

45

81

48

Gate solder joint

50

90

55

1

25

57

106

63

114

32

61

119

70

112

40

67

135

80

Unit : mm

2

50

74

159

90

PN25 Cast Bronze Gate Valve

Non-rising Stem, Solid Wedge Disc.

25 bar at 100C, 10.5 bar at 186C, P-T rating : See page 02

Materials

Parts

Body

Bonnet

Stem

Disc

Gland Packing

Material

Bronze

Bronze

Special Brass*1

Special Brass*1*2/Bronze

Aramid Fibers Graphite

*1: Dezincification Resistand Brass

*2: Size 1/2 only

H

Dimensions

Fig. 207P

Solder joint end valves should not be used in service

where the temperature of line fluid is higher than the

softening point of solder.

inch

12

34

DN

15

20

L

H

D

Solder joint ends: BS 864

210P

Caution

46

81

48

Globe Valve

61

90

55

1

25

72

106

63

114

32

78

119

70

112

40

87

135

80

Unit : mm

2

50

102

159

90

PN16 Cast Bronze Globe Valve

Rising Stem, Screwed Bonnet

16 bar at 100C, 7 bar at 170C, P-T rating : See page 02

Materials

Parts

Body

Bonnet

Stem

Disc

Gland Packing

Material

Bronze

Brass

Special Brass*1

Bronze

Aramid Fibers Graphite

*1: Dezincification Resistand Brass

H

Dimensions

Fig. 210P

Threaded ends: BS21(JIS B0203)

L

H

D

inch

12

34

DN

15

20

48

69

55

53

81

63

1

25

63

95

70

114

32

73

104

80

112

40

81

127

90

Unit : mm

2

50

94

147

100

Bronz e & B r a s s Va l v e s

213P

Globe Valve

PN25 Cast Bronze Globe Valve

Rising Stem, Screwed Bonnet

25 bar at 100C, 10.5 bar at 186C, P-T rating : See page 02

Materials

Parts

Body

Bonnet

Stem

Disc

Gland Packing

Material

Bronze

Brass

Special Brass*1

Bronze

Aramid Fibers Graphite

*1: Dezincification Resistand Brass

Dimensions

Fig. 213P

12

34

DN

15

20

L

H

D

Threaded ends: BS21(JIS B0203)

236P

inch

Swing Check Y-Pattern

53

80

63

65

94

70

1

25

77

104

80

114

32

85

127

90

112

40

100

145

100

Unit : mm

2

50

119

173

110

PN16 Cast Bronze Swing Check Valve

Y-pattern, Screwed Cap

16 bar at 100C, 7 bar at 170C, P-T rating : See page 02

Materials

Parts

Body

Cap

Disc

Hinge Pin

Bronze

Brass

Brass

Copper

Material

Dimensions

Fig. 236P

12

34

DN

15

20

L

H

Threaded ends: BS21(JIS B0203)

230P

inch

56

40

Lift Check

70

49

1

25

80

58

114

32

95

71

112

40

110

80

Unit : mm

2

50

128

95

PN25 Cast Bronze Lift Check Valve

Screwed Cap

25 bar at 100C, 10.5 bar at 186C, P-T rating : See page 02

Materials

Parts

Bronze

Brass

Bronze

Body

Cap

Disc

Material

Fig. 230P

Threaded ends: BS21(JIS B0203)

Dimensions

L

H

inch

12

34

DN

15

20

53

28

65

34

1

25

77

42

114

32

85

50

112

40

100

56

Unit : mm

2

50

119

67

Bro n z e & Bra s s Va lves

380P

Y-Pattern Strainer

PN25 Cast Bronze "Y" Pattern Strainer

304 Stainless Steel Screen

25 bar at 100C, 10.5 bar at 186C, P-T rating : See page 02

Materials

Parts

Material

Bronze

Brass

Stainless Steel (Type 304)

Body

Cap

Disc

L

Fig. 380P

Threaded ends: BS21(JIS B0203)

Dimensions

L

H

inch

12

34

DN

15

20

80

49

100

57

1

25

115

70

114

32

135

82

112

40

160

98

Unit : mm

2

50

195

121

Cast I ron Va l v e s

Gate Valve

500

PN16 Cast Iron Gate Valve

Outside screw, Rising stem

16 bar at 120C, 12.8 bar at 200C, P-T rating : See page 02

Materials

Parts

Material

Body

Bonnet

Stem

Disc

Disc seat ring

Body seat ring

Gland

Grand packing

Gasket

Gland bolt/ nut

Bonnet bolt/nut

Yoke sleeve

Hand wheel

Cast Iron

Cast Iron

Stainless Steel

Cast Iron

Cast Bronze/Stainless Steel

Cast Bronze/Stainless Steel

Specifications

Trim CR13/CR13 (500S) Trim 316/316 (500M)

EN-GJL-200

EN-GJL-200

ASTM A276 Type420

ASTM A276 Type316

EN-GJL-200

ASTM A182 Gr.F6a ASTM A182 Gr.F316

ASTM B62

Carbon Steel + 13CR Carbon Steel + 316

ASTM B62

Ductile Iron

Graphite

Graphite

Carbon Steel

Carbon Steel

Forged Brass / Cast Brass*1

Ductile Iron

Trim B/CR13 (500B)

*1 Size DN250 & DN300

Dimensions

inch

mm

L

H(Open)

D

178

360

180

212

65

190

416

180

3

80

203

458

180

Design Specifications

Face-to-face or End-to-end dimensions

End connection

Wall thickness

Fig. 500

501, 501I

2

50

Gate Valve

4

100

229

561

200

5

125

254

669

250

6

150

267

747

280

8

200

10

250

Unit : mm

12

300

292

330 356

964 1165 1374

300

360 400

BS EN 558 Basic series 3

BS EN 1092-2 PN16

Maker's standard

PN16 Cast Iron Gate Valve

Inside screw, Non-rising stem with Indicator*2

16 bar at 120C, 12.8 bar at 200C, P-T rating : See page 02

Materials

Parts

Material

Body

Bonnet

Stem

Disc

Disc seat ring

Body seat ring

Gland

Grand packing

Gasket

Gland bolt/ nut

Bonnet bolt/nut

Hand wheel

Cast Iron

Cast Iron

Stainless Steel

Cast Iron

Cast Bronze/Stainless Steel

Cast Bronze/Stainless Steel

Specifications

Trim CR13/CR13 (501(I)S) Trim 316/316 (501(I)M)

EN-GJL-200

EN-GJL-200

ASTM A276 Type420

ASTM A276 Type316

EN-GJL-200

ASTM A182 Gr.F6a ASTM A182 Gr.F316

ASTM B62

Carbon Steel + 13CR Carbon Steel + 316

ASTM B62

Ductile Iron

Graphite

Graphite

Carbon Steel

Carbon Steel

Ductile Iron

Trim B/CR13 (501(I)B)

*2 Indicator: 501I only

Dimensions

inch

mm

L

H

D

L

Fig. 501/501I

2

50

178

278

180

212

65

190

311

180

3

80

203

339

180

Design Specifications

Face-to-face or End-to-end dimensions

End connection

Wall thickness

4

100

229

393

200

5

125

254

454

250

6

150

267

501

280

8

200

292

592

300

BS EN 558 Basic series 3

BS EN 1092-2 PN16

Maker's standard

10

250

330

730

360

Unit : mm

12

300

356

852

400

Ca s t Iro n Va l ves

Globe Valve

510

PN16 Cast Iron Globe Valve

Outside screw, Rising stem

16 bar at 120C, 12.8 bar at 200C, P-T rating : See page 02

Materials

Parts

Material

Body

Bonnet

Stem

Disc

Disc seat ring

Body seat ring

Gland

Grand packing

Gasket

Gland bolt/ nut

Bonnet bolt/nut

Yoke bush

Hand wheel

Cast Iron

Cast Iron

Stainless Steel

Cast Iron/Stainless Steel

Cast Bronze

Cast Bronze/Stainelss Steel

Specifications

Trim CR13/CR13 (510S) Trim 316/316 (510M)

