0% found this document useful (0 votes)

383 views2 pagesCNC Machine Maintenance Checklist

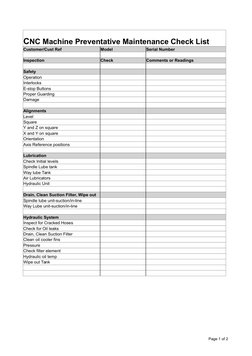

This document is a checklist for performing preventative maintenance on a CNC machine. It lists various systems and components to inspect, including safety features, alignments, lubrication levels, hydraulic and electrical systems, the spindle, conveyors, the ATC/APC, and more. Technicians use the checklist to ensure the machine is properly maintained by checking for issues like damage, leaks, wear, abnormal noises or vibrations, and correct functioning of components. The goal is to inspect all aspects of the machine to catch any potential problems and keep it running optimally.

Uploaded by

Sathyaprakash HsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

383 views2 pagesCNC Machine Maintenance Checklist

This document is a checklist for performing preventative maintenance on a CNC machine. It lists various systems and components to inspect, including safety features, alignments, lubrication levels, hydraulic and electrical systems, the spindle, conveyors, the ATC/APC, and more. Technicians use the checklist to ensure the machine is properly maintained by checking for issues like damage, leaks, wear, abnormal noises or vibrations, and correct functioning of components. The goal is to inspect all aspects of the machine to catch any potential problems and keep it running optimally.

Uploaded by

Sathyaprakash HsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd