Professional Documents

Culture Documents

Multi Stage Centrifugal Compressors Lores

Uploaded by

Miguel Angel GisbertOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multi Stage Centrifugal Compressors Lores

Uploaded by

Miguel Angel GisbertCopyright:

Available Formats

PRODUCTS

Multi-Stage Centrifugal Compressors

Evolutionary Designs Revolutionary Results

A History of Innovation and Success

Product Lines

Since 1910, Elliott Company has earned a reputation

for providing innovative solutions, unmatched

expertise, and first-class service to theglobal

turbomachinery marketplace. Elliott hasdesigned,

tested, and installed some of the industrys most

rugged and dependable equipment. Infact, some

Elliott compressors and turbines installed in the

1940s and 1950s are still in operation today, either

as originally supplied or upgraded to handle new

process conditions or morestringent environmental

standards.

Single/Multi-Stage Centrifugal Compressors

(API 617)

We have been on the cutting edge of technological

advancement throughout our history, consistently

providing advanced technology in aerodynamics,

rotor dynamics, process simulation, and

metallurgy. Our customers have benefited from our

stateoftheart production innovations, including

fabricated casing technology, high-pressure casing

technology, and impeller welding techniques. The

Elliott EDGETM development program evolved from

our commitment to providing new approaches,

processes, and technology while maintaining

thequality and reliability that our customers

havecome toexpect.

Chemical/Petrochemical Plants

We understand that change is essential in achieving

and maintaining a competitive edge in todays

business environment. Together with our customers

and suppliers, we continue to innovate, improve,

and expand our extensive portfolio of products and

services that serve the energy industries.

Axial Air Compressors (API617)

Single/Multi-Stage SteamTurbines (API611)

Multi-Stage Steam Turbines(API 612)

Applications

Oil Refineries

FCC Applications

Ethylene Plants

Gas Lift/Gas Gathering

Gas Injection/Transport

LNG Facilities

Gas to Liquids

Ammonia Plants

Power Generation

Advanced Technology

Superior Performance Through

Advanced Technology

Through our EDGE development program, we

combine our comprehensive knowledge of

turbomachinery with the latest design software,

manufacturing processes, and machine tools. As a

result, Elliotts multi-stage centrifugal compressors

lead the industry in both performance and reliability.

Increased Aerodynamic Efficiency

Elliott uses state-of-the-art interactive design

andprediction tools to optimize aerodynamic

performance and increase flange-to-flange

efficiencies. Compressor impeller and matched

stationary flowpath components are developed

usingComputational Fluid Dynamics (CFD) analyses

and other current design tools. Three-dimensional

blade profiles, diffuser flow angles, crossover bend

curvature, area ratio, and return channel vane

shapes are optimized for each impeller stage to

provide the best possible efficiency. Additional

performance enhancements are achieved by

improving the flow distribution channels at the inlet

and discharge volutes and sidestream mixing areas.

These enhancements allow us to provide some of

the industrys highest operational efficiencies.

Improved Rotor Stability Characteristics

Through extensive research in the fields of

rotordynamic stability, aerodynamic cross-coupling

stiffness, and rotor-bearing systems, we have

developed proprietary analytical tools. Incorporating

these developments into Elliott compressor designs

has produced a number of product enhancements.

For example, weve increased rotor stiffness

by increasing shaft diameter, reducing impeller

weight, and increasing journal bearing sizes. This

allows higher torque transmission capabilities

and higherspeed operation, with improved rotor

stabilitycharacteristics, which are essential as

gasdensitiesand operating pressures increase.

Casing Features

Elliott designed our EDGE compressor casings

toreduce the required manufacturing steps and

simplify field assembly. To achieve higher operating

pressures, we applied state-of-the-art solids

modeling and finite element analysis techniques.

Small and mid-sized horizontally split casing

sectionsare made from a single piece of rolled steel

plate with horizontal flanges that are machined

not weldedinto the side. Cast steel casings are

used forsome applications. High-strength casing

through-bolts provide superior clamping forces.

Endwalls are made from a single solid plate. The

resulting casing has fewer sealing surfaces, is easier

to manufacture and assemble, and has increased

pressure capabilities compared to conventional

designs. Largerhorizontally split casings have

rolled barrel sections with welded-on endplates and

welded-on horizontal flanges.

Vertically split MB-line compressors feature a

complete inner casing assembly. This includes

ahorizontally split inner casing with diaphragms,

stationary seals, rotating elements, bolted-on

endwalls, and shaft end seals. This module can

beinserted or removed from the outer casing

as asingle piece, which simplifies compressor

assemblyand reduces turn-around times.

We typically use milled flats for SAE flanged

connections, including endwall, spray nozzle,

casingdrain, bearing retainer, and equalizing

lineconnections. On smaller casings where space

islimited, SAE flanges provide higher ratings and

morecompact designs than ANSI flanges.

EDGE Casing Advantages

Integral horizontal flanges onsmall and medium

frames

Solid endwalls with machinedflats for bearing

andseal connections

Machined flats with SAE flanges for most drain

or

injection connections

Through-bolts for casing horizontal flanges

Allowable forces and moments per API 617

Three-dimensional solid modeling for improved

design and engineering review capability

Pro/ENGINEER solid modeling files to enhance

precision during component manufacture

Aerodynamic Components

A key achievement of the EDGE development

program is our ability tooffer superior, threedimensional impeller designs and stationary

diaphragms. We do this by maximizing performance

over a broad range ofpressure and flow applications

using the latest aerodynamic design and analysis

technologies. Toverify predicted performance,

single-stage testing is performed in various

configurations, such as with vaneless or vaned

diffusers, or using high or low tip Mach numbers.

Higher and lower flow stage ratings are derived from

the prototype test data to form a family of stages.

Within each stage family, impeller geometry is fixed;

blade heights are varied for higher or lower flows.

Using this methodology, several stage families are

used to span the desired flow coefficient range.

Impellers and stationary components are then scaled

up or down for different frame sizes. For maximum

flexibility, EDGE aerodynamic components are also

scalable from 90percent to 100percent size within

eachcompressor

frame size.

Impeller manufacturing applies five-axis milling to

ensure the quality of the advanced impeller designs.

Impellers are stress relieved, machine finished,

balanced statically and dynamically, spin tested,

andthen mounted with an interference-fit onto

the shaft. Shaft-to-impeller keys are used for extra

stability in high pressure or high power applications.

EDGE compressors use either fabricated steel

diaphragms or a combination cast-and-fabricated

steel design where thickness precludes using

steel plate alone. Precision machining ensures

dimensional accuracy and significantly improves

the diaphragm surface finish. Diaphragms are

horizontally split and finished at all horizontal and

peripheral joints and on gas path surfaces.

Proven Turbomachinery Technology

Cast nozzles reduce manufacture time

and allow higher ratings

Elimination of dished heads

increases pressureratings

Increased journal bearing

and shaft seal sizes

Non-radial inlet guide vanes

improve flow distribution

Increased shaft diameter

enhances rotor dynamics

Precisely designed and

machined diaphragms

CFD ensures proper

sidestream mixing

High-efficiency impellers scale

frame-to-frame

Other Features

As part of our comprehensive EDGE development

program, Elliotts engineers examined each

compressor component to find ways to support

ourgoals of higher efficiency, lower cost, simpler

maintenance, and reduced cycle time. Our designs

reflect our commitment to making our products the

best in the industry, down to the last detail.

Interstage and balance piston sealing is

accomplished through two component features.

First,we use abradable or deflection-tolerant

materials such asfluorosint or nickel-graphite on

stationary sealing surfaces. Second, we machine

teeth onto the rotating surfaces. These features

increase efficiency by reducing gas recirculation

andminimizing the potential for shutdowns resulting

from damaged seals.

Elliott offers shaft seals to meet our customers

needsin all applications. Dry gas seals are

standardand are available as single, tandem,

double,or triple designs. The tandem or triple

gasseal designs include an intermediate labyrinth,

whichcan bebuffered for additional emissions

protection. Ourcustomers realize cost savings

byeliminating expensive seal oil systems and

theneedto disposeof contaminated oil. Gas seal

buffersystemengineering and manufacturing

areavailableat Elliotts Donora, Pennsylvania, plant.

Alternative seal designs include labyrinth or

drycarbon ring seals for low pressure services,

mechanical contact seals (Elliotts patented IsocarbonTM design), and bushing seals (Elliotts

Iso-sleeveTM design). For mechanical contact and

bushing seals, acartridge design is also available.

This enables easier installation and removal ofthe

complete seal assembly. Buffer connections are

standard for all seal designs.

Reliability, quality, and safety are hallmarks of all

Elliott-designed components. For example, as a

design standard, replaceable journal bearings are

steel-backed and babbitt-lined with a five-shoe

tiltingpad. Thrust bearings are double-acting and

selfequalizing. Center pivots typically are used to

make assembly easier and to provide maximum

protection if reverse rotation occurs. Chrome-copper

pads are applied for both journal and thrust bearings

for high oil temperature applications.

Manufacturing and Testing Capabilities

Elliott employs high-quality production techniques that minimize cycle time and costs while providing our

customers withthe most competitive and reliable products. Our engineering and manufacturing facilities in

Jeannette, Pennsylvania, and Sodegaura, Japan, rank among the worlds most advanced forturbomachinery

design, production, and testing.

Our combined manufacturing capabilities include Masterhead machining centers forcasing machining, rotor

machining centers, and diaphragm machiningcenters. Our rotor balancing facilities include astateoftheart

Schenck Trebeldesigned balancing machine housed in a bunker-style vacuum chamber. The top of this

reinforced concrete facility slides away via hydraulic motors, permitting rotors to be lowered onto the balancing

equipment.

Our recently expanded test facilities enable usto validate the mechanical integrity and performance of

ourcomponents and overall systems. Our new main test facility, whichincreased our capacity by50percent,

contains ahighvolume, closed loop, speciallydesigned cooling system with the capacity for testing gas turbinedriven compressor trains atfull loads up to 100,000 HP.

Masterhead casing center

Diaphragm machining cell

Global Service and Support

Elliott offers comprehensive service and support for all types of turbomachinery regardless of the original

manufacturer. Our experienced engineers, metallurgists, technicians, welders and mechanics have the expertise

and experience to keep equipment performance high and maintenance costs low.

Elliotts global service network is ISO 9001:2008 certified and provides installation, maintenance, repair,

overhauls, parts, rerates, modifications and training, 24 hours a day, 7 days a week. Supported by our

service centers throughout the world, field service teams are recognized for their hands-on experience with

comprehensive overhauls; project management; resource planning; subcontractor control; installation and

commissioning and on-site repair. Elliott Technical Services provides practical, timely and cost-effective solutions

for complex turbomachinery problems. Rerates and modifications by Elliott Engineered Solutions enhance

operating efficiency and extend the life of rotating equipment from any manufacturer.

Elliott is fully compliant with all relevant industry standards including API, ANSI, APO, CRN, CSA, and CE/

PED. We are accredited by the American Society of Mechanical Engineers (ASME), holding both the U and the

R Boiler and Pressure Vessel (BPV) certifications, and we adhere to the principals of the American Society of

Nondestructive Testing (ASNT) and are SNT-TC 1A complaint.

Compressor installation

Reverse engineering

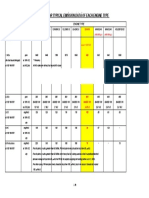

Compressor Frame Summaries

Frame

Max Flow

m3/hr

Impeller Diameter

CFM

Speed

mm

in

RPM

Configuration

M (Horizontal Split)

MB (Vertical Split)

Casing Rating

BARG

PSIG

10

10,900

6,400

264

10.4

19,800

M

MB

69

345

1,000

5,000

15

14,400

8,500

303

11.9

17,300

M

MB

69

689

1,000

10,000

20

19,000

11,200

348

13.7

15,000

M

MB

69

689

1,000

10,000

25

25,000

14,700

401

15.8

13,100

M

MB

69

689

1,000

10,000

29

33,000

19,400

461

18.2

11,400

M

MB

69

689

1,000

10,000

32

43,500

25,600

530

20.9

9,900

M

MB

69

345

1,000

5,000

38

57,400

33,800

610

24.0

8,600

M

MB

69

345

1,000

5,000

46

75,900

44,700

701

27.6

7,500

M

MB

69

217

1,000

3,150

56

100,200

59,000

806

31.7

6,500

M

MB

69

217

1,000

3,150

60

132,500

78,000

927

36.5

5,600

M

MB

69

138

1,000

2,000

70

175,000

103,000

1,066

42.0

4,900

M

MB

52

103

750

1,500

78

231,100

136,000

1,226

48.3

4,300

M

MB

41

103

600

1,500

88

305,800

180,000

1,410

55.5

3,700

M

MB

41

69

600

1,000

103

404,400

238,000

1,622

63.8

3,200

26

380

110

535,200

315,000

1,865

73.4

2,800

100

Note: Table does not include specifications for double flow configuration.

Standardization of Components

In developing the EDGE compressor product line, wefocused on standardizing components and hardware to

reduce costs and improve reliability across a wide array of applications. The EDGE product line consists of 15

standard frame sizes, which are scaled from the 38M median frame size. Casing bores and internal aerodynamic

hardware, such as impellers, diaphragms, and shafts, are scaled. Scaling aerodynamic components improves

performance predictability and increases reliability bypreserving geometric similarity across frame sizes.Bearings

and seals are selected from vendor standard sizes for each application.

10

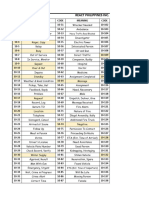

Weights, Dimensions and Configurations

Frame

Size

Minimum

Rotor Length

(in. / mm)

Maximum

Rotor

Length

(in. / mm)

Casing Width

(includes

Casing Height

supports)

(exc. supports)

(in. / mm)

(in. / mm)

Minimum Casing Weight

(lb/kg)

Maximum Casing

Weight

(lb / kg)

Typical Weights and Dimensions for Elliott Horizontal Split Compressors*

10M

35 / 890

64 / 1,625

37.3 / 947.4

36.25 / 921

4,700 / 2,130

9,000 / 4,080

15M

35 / 890

75 / 1,905

42.5 / 1,080

41.38 / 1,051

5,600 / 2,540

12,700 / 5,760

20M

40 / 1,015

80 / 2,030

48.5 / 1,232

47.85 / 1,215

8,200 / 3,720

18,000 / 8,165

25M

45 / 1,145

90 / 2,285

55.1 / 1,400

54.12 / 1,375

11,100 / 5,035

24,500 / 11,100

29M

50 / 1,270

110 / 2,795

65.4 / 1,661

59.25 / 1,505

14,000 / 6,350

32,000 / 14,500

32M

50 / 1,270

124 / 3,150

70.5 / 1,791

65.75 / 1,670

15,700 / 7,120

45,000 / 20,400

38M

55 / 1,400

135 / 3,430

76.3 / 1,938

70.62 / 1,794

23,000 / 10,430

62,000 / 28,100

46M

70 / 1,780

155 / 3,940

66.5 / 1,689

89.5 / 2,273

32,500 / 14,740

87,000 / 39,500

56M

80 / 2,032

175 / 4,445

76 / 1,930

93.38 / 2,372

51,500 / 23,360

127,000 / 57,600

60M

90 / 2,285

190 / 4,825

89.7 / 2,278

97 / 2,464

59,000 / 26,760

170,000 / 77,100

70M

100 / 2,540

230 / 5,840

103.5 / 2,629

113.88 / 2,893

71,000 / 34,000

210,000 / 95,250

78M

100 / 2,540

250 / 6,350

109.5 / 2,781

125.5 / 3,188

95,000 / 43,100

295,000 / 133,800

88M

115 / 2,920

275 / 6,985

133 / 3,378

137.5 / 3,492

130,000 / 59,000

380,000 / 172,400

103M

135 / 3,429

300 / 7,620

156 / 3,962

158.5 / 4,025

215,000 / 97,500

525,000 / 238,100

110M

140 / 3,556

325 / 8,255

182 / 4,623

182 / 4,630

270,000 / 122,470

690,000 / 312,980

In-Line

In-Line

with Side-Streams

In-Line

with Iso-Cooling

Typical Weights and Dimensions for Elliott Vertical Split Compressors*

10MB

35 / 890

62 / 1,575

43 / 1,092

42.5 / 1,080

7,000 / 3,175

13,000 / 5,900

15MB

35 / 890

72 / 1,830

46 / 1,168

48 / 1,219

8,400 / 3,810

17,500 / 7,940

20MB

40 / 1,015

80 / 2,030

50 / 1,270

53.75 / 1,366

12,000 / 5,440

25,000 / 11,340

25MB

45 / 1,145

88 / 2,235

58.5 / 1,486

62 / 1,575

18,400 / 8,345

36,000 / 16,330

29MB

50 / 1,270

105 / 2,670

64.3 / 1,633

64 / 1,626

23,000 / 10,435

49,000 / 22,225

32MB

50 / 1,270

120 / 3,050

71.7 / 1,821

76.5 / 1,943

28,500 / 12,900

69,000 / 31,300

38MB

55 / 1,400

130 / 3,300

78.5 / 1,994

83.25 / 2,115

36,500 / 16,560

89,000 / 40,400

46MB

70 / 1,780

150 / 3,810

96.5 / 2,451

86.5 / 2,197

47,500 / 21,500

115,000 / 52,200

56MB

80 / 2,030

170 / 4,320

104.2 / 2,647

102.12 / 2,594

70,000 / 31,750

160,000 / 72,600

60MB

90 / 1,525

185 / 4,700

113 / 2,870

112.5 / 2,858

90,000 / 41,000

200,000 / 91,000

70MB

100 / 2,540

225 / 5,715

115.2 / 2,926

120.96 / 3,064

100,000 / 45,350

251,000 / 113,900

78MB

100 / 2,540

245 / 6,225

120 / 3,048

140 / 3,556

125,000 / 56,700

315,000 / 143,000

88MB

115 / 2,920

265 / 6,730

137 / 3,480

148 / 3,759

205,000 / 93,000

465,000 / 211,000

Double-Flow

Back-to-Back

Iso-Cooler Optional

11

Elliott Group is a global leader in the

design, manufacture and service of

technically advanced centrifugal compressors, steam turbines, power recover expanders and axial compressors

used in the petrochemical, refining, oil

& gas and process industries, as well as

in power applications. Elliott Group is a

wholly owned subsidiary of Ebara Corporation, a major industrial conglomerate headquartered in Tokyo, Japan.

901 North Fourth Street

Jeannette, PA 15644-1473

Telephone: 724-527-2811

Fax: 724-600-8442

Email: info@elliott-turbo.com

www.elliott-turbo.com

2014 Elliott Group

CMP.2001.00514

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Air Ejector Selection PDFDocument9 pagesAir Ejector Selection PDFmyungkwan haNo ratings yet

- Lempor Ejector Calculator Beta 1.1Document21 pagesLempor Ejector Calculator Beta 1.1myungkwan haNo ratings yet

- Cii Seniorcareindustryreportindia2018 180524043125Document36 pagesCii Seniorcareindustryreportindia2018 180524043125N InbasagaranNo ratings yet

- Cell Transport WorksheetDocument2 pagesCell Transport WorksheetVictoria Niño D100% (1)

- Introduction To Process Plant Start-Up and CommissioningDocument35 pagesIntroduction To Process Plant Start-Up and Commissioning2091979100% (6)

- ZR Handbook Rev2 PDFDocument80 pagesZR Handbook Rev2 PDFmyungkwan haNo ratings yet

- PO6258 RFI+for+S60133-0504+ (GTG+PKG) PDFDocument57 pagesPO6258 RFI+for+S60133-0504+ (GTG+PKG) PDFmyungkwan haNo ratings yet

- University of Hargeisa GIT Pharmacology Review Questions: Name:aniisa Muse Ahmed Faculty:midwifery ID:1716642 Class:3ADocument4 pagesUniversity of Hargeisa GIT Pharmacology Review Questions: Name:aniisa Muse Ahmed Faculty:midwifery ID:1716642 Class:3AAniza Mouse100% (1)

- Selection of Air Ejectors: Part I. Basic Design, Operating Information, and Operation Limitations of Air EjectorsDocument9 pagesSelection of Air Ejectors: Part I. Basic Design, Operating Information, and Operation Limitations of Air Ejectorsmyungkwan haNo ratings yet

- Static Var CompensatorDocument29 pagesStatic Var CompensatorCarlos Fabian GallardoNo ratings yet

- Emission Calculation 2Document12 pagesEmission Calculation 2myungkwan haNo ratings yet

- MotorDocument1 pageMotormyungkwan haNo ratings yet

- Design Concept of Once-Through CW SystemDocument12 pagesDesign Concept of Once-Through CW Systemmyungkwan haNo ratings yet

- Radiator Fan Moterating CalculationDocument20 pagesRadiator Fan Moterating Calculationmyungkwan haNo ratings yet

- PSV Calculation SheetDocument9 pagesPSV Calculation Sheetmyungkwan haNo ratings yet

- Comparision of EmissionDocument13 pagesComparision of Emissionmyungkwan haNo ratings yet

- Motor Power Selection ProcedureDocument4 pagesMotor Power Selection Proceduremyungkwan haNo ratings yet

- Duct Bulk Materials Calculation Sheet Project Name: SraacDocument6 pagesDuct Bulk Materials Calculation Sheet Project Name: Sraacmyungkwan haNo ratings yet

- Comparision Table For Typical Emission Data of Each Engine TypeDocument1 pageComparision Table For Typical Emission Data of Each Engine Typemyungkwan haNo ratings yet

- SJV Selection EjectorsDocument9 pagesSJV Selection Ejectorskumarvns111No ratings yet

- Uponor v. Sioux Chief Mfg.Document5 pagesUponor v. Sioux Chief Mfg.PriorSmartNo ratings yet

- Top Talkers SOPv1Document3 pagesTop Talkers SOPv1Gaurav NayakNo ratings yet

- Piyush Mulkar: Cleveland, OHDocument6 pagesPiyush Mulkar: Cleveland, OHRadha RamineniNo ratings yet

- Mid Term Asssignment - The Five Senses - PrimaryDocument5 pagesMid Term Asssignment - The Five Senses - PrimaryPrajna MoodabidriNo ratings yet

- Tele BRANCHES 01.06.2021Document23 pagesTele BRANCHES 01.06.2021Abhishek BarwalNo ratings yet

- Development LetterDocument3 pagesDevelopment Lettertan balanNo ratings yet

- Biological Monitoring: Pt. Indo TrainingDocument12 pagesBiological Monitoring: Pt. Indo TrainingnursusiartiNo ratings yet

- Ebook PDF Consumer Behaviour Asia Pacific Edition by Wayne D Hoyer PDFDocument41 pagesEbook PDF Consumer Behaviour Asia Pacific Edition by Wayne D Hoyer PDFmarvin.tappen826100% (35)

- Database Efficiency and TuningDocument22 pagesDatabase Efficiency and TuningJyothy SwaroopNo ratings yet

- Algorithm Exam HelpDocument9 pagesAlgorithm Exam HelpProgramming Exam HelpNo ratings yet

- It Didn't Snow On Saturday. It Rained On SaturdayDocument1 pageIt Didn't Snow On Saturday. It Rained On SaturdayAnna Talhammer100% (1)

- Welcome To The Great Logo Adventure!Document4 pagesWelcome To The Great Logo Adventure!scribdmuthuNo ratings yet

- PI Performance Expectations CAT 2022Document46 pagesPI Performance Expectations CAT 2022Gursanjan TiwanaNo ratings yet

- Higher Education Loans Board: Loan Disbursement ReportDocument2 pagesHigher Education Loans Board: Loan Disbursement ReportEdward KalvisNo ratings yet

- AEB Mortgage Services - Capacity Planning and ControlDocument2 pagesAEB Mortgage Services - Capacity Planning and ControlDua LeoNo ratings yet

- Commonly Asked Interview Questions Co Op Version NEWDocument2 pagesCommonly Asked Interview Questions Co Op Version NEWGail T. BorromeoNo ratings yet

- Tom MCQ UNIT 2Document14 pagesTom MCQ UNIT 2Kumar PachareNo ratings yet

- What's in Your BackpackDocument31 pagesWhat's in Your Backpackjohn ezekiel de asisNo ratings yet

- GRP 1Document2 pagesGRP 1Yuva RaniNo ratings yet

- Kuliah 02 - Pengolahan Citra Digital Sampling Quantization 2Document18 pagesKuliah 02 - Pengolahan Citra Digital Sampling Quantization 2Zulkifli Nagh BalitanNo ratings yet

- Energy and Buildings: F. AsdrubaliDocument9 pagesEnergy and Buildings: F. AsdrubaliBogdan BrieNo ratings yet

- Using Snap Test Kits Poster enDocument1 pageUsing Snap Test Kits Poster enMoisés RodríguezNo ratings yet

- Tie Rod Tieback SystemsDocument12 pagesTie Rod Tieback SystemsHarmandeep BhattiNo ratings yet

- Luftansa Case StudyDocument10 pagesLuftansa Case StudyReddy71% (7)

- 10 CodesDocument4 pages10 Codestirso TansoNo ratings yet