EN-GJL-200

EN-GJL-200

ASTM A276 Type420

ASTM A276 Type316

Carbon Steel + 13CR Carbon Steel + 316

EN-GJL-200

ASTM B62

Carbon Steel + 13CR Carbon Steel + 316

ASTM B62

Ductile Iron

Graphite

Graphite

Carbon Steel

Carbon Steel

Cast Brass

Cast Iron

Trim B/CR13 (510B)

Dimensions

inch

mm

L

H(Open)

D

L

2

50

203

322

200

212

65

216

338

200

3

80

241

359

200

Design Specifications

Face-to-face or End-to-end dimensions

End connection

Wall thickness

Fig. 510

Swing Check

520

4

100

292

392

250

5

125

330

438

300

6

150

356

503

300

8

200

495

552

360

10

250

622

639

450

Unit : mm

12

300

698

755

500

BS EN 558 Basic series 10

BS EN 1092-2 PN16

Maker's standard

PN16 Cast Iron Swing Check Valve

16 bar at 120C, 12.8 bar at 200C, P-T rating : See page 02

Materials

Parts

Material

Body

Cover

Hinge pin

Disc

Disc seat ring

Body seat ring

Arm

Gasket

Cover bolt/nut

Plug

Cast Iron

Cast Iron

Stainless Steel

Stainless Steel

Cast Bronze/Stainless Steel

Cast Bronze/Stainless Steel

Specifications

Trim CR13/CR13 (520S)

Trim 316/316 (520M)

EN-GJL-200

EN-GJL-200

ASTM A276 Type420

ASTM A276 Type316

EN-GJL-200

ASTM A182 Gr.F6a ASTM A182 Gr.F316

ASTM B62

Carbon Steel + 13CR Carbon Steel + 316

ASTM B62

Carbon Steel

Graphite

Carbon Steel

ASTM A47

Trim B/CR13 (520B)

Malleable Iron

Dimensions

L

inch

mm

L

H

2

50

203

154

212

65

216

162

3

80

241

176

Design Specifications

Fig. 520

Face-to-face or End-to-end dimensions

End connection

Wall thickness

4

100

292

220

5

125

330

226

6

150

356

307

8

200

495

325

10

250

622

384

Unit : mm

12

300

698

426

BS EN 558 Basic series 10

BS EN 1092-2 PN16

Maker's standard

Cast I ron Va l v e s

Y-Pattern Strainer

530

PN16 Cast Iron Y-Pattern Strainer

Stainless Steel Screen

16 bar at 120C, 12.8 bar at 200C, P-T rating : See page 02

Materials

Parts

Body

Cover

Screen

Gasket

Cover bolt /nut

Plug

Dimensions

Specifications

Trim 304 (530U)

Trim 316 (530M)

EN-GJL-200

EN-GJL-200

304

316

Graphite

Carbon Steel

ASTM A47

Material

Cast Iron

Cast Iron

Stainless Steel

Malleable Iron

inch

mm

L

H

2

50

220

178

212

65

270

177

3

80

290

195

Design Specifications

Fig. 530

10

Face-to-face or End-to-end dimensions

End connection

Wall thickness

4

100

350

243

5

125

390

294

6

150

440

320

8

200

540

397

Maker's standard

BS EN 1092-2 PN16

Maker's standard

10

250

660

480

Unit : mm

12

300

720

557

Y- 023= 02

URL: http://www.kitz.com

1210ITP

You might also like

- Brass DefectsDocument9 pagesBrass DefectstechopelessNo ratings yet

- Fan & Ventilation Practice GuideDocument373 pagesFan & Ventilation Practice Guident_long76100% (3)

- EFM - Unit 2 - Engineering Materials (Edited)Document23 pagesEFM - Unit 2 - Engineering Materials (Edited)truong100% (1)

- SBC Kingkong P8 OutdoorDocument10 pagesSBC Kingkong P8 OutdoorSBC INDONESIA (PT.Tribangun Kreasindo)No ratings yet

- Penulangan Pondasi Tower Crane 2Document1 pagePenulangan Pondasi Tower Crane 2Agung SahdiNo ratings yet

- 2019-008 REV Kepala Biro Umum Setda Pemprov. BantenDocument3 pages2019-008 REV Kepala Biro Umum Setda Pemprov. Bantenridho kusumaNo ratings yet

- Catalog Valve ToyoDocument28 pagesCatalog Valve ToyoMustafa Kamal100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Electrical Cable Jointing ProceduresDocument10 pagesElectrical Cable Jointing Proceduresnt_long76No ratings yet

- BIM Hand BookDocument410 pagesBIM Hand Booknt_long7633% (6)

- Aluminium Composite PanelsDocument46 pagesAluminium Composite PanelsSashwat GhaiNo ratings yet

- Katalog FCU DDB050BWDocument35 pagesKatalog FCU DDB050BWMICAH JEDAH0% (1)

- Ducting Method ENGDocument6 pagesDucting Method ENGSaeful Malik Ginting100% (1)

- PT NGI Price List Kitz Gate Valve 2019Document1 pagePT NGI Price List Kitz Gate Valve 2019Kiki WidyaNo ratings yet

- MizuDocument1 pageMizuPrima Fitra SaputraNo ratings yet

- Socket Weld X Threaded CouplingDocument1 pageSocket Weld X Threaded Couplingmatthewwalls4386No ratings yet

- RAB Penambahan Instalasi Pipa Loading CPODocument1 pageRAB Penambahan Instalasi Pipa Loading CPOMuslim MunawarNo ratings yet

- Kebutuhan Wrapping PipaDocument4 pagesKebutuhan Wrapping Pipapanji uteNo ratings yet

- Standarisasi KabelDocument44 pagesStandarisasi Kabeladzan isaacNo ratings yet

- Technical Drawing PDFDocument170 pagesTechnical Drawing PDFLazzarus Az GunawanNo ratings yet

- BQ Barrier GateDocument2 pagesBQ Barrier GatenanubmatNo ratings yet

- Analisa Harga SatuanDocument15 pagesAnalisa Harga SatuanWeldy Armando Yannes100% (1)

- Mechanical - Anchoring - DynaBolt Plus PDFDocument6 pagesMechanical - Anchoring - DynaBolt Plus PDFAnonymous dSFbLxc9No ratings yet

- Perhitungan TA Terowongan (CP 105-3) - 4 BONJILL BARUDocument52 pagesPerhitungan TA Terowongan (CP 105-3) - 4 BONJILL BARUMozart CilikNo ratings yet

- Kabel MetalDocument2 pagesKabel Metalsri haryadiNo ratings yet

- Sika Flow MetersDocument27 pagesSika Flow MetersdnkNo ratings yet

- BoQ SampleDocument158 pagesBoQ Samplevix Yams setNo ratings yet

- PT - Economie MandiriDocument8 pagesPT - Economie MandiriHariadi Budi SantosoNo ratings yet

- Colour Card Multi-PoxDocument4 pagesColour Card Multi-PoxGunawan MuhamadNo ratings yet

- AMICO Induk BrosurDocument2 pagesAMICO Induk Brosurdzikri nur hNo ratings yet

- FCA Foam ChamberDocument5 pagesFCA Foam ChamberN AfiyahNo ratings yet

- Asahimas Company ProfileDocument6 pagesAsahimas Company ProfileTharra AyurianyNo ratings yet

- Rab Workshop Omega RevisiDocument26 pagesRab Workshop Omega Revisifatahillah12345633% (3)

- Price Fitting Besi 2Document8 pagesPrice Fitting Besi 2opik97No ratings yet

- Federal Cable Catalogue-MinDocument17 pagesFederal Cable Catalogue-MinAhmadBintangNegoroNo ratings yet

- Form Inspeksi Mep Unit Condo Alt-4Document42 pagesForm Inspeksi Mep Unit Condo Alt-4SILVIA SITI RUKMANANo ratings yet

- 3 Painting and Coating Selection Schedules: 3.1 New Construction WorksDocument2 pages3 Painting and Coating Selection Schedules: 3.1 New Construction WorksmuthuvelaaNo ratings yet

- Bms. Prosedure Kerja Pipa HdpeDocument11 pagesBms. Prosedure Kerja Pipa Hdpeaswar100% (1)

- Grooved FittingsDocument156 pagesGrooved FittingsmostafaabdelrazikNo ratings yet

- Tankguard Plus Jotun PaintDocument5 pagesTankguard Plus Jotun PaintGurdeep Sungh AroraNo ratings yet

- Extrana Product CatalogDocument78 pagesExtrana Product CatalogBaswara SadewaNo ratings yet

- Landing-Valve - NaffcoDocument2 pagesLanding-Valve - NaffcoNOMAN100% (2)

- Daftar Harga Satuan Bahan Dan Upah: NO Uraian Satuan Harga Dasar (RP) A TenagaDocument15 pagesDaftar Harga Satuan Bahan Dan Upah: NO Uraian Satuan Harga Dasar (RP) A TenagadaniNo ratings yet

- Penawaran Harga Pipa Refrigrant, Isolasi, Support MaterialDocument2 pagesPenawaran Harga Pipa Refrigrant, Isolasi, Support MaterialAgus Sofiansyah100% (1)

- Form Welding SchematicDocument1 pageForm Welding SchematicZainudinNo ratings yet

- Bagian C - Spesifikasi Pengadaan Pipa Dan AcessoriesDocument15 pagesBagian C - Spesifikasi Pengadaan Pipa Dan AcessoriesSoleh SulaemanNo ratings yet

- Pipa + Fitting PDFDocument4 pagesPipa + Fitting PDFSukiyatno YatnoNo ratings yet

- EXCEL Tabel BajaDocument2 pagesEXCEL Tabel Bajaayu2023No ratings yet

- Analisa Harga SatuanDocument4 pagesAnalisa Harga Satuanqwkerbk090909No ratings yet

- Dyna Bolt Technical DataDocument1 pageDyna Bolt Technical DataSulthan AriNo ratings yet

- Harga Sewa Alat (HSPK Berau 2018) PDFDocument3 pagesHarga Sewa Alat (HSPK Berau 2018) PDFHery KiswantoNo ratings yet

- Daftar Harga Pipa Besi Merk SPS: Pt. Golden Piping IndonesiaDocument1 pageDaftar Harga Pipa Besi Merk SPS: Pt. Golden Piping IndonesiailhamNo ratings yet

- Fuji Electric Kabel (FRC)Document13 pagesFuji Electric Kabel (FRC)Ade WawanNo ratings yet

- Rencana Anggaran Biaya: NO Vulome SAT Spesifikasi Harga Satuan Jumlah Harga A. Persiapan UraianDocument2 pagesRencana Anggaran Biaya: NO Vulome SAT Spesifikasi Harga Satuan Jumlah Harga A. Persiapan UraianAmran AchmadyNo ratings yet

- Cost Bunchpress & Shredder Sunli by BJM 2019 Mei EditDocument1 pageCost Bunchpress & Shredder Sunli by BJM 2019 Mei EditHeryy TanujayaNo ratings yet

- Cara Hitung Kebutuhan Wrapping PipaDocument4 pagesCara Hitung Kebutuhan Wrapping PipahadiNo ratings yet

- Handy FlexDocument3 pagesHandy FlexwinNo ratings yet

- RAB & Spek IGMDocument2 pagesRAB & Spek IGMfatwa1985No ratings yet

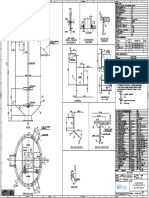

- Agitator Blade Ii: Ga Drawing For 4 KL, Vertical Mixing TankDocument1 pageAgitator Blade Ii: Ga Drawing For 4 KL, Vertical Mixing TankAshokNo ratings yet

- PDS Sika ViscoCrete-8050 SG enDocument3 pagesPDS Sika ViscoCrete-8050 SG enBenedictus CaturNo ratings yet

- Analisa Pekerjaan Pintu Dan Jendela AlumuniumDocument2 pagesAnalisa Pekerjaan Pintu Dan Jendela AlumuniumSandroJanesraGurningNo ratings yet

- PolykenDocument7 pagesPolykenJanllo83No ratings yet

- Catalog Valve KSBDocument58 pagesCatalog Valve KSByoboo100% (1)

- Kitz UK Valves CataloqueDocument20 pagesKitz UK Valves CataloqueTaher YusufNo ratings yet

- Att 2 - EdsDocument30 pagesAtt 2 - Eds정동현No ratings yet

- F7212HDocument9 pagesF7212HSopon SrirattanapiboonNo ratings yet

- Nhung Bai Thuoc Tap 3Document165 pagesNhung Bai Thuoc Tap 3nt_long76No ratings yet

- ALS10 / ALS17: Linear 1" Slot DiffuserDocument1 pageALS10 / ALS17: Linear 1" Slot Diffusernt_long76No ratings yet

- 01 EPS - Pressure 2020Document19 pages01 EPS - Pressure 2020nt_long76No ratings yet

- Method Statement For TestingDocument12 pagesMethod Statement For Testingnt_long76No ratings yet

- Van NH A ASAHI - CatalogueDocument32 pagesVan NH A ASAHI - Cataloguent_long76No ratings yet

- Picture ManagerDocument2 pagesPicture Managernt_long76No ratings yet

- ERICO ERICORE Insulated ConductorsDocument2 pagesERICO ERICORE Insulated Conductorsnt_long76No ratings yet

- Maintaining Swimming Pools, Spas, Whirlpool Tubs and Saunas: Back To Article IndexDocument14 pagesMaintaining Swimming Pools, Spas, Whirlpool Tubs and Saunas: Back To Article Indexnt_long76No ratings yet

- 2013 FireStop Catalogue V3 Final (SM)Document48 pages2013 FireStop Catalogue V3 Final (SM)nt_long76No ratings yet

- BIM Hand Book Edition 2Document521 pagesBIM Hand Book Edition 2nt_long76No ratings yet

- Load Capacities of Threaded Hanger Rods Are Indicated in The Table BelowDocument1 pageLoad Capacities of Threaded Hanger Rods Are Indicated in The Table Belownt_long76No ratings yet

- BIM Hand Book Edition 2Document521 pagesBIM Hand Book Edition 2nt_long76No ratings yet

- Boiler Prefunctional ChecklistDocument6 pagesBoiler Prefunctional Checklistnt_long76No ratings yet

- 1009 HotWaterSystemPumpTestDocument9 pages1009 HotWaterSystemPumpTestnt_long76No ratings yet

- Cabinet Unit Heater Functional TestDocument2 pagesCabinet Unit Heater Functional Testnt_long76No ratings yet

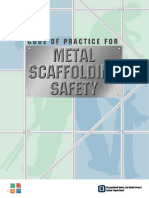

- CoP For Metal Scaffolding SafetyDocument85 pagesCoP For Metal Scaffolding SafetyChenthuran VilvarajahNo ratings yet

- Domestic Hot Water SystemDocument2 pagesDomestic Hot Water Systemnt_long76No ratings yet

- Boiler System Functional TestDocument8 pagesBoiler System Functional Testnt_long76No ratings yet

- Number of Lines Row Height With Times New Roman 12 Point Font 1 19.5 2 36.0 3 52.0 4 65.0 5 83.0 6 98.0 7 8 118.0Document12 pagesNumber of Lines Row Height With Times New Roman 12 Point Font 1 19.5 2 36.0 3 52.0 4 65.0 5 83.0 6 98.0 7 8 118.0nt_long76No ratings yet

- Build Order CreateDocument23 pagesBuild Order CreateDudika 5704No ratings yet

- Color ChartDocument1 pageColor Chartkaniappan sakthivelNo ratings yet

- List of Authorized Recyclers/Utilizers/ Co-Processors of Hazardous WasteDocument11 pagesList of Authorized Recyclers/Utilizers/ Co-Processors of Hazardous WasteTri LokNo ratings yet

- Aurubis Lead-Free Brass BlueBrass Flyer ENDocument4 pagesAurubis Lead-Free Brass BlueBrass Flyer ENPablo SantibáñezNo ratings yet

- Project On Study of Constituents of AlloyDocument15 pagesProject On Study of Constituents of AlloyBhumit MittalNo ratings yet

- Alloy Project: Brass: By: Bryanna Ruiz Gurmani Randhawa Michelle QuirozDocument8 pagesAlloy Project: Brass: By: Bryanna Ruiz Gurmani Randhawa Michelle QuirozGurmani RNo ratings yet

- Disclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)Document20 pagesDisclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)Tanmoy Dutta100% (1)

- Fire Hazards in Chemical Plant From Friction Sparks Involving The Thermite ReactionDocument10 pagesFire Hazards in Chemical Plant From Friction Sparks Involving The Thermite ReactionDavidNo ratings yet

- Glass Balcony Fittings Catalog (Form Cathy) PDFDocument64 pagesGlass Balcony Fittings Catalog (Form Cathy) PDFDamons Foo OoipinNo ratings yet

- Taarkashi Mohan-Lal-Sharma August2020Document14 pagesTaarkashi Mohan-Lal-Sharma August2020shreyaNo ratings yet

- B&M Series 1000 SwitchesDocument12 pagesB&M Series 1000 SwitchesscribdkhatnNo ratings yet

- ArchaeometallurgyDocument13 pagesArchaeometallurgyTom FennNo ratings yet

- Metalife Scheda Filtri INGDocument20 pagesMetalife Scheda Filtri INGOrlando RebeloNo ratings yet

- Selected Formulary Book On Petroleum Lubricants Fats Polishes Glass Ceramics Nitrogenous Fertilizers Emulsions Leather and Insecticides PDFDocument33 pagesSelected Formulary Book On Petroleum Lubricants Fats Polishes Glass Ceramics Nitrogenous Fertilizers Emulsions Leather and Insecticides PDFGhassen KhalilNo ratings yet

- 3 Materials Technology 39-57Document19 pages3 Materials Technology 39-57MILDES100% (1)

- Fundamentals of Professional Welding PDFDocument256 pagesFundamentals of Professional Welding PDFclaudelgo100% (1)

- Asd26 1972Document7 pagesAsd26 1972sajay_suryaNo ratings yet

- Scrap Specifications Circular 2018 PDFDocument62 pagesScrap Specifications Circular 2018 PDFheruNo ratings yet

- Cross-Reference List - 110210 - ENGDocument3 pagesCross-Reference List - 110210 - ENGIlya PikusNo ratings yet

- Broco Catalogue 110214Document6 pagesBroco Catalogue 110214Admiiral PramadyaNo ratings yet

- Plumbing Book Patrick 1Document127 pagesPlumbing Book Patrick 1Patrick Macharia100% (3)

- CatalDocument180 pagesCatalAlessandro RuoccoNo ratings yet

- Globe Valves: Bronze Globe Valve - Series B PN32Document1 pageGlobe Valves: Bronze Globe Valve - Series B PN32Juan ZapataNo ratings yet

- Gate Class 125 Bronze: CODE # 40 (AK125E) ThreadedDocument1 pageGate Class 125 Bronze: CODE # 40 (AK125E) Threadedthilina lakhithaNo ratings yet

- Máy đo độ cứng để bànDocument51 pagesMáy đo độ cứng để bànĐặng Đình TuấnNo ratings yet

- Unit 6-Metals & Non-MetalsDocument8 pagesUnit 6-Metals & Non-MetalsRahul KumarNo ratings yet

- Organ Pipe Metallurgy: Portland Section ACSDocument15 pagesOrgan Pipe Metallurgy: Portland Section ACSjoeNo ratings yet